Showing 21 items matching "ironstone china"

-

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncDomestic object - Ironstone China Wash bowl and jug

... Ironstone China Wash bowl and jug...Ironstone China Wash bowl and jug...Ironstone china pieces were common domestic items during...: "IRONSTONE CHINA/ REGD. SOL 391413/ J & G MEAKIN/ENGLAND Underneath...Ironstone china pieces were common domestic items during ...Ironstone china pieces were common domestic items during the 19th to mid 20th century in many Australian households. This kind of china is not porcelain but porous earthenware, made of clay mixed with feldspar. Patented in 1813 by Charles James Mason in Staffordshire, England, it was an immediate success and became widely produced by a range of Staffordshire potters. J & G Meakin Pottery dates back to 1845 when James Meakin started a pottery business at Lane End in Staffordshire.nIn 1848 he moved the business to Hanley in Staffordshire, before retiring in 1852 and handing the business over to his two sons James and George, who carried on with the pottery, trading as J & G Meakin. The "SOL" and sun face trademarks were registered in 1912. The firm was taken over by the Wedgwood Group in 1970. In 2000, production under the Meakin name ceased. W. H. Grindley was founded at the Newfield Pottery in 1880 by William Harry Grindley (principal partner). Mr Turner and Mr Alfred Meakin were also involved. Early advertisements stated that they produced Earthenware and Ironstone China - particularly for the Canadian, United States, South American and Australian markets. The mark on this jug was used from c1891 until 1925. W. H. Grindley China was manufactured until 1991, making it one of the last Stoke on Trent potteries.These items are representative of a common domestic item used by households in the Wodonga district and throughout Australia, many manufactured specifically for the Australian market.A white ironstone jug and bowl. The jug features a leaf design embossed on the surface. The bowl has a small circle pattern around the rim. They are not as set as the jug bears the mark W. H. Grindley and the bowl was made by J & G Meakin.Underneath Bowl: above and below image of the sun: "IRONSTONE CHINA/ REGD. SOL 391413/ J & G MEAKIN/ENGLAND Underneath jug: above and below the royal insignia: ROYAL IRONSTONE CHINA / W.H. GRINDLEY & CO. / ENGLAND"ironstone, domestic items, staffordshire pottery -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Domestic object - Chamber pot

... , England. Royal ironstone China....Royal ironstone China coat of arms W H Grindley & 02... Mitcham melbourne Browne Dot Royal ironstone China coat of arms W ...Light grey ironstone chambered pot with a relief leaf design. Stamp on underside: Coat of arms WH Grindley & 02, England. Royal ironstone China.Royal ironstone China coat of arms W H Grindley & 02 Englandbrowne, dot -

Mission to Seafarers Victoria

Mission to Seafarers VictoriaDomestic object - Condiment Tureen, 1883-1913

... ironstone china...SAILORS' HOME MELBOURNE on lid on body. ROYAL IRONSTONE... remaining objects from the Sailors' Home. condiment ironstone china ...This item was found in the Bar area of the Flying Angels Club at 717 Flinders St. The inscription "Sailors' Home" may refer to either the establishment formerly on Spencer St or later on Siddeley St built in 1903 and used until 1963. The Sailors' Home and Sailors' Rest were established in various locations in Melbourne and in Williamstown throughout the late19th century and early 20th century. It was of significance as a feature of the township that for some years was the main point of arrival in the early days before establishment and early days of Melbourne. Hugh Ronald Reid, member of the Melbourne Harbour Trust, was a founder of the Sailors' Home. The tureen is one of the rare remaining objects from the Sailors' Home.Small oval shaped condiment tureen or serving dish with lid; white glazed ironstone. Small hole in lid for spoon (missing). Lid and front of tureen have picture of a lifebuoy with a rope around it and "SAILORS' HOME MELBOURNE" written on it. Printed Inscription on the base with pottery crest.SAILORS' HOME MELBOURNE on lid on body. ROYAL IRONSTONE CHINA JOHNSON BROS ENGLAND with a picture of royal arms under base.condiment, ironstone china, johnson bros, sailors' home melbourne, tureen, hugh ronald reid -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Bed Pan, S Maws & Son & Thompson, 1870-1900

... White ironstone china slipper bed pan with pear-shaped base... for use White ironstone china slipper bed pan with pear-shaped ...Item is of British manufacture made of ironstone pottery possible made by or for the Maws Co that provided many glass and ceramic items for hospitals, doctors and chemists. It was used in various types of Hospitals throughout Australia to facilitate a patient's comfort.Item is believed to an early production item and to have been made between 1870 to 1900.These items were made in England for export to Australia by a number of different potteries, further provenance information is unavailable at this time but this type of item was also in production up till the 1940s.White ironstone china slipper bed pan with pear-shaped base and white handlePrinted in black "The New Slipper Bed Pan" then instructions for useflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, bed pan, the new slipper bed pan, medical -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, J & G Meakin, Late 19th or early 20th Century

... On base, 'Ironstone China Reg SOL 391413' with symbol... Ceramic On base, 'Ironstone China Reg SOL 391413' with symbol Bowl ...The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/This bowl was made by renowned pottery company J & G Meakin of England. The firm was established in the mid-1800's. The bowl is an example of kitchenware used in the 19th century and still in use today.Bowl; white ceramic, round and tapering inwards towards base. Made by J and G Meakin England.On base, 'Ironstone China Reg SOL 391413' with symbolflagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, mixing bowl, food preparation, j & g meakin, pottery, stoke-on-trent, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Ewer and Bowl, J & G Meakin, 1912 - 1925

... of cheap ironstone china it produced for the domestic English...Both items have marks "Ironstone China Reqd SOL 39/4/3 STG... was known for the vast quantities of cheap ironstone china ...J & G Meakin was an English pottery manufacturing company founded in 1851 and based in Hanley, Stoke-on-Trent, Staffordshire. In the 19th century, J & G Meakin was known for the vast quantities of cheap ironstone china it produced for the domestic English market and export to Australia, Canada, New Zealand, and the United States. From around 1970, designs included Liberty, Sterling, Trend, Classic, and Heirloom. Some of these were influenced by earlier designs. The newer wares can be distinguished by back stamp markings such as 'permanent colours', 'everlasting colour', or 'dishwasher proof'. J & G Meakin had close family and corporate affiliations to the potteries Johnson Brothers, and Alfred Meakin Ltd, which explains why many patterns are similar, if not almost the same. There was a takeover by J. & G. Meakin in 1968 of Midwinter Pottery. The firm was then taken over by the Wedgwood Group in 1970. In 2000 production under the Meakin name ceased and their long-established works, Eagle Pottery, was then used for the production of Johnson Bros pottery. Eagle Pottery closed in 2004 when production was transferred abroad; the works were demolished in 2005.Item is significant as it is believed to be an early example of the SOL trademark made between 1913-1925.Ironstone wash jug and bowl set, white, often referred to as a ewer and bowl. Both jug and bowl have matching raised embossing of panels with floral motifs within them.Both items have marks "Ironstone China Reqd SOL 39/4/3 STG Meakin England" Trademark of J & G Meakin with sun emblem .flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, jug china white and basin, jug, jug and basin, jug & bowl, ewer, bowl, ewer & bowl, j and g meakin, ironstone ware, bathing, washing, personal hygiene -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBowl, J & G Meakin

... Large white ironstone china bowl. Made by J & G Meakin... bowl Large white ironstone china bowl. Made by J & G Meakin ...Large white ironstone china bowl. Made by J & G Meakin. Hanley England. 15' in diameter.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, china bowl, bowl -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Domestic Object - LARGE CHINA JUG

... with wording J & G Meakin 50L Ironstone China Reg Limited 43758 Hanley... with wording J & G Meakin 50L Ironstone China Reg Limited 43758 Hanley ...Large white china jug with scalloped top, decorated with relief of wheat & vines. Shown on base makers marks showing a sun with wording J & G Meakin 50L Ironstone China Reg Limited 43758 Hanley England.J & G Meakindomestic equipment, ablutions, water jug, k110 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Serving Plate, Alfred Meakin, 1930s

... of cheap ironstone china it produced for the domestic English... was known for the vast quantities of cheap ironstone china ...J & G Meakin was an English pottery manufacturing company founded in 1851 and based in Hanley, Stoke-on-Trent, Staffordshire. In the 19th century, J & G Meakin was known for the vast quantities of cheap ironstone china it produced for the domestic English market and export to Australia, Canada, New Zealand, and the United States and one of these pottery lines was called "EMPRESS" and was in production through the 1930s. From around 1970, designs included Liberty, Sterling, Trend, Classic, and Heirloom. Some of these were influenced by earlier designs. The newer wares can be distinguished by back stamp markings such as 'permanent colours', 'everlasting colour', or 'dishwasher proof'. J & G Meakin had close family and corporate affiliations to the potteries Johnson Brothers, and Alfred Meakin Ltd, which explains why many patterns are similar, if not almost the same. There was a takeover by J. & G. Meakin in 1968 of Midwinter Pottery. The firm was then taken over by the Wedgwood Group in 1970. In 2000 production under the Meakin name ceased and their long-established works, Eagle Pottery, was then used for the production of Johnson Bros pottery. Eagle Pottery closed in 2004 when production was transferred abroad; the works were demolished in 2005.Item is significant as today the "EMPRESS" china pattern from the 1930s by Meakin is today a collectable item and a good example of the Meakin range of china.Plate china white oval with a pattern inscribed along the edge Inscription to base "EMPRESS" warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, alfred meakin, staffordshire potteries, iron stone pottery, serving dish -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Domestic object - Kitchen Equipment, Tea Pot, Between 1885 and 1905 after which the backstamp changed to G & S LTD

... for the vast quantities of cheap ironstone china it produced... for the vast quantities of cheap ironstone china it produced ...Earthenware is lightly fired, readily absorbs water if not glazed, and does not allow light to pass through it. Coarse earthenware is made from clay and grog (ground up fired pot). There are two main types of glazed earthenware: One is covered with a transparent lead glaze; when the earthenware body to which this glaze is applied has a cream colour, the product is called creamware. The second type, covered with an opaque white .in glaze, is variously called tin-enamelled, or tin-glazed, earthenware, majolica, faience, or delft. G&S marking could be Grove & Stark, Longton, England (1871-1884). In the 19th century, J. & G. Meakin ,1851 based in Hanley, Stoke-on-Trent, Staffordshire, was known for the vast quantities of cheap ironstone china it produced for the domestic English market and for export to Australia, Canada, New Zealand and the United States. Grove & Stark were taken over by Meakin early 20thC The Mark could also be Gibson & Sons (Ltd), were notably manufacturers of earthenware Burslem, Stoke-on-Trent. Founded around 1885 and traded until the mid 1970's. They were previously Gibson, Sudlow & Co. Manufactured between 1885 to 1905. Small earthen-ware, black-glazed tea-pot. 8 sided. The body of the tea-pot is decorated with hand-painted gold flowers and raised cream flowers. The lid is also hand -painted with green leaves and flowers. This floral pattern is named "Garland" The lid is not of the same pattern as the base. The spout was broken when brush tailed possum entered Cottage via chimney 27/4/2014. Can be repairedOn the base of the tea-pot. Makers Mark is G & S. "Garland". (Pattern), Rg. No. 175153. Also 'Made in England'. Under glaze there is the word: England.crockery, earthenwarre, gibson & son ltd, grove & stark ltd, pioneers, early settlers, bentleigh, market gardeners, moorabbin, cheltenham, pottery, stoke- on - trent, england, longton, burslem, wedgwood -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Serving Dish, J & G Meakin, 1880 to 1900

... of cheap ironstone china it produced for the domestic English... was known for the vast quantities of cheap ironstone china ...J & G Meakin was an English pottery manufacturing company founded in 1851 and based in Hanley, Stoke-on-Trent, Staffordshire. In the 19th century, J & G Meakin was known for the vast quantities of cheap ironstone china it produced for the domestic English market and export to Australia, Canada, New Zealand, and the United States and one of these pottery lines was called "EMPRESS" and was in production through the 1930s. From around 1970, designs included Liberty, Sterling, Trend, Classic, and Heirloom. Some of these were influenced by earlier designs. The newer wares can be distinguished by back stamp markings such as 'permanent colours', 'everlasting colour', or 'dishwasher proof'. J & G Meakin had close family and corporate affiliations to the potteries Johnson Brothers, and Alfred Meakin Ltd, which explains why many patterns are similar, if not almost the same. There was a takeover by J. & G. Meakin in 1968 of Midwinter Pottery. The firm was then taken over by the Wedgwood Group in 1970. In 2000 production under the Meakin name ceased and their long-established works, Eagle Pottery, was then used for the production of Johnson Bros pottery. Eagle Pottery closed in 2004 when production was transferred abroad; the works were demolished in 2005.Item is significant as today the "EMPRESS" china pattern from the 1930s by Meakin is today a collectable item and a good example of the Meakin range of china.Serving vegetable bowl with two handles on either end, plus a lid with a handle on the top lid also has a pattern around the edge.Inscription to base "J & G Meakin Manley England " warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, alfred meakin, staffordshire potteries, iron stone pottery, serving dish -

Puffing Billy Railway

Puffing Billy RailwayBread Plate, Victorian Railways Black & White, June 1953 "6-53" = "month-year"

... (the '& Co.') They produced Earthenware and Ironstone China... and Ironstone China - particularly for the Canadian, United States ...Victorian Railways Bread Plate - Black & White Maker : W H Grindley & Co (Ltd) Earthenware manufacturer at the Newfield Pottery and then the Woodfield Pottery, Tunstall, Stoke-on-Trent The company was founded at the Newfield Pottery in 1880 by William Harry Grindley (princliple partner) and Mr Turner (the '& Co.') They produced Earthenware and Ironstone China - particularly for the Canadian, United States, South American and Australian markets. In 1891 the company moved to the Woodfield Pottery, Woodland Street, Tunstall. In 1960 the business was purchased by Alfred Clough Ltd. In 1978 renamed Grindley of Stoke (ceramics) Ltd. Federated Potteries Co. Ltd. took them over in 1982 and in 1988 the business was re-purchase by W. H. Grindley. 1991 saw the company in the hands of the receivers. and the same year they were taken over by Woodlands Pottery. DURALINE (trade mark) printed mark used by Grindley Hotel Ware Co Ltd c.1930's onwards The Number i.e "6-53" = "month-year" Supplier to Victorian railways : Loftus Moran, Melbourne: Mr Loftus Henry Moran was well known in the tea trade. Originally employed by Griffiths Bros Ltd, he started his own business, Loftus Moran Pty Ltd, in 1909 In 1913 he purchased the tea business of Mcintyre Bros, and later' that of Steele Bros, and absorbed them in his own company. He had a wide business connection among hotels and guest houses for supplying crockery and other supplies. Ref: DEATH OF MR LOFTUS MORAN (1944, May 27). The Argus (Melbourne, Vic. : 1848 - 1957), p. 4. http://nla.gov.au/nla.news-article11809686 1st Advertisement of the Plates in the papers: CHIPPED CROCKERY. Nothing is more objectionable than chipped crockery--besides its use is illegal. DURALINE Plates, manufactured by The Grindley Hotel Ware Co., are tough as raw-hide. This is why they are used by practically every hotel and institution in Australia. Obtainable only from LOFTUS MORAN PTY. LTD., Hotel Supply Specialists, 131 Queen's Bridge Street, Melbourne South Advertising (29 March 1933, ). The Argus (Melbourne, Vic. ), p. 7. http://nla.gov.au/nla.news-article4726734Historic - Victorian Railways - Refreashment Services crockery - plateceramic Victorian Railways Bread Plate - Black & White Victorian Railways ( in black on fount of plate ) "DURALINE" ( in Black on back of plate ) super Vitrified GRINDLEY HotelWare Co England Loftus Moran Pty Ld Melbourne 8 -53puffing billy, victorian railways, crockery, plate -

Orbost & District Historical Society

Orbost & District Historical Societyplates

One small Broadhurst Dickens Series side plate Mr Pickwick Glides One large dinner plate. Both have white background and oak tree branches as border. Small plate illustration in centre is of people sliding on ice. Large plate centre illustration is David Copperfield + friends on a horse buggy riding bthrough town.Front of smaller plate - Mr Pickwick Glides Front of larger plate - My first fall in life - David Copperfield Back of both "Ironstone Broadhurst Staffordshire England. Dickens series underglaze... plates pottery broadhurst domestic-items china -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Jug, Lynch's Criterion Hotel Warrnambool, 1920s

This china jug has been made in England by Grindley Hotel Ware. The Grindley company that manufactured earthenware and ironstone items was founded in 1880 by William Grindley and was initially based in Tunstall, Stoke-on-Trent, England. The jug has had a red stamp added so that it could be used at the Criterion Hotel in Warrnambool and identified as the hotel property. The jug was used during the licenseeship of Theresa Lynch. The Criterion Hotel was situated on the western side of Kepler Street near Lava Street, Warrnambool. It opened in 1872 with the first licensee, John Tate. In the 1920s there were extensive renovations to the hotel in the Art Deco style. Theresa Lynch was the licensee from 1919 to 1926. In 1922 she bought the hotel and sold it to Harry McGennan in 1926. In 2006 the Criterion Hotel was closed and it was partially destroyed by fire in 2010 and later completely demolished. This jug is of interest as a 1920s souvenir of the Criterion Hotel, Warrnambool that closed in 2006. This hotel was a prominent one in Warrnambool, known in the 1990s for its promotion of live rock music. This is a white china jug with a circular base slightly tapering to an open top with a spout and handle. On the side of the jug there is a red stamp in the shape of a belt with red lettering. The base has a crown image and the maker’s name.‘Lynch’s Criterion Hotel Warrnambool’ Grindley Hotel Ware, Made in England, Patent’. criterion hotel, warrnambool, theresa lynch -

Warrnambool and District Historical Society Inc.

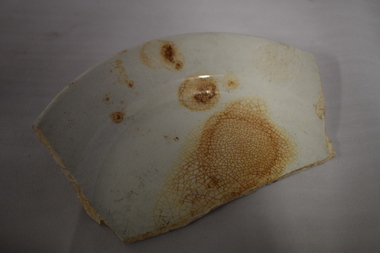

Warrnambool and District Historical Society Inc.Plate, Fragment Hotel Mansions, 1920s

This plate fragment came from the Hotel Mansions in Warrnambool. This building was opened in 1890 as the Grand Ozone Coffee Palace (a temperance hotel) and it was at the corner of Koroit and Kepler Streets in Warrnambool. It was built by a company of local businessmen and was leased out. In 1891 the Coffee Palace was granted a wine licence. In 1895 Thomas Randall was the proprietor and it was re-named the Ozone Hotel. The building was closed in 1915 and re-opened in 1920 as the Hotel Mansions. In 1923 the Hotel Mansions became a fully-licensed hotel. In 1929 it was destroyed by fire and the present day Hotel Warrnambool was built on the site. This plate fragment is significant as it came from the Hotel Mansions in Warrnambool and was probably recovered from the fire that destroyed the building. The Grand Ozone Coffee Palace/Ozone Hotel/Hotel Mansions was the grandest building ever erected in Warrnambool and its destruction by fire was a major loss to the town. This is a piece of a white china plate. On the side of the plate is embedded the name of the hotel in a circular pattern. The plate fragment is badly stained and crazed. ‘H D Hotel Mansions’ ‘Ironstone’ grand ozone coffee palace/ozone hotel/hotel mansions warrnambool -

Mission to Seafarers Victoria

Mission to Seafarers VictoriaDomestic object - Tea Cup, 1980-2000

Representative of ubiquitous tea/coffee cups used at MTSV Simple white glazed ironstone drinking cup, with handle in black ink: 1800-2010/DUDSON/FINEST VITRIFIED/4034/MADE IN STOCK-ON-TRENT/ENGLANDdomestic life, tableware, china -

Mission to Seafarers Victoria

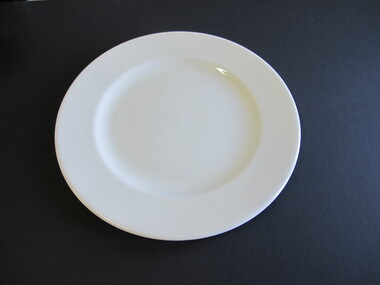

Mission to Seafarers VictoriaDomestic object - Plate, dinner

Representative of ubiquitous dinner plates used at MTSVSimple white glazed ironstone dinner plateMark: SUPER VITRIFIED-ISO 9001-BS 4034-EST 1795 CHURCHILL MADE IN ENGLANDplate, dinnerware, churchill china, ceramics -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionSouvenir - Plate - Bicentenary of Australia, c. 1970

Ironstone is a porous earthenware, made of clay mixed with feldspar. Patented in 1813 by Charles James Mason in Staffordshire, England, it was an immediate success, and ironstone blanks were decorated with transfer patterns or hand painting to imitate Chinese porcelain.Alpine white English ironstone Wood & Sons, plate commemorating bicentenary of Australia, 1770-1970. Black and white depiction of HMS 'ENDEAVOUR', Capt. James Cook, Coats of Arms for states of Australia, Australian Coat of Arms; background of state floral emblems.Front: 'To commemorate the Bi-Centenary of the Discovery of Australia 1770-1970' - black, around inner rim Back: Short history of James Cook's voyage to Australia. History of HMB 'Endeavour'. Makers mark.celebration, souvenir, australian souvenir, 1970, 1770, bicentenary, ironstone, english ironstone -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Dish, Johnson Bros, Circa 1883 (very early Mark)

Johnson Brothers were a British tableware manufacturer and exporter that was noted for its early introduction of "semi-porcelain" tableware. It was among the most successful of the Staffordshire potteries which produced tableware, much of it exported from the 1890s through the 1960s. They were also important manufacturers of large bathroom ceramics. The company was founded in 1883, but from 1968 to 2015 it operated as a part of the Wedgwood Group. However, after the Wedgwood Group was acquired by Fiskars in 2015, the production of Johnson Brothers was discontinued. The company's name derives from the names of the company's founders. The four original "Johnson Brothers" were Alfred, Frederick, Henry, and Robert. Their father married the daughter of a master potter, Alfred Meakin. In 1883, Alfred and Frederick Johnson began production at defunct pottery, known as the Charles Street Works, that they had purchased at a bankruptcy sale in Hanley, Stoke-on-Trent. At first, they specialised in the manufacture of durable earthenware, which they called "White Granite". The success of this venture led to rapid expansion. In 1888, the Rev. Henry Johnson joined them, followed ten years later by a fourth brother, Robert Johnson. Having established a solid reputation producing basic "whiteware", the company developed a product known as "semi-porcelain", a range of pottery that had the characteristics of fine china, but the durability of ironstone ware. This kind of tableware soon became very popular in the United States due to its durability and low cost. In 1889, the Hanley pottery was opened, later the Alexander pottery, and in 1891 the Imperial Works Pottery. In 1896, the Trent Sanitary Works was opened for the production of non-tableware products, and Alfred Johnson left the business to establish his pottery. By 1898, Robert Johnson had relocated to New York City to manage Johnson Brothers' rapid expansion into the North American market. An item that gives a snapshot into the emerging market for tableware that was reasonably priced and serviceable. The company produced "whiteware" but the innervation of the pottery line called semi-porcelain changed the industry. This allowed potteries to produce fashionable pottery items that were affordable to all social classes of the time. Bowl white ceramic decorative with floral decoration around lip. On base, "Royal Ironside China, Johnson Bros England" & crest of lion and unicorn flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, bowl, china bowl, lion and unicorn crest, table ware, kitchen ware, white ware, johnson brothers -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Jug, Baker & Co, 1891 to 1893

W Baker and Co-produced many different types of pottery at their Fenton Potteries, Stoke-on-Trent, Staffordshire England. The company was established in 1790 by Ralph Bourne and William Baker the company was working at capacity by the end of the century. By the late 1820's Bourne and Baker, in partnership with John Bourne, had acquired additional works opposite the first in 1833. With the deaths of John Bourne and William Baker, the partnership was dissolved, and then for a short time, the business was carried on by Ralph Bourne and William Baker junior and John Baker. By the early 1840s, William Baker was running it alone and was then using 'machinery for the potteries manufacturing operations in addition to the mill that was producing the raw clay. The business was subsequently carried on by William Baker and Company that were known for the making of printed, sponged, and pearl-white granite ware for export in the early 1880s at the Fenton works between Manor and Fountain Streets. The original works on the south side of City Road were by then an en-caustic tile works, apparently still in the hands of the Baker family. The pottery works flourished under William Baker’s management and by the middle of the nineteenth century with almost 500 employees was the biggest firm in Fenton. An early piece of ironstone Staffordshire pottery now a collector's item showing the types of domestic items that were exported from England to its colonies towards the end of the nineteenth century and into the beginning of the twentieth.Water pitcher ironstone ceramic white with raised embossed Lilly of the valley decoration around handle and lip sections. Marked on bottom, "Royal stone china, Baker and Co, England" with emblem of lion, crown and unicornflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, jug, kitchen utensil, kitchen ware, water pitcher -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Domestic object - Plate fragment Mansions Hotel, C1920

The Hotel Mansions was formerly the Grand Ozone Coffee Palace, erected in 1890 at a cost of around ten thousand pounds at the corner of Kepler and Koroit Streets by a group of local businessmen and leased out. Within 12 months of construction, it was granted a wine licence and was renamed the Ozone Hotel. Coffee Palaces were temperance hotels which were popular in the latter part of the 19th century. They offered recreation and superior accommodation. The Ozone Hotel operated until 1915 and was then closed before re-opening in 1920 as the Hotel Mansions. It had major renovations including a large theatre area. February 23rd 1929 saw the most spectacular fire in Warrnambool's history when the Hotel Mansions was burnt to the ground. Evelyn O'Brien was granted a temporary licence and in September 1930 she was given permission to rebuild. The new hotel, named Hotel Warrnambool was opened in March 1931. This piece of china is a relic from the fire.This piece of china is a small relic from the biggest fire ever to occur in Warrnambool and as such has strong historical significance.Fragment of burnt white, china plate from Hotel Mansions. There is a Hotel Mansions symbol etched inside an oval design on the front of the plate. The hotel side plate, heavily crazed and brown stained on both front and back.Stamp of "Ironstone Ch..." on back also an etched, sand blasted Hotel Mansions on front too faint to photograph effectively.warrnambool, ozone coffee palace warrnambool, grand ozone coffee palace, hotel mansions warrnambool, fire at the ozone, ozone hotel