Showing 106 items matching "machinery - pumps"

-

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Functional object - Well and pump

... Mitcham melbourne The pump was restored by Alan Mitchell who ...The pump was restored by Alan Mitchell who was an employee of Zerbe Engineering, Ashburn Place, Blackburn. The work was carried out by Alan in their workshop.The pump was patented by Joseph W. Douglas, Middletown Conn. and the patent was assigned to W & B Douglas.A reconstructed well of red bricks. Circular, dome shaped, it has a grill on the flat top of the dome on which the force pump is situated next to the grill. It circulates the water which is held in a tank beneath the brick structure. The force pump is hand operated with a replacement handle made c1965 by Alan Mitchell who restored and donated the pump. The well is located outside the kitchen door of Schwerkolt Cottage.Patented 1842 M--D Conn.civil engineering, water supply, machinery, pumps -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Functional object - Petrol Pump, Bowser

... vehicles machinery pumps This pump with tank and fittings ...Harold Bakes obtained this item from the Hawthorn Line Depot of the P.M.G, at 385 Burwood Road Hawthorn,following up information provided by Stan Boreham..Hand operated petrol pump or bowserThis pump with tank and fittings and equipment is the property of VACUUM OIL CO PTY LTD V2946. on metal plate.on an alloy plate---Self measuring pump|G+B model 1-2179 14* 117704|manufactured by Gilbert + Barker Mfg Co Springfield Mass U.S.A.|important - Keep all Stuffing Boxes tight.transport, motor vehicles, machinery, pumps -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncPump - Centrifugal, Model 70 indicates made in 1970's

... Machinery Pumps Centrifugal Metalwork... goldfields Part of the evolution of Kelly & Lewis pumps. Machinery ...Part of the evolution of Kelly & Lewis pumps.Single stage, end suction centrifugal pump cut away to reveal interior for display purposes. Painted yellow externally, green internally and red on edges of cut away. Mounted on a wooden pallet.On top plate - "Kelly & Lewis Pumps / Division of Mather & Platt Pty. Ltd. / Made in Australia". K & L Model 70 Pump size 2 1/4" - 9, Serial No. AC7232.machinery pumps centrifugal metalwork -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncPump - Centrifugal

... Machinery Pumps Centrifugal Metal... goldfields Machinery Pumps Centrifugal Metal Brass specification ...Painted light green with moving parts and bolts picked out in black. End suction, overshot discharge Bolted to a wooden base. V belt driven.Brass specification on sides - "Suction pump manufactured for Victorian Railways in 1930. Model H" Elaborate monogram in black on side denoting Kelly & Lewis Pumps. Brass plate with Kelly & Lewis Ltd / Centrifugal Pump / Type W.machinery pumps centrifugal metal -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncPump - Centrifugal, Approximately 1954

... Machinery - Pumps; Metalwork.... Machinery - Pumps; Metalwork The pump identification plate has been ...This pump was situated at Mildura Victoria and pumped water from the Murray river to irrigate the fruit blocks.Large double suction centrifugal pump with 36" suction and discharge branches weighing 7500 kg. Cast iron baseplate for the pump measuring 154 x 185 x 22 cm. The pump is fitted with a spring grid coupling. The pump and baseplate are painted pale blue. The pump identification plate has been removed and there are no markings cast on it. The baseplate has Thompsons cast in relief on the top surface. The coupling has a brass nameplate with Richardson Spring Grid Coupling engraved on it.machinery - pumps; metalwork -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncCondenser Air Pump, 1913

... machinery pumps reciprocating metalwork... goldfields machinery pumps reciprocating metalwork On cylinder head ...Vertical cylinder reciprocating condenser air pump with two 107 cm diameter flywheels (one on each end of crankshaft). The operating cylinder at at top of the machine has a centrifugal governor. Access ladder to platform at front. Painted black and red. On cylinder head "63"machinery pumps reciprocating metalwork -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncLeaflets

... MACHINERY - Pumps;... goldfields MACHINERY - Pumps; DOCUMENTS - Pamphlets Seven leaflets ...Seven leaflets each advertising a different pump. Illustrated in black & white. .1) Horizontal Dry Vacuum Pump, single bearing frame type with Outboard Bearing. .2) Direct coupled Single-stage Class "G" Centrifugal Pump. .3) Single-Stage Glass "G" Pump with overhung pulley. .4) Thompson Improved Type Gravel Pump .5) Belt-Driven Class "G" Centrifugal 5inch Single-Stage Pump with Belt striking gear. .6) Direct coupled Two-Stage Class "G" centrifugal pump. .7) Belt-driven Two-Stage Class "G" centrifugal pump.machinery - pumps;, documents - pamphlets -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncPump Casing, Estimated 1990's

... goldfields Machinery Pumps Casing casting for horizontal split casing ...Casing casting for horizontal split casing pump. Possibly for Thompson Kelly & Lewis double suction "Super Titan" pump. Painted blue and bolted to two pieces of wood.machinery, pumps -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncInstruction Manual

... goldfields Books Technical Machinery Pumps Paper covered instruction ...Paper covered instruction book for the Pump Department of Thompsons Engineering & Pipe Co. Ltd.. Printed in black ink. Handwritten notes inside front cover. Bound with tin bats.books, technical, machinery, pumps -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncLeaflets

... goldfields Documents Advertisements Pamphlets Machinery Pumps .1 ....1) Selection criteria for a suitable pump. .2) Boiler feed pumps. Leaflets, each with photographs of a pump.documents, advertisements, pamphlets, machinery, pumps -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncBooklets, 1) Centrifugal Pumps / Class "G". .2) Centrifugal Pumps Class "D"

... goldfields Documents Pamphlets Machinery Pumps engineering Trades ...Two paper covered booklets detailing centrifugal pumps, printed in b & w with photographs. Describing items made by Thompsons Engineering Co.. Stapled.documents, pamphlets, machinery, pumps, engineering, trades, metal working -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncBooklets, 1) Turbine Pumps Class "F". .2) Turbine Pumps Type "E"

... goldfields Documents Pamphlets Machinery Pumps Trades Metal working ...Two pamphlets detailing a type of turbine pump with photographs in b & w. .1) High Lift Single Stage. .2) Multi Stage Pumps. Made by Thompsons Co. Castlemaine. Stapled..1) Publication No. 8 20/1. .2) Publication No. 8 21/1.documents, pamphlets, machinery, pumps, trades, metal working, engineering -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncLeaflet, Thompson / Class "BG" Pumps

... goldfields Documents Pamphlets Machinery Pumps Engineering Single ...Single fold leaflet detailing capacities of single stage centrifugal pumps made by Thompsons (Castlemaine) Ltd.. Page numbering indicates it is part of a larger publication.documents, pamphlets, machinery, pumps, engineering -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncBooklets, 1) Gravel Pumps. .2) Chokeless Pumps

... goldfields Documents Pamphlets Machinery Pumps Engineering Two paper ...Two paper covered booklets with b & w photographs of pumps made by Thompsons Castlemaine. .1) Contains performance and dimension details with some hand written details. .2) Details of specialised pump for unstrained juices in cane sugar mills.documents, pamphlets, machinery, pumps, engineering -

Cheese World Museum

Cheese World MuseumPump, dairy vacuum

... , Allansford Allansford machinery dairy machinery dairying pumps ...From the dairy farm of Leon Miller, Swans Lane, AllansfordMilking machine chain driven vacuum pump made of cast iron, marked on the circular cylinder cap with an identification number.209allansford, machinery, dairy machinery, dairying, pumps, milking machines, leon miller -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - FOUNDRY

... . Some machinery - pumps, lathe etc. Vertical wall of main... to of engineering machine shop. Some machinery - pumps, lathe etc. Vertical ...sepia print mounted on grey board. Adult males (some in working clothes) assembled in lean to of engineering machine shop. Some machinery - pumps, lathe etc. Vertical wall of main building in background. Lorry wheel in right lower foreground.organization, business, foundry -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionRega fire knapsack for use with bulldozer

... of machinery Brass pump handle and adjustable nozzle attached.... Commission Victoria (FCV) Bushfire Planned Burning Fire Pump REGA ...Spraying units were manufactured in Australia by REGA Products Ltd. from 1926. REGA established themselves as leaders in the production of agricultural and horticultural spraying machines, including smaller knapsacks.Metal fire knapsack usually attached to the back of machinery Brass pump handle and adjustable nozzle attached.REGAforests commission victoria (fcv), bushfire, planned burning, fire pump -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionRega fire knapsack for use with bulldozer

... of machinery Brass pump handle and adjustable nozzle attached.... Commission Victoria (FCV) Bushfire Planned Burning Fire Pump REGA ...Spraying units were manufactured in Australia by REGA Products Ltd. from 1926. REGA established themselves as leaders in the production of agricultural and horticultural spraying machines, including smaller knapsacks.Plastic fire knapsack usually attached to the back of machinery Brass pump handle and adjustable nozzle attached.REGAforests commission victoria (fcv), bushfire, planned burning, fire pump -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - Napoleon Main Pump, 1936

... Black and white photograph: pump machinery in underground... photograph: pump machinery in underground at Napoleon (BML) Gold Mine ...Significant to mining history of Bendigo.Black and white photograph: pump machinery in underground at Napoleon (BML) Gold Mine. Image shows machinery, with steel control box at far left hand side. Safety rail in front of machinery. Rock wall behind. Written in pencil on back of photograph : '....(illegible) pump No. 10 plat Napoleon 15/9/36 ''napoleon gold mine, plat, pump -

Whitehorse Historical Society Inc.

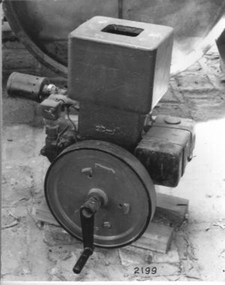

Whitehorse Historical Society Inc.Equipment - Stationary Motor

... equipment such as pumps and machinery on a farm etc. Petrol driven... drive other equipment such as pumps and machinery on a farm etc ...Used by Ted Beddiscomb of Gormandale near Traralgon, brother in law of donor. Ted was a dairy farmer and used the motor for about 10 years to pump water. It is possible it was on his farm for some years prior to this. Tom did some reconditioning and preservation on the unit.3 HP 4 cycle motor primarily used to belt drive other equipment such as pumps and machinery on a farm etc. Petrol driven, magneto ignition and water cooled.Bronze plate 'The Rosebery Engine C25387 RPM 1000 HP3 manufacturer Westinghouse Rosebery Ltd Sydney. 3C-103 on water jacket; 3D-1 on engine housing; 3C-15 on flywheel.rural industry, farm machinery, machinery, engines - internal combustion -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncMounted Display Board, Assembled by Flowserve

... on machinery made be various pump manufacturers associated... used on machinery made be various pump manufacturers associated ...42 sample specification plates and labels of types used on machinery made be various pump manufacturers associated with Thompsons Kelly & Lewis and Flowserve. Mount is of fibreboard, painted brown on the front and black on the back.display -

Bendigo Historical Society Inc.

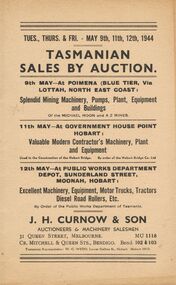

Bendigo Historical Society Inc.Document - IAN DYETT COLLECTION: AUCTION CATALOGUE - TASMANIAN MINING AND CONTRACTOR'S AUCTION

... of Mining machinery,pumps, plant, equipment and buildings... of Mining machinery,pumps, plant, equipment and buildings ...Beige covered catalogue of Tasmanian Sales by Auction held over three days. On Tuesday 9th May 1944 was an auction of Mining machinery,pumps, plant, equipment and buildings at the Michael Moon Mine, Poimena (Blue Tier) and at the AZ Mine, Poimena (Blue Tier). Thursday 11th May 1944 was the sale of Contractor's Machinery, plant and equipment used in the Construction of the Hobart Bridge by order of the Hobart Bridge Co. Ltd. And Friday 12th May 1944 was the auction of machinery, equipment, motor vehicles etc. at the Public Works Depot at Moonah, Hobart. J. H. Curnow & Son were the Auctioneers. Booklet contains description of some of the machinery, Special Notice regarding travelling and freight, Conditions of Sale and an Auctioneer's Notice mentioning the sale is being conducted by permission of the Director of Machine Tools and Gauges under Regulation 59 of the National Security (General) Regulations. Principals only are allowed to bid and buy unless special permission is granted by DMT & G for some person to act on their behalf, and that person must be an employee of the Firm.business, auctioneers, j h curnow & son pty ltd, ian dyett collection - auction catalogue - tasmanian mining and contractor's auction, michael moon mine, a z mines, hobart bridge co ltd, public works department hobart, j h curnow & son, w c wedd, director of machine tools and gauges, national security (general) regulations, the prahran telegraph printing co, c j curnow, h j lowe, f c dyett, j l jamieson & co -

Bendigo Historical Society Inc.

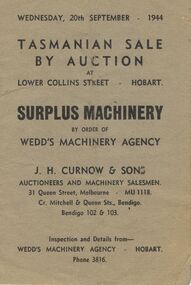

Bendigo Historical Society Inc.Document - IAN DYETT COLLECTION: AUCTION CATALOGUE - TASMANIAN SURPLUS MACHINERY

... machinery, electric motors, pumps, tools, spare parts and a tractor... machinery, electric motors, pumps, tools, spare parts and a tractor ...Small grey covered auction catalogue for a sale of Surplus Machinery situated at Blue Tier, Lottah and at Derwent Bridge Construction Works by order of Wedd's Machinery Agency. Auctioneers J. H. Curnow & Sons. Machinery offered included mining machinery, electric motors, pumps, tools, spare parts and a tractor. Most of the lots have the sale price written beside them.business, auctioneers, j h curnow & son pty ltd, ian dyett collection - auction catalogue - tasmanian surplus machinery, j h curnow & son, wedd's machinery agnecy hobart, derwent bridge construction works, c j curnow, h j lowe, f c dyett, j l jamieson & co, w g wedd, mercury press -

Warrnambool and District Historical Society Inc.

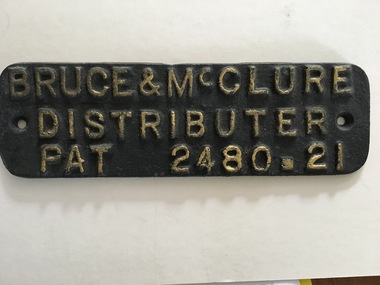

Warrnambool and District Historical Society Inc.Brass Plate, Bruce & McClure Distributer, C early 20th century

... and agricultural machinery including motor engines , pumps, tanks... & McClure were manufacturers of windmills and agricultural machinery ...Bruce & McClure were manufacturers of windmills and agricultural machinery including motor engines , pumps, tanks,and appliances for supplying and conserving water.Also included was brass,iron and steel foundry works. They won 11 first prizes at the Grand national Show of 1907 and in 1914 designed and manufactured a new water boring machine which could also be used for oil and gold exploration They operated from Lava Street well into the 1940's as well as from the geelong area. This plaque is possibly from one of their machines.A tangible link to one of Warrnambool's manufacturing businesses which was innovative and an essential part of the beginnings of machine use in farms and industry in the district. Cast iron plaque with moulded text which is coloured in gold. rectangular with rounded corners. Back is painted grey.Bruce & McClure Distributer Pat 2480.21warrnambool, bruce & mcclure, bruce & mcclure machinery -

Stawell Historical Society Inc

Stawell Historical Society IncArchive, Sands & McDougall, Sands & McDougall's Melbourne and Suburban Directory for 1890, 1890

... . Botttom Worthington Steam Pumping Machinery Printed across... Limited. Botttom Worthington Steam Pumping Machinery Printed ...Hard Cover with missing spine Fron cover: Ads for Melbourne Permanent Builing Society Top Half. Austral + Otis + Elevator and Engineering Company Limited. Botttom Worthington Steam Pumping Machinery Printed across the Pages on top of book: The Sweet Hapsburg Pianos & Organs at Wertheim;'s DEpot 59 Swanston Street. Across The Sides of the Pages: Melbourne Suburbs Green Pages Alphabetical Red Pages: Trade & Professional Yellow Miscellaneous Bottom; The Wonderful Wertheim Sewings Machines, Mangels and Washers 59 Swanston Street -

Ballarat Heritage Services

Ballarat Heritage ServicesPhotograph - Photograph - Colour, Steele's Pioneer Mine Ruins, Yandoit, 2016, 18/01/2016

... Quartz Mining Company fixed steam pumping machinery and commenced... Reef Quartz Mining Company fixed steam pumping machinery ...Steele's Reef was opened in 1859 along with a number of other reefs in the Yandoit area. The reef was worked by small mining parties until the late 1880s. In 1887, the Steele's Reef Quartz Mining Company fixed steam pumping machinery and commenced sinking a shaft. The company were unable to find a profitable ore body and after two years work closed down. By this time their shaft had reached a depth of 150 feet. The mine was then taken over by the Pioneer Quartz Mining Company who appear not to have worked the mine. In 1906, the Steele's Pioneer Company commenced work, erecting a winding winch at the old shaft sunk by the Steele's Company. The next year the company erected a 10-head battery, set of poppet legs, a pumping engine. Sinking the shaft a further 100 feet, the company struggled to find payable ore and soon closed down.Colour photographs of the remnants of Steele's mine at Yandoit, Victoria. steele's mine, yandoit, mining, ruins -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - IAN DYETT COLLECTION: AUCTION CATALOGUE - BIG BELL GOLD MINE

... . Sale consisted of Mining Machinery, Engines, Electrical... of Mining Machinery, Engines, Electrical Equipment, Pumps, Stores ...Two red covered ( one with cloth tape on the spine and edges) auction catalogues for a sale at the Big Bell Gold Mine, Big Bell, Western Australia, held on the 22nd to 27th August 1955 and 29th to 31st August and 1st to 3rd September, 1955. Sale consisted of Mining Machinery, Engines, Electrical Equipment, Pumps, Stores, Housing, Rolling Stock and Costly Equipment by Order of Big Bell Mines Ltd. J. H. Curnow & Son Pty. Ltd. Were the auctioneers. One catalogue has Mr. Curnow written on the front.business, auctioneers, j h curnow & son pty ltd, ian dyett collection - auction catalogue - big bell gold mine, big bell mines ltd, j h curnow & son pty ltd, prahran telegraph printing co pty ltd -

Federation University Historical Collection

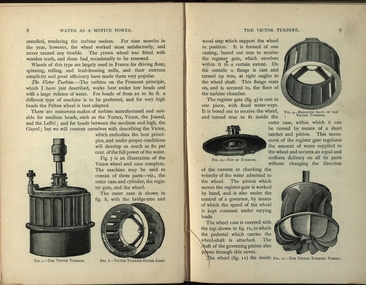

Federation University Historical CollectionBook, Machinery for Metalliferous Mines, 1894, 1894

... engines, hoisting machinery, draining of Mines, pumping engines... engines, hoisting machinery, draining of Mines, pumping engines ...The 1st edition of this famous work, giving an excellent account of the machinery used in late 19th century metal mining in the UK and overseas is very rare. It covers a wide range of equipment - pumps, steam engines, drills, winding engines, stamps & concentration mills, aerial ropeways, tramways and early uses of electricity etc. Brown hard cloth covered book. xvi 564 pages with additional advertisements, with over 300 illustrations and drawings, some fold out. Chapters include Water as a motive power, Wind engines and ventilating machinery, Steam boilers/engines and oil engines, hoisting machinery, draining of Mines, pumping engines, rock drilling machinery, boring machinery, concentration machinery, sizing and classifications trommels, joggers and jigging, fine concentration, milling of gold ores, milling of silver ores, amalgamation plates and machinery, dry and roasting machinery, chlorination and cyandide processes for the extraction of gold, electricity as a motive power for mining, electric lighting and blasting, aerial wire ropeways, transport by rail and road. There a a number of lovely line illustrations in the book including: Poncelot's undershot waterwheel; Fromont furnace;Victor turbine; Pelton waterwheel; Root's positive blower;Cross section and front elevation of Lancashire boiler; Robey's Compound Mill Engine; Portable Winding Plant; Iron Pit Head Gear ; Loading Arrangement in an Incline Shaft; kibble; Worthington Pump; California Pump; Scram's Air Compressor; Rock drill Bits; Special Sharpening tools; Boring tools;Rotating Picking table; Ore Feeder; roller crusher; stamp battery; round buddle; slime table; vanner; amalgamating plant; belt elevator;roasting furnace;splicing wire rope; capel; tipping waggon;mining, cornish pump, linkenbach table, water wheel, ventilation, oil engine, california, america, water, steam boilers, steam engines, oil engines, pumpimg, rock drilling, boring, jiggers, milling, silver, gold, drying and roasting, chlorination, cyaniding, lead, zinc, copper, electricity, electric lighting, wire ropes, transport, wind engine, poppet head -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Diving Compressor, Siebe Gorman & Co. Ltd, 1880-1890

... paper-making machinery, measuring machinery, water-pumps... paper-making machinery, measuring machinery, water-pumps ...This compressor was part of the E.G. Ward Collection. It is connected to the diving suit and boots also in our collection. Siebe Gorman & Company Ltd was a British company that developed diving equipment and breathing equipment and worked on commercial diving and marine salvage projects. The company advertised itself as 'Submarine Engineers'. It was founded by Augustus Siebe, a German-born British engineer chiefly known for his contributions to diving equipment. Siebe Gorman traded as an engineering firm for over 180 years from 1819 to 1999. The early success of the business was due to its founder, the Prussian immigrant Christian 'Augustus' Siebe (1788-1872). For business reasons, he applied for and was granted British citizenship in 1856. He was a gifted engineer who was able to translate theoretical problems into practical, working products. During the industrial Victorian period, the business traded as 'A. Siebe' at 145 High Street Holborn London, but in 1828 new premises were acquired at 5 Denmark Street, Soho. The family firm produced a wide range of manufactured goods including paper-making machinery, measuring machinery, water-pumps, refrigeration equipment and diving apparatus. Augustus Siebe specialised in submarine engineering early on and the company gained a reputation for the manufacture of safe, reliable diving apparatus. Augustus Siebe is best remembered for the development and manufacture of the ‘closed’ Diving Dress based on the ideas of Charles and John Deane, George Edwards and Charles Pasley. Apart from some small modifications to valves and diver communications, the basic 12 bolt ‘closed’ diving dress remained relatively unchanged after the 1870s. Later company successes were also based on innovation, with new products that could be successfully developed and manufactured to high standards. This was largely attributed to the inventive nature, foresight, engineering and entrepreneurial skills of Robert Henry Davis (1870-1965). In 1882, RH Davis joined the company of 'Siebe & Gorman' as a young 11-year-old office boy and he was to remain with the company until he died in 1965. Augustus Siebe retired in 1869 and handed over the company to a new partnership of Henry H. Siebe (1830-1885) and William A. O'Gorman (1834-1904). The new firm traded as 'Siebe & Gorman' (1870-1879) from premises in and around Mason Street, Westminster Bridge Road, Lambeth, London. The two partners soon recognised the potential of R.H. Davis and in 1894, aged 24, he became General Manager of Siebe & Gorman. Davis increasingly ran the company until the surviving partner (W.A. Gorman) died in 1904. The firm was disposed of to the Vickers (armaments) family and a new company 'Siebe Gorman & Co. Ltd.' (1905-1998) was formed. Under the chairmanship of Albert Vickers, R.H. Davis was kept on as Managing Director, and the company forged ahead. However, after WW1, the Great Depression caused manufacturing output and share prices to slump. In 1924 Robert Davis made a deal with the Vickers Board and acquired control of the company through majority shares. Under his leadership, the Siebe Gorman Company flourished and within time, four of his sons also joined the firm. The company gained a worldwide reputation for the manufacture of diving apparatus, decompression and observation chambers, and safety breathing apparatus of all types for use on the land, in the air and under the sea (including mine rescue, tunneling, aircraft, diving, submarine escape and in other hazardous environments). Close research and development links with the MOD (especially the Admiralty), also provided a lucrative outlet for the company products. In 1932, Robert Davis was knighted by King George V, principally for his invention of the ‘Davis Submerged Escape Apparatus’ (D.S.E.A.). Siebe Gorman essentially remained a family firm from the beginning (under A Siebe) until it became a public company for the first time in 1952. However, following WW2, British manufacturing stagnated through stifled investment and post-war austerity, and there was little innovation. Siebe Gorman fortunes began to decline as an ageing Sir Robert Davis failed to invest, or change the company business and management practices. In 1959, Siebe Gorman was acquired by the “Fairy Group” and the ailing Sir Robert was made Life President. Consequently, nothing changed and the slow decline continued until Sir Robert's death in March 1965. Around 1960, Siebe Gorman acquired the diving apparatus manufacturer C E Heinke, and for a brief period, it manufactured some diving equipment under the combined name of Siebe Heinke. Around 1964, Mr. E. 'Barry' Stephens was appointed as the new Managing Director to modernise Siebe Gorman. Changes were made, including a move to a new factory in Wales in 1975. The new company concentrated on fire fighting breathing apparatus and escape equipment, and the move coincided with the loss of many of the older, traditional craft skills. Between 1985 and 1998, Siebe expanded through acquisitions, and several other companies were acquired. The Siebe Gorman (diving apparatus) company has therefore traded as A. Siebe (1819-1870); Siebe & Gorman (1870-1879); Siebe Gorman & Co (1880-1904); Siebe Gorman & Co. Ltd (1905-1998).The compressor is a very significant item as it gives a snapshot into marine history and the development of diving equipment generally especially that used for salvage operations before and during WW2. Siebe & Gorman the company that made the equipment was a leading inventor, developer and innovator of marine equipment with its early helmets and other items eagerly sought after today for collections around the world. The items in the Flagstaff Hill collection give us an insight as to how divers operated and the dangers they faced doing a very necessary and dangerous job during the early days of marine exploration.A single cylinder divers' pump by Siebe Gorman & Co Ltd, London, eccentric hand cranked in brass mounted mahogany case with instructions to the underside of the lid, brass covered pressure gauge and air outlet, brass makers plaque to the front, water inlet and outlet to the rear, green painted lifting rings. Machinery has some blue painted areas on the metal.Plate on the back 'WATER SUPPLY" "WATER OVERFLOW" "WATER DRAIN-IN" Pressure gauge dial "BOURDON'S PRESSURE GAUGE" STEBE GORMAN & CO. LONDON", "LBS PRESSURE" "FEET OF SALT WATER" Plate on the front " PATENT, Siebe Gorman & Co Ltd Submarine Engineers" below emblem (Lion, Crown, Horse)flagstaff hill, warrnambool, flagstaff-hill, maritime-museum, diving compressor, london, siebe gorman & co ltd, marine technology, life saving, deep sea diving, maritime museum, maritime village, manine history -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Diving Suit, boots and weight, 1900

... machinery, measuring machinery, water pumps, refrigeration equipment... paper-making machinery, measuring machinery, water pumps ...This diving suit with helmet, boots and weight is part of the E.G.Ward collection, along with the diving compressor and a photograph of a diver in this equipment. Siebe Gorman & Company Ltd was a British company that developed diving equipment and breathing equipment and worked on commercial diving and marine salvage projects. The company advertised itself as 'Submarine Engineers'. It was founded by Augustus Siebe, a German-born British engineer chiefly known for his contributions to diving equipment. Siebe Gorman traded as an engineering firm for over 180 years from 1819 to 1999. The early success of the business was due to its founder, the Prussian immigrant Christian 'Augustus' Siebe (1788-1872). For business reasons, he applied for and was granted British citizenship in 1856. He was a gifted engineer who was able to translate theoretical problems into practical, working products. During the industrial Victorian period, the business traded as 'A. Siebe' at 145 High Street Holborn London, but in 1828 new premises were acquired at 5 Denmark Street, Soho. The family firm produced a wide range of manufactured goods including paper-making machinery, measuring machinery, water pumps, refrigeration equipment and diving apparatus. Augustus Siebe specialised in submarine engineering early on and the company gained a reputation for the manufacture of safe, reliable diving apparatus. Augustus Siebe is best remembered for the development and manufacture of the ‘closed’ Diving Dress based on the ideas of Charles and John Deane, George Edwards and Charles Pasley. Apart from some small modifications to valves and diver communications, the basic 12-bolt ‘closed’ diving dress remained relatively unchanged after the 1870s. Later company successes were also based on innovation, with new products that could be successfully developed and manufactured to high standards. This was largely attributed to the inventive nature, foresight, engineering and entrepreneurial skills of Robert Henry Davis (1870-1965). In 1882, RH Davis joined the company of 'Siebe & Gorman' as a young 11-year-old office boy and he was to remain with the company until he died in 1965. Augustus Siebe retired in 1869 and handed over the company to a new partnership of Henry H. Siebe (1830-1885) and William A. O'Gorman (1834-1904). The new firm traded as 'Siebe & Gorman' (1870-1879) from premises in and around Mason Street, Westminster Bridge Road, Lambeth, London. The two partners soon recognised the potential of R.H. Davis and in 1894, aged 24, he became General Manager of Siebe & Gorman. Davis increasingly ran the company until the surviving partner (W.A. Gorman) died in 1904. The firm was disposed of to the Vickers (armaments) family and a new company 'Siebe Gorman & Co. Ltd.' (1905-1998) was formed. Under the chairmanship of Albert Vickers, R.H. Davis was kept on as Managing Director, and the company forged ahead. However, after WW1, the Great Depression caused manufacturing output and share prices to slump. In 1924 Robert Davis made a deal with the Vickers Board and acquired control of the company through majority shares. Under his leadership, the Siebe Gorman Company flourished and within time, four of his sons also joined the firm. The company gained a worldwide reputation for the manufacture of diving apparatus, decompression and observation chambers, and safety breathing apparatus of all types for use on the land, in the air and under the sea (including mine rescue, tunnelling, aircraft, diving, submarine escape and in other hazardous environments). Close research and development links with the MOD (especially the Admiralty), also provided a lucrative outlet for the company products. In 1932, Robert Davis was knighted by King George V, principally for his invention of the ‘Davis Submerged Escape Apparatus’ (D.S.E.A.). Siebe Gorman essentially remained a family firm from the beginning (under A.Siebe) until it became a public company for the first time in 1952. However, following WW2, British manufacturing stagnated through stifled investment and post-war austerity, and there was little innovation. Siebe Gorman fortunes began to decline as an ageing Sir Robert Davis failed to invest, or change the company business and management practices. In 1959, Siebe Gorman was acquired by the “Fairy Group” and the ailing Sir Robert was made Life President. Consequently, nothing changed and the slow decline continued until Sir Robert's death in March 1965. Around 1960, Siebe Gorman acquired the diving apparatus manufacturer C E Heinke, and for a brief period, it manufactured some diving equipment under the combined name of Siebe Heinke. Around 1964, Mr E. 'Barry' Stephens was appointed as the new Managing Director to modernise Siebe Gorman. Changes were made, including a move to a new factory in Wales in 1975. The new company concentrated on fire-fighting breathing apparatus and escape equipment, and the move coincided with the loss of many of the older, traditional craft skills. Between 1985 and 1998, Siebe expanded through acquisitions, and several other companies were acquired. The Siebe Gorman (diving apparatus) company has therefore traded as A. Siebe (1819-1870); Siebe & Gorman (1870-1879); Siebe Gorman & Co (1880-1904); Siebe Gorman & Co. Ltd (1905-1998).The items are very significant as a snapshot into marine history and the development of diving equipment generally especially that used for salvage operations before and during WW2. The company that made the equipment was a leading inventor,developer and innovator of marine equipment with its early helmets and other items eagerly sought after today for collections around the world. The items in the Flagstaff Hill collection give us an insight as to how divers operated and the dangers they faced doing a very necessary and dangerous job.Diving suit including helmet, boots and a weight. Diving suit is made of canvas with knitted cuffs. The helmet is metal. The boots have a thick sole and thick leather upper that is held on with leather straps and buckles. The toe of the boot is heavy metal. The weight is worn next to the trunk of the diver and it has an inscription to mark the front. It is worn with straps and buckles holding it in place. Royal Navy Admiralty Pattern 6 bolt No 3 light Siebe Gorman light diving helmet circa 1960 used by the Royal Navy before and after World War 2"Siebe Gorman & Co Ltd Marine Engineers London. Patent" with "E G Ward" on front and back plate. On weight "FRONT"flagstaff hill, warrnambool, diving suit, siebe gorman and co ltd., siebe gorman and co ltd marine engineers london, marine engineers, diving helmet, diving boots, diving weight, marine diving, maritimemuseum, maritime village, maritime history, marine technology, life saving, deep sea diving