Showing 160 items matching "machine parts"

-

Bendigo Historical Society Inc.

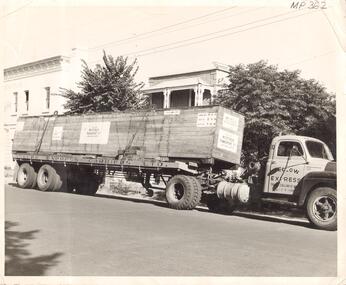

Bendigo Historical Society Inc.Photograph - YELLOW EXPRESS CARRIERS VEHICLE LOADED WITH MACHINE PARTS

... YELLOW EXPRESS CARRIERS VEHICLE LOADED WITH MACHINE PARTS....Yellow Express Carriers loaded with machine parts... Yellow Express Carriers loaded with machine parts. Background ...Yellow Express Carriers loaded with machine parts. Background left is part of Pulfer motors building, Photo taken before mid 1980's when building on left (Pulfer's Motors occupied it) was demolished to make way for the building of Thompson building at Bendigo TAFE. Centre background is second story of Specimen Coittage in Hargreaves Street Bendigobusiness, transport, yellow express carriers., yellow express carriers -

NMIT (Northern Melbourne Institute of TAFE)

NMIT (Northern Melbourne Institute of TAFE)Photographs - CTS 1940-1943, Collingwood Technical School. Defence Training Scheme, 1940-1943

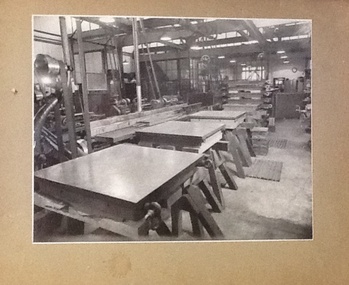

... machine parts... of the machines and machine parts built in class. ... for scraping. 2. Lathe bodies in foreground, with machined / parts... and machine parts built in class. These are high quality professional ...Collingwood Technical School trained apprentices in many trades. CTS was also invlved in Training Schemes during the late 1930s and during World War II. These photographs depict some of the machines and machine parts built in class. These are high quality professional photographs taken circa 1940-1943. At this time , CTS was part of the Defence Training scheme. These photographs are a visual record of this scheme.6 black and white photographs mounted on brown card. Photographs depict various aspects of lathe work undertaken during the Defence Training Scheme, 1940-43. Also a smaller photograph of a Moultar Thread Milling Machine 1941.Each photograph has a hand written caption on the back. Captions: 1. Finished surface plates for R.A.A.F. / standing on trestle after scraping. Stack of / others in background waiting for scraping. 2. Lathe bodies in foreground, with machined / parts of lathes in middle distance, and milling / cutters, gauges and bearings in background. 3. Frames of glass splitting machines, thread / rectifying machines, and two types of milling / machine vises made in technical schools. 4.View of engineering machine shop. Carbon dioxide / freezing box in foreground, and stack of / surface plates for RAAF in middle / distance. 5.Fan geared lathes, 6 inch centres, with / self-contained motor drives, made for / cartridge factory. To be used for making / this 6.Freezing of cast iron surface plates / in layers of solid carbon dioxide / blocks. Smaller photograph has a handwritten note on the reverse: 'this photograph shows how, with the aid of a 3ft. extension mounted in front of the tool box, on which Mr. Grubb sen. is seated, these large milling machine bases ... machinists at Collingwood Technical School. A Strang, Principal 21.4.1941'. collingwood technical school, cts, apprentices, students, defence training scheme, lathes, machinery, machine parts, nmit, -

NMIT (Northern Melbourne Institute of TAFE)

NMIT (Northern Melbourne Institute of TAFE)Photographs - Collingwood Technical School, Allan Studios, Mounted photographs of Trade School CTS, circa 1940, Early 1940s

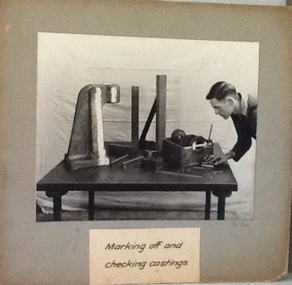

... machine parts... castings 2. Examples of other machine parts, etc., being made.... These photographs depict some of the machines and machine parts built ...Collingwood Technical School trained apprentices in many trades. These photographs depict some of the machines and machine parts built in class. Captions : 1. Marking off and checking castings 2. Examples of other machine parts, etc., being made in Youth Employment classes in engineering machine shop. 3. Cutting the traversing screw for a 5 ¼ inch lathe. 4. Grinding lathe spindle. 5. Cutting helical flutes in a shell end mill. 6. Arbor Press. Another valuable machine produced by Youth Employment and senior technical evening students. 7. Milling angular slides of lathe saddle. 8. 5 ¼ inch lathe product of Collingwood Technical School. These are high quality professional photographs taken circa 1940. 8 black and white photographs mounted on brown card. Photographs depict various aspects of lathe work.Each photograph has a hand written caption on the front. Also handwritten in black pen "Allan Studios".collingwood technical school, cts, apprentices, students, lathes, machinery, machine parts, nmit, -

Bendigo Historical Society Inc.

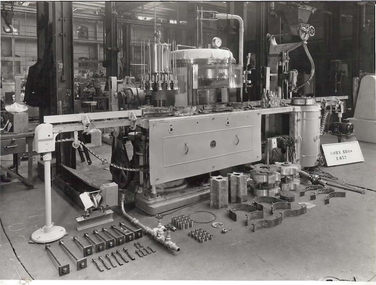

Bendigo Historical Society Inc.Photograph - COHN BROS. MACHINE WITH PARTS DISPLAYED

... COHN BROS. MACHINE WITH PARTS DISPLAYED...Black and white photograph. Machine with parts displayed... BROS. MACHINE WITH PARTS DISPLAYED ...Black and white photograph. Machine with parts displayed on floor in front.'(Australia) Pty Ltd, 18-24 Allen Street, Pyrmont, Sydney' (oval rubber red stamp), 'Received 14 Sep. 1950), (rectangular rubber purple stamp). 'Royal Historical Society of Victoria, Bendigo Branch', (circular rubber blue stamp). On back - T L&R corners 'MP 205', 'B 220, 20, 2'. Inscriptions: in image 'Cohn Bros, E 637' on white rectangular sign. History of object: Previous Acc. No. 'MP 205'.topic, objects, machine -

National Wool Museum

National Wool MuseumMachine, Textile Parts

... Machine, Textile Parts...Parts for grey textile machine manufactured by Scott...-and-the-bellarine-peninsula Parts for grey textile machine manufactured ...Parts for grey textile machine manufactured by Scott Testers Inc, Builders, Providence R.I., USA. -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Slide - HORWOOD COLLECTION: CHEWTON MINING, c1950

... machine. Other machinery parts are there..., possible an old boiler and the wheel of the winding machine. Other... and the wheel of the winding machine. Other machinery parts ...BHS CollectionHorwood Collection - Chewton mining. Mining machinery, possible an old boiler and the wheel of the winding machine. Other machinery parts are there. Markings; noneAgfacolormine, gold, chewton, horwood collection - chewton mining. mining machinery, possible an old boiler and the wheel of the winding machine. other machinery parts are there -

NMIT (Northern Melbourne Institute of TAFE)

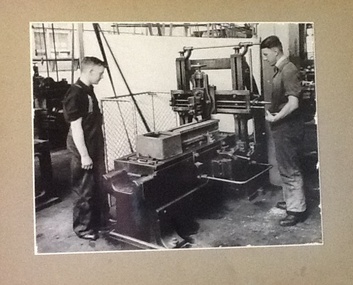

NMIT (Northern Melbourne Institute of TAFE)Photograph - CTS 1938-1940 student, Collingwood Technical School. Unemployed Adults Training Scheme, 1938-1940

... Machine Parts... Lathes Machinery Machine Parts NMIT Photograph has a hand written ...Collingwood Technical School trained apprentices in many trades. In the late 1930s, CTS was involved in ttraining schemes for youth and adults.This photograph depicts two men learning to operate a lathe. This is a high quality professional photograph taken circa 1940. In 1938-1940, CTS was part of the Unemployed Adult Training scheme. This photograph is a visual record of this scheme.1 black and white photograph mounted on brown card. Photograph depicts trainees working with a 5" centre lathe.Photograph has a hand written caption on the back: 'Collingwood Technical School./ Unemployed Adults Training Scheme, 1938-1940./ Trainees planing the cast iron bed of a/ 5" centre lathe. 'collingwood technical school, cts, apprentices, students, unemplyed adult training scheme, lathes, machinery, machine parts, nmit -

Parks Victoria - Maldon State Battery

Parks Victoria - Maldon State BatteryBox

... Currently used to store machine parts. Probably used... Historic Area Maldon goldfields Currently used to store machine ...Currently used to store machine parts. Probably used for storage in the past .Green storage box with compartments and hinged lid, made from wood. Leather and chains attaches lid to the box. It has large wooden handles on either side. -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionMufax machine

... Early fax machine. In two parts. ... Early fax machine. In two parts. Mufax machine. ...Not much is known about this particular machine and where it was usedEarly fax machine. In two parts. Mufaxcommunications, forests commission victoria (fcv) -

The Ed Muirhead Physics Museum

The Ed Muirhead Physics MuseumResistance Bridge Hartmann & Braun

... Machined metal parts, polymer base, wooden box plinth... left corner approx. 0.7-1.0cm in diameter. Machined metal parts ...Machined metal parts, polymer base, wooden box plinth. Uncoated metal, polished wood. Surface finish: wood varnish. [Stamped] on upper face, centre of front edge: Hartmann & Braun A.G./ Frankfurt a.M/ No 13881. [Stamped] on upper face, centre of back edge: Manufacturer’s symbol. Paint dot on upper face in top left corner approx. 0.7-1.0cm in diameter. -

Bendigo Historical Society Inc.

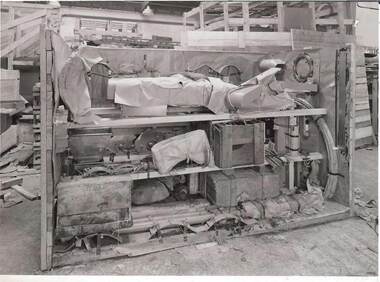

Bendigo Historical Society Inc.Photograph - COHN BROS. MACHINE IN BUILDING

... unpacked machine parts in wood crate (front and top removed... photograph. Machine in building. Partially unpacked machine parts ...Black and white photograph. Machine in building. Partially unpacked machine parts in wood crate (front and top removed). Inscriptions on back: 'MP 209-B,50,13' , 'Cohn Bros No.4, spares and loose parts' typed on back. Stamps on back 'Butlers (Australia) Pty Ltd, 18-28 Allen St, Pyrmont, Sydney' (oval rubber red stamp), History of Object: Previous Acc. No. 'MP 209'. 'Received 14 Sept. 1950' (rectangular rubber purple stamp), 'Royal Historical Society of Victoria, Bendigo Branch' (circular rubber blue stamp).topic, objects, machine, 2000.525.01, 2000.526.01, 2000.527.01, 2000.530.01, 2000.531.01, 2000.532.01, 2000.533.01 -

Greensborough Historical Society

Greensborough Historical SocietyNewspaper Clipping, Diamond Valley Leader, Pushback on punters, 11/10/2017

... A poker machine freeze in parts of Banyule has prompted... Plenty Lower Plenty melbourne A poker machine freeze in parts ...A poker machine freeze in parts of Banyule has prompted calls for reforms to be extended into gambling hot spot Greensborough.News article 1 page, black text.banyule, poker machines, greensborough, greensborough rsl, greensborough hotel -

Stawell Historical Society Inc

Stawell Historical Society IncFunctional object - Realia, New National Treadle Sewing Machine

... Treadle home Sewing machine - pre-electric. Rusted parts... grampians Treadle home Sewing machine - pre-electric. Rusted parts ...Treadle home Sewing machine - pre-electric. Rusted partsBlack "pre-electric treadle sewing machine with "fly wheel" "New national"Gold leaf floral design on machine and flat greyhound trademark inside floral circle, fastened to wooden lid of tableclothing manufacture -

Stawell Historical Society Inc

Stawell Historical Society IncFunctional object - Realia, Sewing Machine Treadley

... Treadle home sewing machine - pre-electric. rusted parts... grampians Treadle home sewing machine - pre-electric. rusted parts ...Treadle home sewing machine - pre-electric. rusted parts, faded gold leaf decorationBlack Pre-Electric Treadle Sewing Machine with 'Fly wheel' " Singergold floral on machine and "singer on machine -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Textile, Dress, promenade, 1880s

... lace (much tattered). The jacket is faded and torn in parts... (much tattered). The jacket is faded and torn in parts. Machine ...There is no information available on this dress which has been in the Historical Society’s collection for many years. It may have been a wedding dress. This is an interesting item as an example of a woman’s dress worn about the 1880s. It is a wonderful display item. This is a claret-coloured dress with a full length skirt with bustle. It is made of good quality heavy satin mounted on organza with a back fastening. There is a rosette in the same fabric with two pendant panels. There is a matching fitted jacket with hooks and eyes to fasten and full length narrow sleeves edged with claret lace (much tattered). The jacket is faded and torn in parts. Machine and handsewn. claret-coloured dress, warrnambool, 1860's ladies dress -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Clock, 1920s

... , a machine parts manufacturer...., a machine parts manufacturer. The item marks a time when clock ...In 1902, William E Sessions and other family members purchased a controlling interest in the E.N. Welch Company, a clock manufacturer located in Forestville, Connecticut. Sessions' father owned a foundry located in the town of Bristol, Connecticut that produced cases for E.N Welch Co. On January 9, 1903, the company was reorganized and registered as The “Sessions Clock Company”. Within a few years the Sessions Clock Company was producing clock movements, cases, dials, artwork and castings for their line of mechanical clocks. Between 1903 and 1933 Sessions produced 52 models of mechanical clocks, ranging from Advertisers, large and small clocks with logos of various businesses, to wall, or regulator clocks, and shelf or mantel clocks, designed for the home. Many of the Session clocks from this period are prized by collectors. In 1930, the company expanded to produce electric clocks and timers for radios, while continuing to produce traditional brass mechanical movements. Beginning at the end of World War II Sessions W Model (electric) was widely used by various casting companies for their clocks. The dial of the W Model read Movement by Sessions. In the early 1950s Sessions begin to produce timers for television. In 1956, Sessions was absorbed by a company interested mainly in their timing devices. In 1959, William K. Sessions, grandson of William E. Sessions left the Sessions Clock Company and formed the New England Clock Company. In 1960, one of the Sessions Clock buildings was sold to the Bristol Instrument Gears Company. Kept as the Sessions Company, the new owners ran the operation until 1969 when changes in the market forced the Sessions Company into liquidation. In 1970, the remaining buildings were sold to Dabko Industries, a machine parts manufacturer.The item marks a time when clock production in America was at it’s peak producing clocks for sale in many countries, they were keenly priced, mass produced and available to all. The company had a relatively short life span life regards clock manufacture later diversifying into electric timer mechanisms. Yet it was perhaps inevitable with the advent of electricity along with stiff competition from other clock manufactures that would ultimately herald the end in 1935 of the Sessions company's ability to continue manufacturing mechanical clocks. Clock mantle type face set in a painted black case designed to represent a Greek building with gold decorative pillars. Free standing with decorative feet. No markings or inscriptions on clock case or mechanism flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sessions, mantel clock, clock, clock industries -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing Machine, Singer Sewing Machine Company, 1922

... on land near Queen Street Station and machinery and machine parts... on land near Queen Street Station and machinery and machine parts ...In 1867 the Singer Company decided that the demand for their sewing machines in the UK was sufficiently high to open a local factory. Glasgow was selected for its iron-making industries, cheap labour, and possibly because at the time the General Manager of the US Singer Sewing Machine Company was George McKenzie, who was of Scottish descent. The company obtained a lease on land near Queen Street Station and machinery and machine parts were shipped over from the US. Demand for sewing machines outstripped production at the new plant and by 1873 a new larger factory was completed near Bridgeton Cross. By now Singer employed over 2,000 people in Scotland but still, they could not produce enough machines. In 1882 George McKenzie, the soon to become President of the Singer Sewing Machine Company undertook the ground breaking ceremony on 46 acres of farmland at Kilbowie, Clydebank and the largest Singer factory in the world started to be built. Originally two main buildings were constructed. Built above the middle wing of the factory was a huge clock tower with the 'Singer' name displayed for all to see from miles around. Many miles of railway lines were laid throughout the factory to connect the different departments and to aid in the shipping of their goods. Railway lines from the factory connected Glasgow, Dumbarton, and Helensburgh stations. The factory was regarded as the most modern facility in Europe at that time. As different departments in the factory were completed, the workers moved from the old sites to the new one at Kilbowie and the factory was finally finished in 1885. With nearly a million square feet of space and almost 7,000 employees producing on average 13,000 machines a week, making it the largest sewing machine factory in the world. The Clydebank factory was so productive that in 1905 the US Singer Company set up the Singer Manufacturing Company Ltd. as a UK registered company. The invention of the sewing machine had several very significant impacts on the lives of many people. It changed the domestic life of many women as more households began to own sewing machines, women as the ones who traditionally stayed home to do chores including making and repairing clothing, found themselves with more free time. Previously several days a week would be dedicated to sewing clothing for herself and her family, a housewife could now complete her sewing in merely several hours, allowing for more free time to pursue hobbies and attain new skills. Sewing and clothing production, in general, became more industrialized activities, taking place less in the home and more in large factories. Industrial sewing machines, in combination with the cotton gin, the spinning jenny, and the steam engine, made clothing production much easier and much cheaper. Sewing machine, treadle operated, "Branded Premier" 5-7-9-2-0-0-" Serial Number Y6243048 (denotes 1922 year of manufacture) flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sewing machine, hand operated, dressmaking, textile machinery, portable, premier sewing machine, premier, singer treadle sewing machine -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing Machine, Singer Sewing Machine Company, 1907 -1920 (see note section this document for further information regards model identification)

... on land near Queen Street Station and machinery and machine parts... on land near Queen Street Station and machinery and machine parts ...In 1867 the Singer Company decided that the demand for their sewing machines in the UK was sufficiently high to open a local factory. Glasgow was selected for its iron-making industries, cheap labour, and possibly because at the time the General Manager of the US Singer Sewing Machine Company was George McKenzie, who was of Scottish descent. The company obtained a lease on land near Queen Street Station and machinery and machine parts were shipped over from the US. Demand for sewing machines outstripped production at the new plant and by 1873 a new larger factory was completed near Bridgeton Cross. By now Singer employed over 2,000 people in Scotland but still, they could not produce enough machines. In 1882 George McKenzie, the soon to become President of the Singer Sewing Machine Company undertook the ground breaking ceremony on 46 acres of farmland at Kilbowie, Clydebank and the largest Singer factory in the world started to be built. Originally two main buildings were constructed. Built above the middle wing of the factory was a huge clock tower with the 'Singer' name displayed for all to see from miles around. Many miles of railway lines were laid throughout the factory to connect the different departments and to aid in the shipping of their goods. Railway lines from the factory connected Glasgow, Dumbarton, and Helensburgh stations. The factory was regarded as the most modern facility in Europe at that time. As different departments in the factory were completed, the workers moved from the old sites to the new one at Kilbowie and the factory was finally finished in 1885. With nearly a million square feet of space and almost 7,000 employees producing on average 13,000 machines a week, making it the largest sewing machine factory in the world. The Clydebank factory was so productive that in 1905 the US Singer Company set up the Singer Manufacturing Company Ltd. as a UK registered company. The invention of the sewing machine had several very significant impacts on the lives of many people. It changed the domestic life of many women as more households began to own sewing machines, women as the ones who traditionally stayed home to do chores including making and repairing clothing, found themselves with more free time. Previously several days a week would be dedicated to sewing clothing for herself and her family, a housewife could now complete her sewing in merely several hours, allowing for more free time to pursue hobbies and attain new skills. Sewing and clothing production, in general, became more industrialized activities, taking place less in the home and more in large factories. Industrial sewing machines, in combination with the cotton gin, the spinning jenny, and the steam engine, made clothing production much easier and much cheaper. Singer sewing machine treadle type wooden stand with six drawers plus instruction manual Lotus decoration to machinewarrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sewing-machine, clothes repair, singer sewing machine -

Orbost & District Historical Society

Orbost & District Historical Societyadding machine, 1964

... machines from US-made parts and later to manufacture the full... machines from US-made parts and later to manufacture the full ...Burroughs Adding Machines Ltd of Detroit Michigan was the first company to occupy a factory at Strathleven. During the European reconstruction in the late 1940's Burroughs built a major new factory at Strathleven in Scotland, initially to assemble machines from US-made parts and later to manufacture the full product range for the British and Commonwealth markets. Most of the post-war calculators and portables found in Australia are from the Strathleven factory.This manually operated calculator predates the the rise of the modern computer.A manually operated Burrough's adding machine. It is a greyish green plastic and has a silver handle. It has 8 columns to add manuaIly and has decimal currency. There is a roll of white (slightly yellowed) paper inserted in the top section.On front -P3981115 mathematics accounting burroughs adding-machine business calculator -

Broadmeadows Historical Society & Museum

Broadmeadows Historical Society & MuseumMachine - Adding Machine

... machines from US-made parts and later to manufacture the full..., initially to assemble machines from US-made parts and later ...Burroughs Adding Machines Ltd of Detroit Michigan was the first company to occupy a factory at Strathleven. During the European reconstruction in the late 1940's Burroughs built a major new factory at Strathleven in Scotland, initially to assemble machines from US-made parts and later to manufacture the full product range for the British and Commonwealth markets. Most of the post-war calculators and portables found in Australia are from the Strathleven factory.This manually operated calculator predates the rise of the modern computer.A manually operated Burrough's adding machine. It is a greyish green plastic and has a silver handle. It has 8 columns to add manually and has decimal currency. There is a roll of white (slightly yellowed) paper inserted in the top section.Burroughs Machine Limited, Strathleven, Scotland Made in Great Britainburroughs adding machine, office, calculator, detroit, michigan -

Bendigo Historical Society Inc.

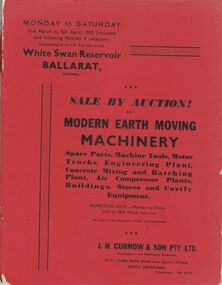

Bendigo Historical Society Inc.Document - IAN DYETT COLLECTION: AUCTION CATALOGUE - WHITE SWAN RESERVOIR

... is missing the cover. Sale of Earth Moving Machinery. Spare Parts... is missing the cover. Sale of Earth Moving Machinery. Spare Parts ...Three auction catalogues, two with red covers and the third is missing the cover. Sale of Earth Moving Machinery. Spare Parts, Machine Tools, Motor Trucks, Engineering Plant, Concrete Mixing and Batching Plant, Air Compressor Plants, Buildings, Stores and Costly Equipment on 31st March to 5th April 1952 (inclusive) at the White Swan Reservoir, Ballarat, Victoria. J. H. Curnow & Son Pty. Ltd. Were the auctioneers. Included in the catalogue is a Locality Plan showing location of lot areas - access roads, etc. Page 4 has a black and white photo showing Super c Tournapull, Lot 63 and Tractor hauling 12-15 cub. Yd. capacity scoop. Page 9 photo is Lot 209, a Sheep's Foot Roller, Page 12 photo is Lots 258, 259 & 260 - Class 1 tractor hauling two 12-15 c yd Te Tourneau Scrapers, and page 68 has a black & white photo of Lot 2377, the Concrete Batching Plant.business, auctioneers, j h curnow & son pty ltd, ian dyett collection - auction catalogue - white swan reservoir, the ballarat water commissioners, j h curnow & son pty ltd, prahran telegraph printing co -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing Machine, Early 20th century

... deal for sewing machines or parts is the direction they went... ever they got the best deal for sewing machines or parts ...Ward Brothers (George and Samuel) registered a company (Australian Sewing Machines Limited Pty Ltd) with the head office address in Errol St, North Melbourne, and Prahan. The earliest newspaper advertisement for this company was in 1897. Around this time the Ward Brothers first imported sewing machines from England and Wertheim placed their decal on them and mounted them in their own Australian made cabinets. David Ward later imported machines from Beisolt & Locke in Germany and registered name A.N.A. (All Native Australian), his shop was in Collingwood Melbourne. Some of these machines had Ward Brothers decals on them as well. The three brothers sold under the same name as Ward Brothers. The early Ward Brothers logo had a map of Australia with a picture of all three brothers on it. In 1911 all three of the Ward Brothers decided to share a stall in the yearly Melbourne exhibition. The A.N.A was the machine that got rave reviews. It was at this time that the Australian Sewing Machine Company Pty Ltd decided to add the A.N.A logo to their logo to cash in on the new found celebrity status that the A.N.A has gained. To cut a long story short. David Ward took his brothers to court to prevent this from happening. This was a long drawn out affair that took quite a few years. The settlement was decided out of court and nothing was disclosed of the deal that was made. David seemed to have left the scene, then the remaining Ward Brothers and A.N.A. combined and then became “Wardana”. There are many Ward Brothers sewing machines in displays, they originated from Japan, England, America, and Germany. It seems that where ever they got the best deal for sewing machines or parts is the direction they went. This is where the Bendigo sewing machine company came into the picture. All imported sewing machines into Australia drew a government tax. Bendigo Cording's Traction Company was given proposed two-pound tariff protection that gave the company a significant price advantage for its machines. As a result, the Ward Brothers purchased a huge number of Bendigo shares to get cheaper machines for their sewing machine cabinets. Ward Brothers then placed one of their company officials on the Board of “Bendigo Sewing Machines Limited” and the rest is history. Ward Brothers had shops Australian wide and in most of the major country towns. History for “Bendigo Sewing Machines Limited” Cordings Traction Company owners (H. Keck MLC, W. Wallace, and W. Ewing) operated their business out of the former W. Webb & Co. building in Queen St. Bendigo. Around 1923-1924 they decided to switch from traction engines to manufacturing sewing machines. The actual date is not known but that year's financial report made note of both Cordings and Bendigo Sewing Machines Limited. The switch was made with the government of the day agreeing to a tariff of two pounds per head for every machine head made completely in Australia. The change from traction engines to sewing machines went well. Government representatives visited the factory in Bendigo to inspect and ensure that the sewing machines were Australian made as a result they agreed on granting the two-pound tariff to the company. After the first 12 months, they built 30, the following 12 months the company had produced 1500 machines probably due to the involvement of the Ward brothers. However, the government proposed a new condition to the tariff agreement which was that the company must produce 20% of Australia's requirements for sewing machines. In 1924 after having had produced 1500 machines resulting in reaching their financial limit for tariff support. According to the government, the requirement was 15,000 machines for the next year had to be produced to qualify for the tariff. The company had already reached its production limit and unfortunately folded. There were several attempts to regain government assistance to save this new industry but it was to no avail. Even a promise to open another factory in Sydney was offered but unfortunately wasn't accepted. An item fabricated in Australia from a majority of imported parts from either Germany, America or England giving a snapshot into the early manufacturing industries that were operating at the time of Federation. Sewing machine, treadle, in timber cabinet. Branded Ward Bros, A.N.A., Australian Sewing Machine Coy. Decorative carved timber cabinet, hinged, fold-out laminated timber top and five drawers; two small on each side with handles and one long, shallow, between side drawers without handle. Thread is on bobbin in a rocket shuttle (both in good condition) plus spare empty shuttle (rusty). Brass ‘Half Yard’ ruler inlaid across front, measuring scale in inches and centimetres. Two metal shuttle cover plates (or throat plate / slide plate); front one is impressed with a gauge for needle and thread. Gold trim and decals on flatbed and machine front and back, serial number under shuttle cover, brand on decals and on round metal plate on back of machine. Front right of machine has a bobbin winder. Treadle belt shows signs of wear and laminate on timber machine cover is peeling slightly.Decal coat of arms on right front of machine: kangaroo on left, man with broad-brim hat, holding pick-axe on right, in centre, top “SEWING MACHINE / THE / A. N. A.” then below it, the rising sun, then below that is state of Victoria shield with the Southern Cross constellation. Wheat sheaves around edge on left and flowering plant on right. Gold ribbon banner at bottom with script “WARD BROS.“ Decal of map of Australia on flatbed of machine. States and capital cities are marked and named (no northern territory), portrait of two men. In centre of map are interwoven letters “A. N. A.” and written in script “WARD BROS.” Decal across front of machine body has large, decorated gold lettering “A. N. A.” Decal across the top of machine “THE AUSTRALIAN SEWING MACHINE COY. PTY. Ltd.” Steel shuttle cover at front has an impressed gage listing cotton and needle sizes and number of stitches. Brass disc on back of machine “A. N. A.” in centre. Brass ruler across front of machine has carved or pressed words in the timber. In centre “INCHES” above ruler and “CENTIMETRES” below ruler, and on right above ruler is “HALF YARD” Decal across back of machine’s body “A.N. A. / MADE IN U.S.A.” Stamped into metal under shuttle cover is “219415” (2 and 5 are partially there, first 1 could instead be a 7) flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, ward bros., australian sewing machine co., a.n.a., treadle sewing machine, rocket shuttle sewing machine, home industry, clothing, wardana, australian sewing machine company, all native australian, dressmaking, clothing manufacturer -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Scale and weights, 1860-1900

The subject item was made in England by W&T Avery a British manufacturer of weights and weighing machines. The company was founded in the early 18th century and took the name W & T Avery in 1818. The undocumented origin of the company goes back to 1730 when James Ford established the business in the town of Digbeth. On Joseph Balden, the then company’s owner’s death in 1813 William and Thomas Avery took over his scale making business and in 1818 renamed it W & T Avery. The business rapidly expanded and in 1885 they owned three factories: the Atlas Works in West Bromwich, the Mill Lane Works in Birmingham and the Moat Lane Works in Digbeth. In 1891 the business became a limited company with a board of directors and in 1894 the shares were quoted on the London Stock Exchange. In 1895 the company bought the legendary Soho Foundry in Smethwick, a former steam engine factory owned by James Watt & Co. In 1897 the move was complete and the steam engine business was gradually converted to pure manufacture of weighing machines. The turn of the century was marked by managing director William Hipkins who was determined to broaden the renown of the Avery brand and transform the business into specialist manufacture of weighing machines. By 1914 the company occupied an area of 32,000m² and had some 3000 employees. In the inter-war period, the growth continued with the addition of specialized shops for cast parts, enamel paints and weighbridge assembly and the product range diversified into counting machines, testing machines, automatic packing machines and petrol pumps. During the second world war, the company also produced various types of heavy guns. At that time the site underwent severe damage from parachute mines and incendiary bombs. Then from 1931 to 1973, the company occupied the 18th-century Middlesex Sessions House in Clerkenwell as its headquarters. Changes in weighing machine technology after World War II led to the closure of the foundry, the introduction of electronic weighing with the simultaneous gradual disappearance of purely mechanical devices. The continued expansion was partly achieved through a series of acquisitions of other companies. After almost a century of national and international expansion, the company was taken over by GEC in 1979. Keith Hodgkinson, managing director at the time, completed the turn-around from mechanical to electronic weighing with a complete overhaul of the product range of retail sales of industrial platform scales. In 1993 GEC took over the Dutch-based company Berkel and the Avery-Berkel name was introduced. In 2000 the business was in turn acquired by the US-American company Weigh-Tronix, who already owned Salter, and is today operating as Avery Weigh-Tronix.An item used by grocers and merchants throughout the then British colonies of England to weigh store-bought goods around the mid to late 19th century. This item gives an insight into the daily lives of early colonial settlers and is a significant part of the era’s social history of the time.Balance scale and weights with removable dish, two round weights glued to tray 4oz and 8oz. Scales 'to weigh up to 28lb. Printed in gold on black labels each side "W & T AVERY LTD", "BIRMINGHAM" warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, scale and weights, food preparation equipment, w t avery ltd, balance scale, grocers scales, james ford, william & thomas avery, birmingham uk -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDecorative object - Sewing Machine, c 1914-1930

Sewing Machine, Medium C S. (item has 10 parts), treadle operated, in wooden cabinet. Machine body is black with floral decals in gold, cream and red. Cabinet has wheels, 4 drawers containing cylinder shuttle, 2x bobbins, handle from a drawer and a bundle of horse hair. Drive belt is missing, cabinet has evidence of borer. Ironwork on right upright has 2 splits, name on plate of treadle is worn off. Decals include English Made and Approved to Her Majesty Queen Victoria. Machine has Serial Number.Pencilled inside machine support " 11/11/10 H M X" Serial Number "66389" Decals include "MEDIUM C.S / APPOINTED TO HER MAJESTY / QUEEN VICTORIA", "ENGLISH MADE".flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, sewing machine, cylinder shuttle sewing machine, dressmaker's equipment, taylor, jones sewing machine, medium c.s. machine, medium cylinder shuttle machine -

Bendigo Military Museum

Bendigo Military MuseumWeapon - TRIGGER PARTS

Various parts of weapon trigger system and trigger guards, Items in the collection of Sgt P.L.James, refer Cat No 7446 for his service details.1. Container - brown rusted metal box with sliding lid. Items 2 - 6 all contained within box. 2. Trigger mechanism - hard curled metal part with curved trigger at one end and swinging lever attached by small screw at other end. 3. Lever tripping - silver metal part of the trigger mechanism of the weapon, highly machined and gear attached to one side. 4. Post spring gear - extended black metal pipe (hollow) with gear mechanism attached to end. 5. Container - various parts of threads, screws, springs etc. 6. Bag and small parts - various screws, bolts and other metal parts.trigger mechanism, ww2 -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyAddressograph Machine

This metal plate machine used plates that contained names, addresses and classifications of each State Electricity Commission of Victoria employee working on the Kiewa Hydro Electric Scheme. The plates were put through the machine onto pay envelopes.See also: KVHS 1046, KVHS 1233The S.E.C.V. employed many people on the Kiewa Hydro Electric Scheme and used the latest technology of the time to pay each of them including providing each one with a pay slip. Metal table with the addressograph machine set into the middle section. The electric machine is belt driven and controlled by three 52 cm long metal pedals. The operator uses 5 stops, 2 knobs and 1 winder while sitting at the machine. There are 5 extra metal parts (or pieces) which belong to this machine. Ref. KVHS 1046 - Ink Rolls - Labelling Cartridges for Addressograph MachineMetal plate attached to front of machine which reads "Class 22000 Serial No. B-01547. Addressograph regd. Addressing machine. Patents Pending Made in England Addressograph Multigraph Limited London.addressograph machine. state electricity commission of victoria. kiewa hydro electric scheme. payroll. office work. -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPayroll Office Machine - S.E.C.V

This machine was used by the State Electricity Commission of Victoria on the Kiewa Hydro Electric Scheme by office workers who worked in the payroll office.The State Electricity Commission of Victoria used the latest technology available for office equipment on the Kiewa Hydro Electric Scheme. This machine was used in the payroll office.Black metal table with machine on top. Electric motor with belt drive to machine which is situated under the rear left side of the table. Safety metal mesh protects the leather belt and is at the rear of the table. The operator faces the machine which has a tray on the left and is divided longitudinally into two and holds new shiny metal plates on each side. There is a brown bakelite wheel on the left and two printing wheels inside a myriad of moving parts that enable the metal plates to be embossed with payroll information i.e. "Gang No. etc. / Names / Pay No. / Rate type. This has to be checked out each time / Date"ULQ 11 10"state electricity commission of victoria. kiewa hydro electric scheme. payroll office. office work. payroll machine. office equipment -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyCream Separator

... side of the machine 3 parts - top brass lid with hollow ...Dairy farms used cream separators to separate the milk and the cream before using it themselves or selling it to the dairy companies, shops or directly to the public.This cream separator was used by P & R Creamer on their dairy farm in the Kiewa Valley.3 parts - top brass lid with hollow cylinder enclosed across its top and extending beyond its circumference. 2. Stainless Steel hollow cylinders that fit the base and the lid but has 2 long curved spouts extending out - one for the milk and one for the cream to come out 3. Black cast iron stand that houses the gear mechanisms that drive the separator cones. The gear speed reduction wheel is on one side. "Alfa-Laval MOB / 80 Gall Capacity per hr / 48 Rev of Crank per Minute / Alfa-Laval Separator / Co. Ltd / 299 Sussex St. / Sydney" - on bottom side of the machinedairy; cream separator; kiewa valley; creamer family -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Cross cut saw

This saw is used for cutting curved edges of timber. It could have been used in the home or for commercial building purposes. The hand-held saw has largely now been replaced by electrically-operated machines. This item has no known local provenance but it is an interesting example of a hand-held tool of the past.This is a hand saw with a thin serrated metal blade. The blade is affixed to the bottom end of a wooden frame with two upright pieces and a cross piece affixed to the upper part of the frame. The top part of the frame has a piece of plaited rope stretched across. The top part of the frame has two wooden handles. The blade is somewhat rusted and the wooden parts and the rope are stained. vintage tools, history of warrnambool -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Domestic object - Washing Machine, 1930s

This washing machine is an early model hand machine which came from Allansford, near Warrnambool.This item is an interesting example of an early washing machine with its primitive and simple parts.This is a cylindrical galvanised metal tub mounted on a metal stand. It has a metal ring around the top of the tub and a wooden handle serving as the washing mechanism. The name of the manufacturer is stencilled on the side of the tub.QUEENS HEAD AUSTRALIAvintage household items, washing machine, mechanical washing machine, warrnambool history