Showing 21 items matching "ginger beer container"

-

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyJar Stone Earthenware, circa early 1900s

... ginger beer container... would have contained ginger beer.... of the Australian "bush" environment. drinking container stone jar ginger ...This type of "stone" jar drinking container was used before glass and later plastic material made it "out of date" as a drink container. The qualities of the glazed pottery (stone) drinking containers made from this natural thermal insulation material was to contain the liquid to a prescribed temperature either hot or cold, as required. This was particularly important in rural environments that lacked adequate refrigeration means. The rural regions where the last areas in Australia where this type of drinking container remained in use. The late 1960's saw a revival of the basic rural ethos by the "hippie" culture of going to basic survival non "commercial" living.This particular stone jar drinking container was also a method of advertising for a Wodonga Stone masonry manufacturer. It is both relevant and significant to the Kiewa Valley because it highlights the type of industry that has breached the evolutionary trend for cheaper "throw away" drinking containers. Although this particular type of container is limited to quality liquids and it is still available in most rural sectors of the Australian "bush" environment.This stone/earthenware jar has a lip 250mm in length and 150mm thick. This lip will allow the thumb and forefinger to be used to grip the container for either pouring its contents out or securing it for any movement. The external glazed surface may become slippery when wet. The jar is heavy even when empty and would be too heavy for small children to carry. By using a cork seal the jar can be reused and therefore become more economical for the longer term. The thickness of the vessel provides a good insulation for the liquid contained. Most of this type of container would have contained ginger beer.Within two elliptical circles are painted (in freehand) "S. MASON" in the top half and "WODONGA" in the bottom half.These are separated by an asterisk on both sides. A large "S" overlaid by a similarly large "M" is within the inner circle. Stamped into the jar when still wet during manufacture is "PINNACLE BRAND" in 5mm lettering.drinking container, stone jar, ginger beer container, s. mason, wodonga earthen ware -

Clunes Museum

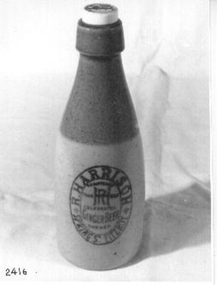

Clunes MuseumContainer - BOTTLE, THE BENDIGO POTTERY, CIRCA 1850

... STONEWARE GINGER BEER CONTAINER FOR COLAC AERATED WATER CO....STONEWARE GINGER BEER CONTAINER FOR COLAC AERATED WATER CO ...STONEWARE GINGER BEER CONTAINER FOR COLAC AERATED WATER CO.STONEWARE GINGER BEER BOTTLE COLAC AERRATED WATER CO. GEO. HAY'S GINGER BEER PHONE 85 - THE BENDIGO POTTERY EPSO BENDIGOlocal history, domestic item, containers, eberhard -

Greensborough Historical Society

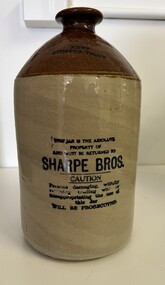

Greensborough Historical SocietyContainer - Jar, Hoffman Australia, Sharpe Bros demijohn, 1930s

This demijohn was made for Sharpe Bros., brewers of non- alcoholic drinks such as Dandelion Ale, ginger beer and cordial. Sharpe Bros began in New Zealand and expanded to Australia in the early 20th century. The company was taken over by Cadbury Schweppes in 1972. The likely manufacturer of this demijohn was Hoffman's Pottery of Brunswick.Glazed stoneware jar with dark brown glaze to top, narrow threaded neck, wire handle and stopper missing.Transfer text on front: "This jar is the absolute property of and must be returned to Sharpe Bros. Australia and New Zealand"sharpe bros., hoffman pottery, stoneware jars -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle - Ginger Beer, early to late 1900's

This glass ginger beer bottle was manufactured and used early to late 1900's, until the time that cheaper containers were invented(plastic bottles). This bottle was so constructed to be easily moved within the ginger beer processing plants from the brewing vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1990s the bottle slowly became phased out of production however boutique suppliers still preferred thick glass to contain any explosive action. Two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co. were the main suppliers for the Victorian State. In the period when this bottle was manufactured and used the major ginger beer brewing plants for the whole of Victoria were located in Melbourne because this was where its greatest consumer base was there and most rural areas were supplied by domestic sources (mother brewing ginger beer for the children). The Kiewa Valley and its region was one rural area which until road invrastructure was enhance covered the ginger beer thirst by local family production. As the population expanded considerably in the late 1940's (SECV Hydro Scheme) with a greater demand for "soft" drinks" being established supplies from larger towns and cities were call for. Each bottle was "branded" during manufacturing to show the contents were from a reputable supplier (H Taylor) and where it originated from. These bottles were recyled by the manufacturer as a way to cut production costs. This method of recycling the bottles back to the specific manufacturer has (except for South Australia)been overtaken by a no cost recycling collection by councils (funded by their communities). This method by passes the user cost principle as the bottles are processed as non generic. The uneconomical "on cost" which was replaced by the "throw away" less costly plastic containers however did not provide the keen domestic brewer of the "beer" with a reusable bottle. This heavy gauged glass ginger beer bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the filling production line. The method of pouring ginger beer into the bottle has been part of the "production line". This bottle has a one and a half pint capacity and is made from "light green" coloured glass(a protection against light penetration). This thick glass bottle, to contain ginger beer, required its thickness because of the extensive handling (man and machine) before final consumption. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck. Ginger beer was a "soft drink" of great demand. On the middle portion of this bottle is a large elongated circle within it and following the spherical line is "H. TAYLOR" ans a star separates this from "MELBOURNE" rounding out the bottom curviture. Within these words are the large initials "T H" . The "T" superimposed onto the "H". On the base and covering the whole bottom is the letter "T". At the opposite side to the manufacturers logo is "THIS BOTTLE CANNOT BE SOLD OR USED BY ANY OTHER PERSON & IS NOT COMPLETE WITHOUT STOPPER" glass bottle, non alcoholic drink, taylor ginger beer bottle, reuseable bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Ginger Beer, circa mid to late 1900's

This glass ginger beer bottle was manufactured and used early to late 1900's, until the time that cheaper containers were invented(plastic bottles). This bottle was so constructed to be easily moved within the ginger beer processing plants from the brewing vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1990s the bottle slowly became phased out of production however boutique suppliers still preferred thick glass to contain any explosive action. Two major glass bottle works companies, e.g. Australian Glass Manufacturers and the Melbourne Glass Bottle Works Co. were the main suppliers for the Victorian State.In the period when this bottle was manufactured and used the major ginger beer brewing plants for the whole of Victoria were located in Melbourne because this was where its greatest consumer base was there and most rural areas were supplied by domestic sources (mother brewing ginger beer for the children). The Kiewa Valley and its region was one rural area which until road invrastructure was enhance covered the ginger beer thirst by local family production. As the population expanded considerably in the late 1940's (SECV Hydro Scheme) with a greater demand for "soft" drinks" being established supplies from larger towns and cities were call for. Each bottle was "branded" during manufacturing to show the contents were from a reputable supplier (PHIBBS Bros) and where it originated from. These bottles were recycled by the manufacturer as a way to cut production costs. This method of recycling the bottles back to the specific manufacturer has (except for South Australia)been overtaken by a no cost recycling collection by councils (funded by their communities). This method by passes the user cost principle as the bottles are processed as non generic. The uneconomical "on cost" which was replaced by the "throw away" less costly plastic containers however did not provide the keen domestic brewer of the "beer" with a reusable bottle.This heavy gauged glass bottle (Ginger Beer) has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the production line. The method of pouring ginger beer into the bottle has been part of the "production line" process of automation. This bottle has a capacity to hold 250ml of ginger beer and is made from "clear" glass. The marority of ginger beer bottles produced in this time frame where made with a "green" tint in them.This tinting helped reduce the sunlight effecting the contentsAround the bottom side of the bottle and blown into the glass is "THIS BOTTLE IS THE PROPERTY OF PHIBBS BROS, ALBURY" above this, in "running script" and sloping up from left to right is "Phibbs Bros" and underneath parallel to it "ALBURY". On the base of the bottle is molded a big "L 289" underneath this "M" and below this "AGM".ginger beer bottle, soft drink bottles, cordial bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyJar/ Demi John Stone Ware, Circa 1860

This kiln glazed container for liquid's, was the type used in the 1700's to mid 1900's to contain fluids mainly for human consumption which needed to retain liquid that could be affected by sunlight and or required to be maintained at a cooler temperatures. Ginger beer and other "brews" for human consumption were the prime target. The ability to refill these vessels were of the utmost importance to the consumer. Over time these containers were reduced in size and produced for "special" liquids e.g. alcoholic Port. This Demi John stone ware was manufactured in Tamworth (England) and imported into Australia during a period when the majority of "quality" domestic items were sourced from "the Mother Country" and the ties between the still "colonial" outpost were very strong. This bondage remained longer in rural communities than in the cities. The "multi-culturalism of the post World War II era resulted in the lessening of the earlier ties. The growing of nationalism, the Aussie evolution, was brought about by the increased social and business/commercial interactions between Australia and the United States of America, post World War II.This container(jug) is very significant to the Kiewa Valley, a rural region that required these type of liquid storage vessels, especially in the late 1800's to the mid 1900's. These were times when household refrigeration, if available, would be from the "block ice" coolers or "cool" storage nooks and crannies within farmhouse locations.This large "stone ware" glazed Demi John, alias Carboy has a capacity of over 20 litres. It has a conical smooth lipped neck top with a wide, flat(three to four finger) carry and poring handle. The top third portion of the jug is caramel in colour and the bottom a darker cream. It has a manufacturer's seal stamped into the surface before glazing. This item would have been corked and then sealed (air tight) with wax.manufacturer's seal "GEORGE SKEY WILNECOTE TAMWORTH"household liquid jar container, 1800's food storage, kiln fired glazed pottery -

Orbost & District Historical Society

Orbost & District Historical SocietyKeg - ginger beer, Early 20th century

... container keg-ginger-beer... container. container keg-ginger-beer 2 Large stoneware ginger beer ...This item is an example of a late 19th century ceramic container.Large stoneware ginger beer keg. Dark cream with darker lines near top. Very pale green stripes near bottom. Cork missing from bottom pouring hole. Missing large cork and wood stopper from top - held with nails.2container keg-ginger-beer -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, 1880s to 1910’s

This handmade green glass bottle was made using the turn-moulded or rotated-moulded method, a variation of the mould-blown process. The bottle has the remnants of a cork seal in its mouth. It possibly contained ginger beer, soda or mineral water, flavoured drinks, liquor or wine. The bottle’s shine has been worn from around 3/4 of its body, indicating that it has been resting horizontally on an abrasive surface, perhaps in the ground or on a river or sea bed. TURN-MOULDED BOTTLE production method This bottle was handmade using the ‘turn-moulded’ process, one of a variety of mould-blown processes that followed the earlier mouth-blown method. The maker would add a portion of hot soft glass to the end of his blowpipe then blow air through the pipe while placing the end inside a bottle mould. The mould was then turned and twisted, giving the bottle a round, seamless body, and usually a round indented base. The cooled body of the bottle would then be finished with the addition of an applied top. A small amount of soft glass would be applied to the top of the bottle and a lip would be formed using a tooling implement. A concentric ring would also form below the lip, caused by the rotated lipping tool. The bases of bottles made with the turn-moulded method were generally not embossed but would commonly have a mamelon or ‘dot’ in the centre of the base. SEALING THE BOTTLE After filling this type of bottle with its contents it is then sealed with a straight, cylindrical cork with the aid of a hand operated tool called a bottle corker. The bottle corker compresses the cork as it is driven into the bottle. Once inside the bottle the cork expands evenly into the opening to tightly seal the contents – the denser the cork the better the seal. Brown, brown glass. Handmade turn-moulded bottle with seamless body and tooled lip. Deeply indented base has push-up mark with a ‘mamelon’ nipple-liker bump in the centre. Bottle is straight from base to half height then tapers to a shoulder over the next quarter, than almost straight up to the mouth. Produced in 1880s to 1910’s. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, brown glass bottle, handmade glass bottle, bottle with indented base, turn-moulded bottle, rotate-moulded bottle, tooled lip on bottle mouth, applied lip bottle, bottle corker, ginger beer bottle -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, 1880s to 1910s

This handmade green glass bottle was made using the turn-moulded or rotated-moulded method, a variation of the mould-blown process. The bottle has the remnants of a cork seal in its mouth. It possibly contained ginger beer, soda or mineral water, flavoured drinks, liquor or wine. TURN-MOULDED BOTTLE production method This bottle was handmade using the ‘turn-moulded’ process, one of a variety of mould-blown processes that followed the earlier mouth-blown method. The maker would add a portion of hot soft glass to the end of his blowpipe then blow air through the pipe while placing the end inside a bottle mould. The mould was then turned and twisted, giving the bottle a round, seamless body, and usually a round indented base. The cooled body of the bottle would then be finished with the addition of an applied top. A small amount of soft glass would be applied to the top of the bottle and a lip would be formed using a tooling implement. A concentric ring would also form below the lip, caused by the rotated lipping tool. The bases of bottles made with the turn-moulded method were generally not embossed but would commonly have a mamelon or ‘dot’ in the centre of the base. SEALING THE BOTTLE After filling this type of bottle with its contents it is then sealed with a straight, cylindrical cork with the aid of a hand operated tool called a bottle corker. The bottle corker compresses the cork as it is driven into the bottle. Once inside the bottle the cork expands evenly into the opening to tightly seal the contents – the denser the cork the better the seal. This turn-moulded glass bottle is made distinctive due to its round seamless body and indented base.Bottle, dark green glass. Handmade turn-moulded bottle with seamless body and tooled lip. Deeply indented base has push-up mark with a ‘mamelon’ bump in the centre. Bottle is straight from base to half height, then tapers to a shoulder over the next quarter, than almost straight up to the mouth. There is a portion of cork in the bottle’s mouth and dry remnants in the bottle’s base. Possibly used for ginger beer. Produced in 1880s to 1910’s. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, green glass bottle, handmade glass bottle, bottle with indented base, turn-moulded bottle, rotate-moulded bottle, tooled lip on bottle mouth, applied lip bottle, bottle corker -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, 1880s to 1910s

This handmade green glass bottle was made using the turn-moulded or rotated-moulded method, a variation of the mould-blown process. The bottle has the remnants of a cork seal in its mouth. It possibly contained ginger beer, soda or mineral water, flavoured drinks, liquor or wine. TURN-MOULDED BOTTLE production method This bottle was handmade using the ‘turn-moulded’ process, one of a variety of mould-blown processes that followed the earlier mouth-blown method. The maker would add a portion of hot soft glass to the end of his blowpipe then blow air through the pipe while placing the end inside a bottle mould. The mould was then turned and twisted, giving the bottle a round, seamless body, and usually a round indented base. The cooled body of the bottle would then be finished with the addition of an applied top. A small amount of soft glass would be applied to the top of the bottle and a lip would be formed using a tooling implement. A concentric ring would also form below the lip, caused by the rotated lipping tool. The bases of bottles made with the turn-moulded method were generally not embossed but would commonly have a mamelon or ‘dot’ in the centre of the base. SEALING THE BOTTLE After filling this type of bottle with its contents it is then sealed with a straight, cylindrical cork with the aid of a hand operated tool called a bottle corker. The bottle corker compresses the cork as it is driven into the bottle. Once inside the bottle the cork expands evenly into the opening to tightly seal the contents – the denser the cork the better the seal. This hand made, green glass bottle is representative of bottle making before mass production and is made distinctive due to its round seamless body and indented base.Bottle, dark green glass. Handmade turn-moulded bottle with seamless body and tooled lip. Deeply indented base has push-up mark with a ‘mamelon’ bump in the centre. Bottle is straight from base to half height, then tapers to a shoulder over the next quarter, than almost straight up to the mouth. There is a portion of cork in the bottle’s mouth and dry remnants in the bottle’s base. Possibly used for ginger beer. Produced in 1880s to 1910’s. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, green glass bottle, handmade glass bottle, bottle with indented base, turn-moulded bottle, rotate-moulded bottle, tooled lip on bottle mouth, applied lip bottle, bottle corker -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, 1880s to 1910s

This handmade green glass bottle was made using the turn-moulded or rotated-moulded method, a variation of the mould-blown process. The bottle has the remnants of a cork seal in its mouth. It possibly contained ginger beer, soda or mineral water, flavoured drinks, liquor or wine. The bottle’s shine has been worn from around 3/4 of its body, indicating that it has been resting horizontally on an abrasive surface, perhaps in the ground or on a river or sea bed. TURN-MOULDED BOTTLE production method This bottle was handmade using the ‘turn-moulded’ process, one of a variety of mould-blown processes that followed the earlier mouth-blown method. The maker would add a portion of hot soft glass to the end of his blowpipe then blow air through the pipe while placing the end inside a bottle mould. The mould was then turned and twisted, giving the bottle a round, seamless body, and usually a round indented base. The cooled body of the bottle would then be finished with the addition of an applied top. A small amount of soft glass would be applied to the top of the bottle and a lip would be formed using a tooling implement. A concentric ring would also form below the lip, caused by the rotated lipping tool. The bases of bottles made with the turn-moulded method were generally not embossed but would commonly have a mamelon or ‘dot’ in the centre of the base. SEALING THE BOTTLE After filling this type of bottle with its contents it is then sealed with a straight, cylindrical cork with the aid of a hand operated tool called a bottle corker. The bottle corker compresses the cork as it is driven into the bottle. Once inside the bottle the cork expands evenly into the opening to tightly seal the contents – the denser the cork the better the seal. This turn-moulded glass bottle is made distinctive due to its round seamless body and indented base.Bottle, dark green glass. Handmade turn-moulded bottle with seamless body and tooled lip. Deeply indented base has push-up mark with a ‘mamelon’ bump in the centre. Bottle is straight from base to half height, then tapers to a shoulder over the next quarter, than almost straight up to the mouth. The shine has been worn from three-quarters of the body of the bottle. There are particles adhered to the inside of the bottle. Possibly used for ginger beer. Produced in 1880s to 1910’s. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, green glass bottle, handmade glass bottle, bottle with indented base, turn-moulded bottle, rotate-moulded bottle, tooled lip on bottle mouth, applied lip bottle, bottle corker -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Stoneware Demijohn, Bendigo Pottery , 1905-1950

This demijohn was made by Bendigo Pottery for Sharpe Bros, brewers of non-alcoholic drinks such as Dandelion Ale, Ginger Beer and cordial. Sharpe Bros began in New Zealand and expanded to Australia in the early 20th century. The company was taken over by Cadbury Schweppes in 1972.An item made during the first half of the 20th century by a Bendigo pottery as a container made for the Sharpe's brewery in Victoria to contain their non alcoholic drinks for retail sale.Glazed stoneware bottle with dark brown glaze to top section, one gallon size, narrow neck glazed stoneware stopper and wire handle missing. SHARPE BROS. AUSTRALIA & NEW ZEALAND Text printed in black on body: 'This bottle is the absolute property of and must be returned to Sharpe Bros. Australia and New Zealand.flagstaff hill, warrnambool, flagstaff hill maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, bottle, stoneware bottle, sharpe bros., drink, non alcoholic drinks, bendigo pottery, demihohn -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, Late 19th century or early 20th century

... Possibly a ginger beer bottle. Container Bottle ...Glass manufacturing has evolved over thousands of years. Glass making has been traced back to 3500 BC in Mesopotamia. The earliest known glass objects were beads, perhaps made by accident while working with metal. In the late Bronze Age, several civilizations discovered how to make vessels and glass bottles by wrapping threads of melted glass around cores of sand or clay. Later, moulds were used to form dishes and table wares. Around the 1st century BC, glassblowing was discovered. This made glass containers less expensive than pottery. Mould-blown glass, the process of blowing a piece of molten glass into a wooden or metal mould, was invented during the 1st century AD. This technique was faster with more consistent results. It paved the way for mass production. It wasn’t until the late 1800s that the production process to become more efficient. In 1887, a company in England created a semi-automatic process that could produce up to 200 bottles an hour. This process has been refined to the point where modern machines can yield more than 600 containers per minute. Blown vs. Manufactured Glass Bottles Nowadays, glass bottles, jars, and cups are usually manufactured on a bigger scale than is found in individual glassblowing studios. If we still depended on hand-blown glass for all of our glass containers, we would see some major differences in the process of creating bottles and jars. First, there's the time. Hand blowing glass takes a significant amount of time, even for one simple container. In contrast, hundreds of jars per minute can be made using modern technology. This leads to the second advantage: price. Because of the automated and streamlined process, the price for manufactured containers is much lower than that of hand-blown glass. Third, manufactured bottles will be much more consistently uniform than bottles blown by hand. Automated glass manufacturing produces nearly identical batches of jars. Glass blowing is awesome for unique, beautiful pieces of art. But for lots of lower priced and uniformly shaped containers, automatic manufacturing is the preferred method to create glass bottles and jars. https://www.containerandpackaging.com/resources/glass-bottles-brief-history The invention and development of glass for domestic items including bottles, has been nothing short of revolutionary. The use of glass bottles, that could be easily washed, led to improved hygiene, and mass manufacturing of drinks of all types, including milk, cordial and alcoholic beverages.Green Glass Bottle Possibly a ginger beer bottle.Concave indentation at the base. Also on base are two raised lumps. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, glass -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Stoneware Demijohn, Bendigo Pottery , 1904-1930s

This Sharpe Bros. one gallon stoneware Demijohn is in excellent condition and includes its original stopper. It was made between 1904 and 1930, the date from the patent of the handle until the time that the factory no long produced returnable items. The bottle was once part of Dr W.R. Angus' household and is part of the W.R. Angus Collection and could have been purchased from Warrnambool's Sharpe Bros. factory. SHARPE BROS. 1903-1972- The first Sharpe Bros. cordial factory was opened in Dunedin, New Zealand, in 1903 by English prohibition brothers John and Percy Sharpe. Sharpe Bros. made ‘health’ beverages that were non-alcoholic drinks such as ginger beer, ginger ale, lime juice, soda and cordials. The containers of these drinks were not sold with the drinks but were marked as returnable items, to be cleaned and re-used, until this practice ceased in the 1930s. Sharpe Bros. made a niche in the soft drink market by delivering drinks by horse and cart to its customers’ homes. John Sharpe patented the unique wire spiral handle in 1904. By 1905 the New Zealand company also had factories in Australia. By 1910 the company had over 20 factories including Wanganui, New Zealand; Adelaide, Albury, Ballarat, Bathurst, Forbes, Geelong, Goulburn, Lithgow, Melbourne, Newcastle, Orange, Sydney, Tamworth, Warrnambool and Wollongong. The Warrnambool factory was established in 1919 and existed until 1951. The company won awards at Australian exhibitions for its carbonated drinks, including First Prize for its ginger beer made in the Brisbane factory. The company was taken over in 1962 by Tarax Drinks Holdings Ltd, which was in turn taken over by Cadbury Schweppes in 1972. W.R. Angus Collection- The W R Angus Collection spans from 1885 to the mid-1900s and includes historical medical and surgical equipment and instruments from the doctors Edward and Thomas Ryan of Nhill, Victoria. Dr Angus married Gladys in 1927 at Ballarat, the nearest big city to Nhill where he began as a Medical Assistant. He was also Acting House surgeon at the Nhill hospital where their two daughters were born. He and his family moved to Warrnambool in 1939, where Dr Angus operated his own medical practice. He later added the part-time Port Medical Officer responsibility and was the last person appointed to that position. Dr Angus and his wife were very involved in the local community, including the early planning stages of the new Flagstaff Hill, where they contributed to the layout of the gardens. Dr Angus passed away in March 1970.This stoneware Demijohn is connected to the history of Warrnambool, as it was owned by the daughter of Dr W. R. Angus and his wife Gladys. It is part of the W.R. Angus Collection, which is notable for still being located at the site connected to Doctor Angus, Warrnambool’s last Port Medical Officer. It is also connected through its manufacturer Sharpe Bros. which had a branch in Warrnambool from 1919 to 1951, overlapping the time when the Angus family resided there from 1939 to the 1970s. The bottle is also significant as an example of the early-20th-century beverages found in local households and could have been purchased from the local Sharpe Bros. factory.This stoneware Demijohn is glazed, with a brown neck with internal thread and shoulders and a cylindrical cream base. The one gallon bottle has a flat, black stopper with a cork stem and a rubber, threaded tip. The ‘U’ shaped wire carry handle has a spiral of wire around the handpiece. An overhanging lip is on top of the bottle’s short neck above its rounded shoulder. The clay has been joined at the base of the neck, shoulder and body. The underneath is unglazed. The brown glazing on the shoulder has a run mark. Inscriptions are on the stopper and bottle. This container is part of the W.R. Angus Collection.Stamped in black on the shoulder: “KEEP THE / STOPPER TIGHT” Stamped in black on the body: “THIS JAR IS THE ABSOLUTE PROPERTY OF AND MUST BE RETURNED TO SHARPE BROS. AUSTRALIA / & NEW ZEALAND. ORIGINAL & LARGEST HYGIENIC BREWERY. CAUTION Persons Damaging, Willfully Retaining, Trading with or Misappropriating the Use of this Jar WILL BE PROSECUTED “ Stamped in script writing: “Sharpe Bros. TRADE - - - ED “ Embossed on the stopper: “AUSTRALIA AND NEW ZEALAND, SHARPE BROS.”flagstaff hill, warrnambool, maritime village, maritime museum, shipwreck coast, great ocean road, dr w r angus, dr roy angus, dr ryan, sharpe bros., bendigo pottery, bottle, stoneware bottle, demihohn, one gallone bottle, soft drink, non-alcoholic drink, drink container, jar, jug, warrnambool soft drink, hygienic brewery, cordial factory, new zealand, australia, john sharpe, percy sharpe, non-alcoholic, spiral wire handle, ginger beer, w.r. angus collection, demijohn -

Clunes Museum

Clunes MuseumContainer - JUG, SHARPE BROS

JUG USED TO CONTAIN GINGER BEERSTONEWARE JUB WITH WIRE HANDLE, BROWN CERAMIC GLAZE AT THE NECK OF THE JUG AND CLAY COLOURED GLAZE AROUND TO JUG BELOW THE BROWN"HEALTH BEVERAGES - WHEN EMPTY RETURN TO SHARPE BROS AUSTRALIA AND NEW ZEALAND" IN BLACK LETTERING ON THE BODY OF THE JUGstoneware, jug, ginger beer -

Clunes Museum

Clunes MuseumContainer - BOTTLE

Ginger beer bottle and cork, stoneware bottle, pale on bottom darker on top, cork tied in with stringOn label; CHAS. COLE & CO. GEELONG GINGER BEER TRADE MARK BESIDE IMAGE OF EAGLEstoneware, ginger beer, bottle -

Clunes Museum

Clunes MuseumContainer - BOTTLE

... BREWED GINGER BEER. CLUNES EBERHARD & CO. BREWED GINGER BEER ...EBERHARD & CO. BREWED GINGER BEER STONE BOTTLEEBERHARD & CO BREWED GINGER BEER. CLUNESlocal history, domestic item, containers, eberhard co. -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Container - Bottle

Has been used as a hot water bottle.Stone ginger beer bottle. Light brown glaze on top.R. Harrison Spring St Fitzroy| Celebrated Ginger Beer Brewed.domestic items, containers -

Clunes Museum

Clunes MuseumContainer - BOTTLE

Stone ginger beer bottle with cork, cork secured with stringSticker marked "46" EBERHARD & CO. CLUNES stamped near base top line illegible, from Bendigocontainer, storage jug -

Greensborough Historical Society

Greensborough Historical SocietyContainer - Bottle, Phibbs Bros. Ginger Beer bottle. Tallangatta & Albury, 1930s

... Bros. Ginger Beer bottle. Tallangatta & Albury Container Bottle ...Small stoneware Ginger Beer bottle made by Phibbs Bros. Tallangatta & Albury.Cream and brown glazed stoneware bottlephibbs bros, ginger beer, tallangatta, albury, stoneware bottles -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, c. 1905

This bottle once contained John Fletcher’s ginger cordial. It was found in August 2014 in the sand dunes at Levy's Point, near McKinnon's quarry, Warrnambool. ABOUT JOHN FLETCHER of WARRNAMBOOL John Fletcher Cordial (or Beverage) Co.. Warrnambool supplied cordial and aerated drinks to the Western District of Victoria. John Fletcher was named as a cordial manufacturer in the Warrnambool Standard of June 13th 1895, when he attended a Publican’s Association meeting. Mr John Fletcher, aerated water and cordial manufacturer of Koroit Street, Warrnambool, had a summary of his factory printed in a short article in the Advocate, Melbourne, in February 1901. The article said, “one of the most complete plants outside the metropolis … spacious … well appointed …old-established business … noted for the excellence of the quality … a trial [of the beverage] is solicited.” John Fletcher and Harold Caffin, trading as J.S. Rowley & Co, cordial manufacturers in 1903, were prosecuted in September that year when the Board of Health found an analysed sample of Raspberry Vinegar to contain coal tar colouring, which could be injurious to health, particularly to the kidneys. The factory was still in operation in December 1924, when sadly, Mr S. Fletcher, who was carrying bottles of aerated water at Mr John Fletcher’s cordial factory, sustained an eye injury when one of the bottles burst. Later, the eye had to be removed at the Warrnambool Base Hospital. ABOUT CODD BOTTLES Many inventions during the mid-to-late 1800s kept the fizz in carbonated drinks, such as ginger ale, soda water, and fruit drinks. Hiram Codd, an English engineer, invented a successful process that he patented as “Codd’s patented globe stopper bottle” in 1872. The Codd-neck bottle (commonly called Codd or marble bottle) is manufactured in two parts. The body of the bottle is cast in two sections. At the time of joining the sections, a glass marble and rubber seal are inserted into the neck section. The lip is then applied to the top of the bottle. The Codd bottle is filled upside down as the pressure of the gas from the carbonated liquid holds the marble up and out of the way. When the bottle stands upright, the gas pushes the marble up against the washer, creating a firm seal to keep the fizz inside. The bottle is opened by pushing the marble down firmly to allow some of the gas to escape. The marble drops down and is caught in a depression formed in the neck. When the bottle is tilted to pour or drink the liquid, the marble rests in a dimple. Some have said that the bottle is a character, the shape having a face with its mouth keeping the marble out of the drink and eyes that catch the marble so that it doesn’t roll into the mouth of the drinker. The Codd bottle was expensive to produce, and children loved to destroy the marbles to play with the marbles inside. Many shops and factories added a deposit to the cost of buying the drink to encourage children to return the bottles rather than break it for the marble. Codd bottles are still being produced in India and Japan for soft drinks. A Codd bottle with the same markings as this one is valued on today’s Australian auction sites from AUD 35 - $75. Bottle, aqua/green glass, with glass marble inside. John Fletcher's Ginger Ale, Warrnambool. Container is often called a "Codd neck bottle", “marble bottle” or “Codd’s patent bottle”. Bottle made by Dobson. Inscription on bottle and base. c. 1905Marks moulded into glass; "JOHN FLETCHER / GINGER ALE / WARRNAMBOOL" and “DOBSON” and on base “G”. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, codd bottle, codd neck bottle, marble bottle, ginger beer bottle, john fletcher soft drinks, warrnambool soft drinks and cordials, john fletcher cordial (or beverage) co ., codd neck bottle, glass stopper bottle, hiram codd, antique bottle, harold caffin, john fletcher