Showing 78 items matching "heating iron"

-

Kiewa Valley Historical Society

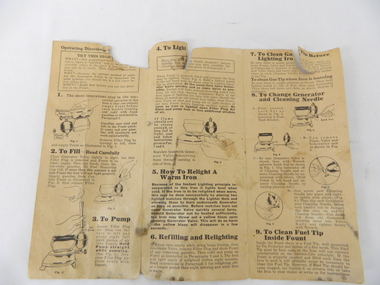

Kiewa Valley Historical SocietyDocument Instruction and Parts Sheet, Instructions for Operating the Coleman Self Heating Iron Model No. 4 Instant Lighting, circa 1950

... Instructions for Operating the Coleman Self Heating Iron... for Operating the Coleman Self Heating Iron Model No. 4 Instant Lighting ...This operating and parts information sheet was supplied to consumers to help users of this kerosene iron, not only understand the operation of this self lighting iron, but also to be able to order any replacement parts that may be required for this high level usage appliance. At this period in time(1950's), this item was at the leading edge of ironing technology. During the earlier 1900's and before "the throw away" culture evolved(circa 1950's), reliability and long term application of domestic appliances was a necessity above all costs, especially in isolated rural areas. The construction of these appliances was geared to a longer service life and not to a cheaper two to three year life warranty. With levels of world wide technology at an ever increasing pace, long term reliability of any appliance was no longer sought after. Appliance upgrades and new improved model accessibility especially in rural areas has changed rural consumer's buying patterns. Although the concept of instructional and parts/warranty information booklets has not become obsolete, the ability to access information via electronic means has vastly improved the ability to obtain qualified technical help through local avenues. This access was not available in the time period(circa 1950), when the appliance covered by this document was issued. The rate of development within the home appliance field has mushroomed during the time period post 1950. The costs and the increased levels of product choices and consumer awareness has provided rural areas (once isolated e.g. Kiewa Valley) with a greater ability to satisfy their needs because of a greater diverse range of domestic appliances offered.This discoloured, sepia paper has black print and is folded into three equal pages. The information contained covers operational and part numbers for the kerosene fired hand held iron. there are kerosene stains on the last page and these have soaked through onto the second page. The form no.-3-3C- McACO.-4363Printed in U.S.A.instructions, household appliances, ironing, domestic ironing -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageIron

... heating iron..."Comfort Self Heating" clothes iron. Spirit iron... the iron rather than earlier flat irons that required heating ...This iron used its own fuel to heat up the iron rather than earlier flat irons that required heating on top of the stove."Comfort Self Heating" clothes iron. Spirit iron with wooden handle and metal tank for spirit fuel (probably benzene.). Different fuels were used, some with dire resultsflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, spirit iron, self, heating iron, comfort iron, comfort self heating iron -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Iron

... self heating iron...Self Heating Family Charcoal Iron. Box iron with wooden... heating iron coal iron laundry Family charcoal iron T & G Clair ...Self Heating Family Charcoal Iron. Box iron with wooden handle and brass finger guard. The finger guard has two round emblems and the inscription "Awarded To T & G Clark & Co" on it.Two emblems within circles plus the inscription "Awarded To / T & G Clark & Co. on the finger guardflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, iron, self heating iron, coal iron, laundry, family charcoal iron, t & g clair & co -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyIron - Kerosene

... stem on top. This is a self-heating iron....Comfort iron / Self Heating Comfort Iron MFD by / National... kerosene shelite Comfort iron / Self Heating Comfort Iron MFD ...Kerosene irons were used c1930 - 1950 especially where electricity wasn't available. Shelite was another fuel that could be used instead of kerosene. The advantage of the kerosene iron was that it didn't require a stove to be lit (especially in summer) to heat the iron and it didn't require electricity.Residents in the Kiewa Valley used kerosene irons.This black iron is made of cast iron with a steel base and a black wooden handle. This Comfort iron has a ball shaped container with a screw-on lid to hold the fuel (kerosene or Shelite). At the bottom of this ball is a pipe going down then meeting another pipe at right angles to it leading into the iron. At the pipe junction there is a handle on a screw to limit the amount of fuel. The Kerosene would flow through this pipe. There is a filler plug air stem on top. This is a self-heating iron.Comfort iron / Self Heating Comfort Iron MFD by / National Stamping and Electric Works / made in U.S.A. Chicago iron, domestic, laundry, pressing clothes, household, kerosene, shelite -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncDomestic object - COLEMAN Fuel Iron

... A self-heating iron which made from metal and enamel plate.... Domestic appliances Coleman Fuel Irons A self-heating iron which ...Coleman, originally known for making lanterns, made over 30 different models of irons from 1929 to 1948. They generally came in an enamel coloured finish. The best known and most commonly found today is the “Cool Blue” enamel Coleman’s 4A gasoline iron. The Coleman 4A gasoline iron was much lighter than the previous ‘sad irons’ and no longer required to be heated on the stove or by charcoal. Instead, the pump was used to build up pressure in the fuel tank and a match was lit underneath the iron, making a flame inside the iron that would distribute the heat on the surface. Despite these benefits, fuels irons made ironing a potentially dangerous job. They had a very real possibility of causing a fire or exploding. Gas-pressure irons, that had been manufactured as early as 1900, were eventually replaced by electric-powered steam irons, in the 1970s as an affordable and safer alternative.This item is significant because it is an example of domestic appliances used widely throughout the Wodonga District.A self-heating iron which made from metal and enamel plate which included a small tank for fuel which powered the unit. A small wooden pump was used to build up pressure in the iron’s fuel tank. It has a wooden handle.domestic appliances, coleman fuel irons -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Fire poker

... Shipwreck Coast poker fire poker fire iron heating cooking laundry ...This fire poker is a basic design that has been used throughout the centuries to attend to a fire for cooking, heating, firing a boiler and similar domestic activities.This object is significant as an example of an item in common use in the 19th and early 20th centuries and is still in use today.Fire poker; a flat metal bar shaped with ring at one end and a right angle bend at the base. It is painted black.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, poker, fire poker, fire iron, heating, cooking, laundry, tending a fire -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyCan Fuel Measuring, circa 1950

... in the average household. The hand held self heating(kerosene) iron... with the Coleman self heating kerosene iron (see KVHS 0347A). On one side... household. The hand held self heating(kerosene) iron for which ...The 1950's saw a revolution in small appliances for use in the average household. The hand held self heating(kerosene) iron for which this filling can was provided ,was introduced as a time saving and more convenient iron for pressing clothes and other cloth fabrics. It replaced irons needing an external fire source to heat the ironing plate. These irons continued to be in service, even when electricity was available in cities and larger rural towns. This item was used before and during the electricity supplies available from the Kiewa Hydro Electricity Scheme. These irons remained in use within regional rural areas that had limited or unreliable electrical reticulation and the ability to service them from this filling can was an essential part.n the 1950s and later the Kiewa Valley was still a relatively isolated region which was home to rural properties and small settlements. The availability of electricity and or the financial means to afford new types of electric hand irons ensured that older and sometimes less efficient ironing appliances remained for an extended period covering the 1960s to 1970s. Kerosene products, such as the kerosene self heating (KVHS 0347A) iron and this kerosene filling item, was a cheaper method for farm based domestic and other rural activities requiring a heat source. The use of kerosene as a heat/light source was able to be supplied in bulk and able to be used when floods severed vital roads into this region. The supply of electricity was in summer time subject to interruption from bush fire damaged wooden poles carrying the electrical cables. Self sufficiency by rural populations was the backbone of survival and the ability to store energy sources "on the farm" was a prerequisite of isolated regions, such as the Kiewa Valley, circa 1950s.This specially spout fitted can was provided with the Coleman self heating kerosene iron (see KVHS 0347A). On one side of the half enclosed top of the can there is a small spout(for poring the appropriate liquid into the egg shaped fount container) at the rear end of the hand iron. The can is made from tin. See KVHS 0347B- Instruction sheet; KVHS 0347C- Wrench.On one side of the can in black print on yellow background is "FUEL MEASURING CAN" underneath is "For Coleman Instant-Lite Iron" underneath are four numbered paragraphs detailing the use of this can. Below this is the name and places of manufacture. On the other side of the can is printed "BE SURE" with filling and maintenance instructionskerosene can, ironing, domestic appliances, household appliances -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyIron Hand Kerosene, mid to late 1900s

... in the average household. This hand held self heating(kerosene) iron... the heat for this advertised "self heating iron(instant lighting... household. This hand held self heating(kerosene) iron was introduced ...The 1950's saw a revolution in small appliances for use in the average household. This hand held self heating(kerosene) iron was introduced as a time saving and more convenient iron for pressing clothes and other cloth fabrics. It replaced irons needing a separate fire source to heat the ironing plate. These irons continued to be in service, even when electricity was available in cities and larger rural towns (domestic electric steam irons were invented in 1938). This item was used before and during the electricity supplies available from the Kiewa Hydro Electricity Scheme. These irons remained in use within regional rural areas that had limited or unreliable electrical reticulation.In the 1950s and later the Kiewa Valley was still a relatively isolated region which was home to rural properties and small settlements. The availability of electricity and or the financial means to afford new types of electric hand irons ensured that older and sometimes less efficient ironing remained for an extended period covering the 1960s to 1970s. Kerosene products, such as this kerosene iron was a cheaper method for farm based domestic and other rural activities requiring a heat source. The use of kerosene as a heat/light source was able to be supplied in bulk and able to be used when floods severed vital roads into this region. The supply of electricity was in summer time subject to interruption from bush fire damaged wooden poles carrying the electrical cables. Self sufficiency by rural populations was the backbone of survival and the ability to store energy sources "on the farm" was a prerequisite of isolated regions, such as the Kiewa Valley, circa 1950s.This Coleman kerosene iron has a solid steel chrome plated(press) base with a painted (blue) wooden handle. The handle is stud fastened onto an oblong shaped rolled steel handle frame and screwed (two screws) onto the base plate. Both the heating plate and the top securing plate are shaped similar to a river boat. The main housing enclosing the heating element is enamel coated(blue in colour) steel and has a half hole for lighting the kerosene at the rear end. Behind the handle and protruding upwards is a stainless steel fully enclosed container (bowl shaped) for the main supply of kerosene to the burner or generator(enclosed within the main body of the iron. The bowl has an air valve and inlet for pressurised air intake (hand pump) On the bottom rear of the fuel bowl there is a screw regulated fuel pump. The fuel heated base plate provides the heat for this advertised "self heating iron(instant lighting). See KVHS 0347B- Instruction sheet; KVHS 0347C- Wrench; and KVHS 0347D Fuel can.Stamped on the base plate of the handle, front region "COLEMAN LAMP & STOVE CO." below this "WICHITA KAN" below this"TORONTO CAN". In the middle of the handle base and in larger print "COLEMAN Instant-Lite" At the rear location in large print "MODEL 4" in smaller print below "MADE IN U.S.A." below this "PAT#1718473"household appliances, alternative non electrical ironing appliances, domestic appliances, kerosene appliances -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Domestic object - Petrol Iron

... On box: Handi British Self Heating Pumpless Iron...domestic items irons On box: Handi British Self Heating ...Silver iron on stand with black handle and knobs. Cylindrical tank at back. Original cardboard box contains: instruction sheet, small carton containing spare part, spanner and spare knob.On box: Handi British Self Heating Pumpless Iron.|On instruction sheet: Directions for operating the improved Handi pumpless iron, 3 pages of detailed instructionsdomestic items, irons -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageIron

... Charcoal Box iron, self heating family charcoal iron... Box iron, self heating family charcoal iron. Hinged top ...Charcoal Box iron, self heating family charcoal iron. Hinged top with wooden handle and grate inside. Has hand heat shield Also metal protecting plate for hand. Manufactured by C. H. Crane, Wolverhampton, England H22.5 x W 12 x L 24 flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyIron - Electric

... A small electric iron, for heating only. "Hot Point" brand... in Australia A small electric iron, for heating only. "Hot Point" brand ...This iron was used when electricity became available. It was possibly used for smaller items that didn't require a lot of time. Residents of the Kiewa Valley used irons for pressing the family's clothes and linen - usually by the women as it was considered to be part of their domestic duties.A small electric iron, for heating only. "Hot Point" brand with a steel body and a black plastic (or could be Bakelite) upper body that is chromed. The electric cord is detachable and not with the iron.Hotpoint Cat No. 6266 G7 Watts 575 - Volts 240. Ps 7 Made in Australiairon, laundry, domestic, pressing clothes, household, electric -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyWrench Coleman, circa 1950

... for the Coleman self heating kerosene (KVHS 0347A) iron and used... for the Coleman self heating kerosene (KVHS 0347A) iron and used ...The 1950's saw a revolution in small appliances for use in the average household. This hand held wrench was provided exclusively for the Coleman self heating kerosene (KVHS 0347A) iron and used for the regular changing the kerosene used in it. The iron was used before and during the electricity supplies available from the Kiewa Hydro Electricity Scheme. These irons remained in use within regional rural areas that had limited or unreliable electrical reticulation. Kerosene supplies were cheaper than electricity but also more inconvenient than electric. Electrical appliances become cheaper to buy and maintain in the later part of the 1900's and the now older kerosene iron was faded out.This wrench was required to open the fuel container which stored kerosene in the Coleman hand iron(see KVHS 0347A). This item was part of the maintenance requirement of this particular hand iron. In the 1950s and later the Kiewa Valley was still a relatively isolated region which was home to rural properties and small settlements. The availability of electricity and or the financial means to afford new types of electric hand irons ensured that older and sometimes less efficient ironing remained for an extended period covering the 1960s to 1970s. Kerosene products, such as this kerosene iron was a cheaper method for farm based domestic and other rural activities requiring a heat source. The use of kerosene as a heat/light source was able to be supplied in bulk and able to be used when floods severed vital roads into this region. The supply of electricity was in summer time subject to interruption from bush fire damaged wooden poles carrying the electrical cables. Self sufficiency by rural populations was the backbone of survival(use of this wrench was a part of rural life). The ability to store energy sources "on the farm" was a prerequisite of isolated regions, such as the Kiewa Valley, circa 1950s.This item is a flat cast iron wrench, which has been specifically made for KVHS 0347A (kerosene iron). The wrench has four specific forms cut into the steel which fit firmly around their targeted nut and other fixtures. Also see See KVHS 0347B- Instruction sheet; and KVHS 0347D Fuel can.ironing, iron maintenance tool, domestic appliances, household -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Platform Scales

... . of heating and cook stoves, cast iron ploughs, and other items. His...) was an American inventor. of heating and cook stoves, cast iron ploughs ...Thaddeus Fairbanks (1796 –1886) was an American inventor. of heating and cook stoves, cast iron ploughs, and other items. His greatest success was the invention and manufacture of the platform scale, which allowed the weighing of large objects accurately. Fairbanks was born in Brimfield, Massachusetts, on January 17, 1796, the son of Joseph Fairbanks (1763–1846) and Phebe (Paddock) Fairbanks (1760–1853). His uncle was Ephraim Paddock, the brother of Phebe Paddock. In 1815 he moved to St. Johnsbury, Vermont, and set up a wheelwright's shop above his father's gristmill. In 1820 he married Lucy Peck Barker and In 1824 he built an iron foundry. his brother Erastus joined him to establish E. and T. Fairbanks, a partnership to manufacture heating stoves, cast iron ploughs a design for which he patented in 1826. In 1830 Fairbanks and Erastus became interested in the raising and processing of hemp. Fairbanks went on to patent a hemp and flax dressing machine and became the manager of the St. Johnsbury Hemp Company. He also built a set of scales that would measure large loads of hemp accurately, as there were no reliable scales at the time. Upon the success of building these scales, his brothers recommended that he make and sell these for general use. Fairbanks' most famous invention then became the platform scale for weighing heavy objects. These are commonly known as the Fairbanks Scales, for which he patented his original design in 1830. Before this time, accurate weighing of objects required hanging them from a balancing beam as a result, particularly heavy or ungainly objects could not be weighed accurately. A platform scale, if large enough, could weigh an entire wagon. By placing a full wagon on the scale, unloading it, and then placing it on the scale when empty, it became possible to easily and accurately calculate the weight and value of farm produce and other loads. In 1834 Fairbanks and his brother formed "E. and T. Fairbanks and Company" to manufacture and sell these platform scales. These scales were well known in the United States and around the world resulting in the company doubling in volume every three years from 1842 to 1857. There was a temporary slow down during the American Civil War, however, the business took off again after the war. Their partnership was incorporated in 1874 into a firm known as "Fairbanks Scale Company". These platform scales revolutionized weighing methods of large loads and have been in use ever since. Portable platform scales are found in almost every hardware store, physician's office, and manufacturing factory throughout the United States and the world. The first railway track platform scale patent was granted to Fairbanks on January 13, 1857, as Patent No. 16,381. In 1916 the company was purchased by ”Fairbanks, Morse and Company”. Ownership of the company has since changed several times, but Fairbanks Scales continue to be made in St. Johnsbury Vermont to this day. Fairbanks had received 43 patents in his lifetime with the last one at the age of 91. He died on April 12, 1886, and is buried at St. Johnsbury, Vermont, at the Mount Pleasant Cemetery. An early example of the first type of platform scale that revolutionised the weighing of goods throughout the world made in the USA around the turn of the 19th century. Commercially built platform scale on wheels. Cast iron base supports iron weighing platform with wooden floor. At back, square hollow wooden post supports a hooded rod which bears the weight of the platform and which hooks onto a brass balancing arm, marked in pounds up to 50. There is a cylindrical sliding weight and on the end a loop for a metal weight holder. The holder is designed for three circular pieces of metal with a slit to the centre. The weights used are 50, 100 and 200 lbs.Embossed to base Fairbanks Patent No 11 1/2, flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, platform scales -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Platform Scales, Thaddeus Fairbanks, 1880-1910

... . of heating and cook stoves, cast iron ploughs, and other items. His...) was an American inventor. of heating and cook stoves, cast iron ploughs ...Thaddeus Fairbanks (1796 –1886) was an American inventor. of heating and cook stoves, cast iron ploughs, and other items. His greatest success was the invention and manufacture of the platform scale, which allowed the weighing of large objects accurately. Fairbanks was born in Brimfield, Massachusetts, on January 17, 1796, the son of Joseph Fairbanks (1763–1846) and Phebe (Paddock) Fairbanks (1760–1853). His uncle was Ephraim Paddock, the brother of Phebe Paddock. In 1815 he moved to St. Johnsbury, Vermont, and set up a wheelwright's shop above his father's gristmill. In 1820 he married Lucy Peck Barker and In 1824 he built an iron foundry. his brother Erastus joined him to establish E. and T. Fairbanks, a partnership to manufacture heating stoves, cast iron ploughs a design for which he patented in 1826. In 1830 Fairbanks and Erastus became interested in the raising and processing of hemp. Fairbanks went on to patent a hemp and flax dressing machine and became the manager of the St. Johnsbury Hemp Company. He also built a set of scales that would measure large loads of hemp accurately, as there were no reliable scales at the time. Upon the success of building these scales, his brothers recommended that he make and sell these for general use. Fairbanks' most famous invention then became the platform scale for weighing heavy objects. These are commonly known as the Fairbanks Scales, for which he patented his original design in 1830. Before this time, accurate weighing of objects required hanging them from a balancing beam as a result, particularly heavy or ungainly objects could not be weighed accurately. A platform scale, if large enough, could weigh an entire wagon. By placing a full wagon on the scale, unloading it, and then placing it on the scale when empty, it became possible to easily and accurately calculate the weight and value of farm produce and other loads. In 1834 Fairbanks and his brother formed "E. and T. Fairbanks and Company" to manufacture and sell these platform scales. These scales were well known in the United States and around the world resulting in the company doubling in volume every three years from 1842 to 1857. There was a temporary slow down during the American Civil War, however, the business took off again after the war. Their partnership was incorporated in 1874 into a firm known as "Fairbanks Scale Company". These platform scales revolutionized weighing methods of large loads and have been in use ever since. Portable platform scales are found in almost every hardware store, physician's office, and manufacturing factory throughout the United States and the world. The first railway track platform scale patent was granted to Fairbanks on January 13, 1857, as Patent No. 16,381. In 1916 the company was purchased by ”Fairbanks, Morse and Company”. Ownership of the company has since changed several times, but Fairbanks Scales continue to be made in St. Johnsbury Vermont to this day. Fairbanks had received 43 patents in his lifetime with the last one at the age of 91. He died on April 12, 1886, and is buried at St. Johnsbury, Vermont, at the Mount Pleasant Cemetery. An early example circa 1900 of the first type of platform scales used in a grocery store. This design for accurately measuring goods that were sold over the counter revolutionised the weighing of goods throughout the world. Platform scale metal black with removable tray & pan. Has horizontal brass arm with a brass slide weight black removable weight hook and 2 x 2 lb. weights. Fairbanksflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

The Beechworth Burke Museum

The Beechworth Burke MuseumGeological specimen - Copper Ore

This specimen was recovered from Silverton Mine in Broken Hill, New South Wales. Otherwise known as the 'Day Dream Mine', the Silverton Mine was first established in 1883, when silver and lead deposits where discovered. Within a few short years, the population of Broken Hill reached 3000 people. As of today the Silverton Mine is still open, and has produced over 200 million tonnes of ore, which has generated over $100 billion. The Silverton Mine was also famous for a number of specimens such as silver, iron and zinc.Copper is considered to be a rare ore in that finding it in its pure form is rare. Nowadays when mining for Copper it is often found in mixed in with other minerals or it is recycled from use. Moreover, Copper is found in a range of everyday uses such as coins, cookware, pipes, heating conductors and anything that generate electricity. The fact that Copper is heat a heat conductor, electricity conductor and it does not corrode easily, makes this ore a versatile and useful. This specimen is part of a larger collection of geological and mineral specimens collected from around Australia (and some parts of the world) and donated to the Burke Museum between 1868-1880. A large percentage of these specimens were collected in Victoria as part of the Geological Survey of Victoria that begun in 1852 (in response to the Gold Rush) to study and map the geology of Victoria. Collecting geological specimens was an important part of mapping and understanding the scientific makeup of the earth. Many of these specimens were sent to research and collecting organisations across Australia, including the Burke Museum, to educate and encourage further study.A solid hand-sized cube-shaped sulfide and oxide with shades of green, grey and brown throughout. Copper is typically found as nuggets in the ground. It can be found in a range of forms such as its native state; mixed with other ores, such as zinc and iron; as porphyry copper deposits; and as major deposits. Porphyry deposits are when the mineral is scattered evenly throughout the rock. Major deposits are when the mineral is scattered amongst other minerals.burke museum, beechworth, indigo shire, beechworth musum, geological, geological specimen, mineraology, copper, copper ore, copper ore speciment, broken hill, new south wales -

The Beechworth Burke Museum

The Beechworth Burke MuseumGeological specimen - Brown coal

This particular specimen was recovered from the Lal Lal Coal and Iron Mine in Victoria, 19km from Ballarat. Brown Coal was discovered here in 1857, just alongside the Geelong to Ballarat Railway line. This discovery of lignite (brown coal) was the first in Victoria, which would bring important benefits to the region and state, both of which had previously been reliant on coal imports. In the 1860s, iron ore was found just 5km from Lal Lal, and the area was converted into an Iron Ore Mine. The Lal Lal Iron Mining Company took over operations in 1874, who then peaked iron production in 1884. This mine continued operations until June 1884, when the blast furnace was extinguished and never recommenced. The blast furnace at Lal Lal is considered one of the most important and highly significant sites ion early industrial history in Australia, as it is the only remaining best furnace from the nineteenth century in the Southern Hemisphere. The furnace ruins are 17 metres high, and are clearly visible today on Iron Mine Road, Lal Lal, near the Bungal Dam. This specimen of Lignite (brown coal) is significant, as it was mined from the area where brown coal was first discovered in Victoria, leading to an important and controversial future of the mining and use of brown coal in this State. The Victorian Heritage Database has listed the Lal Lal Coal Mine with local significance, with their Statement of Significance stating: "The Lal Lal coal mine is historically significant as the site of the first discovery of lignite (brown coal) in Victoria, and one that promised important benefits to regional and state industries that were reliant on coal imports at the time. The significance of the stie is reduced by the poor state of preservation of the coal mining and processing fabric". This specimen is part of a larger collection of geological and mineral specimens collected from around Australia (and some parts of the world) and donated to the Burke Museum between 1868-1880. A large percentage of these specimens were collected in Victoria as part of the Geological Survey of Victoria that begun in 1852 (in response to the Gold Rush) to study and map the geology of Victoria. Collecting geological specimens was an important part of mapping and understanding the scientific makeup of the earth. Many of these specimens were sent to research and collecting organisations across Australia, including the Burke Museum, to educate and encourage further study.A hand-sized light-weight, soft and combustable sedimentary rock specimen, that is dark brown in colour. The specimen has jagged edges, as though parts of the rock have crumbled away. Brown coal, or Lignite, is formed naturally from compressed peat, and is typically found in natural basins. The stages to the formation of coal ('coalification') begin with plant material and wood, which will decay if it is not subjected to deep burial or heating, and turn into Peat. Peat, when sufficiently compressed naturally, will turn into Brown Coal (Lignite), and finally into Black Coal (sub-bituminous, bituminous and anthracite). Each successive stage has a higher energy content and lower water content. It is brownish-black in colour. Brown Coal has a high moisture content, between 50 and 75 percent, and a low carbon content. Some Brown Coals may be stratified, with layers of plant matter, which means little coalification has occurred beyond the peat natural processing stage. When Brown Coal is submerged in dilute nitric acid or boiling potassium hydroxide solution, it reacts to produce a reddish solution, of which higher-ranked coals do not. When brown coal is pulverised and burned in boilers, the steam is used to drive turbines, which generates electricity. It is the lowest rank of coal, as when burned, it creates a relatively low heat content, which in turn does not create a great output of steam. burke museum, beechworth, indigo shire, beechworth museum, geological, geological specimen, mineralogy, brown coal, brown coal specimen, lignite, lal lal, lal lal coal mine, lal lal iron mine, ballarat, blast furnace -

Orbost & District Historical Society

Orbost & District Historical Societybranding iron, late 19th -mid 20th century

Branding irons are used to print a burn an identifying marker on the hide of horses or cattle so that they may be later identified if they become lost or escape from their pasture. The irons were typically forged by blacksmiths using a toolset that included hammers, anvils and chisels. The branding irons were used by heating the end bearing the owner’s initials to a very high temperature in a furnace, and then burnishing it against the skin of the cow. Brands were registered with state governments as unique marks. This allowed for a state registry to be maintained. This is an example of an implement used locally in the livestock industry.A branding iron with letter R on circular end. Handle loop is oval shaped. It has been painted blue to half way.branding-iron rural-industry -

Orbost & District Historical Society

Orbost & District Historical Societybranding iron, Late 19th -mid 20th century

Branding irons are used to print a burn an identifying marker on the hide of horses or cattle so that they may be later identified if they become lost or escape from their pasture. The irons were typically forged by blacksmiths using a toolset that included hammers, anvils and chisels. The branding irons were used by heating the end bearing the owner’s initials to a very high temperature in a furnace, and then burnishing it against the skin of the cow. Brands were registered with state governments as unique marks. This allowed for a state registry to be maintained. This item was used in Orbost in the livestock industry.This item is an example of an implement once used in the livestock industry in Orbost.A branding iron with the letter W on the end. It has a long iron handle with a ring grip at the top.branding-iron rural-industry -

Orbost & District Historical Society

Orbost & District Historical Societybranding iron, late 19th -mid 20th century

Branding irons are used to print a burn an identifying marker on the hide of horses or cattle so that they may be later identified if they become lost or escape from their pasture. The irons were typically forged by blacksmiths using a toolset that included hammers, anvils and chisels. The branding irons were used by heating the end bearing the owner’s initials to a very high temperature in a furnace, and then burnishing it against the skin of the cow. Brands were registered with state governments as unique marks. This allowed for a state registry to be maintained. This item was used in Orbost in the livestock industry.This item is an example of a common implement used in rural industry in Orbost.A branding iron with the letter J on the end. It has a long handle with a ring grip at the top.branding-iron livestock-industry rural-industry -

Orbost & District Historical Society

Orbost & District Historical Societybranding iron

Branding irons are used to print a burn an identifying marker on the hide of horses or cattle so that they may be later identified if they become lost or escape from their pasture. The irons were typically forged by blacksmiths using a toolset that included hammers, anvils and chisels. The branding irons were used by heating the end bearing the owner’s initials to a very high temperature in a furnace, and then burnishing it against the skin of the cow. Brands were registered with state governments as unique marks. This allowed for a state registry to be maintained. This item is an example of a common implement used in the livestock industry in Orbodt.A long-handled branding iron with an S or 2 on the end. There is a loop at the top for hanging.branding-iron rural livestock-industry -

Orbost & District Historical Society

Orbost & District Historical Societybranding iron, Late 19th century - mid 20th century

Branding irons are used to print a burn an identifying marker on the hide of horses or cattle so that they may be later identified if they become lost or escape from their pasture. The irons were typically forged by blacksmiths using a toolset that included hammers, anvils and chisels. The branding irons were used by heating the end bearing the owner’s initials to a very high temperature in a furnace, and then burnishing it against the skin of the cow. Brands were registered with state governments as unique marks. This allowed for a state registry to be maintained. This branding iron was used in Orbost. This item is an example of an implement commonly used in the livestock industry in Orbost.A long-handled branding iron with J H at the end. There is a hanging loop at the top.branding-iron rural livestock-industry -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Flat Iron, circa 1900

Blacksmiths started forging simple flat irons in the late Middle Ages. Plain metal irons were heated by a fire or on a stove. Some were made of stone. Earthenware and terracotta were also used, from the Middle East to France and the Netherlands. Flat irons were also called sad irons or smoothing irons. Metal handles had to be gripped in a pad or thick rag. Some irons had cool wooden handles and in 1870 a detachable handle was patented in the US. This stayed cool while the metal bases were heated and the idea was widely imitated. Cool handles stayed even cooler in "asbestos sad irons". The sad in sad iron (or sadiron) is an old word for solid, and in some contexts this name suggests something bigger and heavier than a flat iron. Goose or tailor's goose was another iron name, and this came from the goose-neck curve in some handles. In Scotland people spoke of gusing (goosing) irons. At least two irons were needed on the go together for an effective system, one would be in use, and the other re-heating. Large households with servants had a special ironing-stove for this purpose. Some were fitted with slots for several irons, and a water-jug on top. An early domestic object that gives an insight into how the ironing of clothes was done before the electric type irons we use and take for granted today. Iron; small flat domestic iron.Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, iron, flat iron, domestic iron, laundery, ironing equipment, sad iron -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Iron

Before the introduction of electricity, irons were heated by combustion, either in a fire or with some internal arrangement. An "electric flatiron" was invented by American Henry Seely White and patented on June 6, 1882. It weighed almost 15 pounds (6.8 kg) and took a long time to heat. The UK Electricity Association is reported to have said that an electric iron with a carbon arc appeared in France in 1880, but this is considered doubtful. Two of the oldest sorts of iron were either containers filled with a burning substance, or solid lumps of metal which could be heated directly. Metal pans filled with hot coals were used for smoothing fabrics in China in the 1st century BC. A later design consisted of an iron box which could be filled with hot coals, which had to be periodically aerated by attaching a bellows. In the late nineteenth and early twentieth centuries, there were many irons in use that were heated by fuels such as kerosene, ethanol, whale oil, natural gas, carbide gas (acetylene, as with carbide lamps), or even gasoline. Some houses were equipped with a system of pipes for distributing natural gas or carbide gas to different rooms in order to operate appliances such as irons, in addition to lights. Despite the risk of fire, liquid-fuel irons were sold in U.S. rural areas up through World War II. In Kerala in India, burning coconut shells were used instead of charcoal, as they have a similar heating capacity. This method is still in use as a backup device, since power outages are frequent. Other box irons had heated metal inserts instead of hot coals. From the 17th century, sadirons or sad irons (from Middle English "sad", meaning "solid", used in English through the 1800s[4]) began to be used. They were thick slabs of cast iron, triangular and with a handle, heated in a fire or on a stove. These were also called flat irons. A laundry worker would employ a cluster of solid irons that were heated from a single source: As the iron currently in use cooled down, it could be quickly replaced by a hot one. https://en.wikipedia.org/wiki/Clothes_ironThis iron is typical of the clothes iron used before electric irons superseded it.Salter iron no. 6, painted black but with rust showing through. Salter iron no. 6.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, iron, clothes, laundry -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyIron - Charcoal, c1850 - 1920

This iron was used by women, in their domestic role, to press the clothes from the mid 19th century. Coal embers were put inside, heating the base of the iron, to press the family's clothes and linen. Small bellows were used to fire up the embers to keep the iron hot. In the Kiewa Valley the embers would have been from the local hard wood growing on the farms.Ron White worked for the SEC on the Kiewa Hydro Electric Scheme. The iron belonged to his mother. Ron remembers being a boy of approximately 8 years of age, watching his mother do her ironing with this charcoal iron in the c1920s.This iron is made of cast iron. It has a hinged lid so that coal embers can be put inside for heat. The lid has a curved funnel. Bellows are used to blow air into the iron and keep the coals burning. It has a wooden handle and a lever (also with a wooden handle) to open the lid. There is a 2 and a half centimetre hole at the back of the iron to check the coals. The hole has a swivel cover.There is an embossed "S" on the swivel cover.iron, laudry, household, charcoal, antique, domestic, pressing clothes -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPump - Small Brass - for Coleman Iron, 1920s - 1930s

... was available. The iron was self heating and required a pump... This kerosene iron was used before electricity was available. The iron ...This kerosene iron was used before electricity was available. The iron was self heating and required a pump to pressurise it. It came with instructions, full measuring can and a wrench / key. Used by a resident in the Kiewa Valley.Small brass pump for pressurising cylinder on Coleman Iron. Brass with a wooden handle knob. Used with a bike pump action.iron, laundry, household, domestic, kerosene, pump for iron -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Wood Stove, circa 1880-1920

Stoves of this design are used for heating domestic places and were available in many designs and shapes. They commonly used wood as fuel and were not only used for heating but cooking as well. This stove was part of the original furnishings of the 1922 vessel 'Reginald M a South Australian costal trader it was made from material and fittings obtained from salvage yards. The vessel “Reginald M” was a two-masted coastal ketch, owned and built by Mr. Jack (John) Murch of Birkenhead, Port of Adelaide, South Australia. Its construction took approximately 6 months and it was launched at Largs Bay in 1922. Reginald M had a very shallow draft and a flat bottom that enabled it to come close to shore and to sit high and dry at low tide or to be beached on sand. The flat bottom was also to make the ship able to skim over reefs. Wagons could load and unload direct from her side. Her cargo included Guano, Barley, Wool, Horses, Cattle, Timber, Explosives, Potatoes, Shell Grit and Gypsum. On April 9th 1931Reginald M weathered a large storm in St Vincent Gulf, SA. The vessel suffered much damage; mast snapped and the crew labored for four hours to free her by chopping off the past and rigging. The crew patched her up and slowly returned to Port Adelaide with only a portion of the insured cargo being damaged. Her crew members at the time were owner Mr John H Murch of Wells Street Largs Bay, Skipper Mr R Murch John’s brother, Murray – son of Captain Murch and Seaman John Smith. Reg Webb purchased Carribie Station, at Marion in the Warooka District, south of Adelaide, in 1921. He cleared the land and farmed sheep and grain. In 1923 he shipped his own wool and grain from Marion Bay, having first carted 300 bags of the barley grain, 12 bags at a time, along the unmade track to the jetty. A photograph donated to Flagstaff Hill, dating about 1929 - 1942, shows two men on the Reginald M, holding between them their fishing catch of a large hammer shark. The photograph is stamped “GRENFELL STUDIO PORT LINCOLN PRINT” and titled “hammer shark caught on Reginald M”. The donor’s family lived on the Your Peninsular and dispatched their grain from a chute at Gleeson’s Landing to the awaiting transport vessel. Reg knew the Murch Brothers from Port Adelaide. The brothers had been using their ketch REGINALD M to ship Guano from the Islands, led by Captain Richard Murch. Reg approached them in 1934 about shipping grain from Marion Bay. The brothers visited the bay and thought it was an ideal place. They showed Reg where to stack his grain and they measured up the cliffs. When Reg was ready, they brought down and installed a ninety foot wooden chute. The bags of grain were then individually sent down the chute, landing in a waiting small boat then rowed to REGINALD M, 14 bags at a time. After 10 hours REGINALD M would be fully loaded with 1300 bags of grain and shipped to waiting ports. At one time a wild storm destroyed the chute but it was rebuilt and strengthened. REGINALD M was involved in shipping the grain from there until 1938. In 1940 Able Seaman Allan H Lucas served on Reginald M between September and December, being engaged and discharged from Port of Adelaide. His Certificate of Discharge was signed by ship’s Master W S Murch. It seems that at some stage Reginald M was used as a Customs vessel, as one photograph in Flagstaff Hill’s collection shows “H.M.C. No. 3, Pt Adelaide” on the bow. In 1969 the last freight left Marion Bay on the ketch REGINALD M carrying grain, wool and explosives. In late 1970 she was sold to the Mt. Lyell Mining and Railway Company and was used by them as a barge to carry explosives. In 1972 the Navy League of Strahan, Tasmania, purchased her for use by the Strahan Sea Cadet Unit to use at Macquarie Harbour and renamed her T.S. Macquarie. However this plan for use of Reginald M did not come to pass. In 1974 Mr. Andrew Rennie, of East Brighton, Melbourne, bought her for a similar purpose. , paying $5,000 and donating a ‘Cadet of the Year” trophy to the Sea Cadets. He sailed her from Strahan to Melbourne, planning to use her for pleasure sailing. In 1975 Reginald M was sold to Melbourne Ferry Company at auction. Later in 1975 the Reginald M was bought by Flagstaff Maritime Museum for $20,000 . She has been restored and is now one of the exhibits in the Village lagoon or lake. It was restored in 2006 using funds from a $4,000 government grant. Flagstaff Hill Maritime Village’s Collection holds several other artefacts associated with Reginald M. They include photographs of the Reginald M, including one photograph of her in Outer Harbour, S.A. dated 1947, with Skipper- R.F. Dale and Owner- John Murch. Another shows her docked at Port Adelaide, with the lettering H.M.C. No. 3 Pt ADEL (standing for His or Her Majesty’s Customs). The stove is significant as it represents the heating and cooking appliances used in late 19th and early 20th century, both on board vessels as well as for domestic purposes. The stove has additional significant for its association with the vessel "REGINALD M" a coastal trading ketch from South Australia built in 1922 at Largs Bay. It is one of very few sailing coastal trading vessels built in Australia with its flat bottom, single chine shape designed for navigating shallow water. See additional comments in the Production section this documents under Comments for further information regards the stove. Stove a cast-iron, rectangular, four-legged stove with a hinged front door. This stove was part of the original furnishings of the vessel 'Reginald M', built in Adelaide 1922. Image of a log cabin with an illegible inscription below it.flagstaff hil, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, coastal trader, trading vessel, vessel reginald m, ketch, john murch ship builder, reg webb, carribie station, mt lyell copper company, queenstown navy league, andrew rennie, melbourne ferry company, r.f. dale, port adelaide vessel reginald m, macquarie training vessel, grenfell studio port lincoln, stove, domestic heating, domestic cooking, heater, cooking unit, wood fired stove, wood stove, wood-burning stove -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Clothes Iron, last quarter of the 19th century

Blacksmiths started forging simple flat irons in the late Middle Ages. Plain metal irons were heated by a fire or on a stove. Some were made of stone. Earthenware and terracotta were also used, from the Middle East to France and the Netherlands. Flat irons were also called sad irons or smoothing irons. Metal handles had to be gripped in a pad or thick rag. Some irons had cool wooden handles and in 1870 a detachable handle was patented in the US. This stayed cool while the metal bases were heated and the idea was widely imitated. Cool handles stayed even cooler in "asbestos sad irons". The sad in sad iron (or sadiron) is an old word for solid, and in some contexts this name suggests something bigger and heavier than a flat iron. Goose or tailor's goose was another iron name, and this came from the goose-neck curve in some handles. In Scotland people spoke of gusing (goosing) irons. At least two irons were needed on the go together for an effective system, one would be in use, and the other re-heating. Large households with servants had a special ironing-stove for this purpose. Some were fitted with slots for several irons, and a water-jug on top.An early domestic object that gives an insight into how the ironing of clothes was done before the electric type irons we use and take for granted today.Clothes Iron, wedge shaped, cast iron painted black with cylindrical handle small funnel through centre of handle.Noneflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, iron, flat iron, laundry equipment, sad iron, domestic object -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Clothes Iron, last quarter of the 19th century

Blacksmiths started forging simple flat irons in the late Middle Ages. Plain metal irons were heated by a fire or on a stove. Some were made of stone. Earthenware and terracotta were also used, from the Middle East to France and the Netherlands. Flat irons were also called sad irons or smoothing irons. Metal handles had to be gripped in a pad or thick rag. Some irons had cool wooden handles and in 1870 a detachable handle was patented in the US. This stayed cool while the metal bases were heated and the idea was widely imitated. Cool handles stayed even cooler in "asbestos sad irons". The sad in sad iron (or sadiron) is an old word for solid, and in some contexts this name suggests something bigger and heavier than a flat iron. Goose or tailor's goose was another iron name, and this came from the goose-neck curve in some handles. In Scotland people spoke of gusing (goosing) irons. At least two irons were needed on the go together for an effective system, one would be in use, and the other re-heating. Large households with servants had a special ironing-stove for this purpose. Some were fitted with slots for several irons, and a water-jug on top.An early domestic object that gives an insight into how the ironing of clothes was done before the electric type irons we use and take for granted today.Clothes Iron, wedge shaped, cast iron painted black with cylindrical handle small funnel through centre of handle.Noneflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, iron, flat iron, laundry equipment, sad iron, domestic object -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Try pot, c. 20th century

This try-pot is one of a set of three. Whalers used large iron pots, called try-pots to liquefy large chunks of whale blubber down into oil. Early on in the history of whaling, small whaling boats had no means to process blubber at sea and had to bring it into whaling stations for processing at shore-based try-works. Later, when bay whaling evolved and large scale vessel were utilised for hunting whales, try pots were mounted onto the top deck. This advance had its benefits as the processing facilities were mobile, whalers could move operations to follow whales and discover new whaling grounds. The deceased whale would be tied up alongside the ship, the crewmen cut away the blubber, or outer fat layer, in long strips. They hauled the strips aboard, cut them into smaller pieces, and tossed them into boiling cauldrons on deck to render the fat into oil. The whale oil was stored in barrels in the cargo hold, and brought to put for sale. The oil was much sought after as a good quality fuel tor heating, light and lubrication. Try pots were used in the whaling industry, one of the very early industries in Colonial Australia, including here on the southwest coast of Victoria. The high grade oil was a much sought after product and used for essential services such as fuelling the lights of the lighthouses. Commercial whaling ceased in Australia in 1979.Try pot, one of a set of three. A large cast-iron cauldron of about 200 gallons in capacity. Round metal container with rounded base and flat extended lip. flagstaff hill, warrnambool, maritime museum, shipwreck coast, try pot, trypot, cauldron, whale oil, whaling, fuel -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Try pot, c.20th century

This try-pot is one of a set of three. Whalers used large iron pots, called try-pots to liquefy large chunks of whale blubber down into oil. Early on in the history of whaling, small whaling boats had no means to process blubber at sea and had to bring it into whaling stations for processing at shore-based try-works. Later, when bay whaling evolved and large scale vessel were utilised for hunting whales, try pots were mounted onto the top deck. This advance had its benefits as the processing facilities were mobile, whalers could move operations to follow whales and discover new whaling grounds. The deceased whale would be tied up alongside the ship, the crewmen cut away the blubber, or outer fat layer, in long strips. They hauled the strips aboard, cut them into smaller pieces, and tossed them into boiling cauldrons on deck to render the fat into oil. The whale oil was stored in barrels in the cargo hold, and brought to put for sale. The oil was much sought after as a good quality fuel tor heating, light and lubrication. Try pots were used in the whaling industry, one of the very early industries in Colonial Australia, including here on the southwest coast of Victoria. The high grade oil was a much sought after product and used for essential services such as fuelling the lights of the lighthouses. Commercial whaling ceased in Australia in 1979.Try pot, one of a set of three. A large cast-iron cauldron of about 200 gallons in capacity. Round metal container with rounded base and flat extended lip. It was used to heat whale blubber to remove the oil.flagstaff hill, warrnambool, maritime museum, shipwreck coast, try pot, trypot, cauldron, whale oil, whaling, fuel