Showing 37 items matching "leather making tools"

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageLap Skiver, J Dixon, 1900s

... Leather making tools... industries Leather making tools Tools J Dixon J Dixon Lap Skiver has ...Walsall in England was regarded as the world`s greatest centre of the saddlery trade. The town's craftsmen began to specialise in making bits, stirrups and spurs in the Middle Ages, developing into fully-fledged makers of saddlery and harness, by the end of the nineteenth century. As a result, over a hundred firms were exporting their products throughout the British Empire and beyond. The Walsall firms flourished as horses were so vital to everyday life in Victorian Britain and the colonies. The Walsall area emerged as a major supplier of military saddlery and harnesses, with one company supplying an astonishing 100,000 saddles for the British army in the First World War. The twentieth century saw the rise of light leather goods, such as handbags, cases and gloves. With the coming of the motor car, these products became the mainstay of the Walsall leather industry. Many companies supplied this trade and Dixon tools was one, as a commercial and industrial equipment supplier to the trade. The company started in 1843 and has continued to produce tools for the leather industries up and till August 2017 when the company was dissolved.A vintage item used in the leather working industries see additional notes at end of document for clarity on how the item was used and it's importance in making leather goods.Lap Skiver has a roller missing. Painted reddish brown J Dixonflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, lap skiver, leather industries, leather making tools, tools, j dixon -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionTool - Saddler's tool/ Leather working, n.d

... leather tools. They began in 1843. Tools have been marked with T...) was an English company making leather tools. They began in 1843. Tools ...T Dixon & Sons (Thomas) was an English company making leather tools. They began in 1843. Tools have been marked with T Dixon, Joseph Dixon at various times.Saddler's tool, curved iron rod, flat sides, shaped head, with small square bolt through it, attached to teardrop shaped wooden handle. 'T.DIXON' stamped on one side of rod.T Dixon stamped on the toolsaddler, tools, leather making, thomas dixon -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, steel leather punch, c1900

This steel leather punch would be used by early settlers in Moorabbin Shire c1900when making and repairing, farm and household leather goods.Early settlers in Moorabbin Shire had to be self sufficient and made and repaired their farm and household equipment. Blacksmiths made the toolsA solid steel leather punchleatherwork, craftwork, moorabbin, bentleigh, cheltenham, early settlers -

Federation University Historical Collection

Federation University Historical CollectionNewspaper, The Machinery Market, 02/12/1889

It's assumed that this journal was read at the Ballarat School of MinesA small illustrated journal with advertisements and pictures. pages 328-356 (and 26 pages of illustrated advertisements). Illustrations include machinery, corn crushers, condensers, chlorination plants. stea, hammers, steam engines, steam pumps, lamps, saw bench, leather belting, casks, barrels, machinery, boiler, cohran and co, birkenhead, stern, cowles syndicate company, electric smelting works, aluminium manufacturing, w t glover and co, rope machine, steam travelling crane, webster wood fibre machine, automatic govenor expansion gear, international exhibition edinburgh, beacon light, air propeller, well boring tools and pumps, cochran and co.'s launch, tug and boat building yard, s.s. jeanette, cochran boiler, cochran and co's boiler shop, stern wheel steamer, s.s. esperanca, cowles syndicate co, milton, w.t. glover & co.'s patent compound rope making machine, bendh drilling machine, steam launch, bicycle, well-boring tools -

Federation University Historical Collection

Federation University Historical CollectionObject - Tool: Leather work, Skiver - leather thinning tool

... of the tools that would have been used tool leather boot making ...Ballarat School of Mine had a boot making department. This one of the tools that would have been usedBlade tool - wooden handles and brass blade section"EDMUNDSON - LANCASTER" engraved on blade section "LEITCH" on both wooden handles tool, leather, boot making, ballarat school of mines, skiver, edmundson, lancaster -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumFootwear - Template - shoe sole, 1940's

Made by internee at Camp 3|Part of a set of tools and templates used in the making of leather bags,Cardboard templates for shoe soles. Some with cutouts, holes for nails template, bissinger g, wied k and n, camp 3, tatura, ww2, trades, shoemaking -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumTemplate - shoe sole, 1940's

Made by internee at Camp 3.|Part of a set of tools and templates used in the making of leather bags, handbags and shoes.Cardboard template for shoe. Sole has 12 holes punched in. Black pencil outline around the holes connected in pairs by black pencil lines.Mit Absetztemplate, bissinger g, wied k and n, camp 3, tatura, ww2, trades, shoemaking -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumTemplate - shoe sole, 1940's

Made by internee at Camp 3, Tatura|Part of set of tools and templates usedd in the making of leather bags, handbags and shoes.Hard card template/pattern for a wooden shoe sole.template, bissinger g, wied g, camp 3, tatura, ww2, trades, shoemaking -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumTemplate - shoe sole, 194's

Made by internee at Camp 3. Part of set of tools and templates used in the making of leather bags, handbags and shoesCardboard template for shoesole.Karl Wied|Holzschuhetemplate - shoemaking, bissinger g, wied k & n, camp 3, tatura, ww2, trades, shoemaking -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumBootmaker's hook, c1940

made and used by internees in Camp 3 Tatura during WW2 for making shoes and bootsHand tool used for bootmaking, hook for leatherhook, bootmakers kit, haering, manfred, camp 3, tatura, hand tool, !, trades, bootmaking -

Port Fairy Historical Society Museum and Archives

Port Fairy Historical Society Museum and ArchivesTool - Sailmakers Palm, Late 1800s early 1900s

used by fishermen and sailors to protect their hands as they made and repaired sails with large needlesThis object is not used so much today because of industrial machines taking over the job of making sailsLeather palm protector with metal inset fastened around hand with leather strap and buckle fastenerlocal history, maritime technology, sail making, fishermen, sailors -

Mont De Lancey

Mont De LanceyPeg Tool

... Peg Tool for shoe-making. Metal tool with leather handle...-making. Metal tool with leather handle, pointed one end and round ...Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Peg Tool for shoe-making. Metal tool with leather handle, pointed one end and round disc on other end.bootmaking tools -

Mont De Lancey

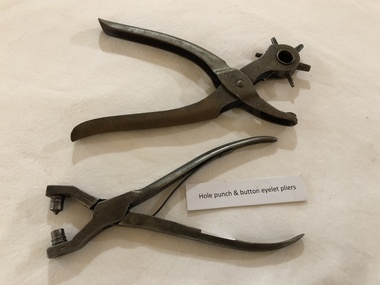

Mont De LanceyHole Punch and Button Eyelet Pliers

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.A metal hole punch, and metal button eyelet pliers, both used for shoe-making.AMG Darholeybootmaking tools -

Mont De Lancey

Mont De LanceyLegging

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Handmade leather legging with 4 metal clips.boot covers, leggings -

Mont De Lancey

Mont De LanceyLasts

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.2 x wooden Lasts (Adult size) with metal screws. 1 x cast iron Last (Child size) with holes in base and a removable elevated top.Wooden: Size 6 (80) Cast Iron: Size 9 Dbootmaking tools, boot lasts -

Mont De Lancey

Mont De LanceyLast

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast Iron Last on a four-footed base/stand. Last is removable from stand, and can be moved into different positions on top of the stand.bootmaking tools, boot lasts -

Mont De Lancey

Mont De LanceyLast

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron double-ended Lap Last.bootmaking tools, boot lasts -

Mont De Lancey

Mont De LanceyBootmaker's Repair Stand

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Wooden bookmaker's repair stand, opens slightly at one end. Two pieces of wood connected by two screws.bootmaking tools -

Mont De Lancey

Mont De LanceyHeel and Sole Cutters, Mobbs & Lewis

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast Iron pieces - 1 Heel cutter and 1 Sole cutter.bootmaking tools -

Mont De Lancey

Mont De LanceyNail Bag, Wandin Thomas Sebire JP

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Brown leather handmade nail bag, with strap.tool bags -

Mont De Lancey

Mont De LanceyHalf-Moon Knife

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron handmade knife with a wooden handle, attached by a nail.bootmaking tools, cutting tools -

Mont De Lancey

Mont De LanceyCircular Welt Cutter, Wandin Thomas Sebire JP

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron Welt Cutter with a wooden handle. -

Mont De Lancey

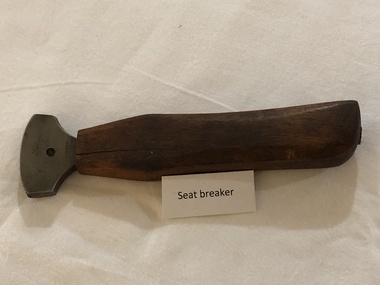

Mont De LanceySeat Breaker

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron Seat Breaker with a wooden handle. -

Mont De Lancey

Mont De LanceyFudge Wheel

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron Fudge Wheel with a wooden handle. -

Mont De Lancey

Mont De LanceyFoot Measure/Ruler

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Wooden, folding, foot measure/ruler with brass clasps.bootmaking tools, measures, rulers -

Mont De Lancey

Mont De LanceyHammer and 2 Knives/Cutters

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron hammer with a wooden handle. Larger Cutter/knife, cast iron with a wooden handle. Smaller Cutter/knife, cast-iron with a wooden handleHammer: "London" Larger knife: "Pettys Sheffield".bootmaking tools, hammers, cutting tools -

Mont De Lancey

Mont De LanceyBootmaking Equipment

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron Heel plate. Miscellaneous Sole plates. Hobnails and a tin of wooden sprigs.bootmaking tools, nails -

Mont De Lancey

Mont De LanceyHeel Shave and 2 Heels

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast Iron Heel Shave. 1 larger Leather heel piece. 1 smaller Leather heel piece.bootmaking tools, shaves -

Mont De Lancey

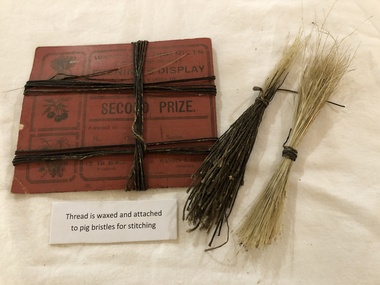

Mont De LanceyBootmaking Equipment, Wandin Thomas Sebire JP

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Handmade Waxed Thread attached to pig bristles, for boot stitching .bootmaking tools, thread waxers, threads -

Mont De Lancey

Mont De LanceyAwls and Awl Tips

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.5 x Cast iron Awls, all with wooden handles. 1 x container of spare Awl metal tips.bootmaking tools, awls, piercing tools