Showing 12 items matching "inlet valve"

-

Federation University Historical Collection

Federation University Historical CollectionDocument - Document - Design, E J Barker: University of Melbourne: Bachelor of Mechanical Engineering; Engineering Design Part II, 1946

... inlet valve..., valve gear and inlet and exhaust valves for a 6 cylinder truck..., valve gear and inlet and exhaust valves for a 6 cylinder truck ...Four folders containing an Engineering Design Part II Project. Each has detailed written information and drawings. No.1: To design an Extruder Addition to the hydraulic press in the plate shop to enable it to be used as an extruding press to operate on materials similar in behaviour to a wax. No. 2: To design a flywheel of uniform strength of not less than 25 feet. No 3: To design cams, valve gear and inlet and exhaust valves for a 6 cylinder truck engine. No 4: To design an experimental brown coal autoclave for drying brown coal in 10 kilogram lots. Jack chose to do Engineering while still at Footscray Technical School as it gave access to Diploma Courses and tertiary studies. This enabled him to enter the University of Melbourne and do a Bachelor in Mechanical Engineering - 1945, 1946, and 1947. In 1948 he did a Diploma in Education at Melbourne University. From this path he was able to follow a career in teaching and his first appointment was at the School of Mines in Ballarat, (SMB) 1949. He became the first Vice Principal of SMB in 1960 and then Principal in 1964 to 1976. From 1976 to his retirement in 1987, he was the Foundation Director of Ballarat College of Advanced Education (BCAE). The Library building at Mount Helen Campus is named after him.Four manila folders with design assessment in each. Each folder has written descriptions and detailed drawings.e j barker, jack barker, melbourne university, engineering, diploma of mechanical engineering, diploma of electrical engineering, school of mines ballarat, smb, diploma in education, vice principal, principal, foundation director, ballarat college of advanced education, bcae, bachelor of mechanical engineering, library, mount helen campus, engineering drawing, design, specifications, manufacture, extruder addition, hydraulic press, flywheel, cams, valve gear, inlet valve, exhaust valve, 6 cylinder truck engine, autoclave, brown coal -

Geoffrey Kaye Museum of Anaesthetic History

Geoffrey Kaye Museum of Anaesthetic HistoryEquipment - Vaporiser, c. 1958

... body housing the bimetallic coil. Inlet valve with a brass...Stamped on Inlet and outlet valve: INLET OUTLET Stamped.... Inhaler Fluotec mark II Stamped on Inlet and outlet valve: INLET ...The Fluotec vaporizer was made to administer only halothane (Fluothane). It was one of the first vaporizers made for use with only one anesthetic, and one of the first to use a bimetallic coil for temperature compensation.The bimetallic coil is part of the valve that controls how much of the carrier gas enters the vapor chamber to vaporize the anesthetic.Modern vaporisers still use this bimetallic coil technology today. Serial No: 5040 Patent No: 814427 A ready reference “calibration card” came attached to these vaporizers. The card was printed with a scale that indicated the concentration of halothane produced at different flow rates and dial settings.This item does not have a reference card with it.This Flotec vaporiser holds historic significance as a very good example of an early model piece of equipment for halothane only administration. Modern vaporisers still use the bimetallic coil technology and therefore this object has scientific and research significance.Small metal stand with 3 rubber feet, Main metal cylinder body housing the bimetallic coil. Inlet valve with a brass attachment and metal outlet valve. Metal dial that controls % Penthrane. Dial notches range from OFF to 1.5. Small silver chain hangs from the top of the dial lever. Small silver metal box held by 4 screws and a round bakelite window with FULL inscribed in white text located on the front of the main cylinder Fluothane Cyprane vaporiser. Fluotec Mark II by Pentec, with stand. Royal Children's HospitalStamped on Inlet and outlet valve: INLET OUTLET Stamped on to a plate on the front of the vaporiser: KEEP UPRIGHT / PENTHRANE / WHEN CHARGEDinhaler, fluotec mark ii -

Geoffrey Kaye Museum of Anaesthetic History

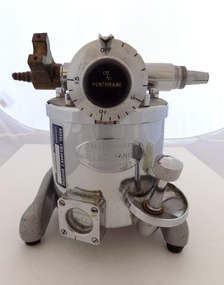

Geoffrey Kaye Museum of Anaesthetic HistoryEquipment - Vaporiser, Penthrane, Cyprane Ltd, c. 1982

... plate sitting on top of the dial and the inlet/outlet valve. ... CHARGED •Inscribed on inlet & oulet valve plate: PENTEC 2/ SERIAL... •Inscribed on inlet & oulet valve plate: PENTEC 2/ SERIAL NO 252939 ...This vaporiser has a main cylindrical body with a step up to the dial plate with a small red latch to lock dial in to place.On the front of the body sits a square gauge to indicate the level FULL along with a long rectangular shape.There is an Inlet and outlet valve that sits behind the metal dial.There is a manufacturers plate sitting on top of the dial and the inlet/outlet valve. Inscribed on top plate: KEEP UPRIGHT/ PENTEC 2/ WHEN CHARGED •Inscribed on inlet & oulet valve plate: PENTEC 2/ SERIAL NO 252939/ PATENTS PENDING •MADE IN / ENGLAND BY/ CYPRANE LTD / KEIGHLEY •Metal dial has inscribed: OFF/.2 .5 1 1.5 2 Max •Inscribed on front plate in green writing: USE ONLY/ PENTHRANE/ (METHOXYFLURANE)penthrane, vaporizer, anaesthesia, anaesthetic machine -

University of Melbourne, Burnley Campus Archives

University of Melbourne, Burnley Campus ArchivesMachine - Cutaway Model, Cutaway Pump and Drive Shaft

... inlet/outlet valves at top. Used for teaching Arboriculture... Model of a pump (water?) and drive shaft for motor showing inlet ...Model of a pump (water?) and drive shaft for motor showing inlet/outlet valves at top. Used for teaching Arboriculture. Bolted to a metal stand. Painted bright contrasting colours.arboriculture, teaching, pump, drive shaft, motor, artifact -

Stawell Historical Society Inc

Stawell Historical Society IncPhotograph, Stawell's Water System 1999 -- 8 Photos -- Coloured

... Valve house Pomonal b. Old Valve house & inlet grating from... Valve house Pomonal b. Old Valve house & inlet grating from ...Eight coloured photos of Stawell's Water system. a. Old Valve house Pomonal b. Old Valve house & inlet grating from tunnel cutting. c. Old Valve house & Main ground grill. d. Sludge trap. e. interior of water supply tunnel at Pomonal. f. Tunnel showing outlet litter trap with rake for cleaning trap. g. Tunnel entrance at Pomonal. h. Vandal shattered cncrete pipe with multiple wire reinforcing (old?) Eight colour photographs of buildings, tunnels and equipment in bush setting.grampians water supply -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyIron Hand Kerosene, mid to late 1900s

... the main body of the iron. The bowl has an air valve and inlet.... The bowl has an air valve and inlet for pressurised air intake ...The 1950's saw a revolution in small appliances for use in the average household. This hand held self heating(kerosene) iron was introduced as a time saving and more convenient iron for pressing clothes and other cloth fabrics. It replaced irons needing a separate fire source to heat the ironing plate. These irons continued to be in service, even when electricity was available in cities and larger rural towns (domestic electric steam irons were invented in 1938). This item was used before and during the electricity supplies available from the Kiewa Hydro Electricity Scheme. These irons remained in use within regional rural areas that had limited or unreliable electrical reticulation.In the 1950s and later the Kiewa Valley was still a relatively isolated region which was home to rural properties and small settlements. The availability of electricity and or the financial means to afford new types of electric hand irons ensured that older and sometimes less efficient ironing remained for an extended period covering the 1960s to 1970s. Kerosene products, such as this kerosene iron was a cheaper method for farm based domestic and other rural activities requiring a heat source. The use of kerosene as a heat/light source was able to be supplied in bulk and able to be used when floods severed vital roads into this region. The supply of electricity was in summer time subject to interruption from bush fire damaged wooden poles carrying the electrical cables. Self sufficiency by rural populations was the backbone of survival and the ability to store energy sources "on the farm" was a prerequisite of isolated regions, such as the Kiewa Valley, circa 1950s.This Coleman kerosene iron has a solid steel chrome plated(press) base with a painted (blue) wooden handle. The handle is stud fastened onto an oblong shaped rolled steel handle frame and screwed (two screws) onto the base plate. Both the heating plate and the top securing plate are shaped similar to a river boat. The main housing enclosing the heating element is enamel coated(blue in colour) steel and has a half hole for lighting the kerosene at the rear end. Behind the handle and protruding upwards is a stainless steel fully enclosed container (bowl shaped) for the main supply of kerosene to the burner or generator(enclosed within the main body of the iron. The bowl has an air valve and inlet for pressurised air intake (hand pump) On the bottom rear of the fuel bowl there is a screw regulated fuel pump. The fuel heated base plate provides the heat for this advertised "self heating iron(instant lighting). See KVHS 0347B- Instruction sheet; KVHS 0347C- Wrench; and KVHS 0347D Fuel can.Stamped on the base plate of the handle, front region "COLEMAN LAMP & STOVE CO." below this "WICHITA KAN" below this"TORONTO CAN". In the middle of the handle base and in larger print "COLEMAN Instant-Lite" At the rear location in large print "MODEL 4" in smaller print below "MADE IN U.S.A." below this "PAT#1718473"household appliances, alternative non electrical ironing appliances, domestic appliances, kerosene appliances -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPhotographs – SECV – Clover Power Station

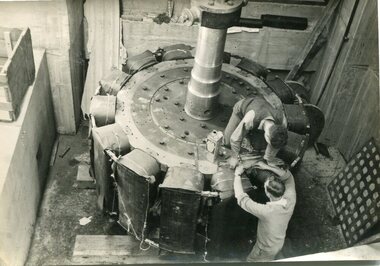

The Junction Dam and Clover Dam Power Station, stages of the Kiewa Hydro-Electric Scheme, were needed to meet the increased power demands of the wartime industry in Victoria. Clover added 26 megawatts to the grid. Junction Dam was completed and ready to hold water by September 1943, but was emptied in December 1943 and not filled again until May 1944. Construction of Clover Power Station commenced in July 1941 and both turbines were in service by May 1945.Clover Power Station and Junction Dam were part of the Kiewa Hydro Electric Scheme constructed by the State Electricity Commission of Victoria.Set of 21 black and white photographs taken by the official SECV photographer who gave each photo a number prefixed by K (for Kiewa) K1367- 19 Nov 1943 The rotor for the generator K1368- 19 Nov 1943 Base of the generator K1377- 2 Dec 1943 Generator under construction K1380- 2 Dec 1943 Power Station under construction K1381- 2 Dec 1943 Generator being assembled K1386- 3 Dec 1943 Part of the generator K1389- 30 Dec 1943 Inlet pipe work K1391- 30 Dec 1943 Inside the power station K1392- 30 Dec 1943 Inlet pipe work K1396- 27 Jan 1944 Equipment in the power station K1410- 4 FGeb 1944 Unpacking equipment for the power station K1422- 16 Feb 1944 Generator being assembled K1425- 22 Feb 1944 Water way – power station K1433- no date Generator being assembled K1434- 3 Mar 1944 Constr5ucting the power station K1448- no date Generator inside the power station K1450- 17 Mar 1944 Clover Power station K1452- 17 Mar 1944 Looking down on the valve-water release from the power station K1456- 22 Mar 1944 ‘half Travel Opening- No 1 Relief Valve’ Overflow from the power station K1458- 22 Mar 1944 Outlet from the power station K1462- 22 Mar 1944 Inside the power station On the back- each photograph has a handwritten reference number starting with K and the date stamped or writtensecv; kiewa hydro electric scheme; clover power station; junction dam; bogong -

Seaworks Maritime Museum

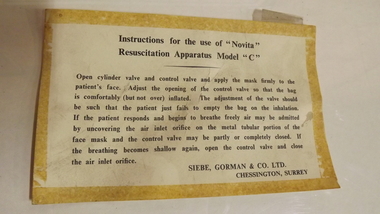

Seaworks Maritime MuseumInstructions Novita Resuscitation apparatus

Instruction card for Novita resuscitation apparatus model CInstructions for the use of "Novita"/Resuscitation Apparatus Model "C"/Open cylinder valve and control valve and apply the mask firmly to the/patient's face.Adjust the opening of the control valve so that the bag/is comfortably (but not over) inflated. The adjustment of the valve should/be such that the patient just fails to empty the bag on the inhalation./If the patient responds and begins to breathe freely air may be admitted/by uncovering the air inlet orifice on the metal tubular portion of the/face mask and the control valve may be partly or completely closed. If/the breathing becomes shallow again, open the control valve and close/the air inlet orifice./ SIEBE, GORMAN & CO. LTD./ CHESSINGTON, SURREYport melbourne authority (pma) -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pump, circa 1930's - 1940's

This pump is an Ajax Type L2 Series A model, made and sold by McPherson’s Pty Ltd of Melbourne circa 1930’s to 1940’s, is a mechanical, hand operated, constant flow pressure pump. It would have been used to pump fluids from one area to another, for example from a dam to a tank or used as a bilge pump on a small vessel, mounted on the vessel’s bulkhead, floor or deck. This type of hand pump is sometimes called a ‘Reciprocating Suction Pump’. It has a mechanical pumping action of the lever moves the piston inside the pump up and down. The water is lifted from below the pump through the inlet pipe and into the pump’s cylinder. This action causes the lower valve to close and the piston’s valve opens and the pressure within the pump forces the water out of the pump through the exit pipe. The limitation of this type of pump is that it can only raise the water a maximum of about 7 metres from beneath the ground and yields 24-26 Litres per minute. This type of pump could be used for many purposes such as pumping water or fuel. McPherson’s 1940’s advertisement proclaims “For all jobs on the land – irrigation, spraying, tank, plumbing, fire-fighting – there’s a suitable “Ajax” pump. Send us the details of you pumping problem. Our Expert’s advice will help you choose the right pump – the one that will give you most years of PROFITABLE PUMPING.” (The Australasian (Melbourne) Sat. 26th October 1940.) McPherson’s Pty Ltd, the manufacturer, advertised a similar pump to this one in The Australasian (Melbourne) in 1936, calling it the Ajax Double Acting Hand Pump. In 1942 another advertisement advised that a representative for a fire-fighting equipment supplier was visiting the western district of Victoria. The company could now supply double-action two-spray Ajax pumps at lower prices than similar pumps the district had recently purchased from Adelaide. McPHERSON’S FOUNDER and COMPANY TIMELINE 1860 – Thomas McPherson, a Scottish immigrant (c. 1853 ), founded McPherson’s in Melbourne, supplying pig iron (lead ingots imported as ballast in ships) to local manufacturers. 1882 – Thomas McPherson established a warehouse in Collins St Melbourne and included tools, steam fittings and machinery in his wares. The business expanded to include steam saw mills and became known as Thomas McPherson and Sons (William Murray and Edward). 1888 – Thomas passed away and his sons inherited the business. In 1896 William Murray became the sole proprietor after his brother Edward’s death. 1900 – The firm expanded, establishing Acme Bolt Company to manufacture nuts and bolts. 1912 – McPhersons Pty Ltd established a machinery warehouse and showroom in 554-556 Collins St Melbourne. McPherson’s went on to establish branches in Sydney (1911), Adelaide (1921) and Perth (1930) 1917 - McPherson’s supplied ‘dog spikes’ for the transcontinental railway, running from Eastern to Western Australia. 1918 – A tool works set up in Kensington, Melbourne, manufacturing Macson lathes and made machine tools that previously had to be imported. 1924 – The Bolt Works was transferred to a new building in Melbourne. McPhersons began making pumps. 1929 – McPherson retired. His son (Sir) William Edward McPherson (known as ‘WE’), was born in Hawthorne, Melbourne, in 1898. After his education he began work in his father’s Melbourne hardware and machinery business He took over as governing director when his father retired. 1929-1932 – McPherson’s supplied thousands of tons of rivets from its Richmond (Melbourne) Bolt Works for the construction of the Sydney Harbour Bridge. 1936 – McPherson’s Pty Ltd is advertising Ajax Pumps in newspapers 1934 – McPhersons purchased the property adjoining the warehouse in Collins Street, and during 1935-1936 built a new office and showrooms on the site of 546-445 Collins St. 1939 - McPherson’s acquired the Tool Equipment Co. Pty. Ltd and Associated Machine Tools Australia Pty Ltd was formed to separate McPherson’s machine-tool manufacturing and merchandising interests. 1939 – Ajax Pump Works, a foundry and pump manufacturing plant, was established in Tottenham, Melbourne, and the Ajax Bolt and Rivet Co Pty Ltd began manufacturing in New Zealand. 1944 - McPherson’s became a public company, McPherson’s Ltd. 1948 - The Ajax Pump Foundry opened at Kyneton, Victoria and in the post war years it grew to became a large manufacturer. 1980’s – Ajax Pumps brochure lists the address as 6 Buckhurst St, South Melbourne, Vic 3205 with the Telephone number 03 669 3588 1988 - Ajax Pumps acquired the Forrers Company, which was established in 1921. Manufacturing in Ipswich, Queensland, specialising in submersible sewage pumps. 1991 – KSB Ajax was formed, bringing together the companies KSB and Ajax Pumps 1993 – Manufacturing was moved to state-of-the-art premises in Tottenham, Victoria 2001 - The Forrers facility was moved to Tottenham. 2007 - Company name KSB Ajax Pumps was changed to KSB Australia Pty Ltd. 2009 - KSB Australia opened a branch in Townsville, Queensland. 2011 - KSB Australia moved to its dedicated Water and Waste Water Competence Centre in Bundamba, Queensland. DISPLAY OF THIS AJAX PUMP This pump was installed at Flagstaff Hill Maritime Village as part of a working display in the village by the Friends of Flagstaff Hill, in acknowledgement of the dedicated involvement of one of its long serving members, Bob Crossman. The display was officially opened 31st March 2018 and incorporates a restored Furphy Tank and Water Pipe Stand. The pump is used to draw water from the lake, through the water stand pipe and into the reconditioned Furphy Tank. This Ajax pump made by McPherson’s Pty Ltd is significant for its association with McPherson’s, a prominent manufacturer of hardware in Victoria. McPherson’s is famous for supplying ‘dog-spikes’ for the transcontinental railway (eastern to western Australia, 1917) and rivets for the Sydney Harbour Bridge (1929-1932). The Ajax pump is also of significance because of its association with McPherson’s Governing Director (Sir) William McPherson, former premier and treasurer in Victoria 1928-1929. The former McPherson’s Pty Ltd building in Collins Street Melbourne is now on the Victorian Heritage Register VHR H0942 This pump is representative of mechanical pumps popular in the early to mid-1900’s and still used today. Hand operated pressure pump, double acting. Cast metal case, painted red, with steel hose attachments and long metal lever. Pump is bolted to wooden plank. Model of pump is AJAX, Type L2, Series A pump. Embossed on lower section of pump "L2 - 10", "L2 - -1", "AJAX" “(?) –2-1” Embossed on lower handle “3-7” “L – 4” Embossed on attached plate “FOR SPARE PARTS / TYPE L2 / SERIES A / PUMP ASSEMBLED BY T R” Manufactured by McPherson’s Pty Ltd of Melbourne circa 1930’s - 1940’s.flagstaff hill, warrnambool, flagstaff hill maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, ajax pump works tottenham melbourne, ajax pump factory kyneton, william edward mcpherson, thomas mcpherson of melbourne, mcpherson’s pty ltd melbourne, acme bolt company, tool equipment co. pty. ltd, associated machine tools australia pty ltd, ajax bolt and rivet co. pty ltd new zealand, forrers company ipswich queensland, ksb ajax pumps, ksb australia pty ltd, macson lathes, tool manufacturer early to mid- 20th century, ajax double acting hand pump, ajax type l2 series a pump, qisjax pumps, water pump 1940’s, fuel pump 1940’s, hand operated constant flow pressure pump, reciprocating suction pump, agricultural hand pump, plumber’s hand pump, portable hand pump -

Stawell Historical Society Inc

Stawell Historical Society IncTool - Realia, Glass working bench torch burner, 1960's

Can be operated on Natrua Gas, Town Gas, and Bottled Gas, Needle valves for gas and Air Supplies allows fine flame adjustment. Burner Nozzle canTripod shaped base with ball joint nozzle and two gass inletsscience, education -

Trafalgar Holden Museum

Trafalgar Holden MuseumVehicle - VZ Holden Executive, 2004

... (255 hp), the Alloytec V6 gains variable valve timing on both... (255 hp), the Alloytec V6 gains variable valve timing on both ...Released in August 2004, the VZ series was a minor facelift of the previous VY series that featured a new V6 engine in different tune guises. The powerplants included 175 and 190 kW (235 and 255 hp), 3.6-litre Alloytec V6 engines in place of the older 3.8-litre Ecotec V6. Other changes to the V6 was the loss of the supercharger that was included in the S models The VZ Commodore was available in several model variations, most of which carried over from the VY range, with the exception of the newly introduced SV6, a specification level that replaced the S range. All models in the Commodore range (Executive, Acclaim, Berlina, Calais, SV6, SV8 and SS) were available as sedans. The advanced 3.6-litre Alloytec engines were more powerful, responsive and fuel-efficient than the outgoing Ecotec V6. To achieve 190 kW (255 hp), the Alloytec V6 gains variable valve timing on both inlet and exhaust sides as well as a dual stage intake manifold, while the 175 kW (235 hp) version retains variable valve timing on the inlet side only. Sales of the VZ series failed to match those of the preceding VY in light of rising small car sales, higher fuel prices and growing interest in the whole new replacement, the VE series. Selected models bring advanced active safety features that electronically assist the driver to maintain vehicle control in emergency situations. VZ Holden 4 door sedan with red body paint and fabric upholsteryLion badge front grille,V6 badge on mudguards. Executive badge on RHS of boot and Comnmodore on LHS. Lion badge on middle of bootvehicle, vz holden, car -

Moorabbin Air Museum

Moorabbin Air MuseumManual - Holley Aircraft Carburettors, Holley Aircraft Carburettors Instruction Manual Third Edition

... Fuel valves Inlets Limits Mixture control Nozzle bar Overhaul ...Instructions on servicing & maintenance of Holley aircraft carburetors, circa 1941Appears to be a duplicate itemnon-fictionInstructions on servicing & maintenance of Holley aircraft carburetors, circa 1941accelerating pump, cam, carburetor, clearance chart & diagra, compensator jet/needle/seat/spring/unit, diaphragm unit & vents, end blocks, fixtures & tools, fuel valves, inlets, limits, mixture control, nozzle bar, overhaul sheets, primers, power mixture valve, stabilizer valve, test stand, throttles, vapor separator, vent ring, venturi