Showing 28 items matching "machinery erecting"

-

Federation University Historical Collection

Federation University Historical CollectionBook - Book - Prospectus, W.M.C Printing Classes, The Working Men's College, The Melbourne Technical School, Prospectus, 1919, 1919

... machinery erecting... parkin pattern-making w penrose turning and fitting machinery ...The Working Men’s College was founded in 1881 by a prominent grazier and philanthropist, The Hon. Francis Ormond, who donated £5000 towards the establishment of the college. The Council of the Melbourne Trades Hall then matched Ormond's initial donation by rallying its members. On 4 June 1887, the college opened in its purpose-built building on the corners of Bowen Street and La Trobe Street in Melbourne, with a gala ceremony. It became the third official provider of higher education in the new Colony of Victoria (the Melbourne Athenaeum was founded in 1839 and the University of Melbourne in 1853). The college was the predecessor to the current-day Royal Melbourne Institute of Technology (RMIT University). Adjoining the college in the 1890s were the Supreme Court of Victoria (later the Melbourne Magistrates' Court) and the Melbourne Gaol - both which are now part of RMIT today. An Index at the back lists all courses available. There is also an Index to Advertisements. Orange/red soft covered book with assorted photographs and advertisements.Office Jun Tech written on front cover.melbourne, prospectus, w.c. kernot, james smith, thos smith, a.e. smith, c.e. oliver, r. solly, s. barker, r. fiddes brown, t.f. bride, daniel white, f.e. shillabeer, d.avery, a.h. merrin, chas gray, w.h. haigh, j.h. hewison, h. burgess, sir d.v. hennessy, w.s. busby, r.b. lemmon, s.n. rodda, j. lemmon, r.b. mccomas, working men's college, melbourne technical school, charles gray, heads of departments, j sarvaas engineering, g b pritchard mining and metallurgy, e s richards chemistry, a hart mathematics, g r pitkeithly art and applied art, r j haddon architecture, instructors-in-charge, e carlton, coach and body building, r j dorey, blacksmithing, j dewar, plumbing gasfitting sheet metal work, h haile, sheep and wool, g leslie, printing, r h mcleod, correspondence courses, f parkin, pattern-making, w penrose, turning and fitting, machinery erecting, d skidmore, moulding, librarian a hart -

Falls Creek Historical Society

Falls Creek Historical SocietyPhotograph - Bogong, c1950

... Black and white square photograph of man using machinery... Black and white square photograph of man using machinery ...This photo is part of the Fred Griffith Photographic Collection documenting his time with the Australian Alpine Club and the formation of the Albury Ski Club. Frederick Charles “Fred” Griffith was born in Albury, NSW on 2 March 1910. Educated in Albury and Geelong Grammar. Beginning in 1927 he spent many years working first as a jackeroo and on a range of prominent pastoral and merino stud properties in NSW and Queensland. In 1935 he repurchased his former family property “Toonallook", Bowna, NSW and developed it to be the largest Romney Marsh stud in the world, exporting rams to Argentina. He introduced many innovative practices on his property including rabbit control measures and aerial crop dusting. He was an active member of the Albury Show Society and in 1949 established the Albury Sheep Show. Fred was also the Albury representative on the Graziers’ Association Council for over 30 years. He became a life member of both the Albury and Commercial Clubs. Fred’s greatest hobby was snow skiing. His first visit to the snow was to Kosciusko in 1919. The Albury Ski Club was formed in 1935 and Fred was an inaugural member. In 1949 they were granted a site at Falls Creek to build their own lodge. Fred guaranteed the Club for finance from the Bank of NSW. The first portion of the prefabricated building was constructed in Albury. It was transported to Falls Creek on the back of Fred’s truck and erected in one day. This was the bathroom section and the rest was completed in 1950. The original lodge was burned down in 1952 and a new one built the following year. In 1955, Fred also built the Bowna Lodge for his family in partnership with David Fairbairn. He became head of the North Eastern District Skiing Association (N.E.D.S.A.) and successfully applied to run the Australian Ski Championships. Fred also inaugurated children’s races at Falls Creek and ran them for about 20 years. He also formed the company “Falls Creek Ski Tows”. In 1956 Fred along with a group of key people selected the site for Thredbo Village. Fred and his brother sold Toonallook in sections between 1951 and 1974. He moved to Albury and set up as a landscape gardener and fencing contractor. After a serious work accident, Fred retired in 1985 and moved to Rosebud, Victoria where he died on 19 August 1992.Black and white square photograph of man using machinery to erect a power pole at corner of lodge. Woman is watching on the right.bogong, falls creek, snow, snowfields -

Bendigo Historical Society Inc.

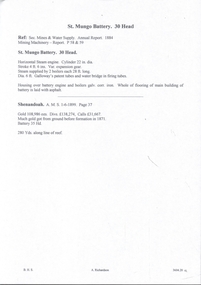

Bendigo Historical Society Inc.Document - MINING REPORTS - MINING REPORTS - ST MUNGO, SHENANDOAH

... for the Shenandoah Mine and contractor erecting machinery at the St. Mungo... Shenandoah Sec Mines & Water Supply Annual Report Mining Machinery ...Handwritten extracts mentioning the St. Mungo Battery, the Shenandoah, and the St. Mungo, E'hawk. Notes mention engine, boilers and engine & boiler housing. Also mentioned are gold yields, Dividends, Calls, battery and distance along the reef for the Shenandoah Mine and contractor erecting machinery at the St. Mungo Mine.document, gold, mining reports, mining reports st mungo shenandoah, sec mines & water supply annual report, mining machinery report p 58 & 59, st. mungo battery, shenandoah, a m s 1/6/1899 page 37, st mungo mine, 'the federal australian' extracts from mining notes s'hurst -

Bendigo Historical Society Inc.

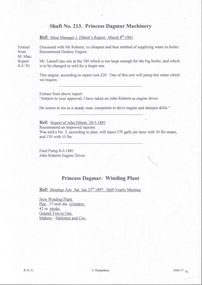

Bendigo Historical Society Inc.Document - MINING REPORTS - EXTRACTS FROM PRINCESS DAGMAR MINE MANAGER'S REPORT

... , contractors erecting machinery, crushings, repair to shaft, new ropes... erecting machinery, crushings, repair to shaft, new ropes, broken ...Two copies of handwritten extracts from the Mine Managers of the Princess Dagmar Mine, Garden Gully line. Mine managers were J. Ebboth, Charles Gambetta, A. Williams and S. Richards. Subjects reported on include supply of water to boiler, new engine- driver, stolen gold, engine house destroyed by fire, painting and cementing the chimney stack, sale of galvd iron and oil barrels, contractors erecting machinery, crushings, repair to shaft, new ropes, broken indicator on winding engine and work stopping and recommencing seven months later. Reports range in date from 1881 to 1914.document, gold, mining reports, extracts from princess dagmar mine manager's report, john ebbott, mr roberts, mr lansell, john roberts, bendigo advertiser sat jan 23rd 1897, harkness and coy, almond williams, mr r eddy, f warren, s richards -

Federation University Historical Collection

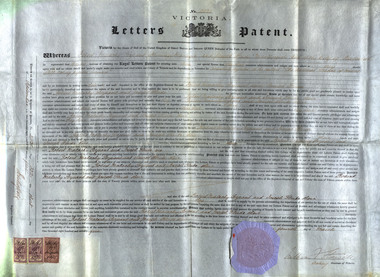

Federation University Historical CollectionDocument, Indenture Between Robert M. Serjeant, Joseph Flude and the Trustees of the Ballarat School of Mines regarding Letters of Patents for the Benefit of the Ballarat School of Mines, 1877, 04/03/1875

... . It is in contemplation also to erect machinery shops in connection... be an accomplished fact. It is in contemplation also to erect machinery shops ...R.M. Serjeant was listed as a mining manager and Joseph Flude as a metallurgist. In 1875 they were both living in Ballarat. The patent number is A.D.1875, 4th March. No 2031. According to the patent the hearth of the furnace is in the form of a cone revolving horizontally. The feed is supplied to the apex of the cone by an archimedian screw. The crown of the furnace comprises a double covering or roof with an intermediate chamber for receiving heated air. The inner covering is pierced to admit of the heated air being brought into contact with the pyrites on the face of the revolving hearth. The discharge of the roasted substance is affected by means of a scraper at the base of the cone. It was claimed that this was a new mode of introducing heated air, and the exclusion of flame during the operation of roasting pyrites. The self-acting charge and discharge of the furnace and the peculiar construction of the hot air chambers, and the use of perforated bricks through which the supply of air is affected were also new. (http://patentsvictoria.net/002031.html) From the Goulburn Herald, 14 September 1878 "A feature connected with the school of mines is the yet unfinished pyrites works. The extraction of the gold from pyrites and the utilization for commercial purposes of other substances connected with pyrites are peculiarly important to Ballarat, because were a simple and inexpensive method devised there are millions and millions of tons of quartz that would then be made remunerative. With this thought in their minds two scientific gentlemen invented the school of mines self-acting rotatory furnace. This, for lack of funds, has not been completed as yet, but the amount in hand for the purpose is daily increasing, and it will eventually be an accomplished fact. It is in contemplation also to erect machinery shops in connection with the school, and it is purposed to con struct a steam-engine to do at once the work of the pyrites treatment and the ma chine room. A model shaft and mine too are being prepared for on the reserve, so that practical mining of the most thorough character may be taught on the ground.'Large indenture on red bordered vellum. The indenture was regarding a patent for the benefit of the Ballarat School of Mines. Letters Patent for an Invention for Roasting Pyrites to be called 'the Ballarat School of Mines self-Acting Pyrites Furnace" to Robery Malachy Serjeant and Joseph Flude. The large document is on a vellum type paper complete with stamps and seal. The document is signed by Acting-Governor William Stawell. Inscriptions and Markings Written on verso: "Date of Patent 4th March 1875 No 2031 Letters Patent for An invention for roasting pyrities to be called "The Ballarat School of Mines Self-acting Pyrities Furnace" to Robert Malachy Serjeant and Joseph Flude Melbourne, Victoriaballarat school of mines, serjeant, r.m. serjeant, robert m. serjeant, flude, joseph flude, patent, barry, redmond barry, rogers, judge rogers, bland, rivett henry bland, john airy, warrington rogers, establishment, indenture, legal, cuthbert, ballarat school of mines trustees, william stawell, john warrington rogers -

Federation University Historical Collection

Federation University Historical CollectionDocument, Letters Patent for an Invention for Roasting Pyrites, 1875, 1875

... be an accomplished fact. It is in contemplation also to erect machinery shops... to erect machinery shops in connection with the school ...R.M. Serjeant was listed as a mining manager and Joseph Flude as a metallurgist. In 1875 they were both living in Ballarat. The patent number is A.D.1875, 4th March. No 2031. According to the patent the hearth of the furnace is in the form of a cone revolving horizontally. The feed is supplied to the apex of the cone by an archimedian screw. The crown of the furnace comprises a double covering or roof with an intermediate chamber for receiving heated air. The inner covering is pierced to admit of the heated air being brought into contact with the pyrites on the face of the revolving hearth. The discharge of the roasted substance is affected by means of a scraper at the base of the cone. It was claimed that this was a new mode of introducing heated air, and the exclusion of flame during the operation of roasting pyrites. The self-acting charge and discharge of the furnace and the peculiar construction of the hot air chambers, and the use of perforated bricks through which the supply of air is affected were also new. (http://patentsvictoria.net/002031.html) From the Goulburn Herald, 14 September 1878 "A feature connected with the school of mines is the yet unfinished pyrites works. The extraction of the gold from pyrites and the utilization for commercial purposes of other substances connected with pyrites are peculiarly important to Ballarat, because were a simple and inexpensive method devised there are millions and millions of tons of quartz that would then be made remunerative. With this thought in their minds two scientific gentlemen invented the school of mines self-acting rotatory furnace. This, for lack of funds, has not been completed as yet, but the amount in hand for the purpose is daily increasing, and it will eventually be an accomplished fact. It is in contemplation also to erect machinery shops in connection with the school, and it is purposed to con struct a steam-engine to do at once the work of the pyrites treatment and the ma chine room. A model shaft and mine too are being prepared for on the reserve, so that practical mining of the most thorough character may be taught on the ground.'Letters Patent for an Invention for Roasting Pyrites to be called 'the Ballarat School of Mines Self-Acting Pyrites Furnace' to Robert Malachy Serjeant and Joseph Flude. The large document is on a vellum type paper complete with stamps and seal. The document is signed by Acting-Governor William Stawell.Written on verso: "Date of Patent 4th March 1875 No 2031 Letters Patent for An invention for roasting pyrities to be called "The Ballarat School of Mines Self-acting Pyrities Furnace" to Robert Malachy Serjeant and Joseph Flude Melbourne, Victoriaballarat school of mines, serjeant, r.m. serjeant, robert m. serjeant, flude, joseph flude, richard gibbs, stawell, william stawell, pyrities furnace, philately, statute stamp, seal (victoria), ballarat school of mines self-acting pyrities furnace, ballarat school of mines self-acting pyrites furnace -

The Beechworth Burke Museum

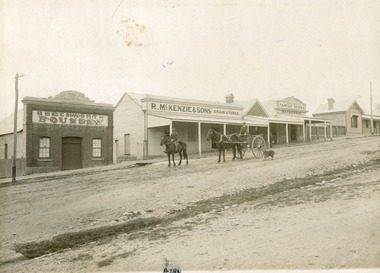

The Beechworth Burke MuseumPhotograph, 1910

Taken in 1910, this photograph depicts a scene of Bridge road in Newtown, Beechworth. Walking on the road are two men on horseback, one of which is pulling a carriage with a small dog standing beside it. Behind them are a line of small buildings and shops. Small industries began to expand dramatically in Beechworth, particularly during the 1860s, leading to a strengthening of the towns economy. As early as 1853, areas surrounding the waterway known as Spring Creek were surveyed with the intent of mapping out plans for new roads and building allotments. Land was sold and new buildings were erected, creating an expansion of the Beechworth township and retail services. One building shown in this photograph is Straughair and Duncan's Beechworth Foundry. This business was established in 1858 through the partnership of Mark Straughair and John Duncan. It dealt mostly in the manufacturing of castings and mining machinery, receiving orders from all over the Ovens district. The Business eventually collapsed after the deaths of Straughair in 1882 and Duncan in 1896 but was reopened by W.H. Phillips in 1905. The two other buildings are both associated with the name McKenzie. Evidence suggests that the McKenzie family has a long association with the town of Beechworth. This photograph is historically significant as it provides insight into the nineteenth and twentieth century industrial expansions that happened in the area of Newtown, leading to the urbanisation of Beechworth. Black and white rectangular photograph printed on matte photographic paper mounted on card.Reverse: Newton / 1997.2648 / 33 Newton Beechworth / 84-219-1 / McKenzies / BMM3055 / newtown beechworth, bridge road, 1910, j. duncan, r. mckenzie, m. straughair, industrial growth, ford street, beechworth foundry, straughair and duncan, mckenzie and sons grainstore, mckenzie family store -

Warrnambool and District Historical Society Inc.

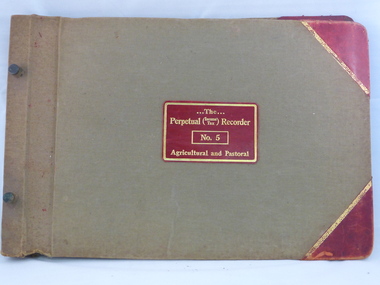

Warrnambool and District Historical Society Inc.Ledger, Ledger and Correspondence (Swinton), 1930s

.1 This is a ledger which was originally printed for the recording of agricultural and pastoral sales but has been used by the Warrnambool firm of Swintons Pty Ltd. to record sales of farm products and machinery from 1934 to 1945. .2 These are 13 items of correspondence, receipts, insurance documents, agreements etc. associated with the Warrnambool business firm of Swintons Pty Ltd. These were contained within the ledger referred to above. William and Ann Swinton migrated to Australia in 1854 and William Swinton worked as a builder and carpenter for a decade, erecting many buildings in the Warrnambool area, including the Wangoom Presbyterian Church. In 1865 he opened a shop in Timor Street, Warrnambool selling groceries, glassware and china. In 1888 the business was known as William Swinton and Sons. Branch stores were opened in Wangoom, Cudgee, Nullawarre, West Warrnambool and South Warrnambool. When William died his son Robert became the first managing director of Swintons Pty Ltd. In 1934 the business split in two with George Swinton and Sons selling furnishings, clothing and glassware and Swintons Pty Ltd selling produce, hardware and seeds. Today the Swinton family still operates a furniture and bedding store in Timor Street. This ledger and the accompanying paper material are of considerable importance as they are associated with the Swinton businesses in Warrnambool. The ledger contains lists of customers of the Swinton business in the 1930s and 40s and provides names, addresses and the cost of the product sold. This is very useful to researchers. The current Swinton business in Timor Street is the oldest family business in Warrnambool and, with the Swinton name associated with businesses in Timor Street for 152 years, is among the oldest family businesses in Australia..1 This is a hard cover ledger. It is beige-coloured with red leather edging on the corners and a red and gold label on the front cover. The pages are held in the folder with metal studs. The pages are white with red and blue printed lines and red leather tabs numbering 1 to 9. The entries are handwritten in blue and black ink. The ledger cover is slightly scuffed. .2 These are 13 items of correspondence from the 1930s and 40s. There is both handwritten and printed material. ‘The Perpetual Income Tax Recorder. No 5. Agricultural and Pastoral’. swinton family warrnambool, history of warrnambool -

Greensborough Historical Society

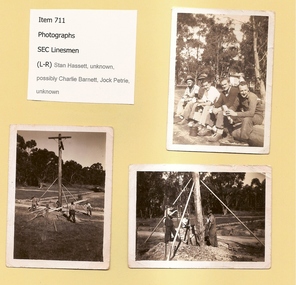

Greensborough Historical SocietyPhotographs, Linesmen 1950s, 1950c

Photograph 1 shows 5 men (linesmen) on lunch break. (L-R) Stan Hassett, unknown, possibly Charlie Barnett, Jock Petrie, unknown. Photos 2 and 3 show the crew erecting power poles.These photos are significant as they show some Greensborough men at work, and the method of erecting power poles before heavy machinery was used.3 black and white photographs. Subject is electrical linesmen and the erection of electricity poles.sec, linesmen, power poles, state electricity commission, stan hassett, charlie barnett, jock petrie -

Federation University Historical Collection

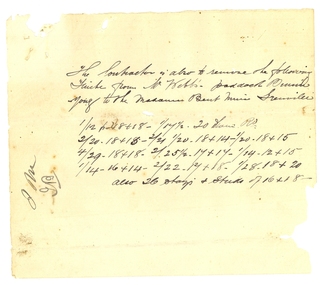

Federation University Historical CollectionDocument, Contract for the Madame Bent Gold Mining Company, 1886, 1886

Handwritten on foolscap paper, with red seal on last page.1) The Subcontractor is also to remove the following [ ? ] from Mr Webb's paddock ... to the Madame Bent Mine Grenville ... .2) Specification for the taking doan, removal and reerection 2 Engines 2 boilers pumping gear, Bob, Poppett heads and Capstone etc, for teh Mdame Bent G.M.Cy Grenville. The company will provide ... .3) Morey's Coys yard, together with holding down bolts, and the following ... .4) to the extent of Bed ... Carpentry Work - To carefully take down the poppet heads and co... and erect the same on the claim complete ... .5) Engine Framing as shown for the winding engines and pumping engines. Properly fitted to get ... .6) The boilers to be fed in front. The contractor to cut and drill all necessary holes in the boilers and pipes - to fire blow ... The contractor to make good any damage or breakage or loss to machinery or any part hereof that may occur to it during the removal of the reerection of same. The loss or damage, if any, not being made good by the contractor, or in the event of the works not being proceeded with to the satisfaction of the Company;s Engineer, The company's Engineer hereby ... .7) of the whole of the works, and in default thereof the COntractor shall forfeit the sum of two pounds ... Signed James Malcolm Witness L. Menz The Common seal of the company was affixed this thirteenth day of December:/86 by its manager James Burrell in the presence of [illegible] managers Seal - Madame Bent Gold Mining Company Durham Lead Buninyongmadame bent gold mining company, richard squire, james malcolm, james burrell -

National Wool Museum

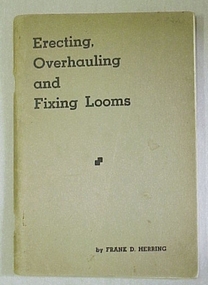

National Wool MuseumBook, Erecting, overhauling and fixing looms

"Erecting, overhauling and fixing looms"- Frank D Herring"Erecting, overhauling and fixing looms"- Frank D Herring.textile industry - history textile machinery weaving textile industry - education, weaving looms, weaving machinery, textile industry - history, textile machinery, weaving, textile industry - education -

Stawell Historical Society Inc

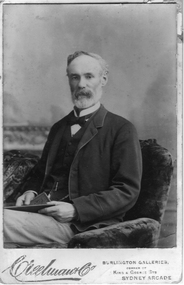

Stawell Historical Society IncPhotograph, Mr Edmund Craigie Grant

... . The firm Grant, Lamont & Coy were the first to erect Quartz.... The firm Grant, Lamont & Coy were the first to erect Quartz ...Edmund Craigie Grant died 1894 63 years. Married 1862. The firm Grant, Lamont & Coy were the first to erect Quartz Crushing machinery at Concongella Creek and later in Stawell at what became North Park. They built a house called "ALVIE" 39 Darlington Road (still standing 2005).Black & white photograph of Edmond Craigie Grant sitting in a chair holding a manuscript or magazine. Creelwaut Co (?) Burlington Galleries, corner of King & George Sts. Sydney Arcadestawell portrait -

Rutherglen Historical Society

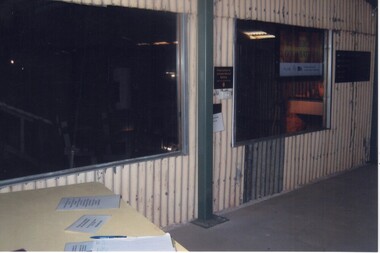

Rutherglen Historical SocietyImage, c1990

This photograph is of the viewing room inside the building, this side with windows overlooking the machinery and a video screen with a switchboard to run the video. One of a series of photographs of the Rutherglen Gold Battery. Its purpose was to crush quartz from nearby quartz reefs and extract gold from within. The battery was erected in 1908 and consists of a five-head battery, Wilfrey table, Bergin pan, portable steam engine and shed. The battery was restored in 2011/12 and can be viewed daily between 9.00am and 5.00pm. See website for details.Colour photograph of the interior of a building showing two large windows and a video screen on a corrugated iron wall.gold battery, gold processing -

Rutherglen Historical Society

Rutherglen Historical SocietyImage, c1990

This photograph is of Battery Box, showing the mouth where quartz is fed in. The five stamper rods can also be seen. This is one of a series of photographs of the Rutherglen Gold Battery. The battery's purpose was to crush quartz from nearby quartz reefs and extract gold from within. The battery was erected in 1908 and consists of a five-head battery, Wilfrey table, Bergin pan, portable steam engine and shed. The battery was restored in 2011/12 and can be viewed daily between 9.00am and 5.00pm. See website for details. Colour photograph of a large piece of machinery inside a buildinggold battery, gold processing -

Rutherglen Historical Society

Rutherglen Historical SocietyImage, c1990

This photograph is a view from the lower side of the stamper, showing amalgam table, box and stampers. This is one of a series of photographs of the Rutherglen Gold Battery. The battery's purpose was to crush quartz from nearby quartz reefs and extract gold from within. The battery was erected in 1908 and consists of a five-head battery, Wilfrey table, Bergin pan, portable steam engine and shed. The battery was restored in 2011/12 and can be viewed daily between 9.00am and 5.00pm. See website for details. Colour photograph of a large piece of machinery inside a buildinggold battery, gold processing -

Rutherglen Historical Society

Rutherglen Historical SocietyImage, c1990

This photograph is a view of the flywheel that drives the stampers. This is one of a series of photographs of the Rutherglen Gold Battery. The battery's purpose was to crush quartz from nearby quartz reefs and extract gold from within. The battery was erected in 1908 and consists of a five-head battery, Wilfrey table, Bergin pan, portable steam engine and shed. The battery was restored in 2011/12 and can be viewed daily between 9.00am and 5.00pm. See website for details. Colour photograph of a large piece of machinery inside a buildinggold battery, gold processing -

Rutherglen Historical Society

Rutherglen Historical SocietyImage, c1990

This photograph shows the workers' amenities at the Gold Battery. The building has a bedroom and kitchen. In front is a Baler Bucket and a cage. This particular cage was for raising and lowering the skips which brought the material to the surface. This is one of a series of photographs of the Rutherglen Gold Battery. The battery's purpose was to crush quartz from nearby quartz reefs and extract gold from within. The battery was erected in 1908 and consists of a five-head battery, Wilfrey table, Bergin pan, portable steam engine and shed. The battery was restored in 2011/12 and can be viewed daily between 9.00am and 5.00pm. See website for details.Colour photograph of a corrugated iron cottage, with several pieces of machinery around it.gold battery, gold processing -

Rutherglen Historical Society

Rutherglen Historical SocietyImage, c1990

This photograph is a general view of the machinery of the Gold Battery. The Bergin Pan is on the left, Stamper Box and in foreground concrete bed for Wilfrey table which has been removed. This is one of a series of photographs of the Rutherglen Gold Battery. The battery's purpose was to crush quartz from nearby quartz reefs and extract gold from within. The battery was erected in 1908 and consists of a five-head battery, Wilfrey table, Bergin pan, portable steam engine and shed. The battery was restored in 2011/12 and can be viewed daily between 9.00am and 5.00pm. See website for details.Colour photograph of a number of large pieces of machinery inside a buildinggold battery, gold processing -

Rutherglen Historical Society

Rutherglen Historical SocietyImage, c1990

This photograph is of machinery in the yard of the Gold Battery. The Baler Bucket is at the rear, the cage in the centre and the skip at the front. This is one of a series of photographs of the Rutherglen Gold Battery. The battery's purpose was to crush quartz from nearby quartz reefs and extract gold from within. The battery was erected in 1908 and consists of a five-head battery, Wilfrey table, Bergin pan, portable steam engine and shed. The battery was restored in 2011/12 and can be viewed daily between 9.00am and 5.00pm. See website for details.Colour photograph of a pieces of machinery in the yard of the Gold Batterygold battery, gold processing -

Rutherglen Historical Society

Rutherglen Historical SocietyImage, c1990

This photograph is of the side of the main building of the Gold Battery with workshop at rear (now demolished). Beside building is a hand windlass, along with some old pulleys and various parts. This is one of a series of photographs of the Rutherglen Gold Battery. The battery's purpose was to crush quartz from nearby quartz reefs and extract gold from within. The battery was erected in 1908 and consists of a five-head battery, Wilfrey table, Bergin pan, portable steam engine and shed. The battery was restored in 2011/12 and can be viewed daily between 9.00am and 5.00pm. See website for details.Colour photograph of the side of a corrugated iron building with a smaller building at the left, and a number of pieces of machinery next to the buildinggold battery, gold processing -

Rutherglen Historical Society

Rutherglen Historical SocietyImage, c1990

This photograph is of the back end of the side of the main building of the Gold Battery with workshop at rear (now demolished). Beside building is a hand windlass, along with some old pulleys and various parts. This is one of a series of photographs of the Rutherglen Gold Battery. The battery's purpose was to crush quartz from nearby quartz reefs and extract gold from within. The battery was erected in 1908 and consists of a five-head battery, Wilfrey table, Bergin pan, portable steam engine and shed. The battery was restored in 2011/12 and can be viewed daily between 9.00am and 5.00pm. See website for details.Colour photograph of the side of a corrugated iron building with a smaller building at the left, and a number of pieces of machinery next to the buildinggold battery, gold processing -

Ballarat Heritage Services

Ballarat Heritage ServicesPhotograph - Photograph - Colour, Steele's Pioneer Mine Ruins, Yandoit, 2016, 18/01/2016

Steele's Reef was opened in 1859 along with a number of other reefs in the Yandoit area. The reef was worked by small mining parties until the late 1880s. In 1887, the Steele's Reef Quartz Mining Company fixed steam pumping machinery and commenced sinking a shaft. The company were unable to find a profitable ore body and after two years work closed down. By this time their shaft had reached a depth of 150 feet. The mine was then taken over by the Pioneer Quartz Mining Company who appear not to have worked the mine. In 1906, the Steele's Pioneer Company commenced work, erecting a winding winch at the old shaft sunk by the Steele's Company. The next year the company erected a 10-head battery, set of poppet legs, a pumping engine. Sinking the shaft a further 100 feet, the company struggled to find payable ore and soon closed down.Colour photographs of the remnants of Steele's mine at Yandoit, Victoria. steele's mine, yandoit, mining, ruins -

City of Greater Bendigo - Civic Collection

City of Greater Bendigo - Civic CollectionCeremonial object - Engraved Silver Trowel, c 1899

Abraham Harkness was Mayor of the City of Bendigo when St Andrew's Presbyterian Church school hall was erected. The foundation stone was laid on Wednesday the 15th March 1899 to much ceremony including hymns and speeches. Abraham Harkness had arrived in Victoria in 1857 aged 28. He was initially successful in his search for gold and after a return trip to England in 1862 returned to Bendigo were he opened a general store and then a foundry whereby his company manufactured mining machinery. He stood for council from in 1880 and was elected a further eight times over the next twenty years. Cr Harkness served as Mayor in 1882, 1897 and 1898. His son Andrew became Mayor in 1908-09. Abraham Harkness married Jane Noble in Bendigo in1864 and together they had six sons and five daughters. Abraham died in 1912 and Jane in 1927.Sterling Silver ceremonial trowel with silver collar and bone handle. Front surface is ornately engraved with fern leaf pattern scrolled around central middle section which holds the engraved dedication. Back section is plain. Engraved: PRESENTED / TO / A. HARKNESS. ESQ. J.P. / MAYOR OF BENDIGO / ON THE OCCASION OF HIS LAYING / THE / FOUNDATIONAL STONE / of / St Andrew's School Hall / 15th March, 1899. Hallmark: P.A & S E P (Peter Atkin ?) + (windmill or pump) mayor harkness, mayoress harkness, city of greater bendigo education -

Tarnagulla History Archive

Tarnagulla History ArchivePhotograph - Photograph: Company's Dam and Flour Mill, Tarnagulla, c. 1880 - 1920

Williams Family Collection. On the 20th December 1873 it was reported in the Tarnagulla Courier that arrangements were being made for the erection of a steam flour mill at Tarnagulla. Mr Bristol had purchased the necessary plant which would be erected with as little delay as possible. The site chosen was the premises occupied previously by Mr John Pierce, grocer and wine and spirit merchant, at the corner of King and Commercial Road. These premises were incorporated in the mill building. Suitable buildings for receiving and storing grain and flour had been erected already. On 10th January, 1874 an advertisement in the Courier called for tenders from masons, bricklayers and carpenters for the erection of a flour mill at Tarnagulla for H. C. Bristol, Esq. with all enquiries to be made from G. Minto, Engineer. In December 1881 the proprietors made a request to the Tarnagulla Borough Council for permission to lay pipes to the Municipal Dam, which was generally known as the Company's Dam, and to obtain water from the dam for milling purposes. This was granted. Steam was got up for the first time on 30th of March, 1882. A large quantity of wheat was stored ready for milling. Just prior to 29th of April 1882 the boiler at the mill burst, as the result of which two men, J. H. Smith and W. Hargreaves died and H. Joyce Bousfield, senior and junior, were seriously injured. The mill commenced operations on 13th June, 1882 with Mr W Fitzgerald as manager. The price offered for wheat was thirty-seven pence per bushell. It operated with grinding stones until considerable renovations were done in the early part of 1899 when new rollers and more up to date equipment installed. The mill was then known as the Tarnagulla Flour Mill Co., with Thos. Comrie as proprietor, Mr Fitzgerald was still manager, and Mr T. Leonard was the traveller. Much new equipment was put in and each of the three floors had different processes. The rollers were on the ground floor, the purifiers and elevators reel were on the second floor, plus the clean wheat bin directly over the Ganz rollers. On the top floor was the chop reel, bran reel, inter-elevator reels, brush machine cyclone sack hoist, dirty wheat shaker, clean wheat bin, dust rooms and also double damping rooms. A plant was also erected for the making of an improved quality of wheaten meal, for which purpose special machinery was procured and a pair of stones was left for grinding the meal. A complete plant for the crushing of oats etc was also erected. The driving power of the mill was supplied by a new engine complete with 16 inch cylinder, manufactured and erected by Bousfield & Co. of Eaglehawk. It was fitted with Pickering governors, connected with the cylinder was a super heater. The boiler was tested and all connections etc. overhauled, with much of it being completely renewed. There was a complete network of belts, spouts, elevators etc. all over the building, all conveniently placed. The plans etc for the new plant were drawn up by Mr J. Kilborn, manager of the firm of Bodington & Co., engineers and millwrights of Carlton, which supplied the whole of the machinery, excepting the engine. The work of erection was carried out by Mr Kilborn and his assistants to the entire satisfaction of Mr Comrie, who had gone to considerable expense to bring the mill to a completely up-todate machine, fitted with all of the most modern appliances available. An advertisement on May 6th, 1899 read: "Tarnagulla Flour Mill Co., Patent Roller Flour. Also their Digestive Wheaten Meal specially prepared for Porridge or Bread." In January 1901, 6000 bags of wheat were received weekly at the mill and it was a common sight to see the streets lined with wagons. In May 1902 the mill was lighted by gas and in July 1906 an application was made to the Tarnagulla Borough Council for permission to lay a tram track from the mill to the Railways Station. Council was agreeable to this provided suitable plans were submitted. In 1913, 15,000 bags of wheat were bought at three shillings and four pence per bushell. In January 1914 the mill was renovated. At this time 1500 bags of wheat were coming in daily, with 20,000 bags in storage. On 15th December, 1917 the mill was advertised for sale, to be sold on Friday, 21st December,.1917, on behalf of the Estate of the Late Thomas Comrie, who had died on 4th August, 1910. The Courier at that time recorded him as being responsible for the building of the mill and with being the sole proprietor. The mill was closed, apparently, for a short period. The Courier reported on 13th of September, 1918 that the mill had been sold to Mr O. Albert of Talbot and that it would re-open. An advertisement read: ALBERT. O. & SON, MILLERS. During 1920 the mill was closed and pulled down. It was later re-erected at Mildura where it operated for many years. (by Donald Clark)Monochrome photograph depicting view of Company's Dam and the flour mill in Tarnagulla. Handwritten on reverse: 'J. Caldwell and photographer's stamp 'C. Bock Photo Tarnagulla'.tarnagulla -

Tarnagulla History Archive

Tarnagulla History ArchivePostcard - Photographic postcard: Company's Dam and Flour Mill, Tarnagulla, c. 1880 - 1920

Williams Family Collection. On the 20th December 1873 it was reported in the Tarnagulla Courier that arrangements were being made for the erection of a steam flour mill at Tarnagulla. Mr Bristol had purchased the necessary plant which would be erected with as little delay as possible. The site chosen was the premises occupied previously by Mr John Pierce, grocer and wine and spirit merchant, at the corner of King and Commercial Road. These premises were incorporated in the mill building. Suitable buildings for receiving and storing grain and flour had been erected already. On 10th January, 1874 an advertisement in the Courier called for tenders from masons, bricklayers and carpenters for the erection of a flour mill at Tarnagulla for H. C. Bristol, Esq. with all enquiries to be made from G. Minto, Engineer. In December 1881 the proprietors made a request to the Tarnagulla Borough Council for permission to lay pipes to the Municipal Dam, which was generally known as the Company's Dam, and to obtain water from the dam for milling purposes. This was granted. Steam was got up for the first time on 30th of March, 1882. A large quantity of wheat was stored ready for milling. Just prior to 29th of April 1882 the boiler at the mill burst, as the result of which two men, J. H. Smith and W. Hargreaves died and H. Joyce Bousfield, senior and junior, were seriously injured. The mill commenced operations on 13th June, 1882 with Mr W Fitzgerald as manager. The price offered for wheat was thirty-seven pence per bushell. It operated with grinding stones until considerable renovations were done in the early part of 1899 when new rollers and more up to date equipment installed. The mill was then known as the Tarnagulla Flour Mill Co., with Thos. Comrie as proprietor, Mr Fitzgerald was still manager, and Mr T. Leonard was the traveller. Much new equipment was put in and each of the three floors had different processes. The rollers were on the ground floor, the purifiers and elevators reel were on the second floor, plus the clean wheat bin directly over the Ganz rollers. On the top floor was the chop reel, bran reel, inter-elevator reels, brush machine cyclone sack hoist, dirty wheat shaker, clean wheat bin, dust rooms and also double damping rooms. A plant was also erected for the making of an improved quality of wheaten meal, for which purpose special machinery was procured and a pair of stones was left for grinding the meal. A complete plant for the crushing of oats etc was also erected. The driving power of the mill was supplied by a new engine complete with 16 inch cylinder, manufactured and erected by Bousfield & Co. of Eaglehawk. It was fitted with Pickering governors, connected with the cylinder was a super heater. The boiler was tested and all connections etc. overhauled, with much of it being completely renewed. There was a complete network of belts, spouts, elevators etc. all over the building, all conveniently placed. The plans etc for the new plant were drawn up by Mr J. Kilborn, manager of the firm of Bodington & Co., engineers and millwrights of Carlton, which supplied the whole of the machinery, excepting the engine. The work of erection was carried out by Mr Kilborn and his assistants to the entire satisfaction of Mr Comrie, who had gone to considerable expense to bring the mill to a completely up-todate machine, fitted with all of the most modern appliances available. An advertisement on May 6th, 1899 read: "Tarnagulla Flour Mill Co., Patent Roller Flour. Also their Digestive Wheaten Meal specially prepared for Porridge or Bread." In January 1901, 6000 bags of wheat were received weekly at the mill and it was a common sight to see the streets lined with wagons. In May 1902 the mill was lighted by gas and in July 1906 an application was made to the Tarnagulla Borough Council for permission to lay a tram track from the mill to the Railways Station. Council was agreeable to this provided suitable plans were submitted. In 1913, 15,000 bags of wheat were bought at three shillings and four pence per bushell. In January 1914 the mill was renovated. At this time 1500 bags of wheat were coming in daily, with 20,000 bags in storage. On 15th December, 1917 the mill was advertised for sale, to be sold on Friday, 21st December,.1917, on behalf of the Estate of the Late Thomas Comrie, who had died on 4th August, 1910. The Courier at that time recorded him as being responsible for the building of the mill and with being the sole proprietor. The mill was closed, apparently, for a short period. The Courier reported on 13th of September, 1918 that the mill had been sold to Mr O. Albert of Talbot and that it would re-open. An advertisement read: ALBERT. O. & SON, MILLERS. During 1920 the mill was closed and pulled down. It was later re-erected at Mildura where it operated for many years. (by Donald Clark)Photographic postcard, front image depicting view of Company's Dam and the flour mill in Tarnagulla. Handwritten on reverse: 'A Merry Christmas and a Happy New Year, E. Bool' and photographer's stamp 'C. Bock Photo Tarnagulla'.tarnagulla -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - NEW CHUM & VICTORIA TRIBUTE COY - EXTRACT OF MEETING

New Chum and Victoria Tribute Coy. Formation of Coy. Extract from Bendigo Advertiser Saturday July 22, 1871. Meeting held at Sterry's Gold Mines Hotel. Mr. Sterry in Chair. 18 shareholders representing 504 shares present. Extracts from Director's Report. After striking water which appeared to be of a permanent nature, it was decided to purchase a plant. Machinery consisting of a 14-inch dia. Cylinder with double winding drums, winding engine, plus boiler etc. from Buningong. Same erected for 750 pounds. Everything going well. It was decided, the best place to erect it was on Burrows and Sterry's ground. Permission was granted.document, gold, new chum & victoria tribute coy, extract of meeting new chum & victoria tribute coy, bendigo advertiser, mr sterry, gold mines hotel, mr burrows -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Codd neck bottle, E. Rowlands, 1921

The design of the bottle is called a Codd, sometimes referred to as a marble bottle or "Codd's patent bottle". During the mid-to-late 1800s, there were many inventions to keep the fizz in carbonated drinks such as ginger ale, soda water, and fruit drinks. Hiram Codd, an English engineer invented a successful process that he patented as "Codd's patented globe stopper bottle" in 1872. The Codd-neck bottle (commonly called Codd or marble bottle) is manufactured in two parts. The body of the bottle is cast in two sections. At the time of joining the sections, glass marble and rubber seal are inserted into the neck section. The lip is then applied to the top of the bottle. The Codd bottle is filled upside down as the pressure of the gas from the carbonated liquid holds the marble up and out of the way. When the bottle stands upright the gas pushes the marble up against the washer, creating a firm seal to keep the fizz inside. The bottle is opened by pushing the marble down firmly to allow some of the gas to escape. The marble drops down and is caught in a depression formed in the neck. When the bottle is tilted to pour or drink the liquid the marble rests in a dimple. Two Ballarat miners, Evan Rowland and Robert Lewis started manufacturing mineral and aerated waters, bitters, cordials, and liqueurs in 1854, in a tent on the shores of Lake Wendouree Ballarat. Another 13 firms at that time employed manual operations, whereas they introduced Taylor's No. 1 machine that speeded up the process and laid the foundation for their fortune. Evan Rowland was a pioneer in the aerated water trade in Australia. He was born on August 2, 1826, in North Wales. In 1852, during the gold rush, he emigrated to Melbourne, and in 1854 he went to Ballarat and formed a partnership with Robert Lewis, the firm being called ‘‘Rowlands & Lewis’’. Their next step was to secure a supply of pure water. Using mineral Waters that they found via a natural spring at Warrenheip, Victoria. From the outset, the beverages made from this water gained repute and were in great demand. Their business prospered so well that in 1858 they were able to build a factory at the corner of Sturt and Dawson Streets, Ballarat, and to fit with the most up-to-date machinery then in use. By 1870 their business had increased so much and demand had grown to such an extent that Mr. Rowlands erected another factory, covering over an acre of ground at the corner of Dana and Doveton Streets, costing £13,000. The factory was fitted with the most modern equipment of the time to manufacture cordials and aerated water. In 1873 Rowlands established an agency at 116 Collins St, Melbourne, because the demand for the products of the Melbourne factory became so large. The company expanded to Sydney opening a factory at the corner of Burns & Hay Streets Darling Harbour obtaining spring water to supply this plant from Katoomba in the Blue Mountains. The water was brought to Sydney by rail. In the meantime, the Melbourne concern had progressed so rapidly that in 1888 a magnificent factory embodying all the latest ideas and equipment was built in King Street Melbourne. Robert Lewis was a fellow Welshman born in 1816, and he arrived in Port Phillip in 1853 and became a partner in the early day with Evan Rowland but with lesser and shorter involvement in the firm, from which he retired in 1876. Robert Lewis was perhaps better known as Ballarat's first mayor and a Member of the Legislative Assembly. He was a strong supporter of local charities, president/treasurer of the Eisteddfod Committee, a major force in the development of the Ballarat Hospital, and he was the mayor of Ballarat five times, the first in 1863, (having been a counsellor as early as 1859) and for the last time in 1881. Lewis died in 1884 of a stroke in Ballarat. Rowlands continued in the firm and invented and patented an improved soda water bottle. The water used in Rowlands products was filtered four times but his attempts to use local corks failed on quality grounds. He was a stickler for quality, which was so good that many outside Victoria were prepared to pay the 'premium' imposed by inter-colonial customs duty payable at that time. By the 1890s, Rowlands had factories in Ballarat, Melbourne, Sydney, and Newcastle. He died in 1894 but his company continued until well after the Second World War when it was sold to Schweppes. Bottles such as this popular brand, containing soda water, were often used on paddle steamers for refreshments.An early manufacturing process producing the first mineral waters in Australia was invented and developed by an early Welsh migrant to Australia. The Evan Rowlands story gives an insight into the early development of manufacturing industries in Australia that allowed their workers and the towns they were situated in to prosper and develop into what they are today. A good example of hand blown glass.Bottle; clear glass Codd neck bottle with small marble in top. Once contained soda water or soft drink. Manufactured in 1921 by E. Rowlands of Ballarat, Melbourne, Katoomba and Sydney. The bottle is 'recyclable' - the message on the base says that it remains the property of E. Rowlands Pty Ltd. Inscriptions on three adhesive labels at time of donation"E. ROWLANDS BALLARAT MELBOURNE KATOOMBA AND SYDNEY". Imprinted into bas "1921" "THIS BOTTLE REMAINS THE PROPERTY OF E. ROWLANDS PTY LTD" On adhesive labels (3) " 1921 ON BASE (LASTED 1924) CODD PATENT 702" "SMALL SIZE. MARBLE TOP SODA WATER PAPER LABEL. USED" "ON PADDLE STEAMERS. POPULAR BRAND"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, bottle, codd bottle, hiram codd, glass marble bottle, e. rowlands bottle manufacturer, soda bottle australia, early recyclable bottle, codd's patent bottle, marble bottle, refreshments, soda water, marble top, 1920s, codd patent 702, handmade, blown -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - Napoleon Gold Mine Winder, 1935

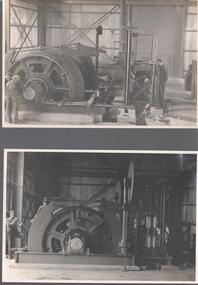

Significant to mining history of Bendigo.Black and white photographs: winder. Winder inside corrugated iron shed. Two winder wheels, metal framework on right hand side. (a) Winding wheels erected 1/7/35, three men inspecting various aspects of the machinery. (b) Winder in shed, side view with two men putting on winder ropes. Written in pencil on back of photographs : (a) 'Napoleon winder 1/7/35. (b) Napoleon winder putting on ropes 30.8.35. napoleon gold mine, winder, bedplate