Showing 30 items matching "manual labour"

-

City of Kingston

City of KingstonPhotograph - Black and white, Red Cross Workers Bentleigh, 1915

... Manual labour... suggesting manual labour with crutches leaning against the shed.... Community World War I First World War WWI Manual labour Repurposing ...Red Cross Workers in Bentleigh are preparing stretchers and other convalescent aids for fighting men overseas. In the background wooden crutches are leaning against the shed wall and beach chairs are being repurposed in the front of the image.Black and white image of a group of eight men standing in front of a shed with several of the men wearing work aprons suggesting manual labour with crutches leaning against the shed and beach chairsHand written in red ink enclosed in a circle: A18 / 70%community, world war i, first world war, wwi, manual labour, repurposing, red cross, crutches, bentleigh -

City of Kingston

City of KingstonPhotograph - Black and white, c. 1920

... Manual labour...Horses were frequently used to assist in the manual labour... Parkdale Horses were frequently used to assist in the manual labour ...Horses were frequently used to assist in the manual labour of farming right up to the mid twentieth century. This image was taken while ploughing market garden fields in Moorabbin.Black and white image of two Clydesdale horses attached to harness and pulling a plough. Two men are behind the horses, one is holding the handles of the plough and the other is standing next to him with his hands on his hips.Handwritten in red ink on reverse: 70% Printed in black text on white round sticker adhered to reverse: 41horses, manual labour, farming, moorabbin -

City of Kingston

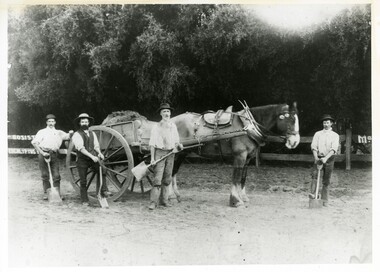

City of KingstonPhotograph - Black and white, c 1900

... Manual labour... Parkdale Sport Horse Manual labour Handwritten in red ink ...Black and white photograph of workers with a horse and card preparing the Sandringham Oval, possibly for football. Person 2 and 3 (from L to R) identified as William John Selby and [no first name] McInerneyHandwritten in red ink on reverse: 55% Black printed text on white round sticker adhered to reverse: 48sport, horse, manual labour -

Bendigo Historical Society Inc.

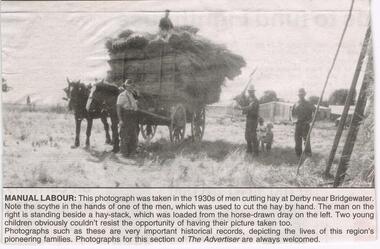

Bendigo Historical Society Inc.Newspaper - JENNY FOLEY COLLECTION: MANUAL LABOR

... , 2004. Manual labour: this photograph was taken in the 1930s... "The way we were" from Monday, May 17, 2004. Manual labour ...Bendigo Advertiser "The way we were" from Monday, May 17, 2004. Manual labour: this photograph was taken in the 1930s of men cutting hay at Derby near Bridgewater. Note the scythe in the hands of one of the men, which was used to cut the hay by hand.newspaper, bendigo advertiser, the way we were -

National Wool Museum

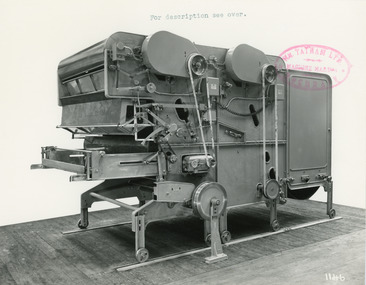

National Wool MuseumPhotograph - Product Photograph, Automatic Feeding Machine

... . This eliminated the manual labour previously needed for the initial... supply is received. This eliminated the manual labour previously ...These are sales photographs for William Tatham Ltd. of Rochdale. These photographs are taken in the fitting shop at William Tatham Ltd. where final assembly would have taken place. The Automatic Feeding Machine automatically dispenses wool to a carding machine, so that an even, constant supply is received. This eliminated the manual labour previously needed for the initial weighing and feeding of wool. The photographed machine was made by William Tatham Ltd, a textile engineering company based in Rochdale, UK. Established in 1866, Tatham developed innovative textile machinery and sent their products to Australia and other countries around the world.Two black and white photos of an Automatic Feeding Machine in a landscape format. The first photo is of the front of the machine, the second is of the rear.8037.1 - Front - top margin: For description see over. Front mide right edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1146 Rear - 78” wide Automatic Feeding Machine having Dual Hoppers in which the first and large section feeds the second Hopper so as to maintain a constant level of material in the latter. The driving of both spiked lattices is by electro-magnetic clutches, the one in the first Hopper being actuated by a sensitive feeler motion in the second, the second spiked lattice however, being controlled, of course, from the Scale Pan. Through a mercury switch. The scale is of our latest super-sensitive pattern mounted diagonally across the Feed. Only the opening doors are used in the actual weighting and the trap doors placed over the scale which close immediately the correct weight is deposited, operate through a solenoid. The machine incorporates many other features and is arranged to divide for facility in cleaning. 8037.2 - Front mide right edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1147 Rear - Showing opposite side of Dual Automatic Feed illustrated in photo 1146textile machinery, automatic feeding machine, tatham, feeding machine -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - Hand operated seed broadcaster

... requires a lot of time and manual labour if used in larger areas... of time and manual labour if used in larger areas. It was most ...Seed broadcaster were used to distribute seed across a small area or to fill in patches where seeding has been missed. This method does not ensure a uniform distribution of seeds unless the person using the machine walks at a very measured pace. It also requires a lot of time and manual labour if used in larger areas. It was most used for planting cover crops, grains, grasses and similar plants that do not need to be in neat rows. The hand-crank broadcast seed spreader was invented in 1868 by Samuel S. Speicher (aka. Spyker) in Indiana, USA. By 1955 new developments included the invention of a seed broadcaster on wheels and these smaller spreaders started to disappear.This item is representative of agricultural machinery used on a local, national and international level in the late 19th and early 20th century.A metal hand seed broadcaster. A hopper at the top was the receptacle for seed. The wheel with a handle on the side when turned drives the cogs attached to an axle. This action rotates the attached spindle with blades to propel seed out the front of the broadcaster. The broadcaster would have had a shoulder strap and a bag of seed would have been added to the hopper and secured with twine through the holes around the top.agricultural tools, farm machinery -

Forests Commission Retired Personnel Association (FCRPA)

Forests Commission Retired Personnel Association (FCRPA)Rakut - Fire rake, Unknown FCV District, c 1952

... , developed over centuries of manual labour, and readily available... and logging tools, developed over centuries of manual labour ...Bushfire perimeter rather than bushfire area is the main control problem for firefighters on the ground. A conundrum rapidly compounded by spot fires. A small 5 ha fire can be nearly 1 km around the perimeter. That's a long way to build a control line by hand in rough bush. Dry firefighting techniques by hand were mostly confined to “knocking down” or “beating out” the flames, as well as "digging out". Digging or raking a “mineral earth” trail down to bare dirt proved most effective in forest fuels which, unlike grass, tend to retain heat and smoulder. Early tools were whatever happened to be close at hand. They were simple and primitive and included shovels, slashers, axes, hoes, beaters and rakes. A cut branch to beat the flames was often the only thing available. Farming and logging tools, developed over centuries of manual labour, and readily available at local hardware stores came into use, but little thought was given to size, weight, and balance. For years foresters experimented with combination tools. In about 1952 fire beaters and other implements were being replaced with Rakuts.Fire tool used before the introduction of RakehoesRakut - Fire Rake and cutting toolGreen and red coloured handle and 020 marking indicated which FCV District the tool belonged tobushfire -

Forests Commission Retired Personnel Association (FCRPA)

Forests Commission Retired Personnel Association (FCRPA)Fire Beater - Leather, c 1940s

... , developed over centuries of manual labour, and readily available..., developed over centuries of manual labour, and readily available ...Bushfire perimeter rather than bushfire area is the main control problem for firefighters on the ground. A conundrum rapidly compounded by spot fires. A small 5 ha fire can be nearly 1 km around the perimeter. That's a long way to build a control line by hand in rough bush. Dry firefighting techniques by hand were mostly confined to “knocking down” or “beating out” the flames, as well as "digging out". Digging or raking a “mineral earth” trail down to bare dirt proved most effective in forest fuels which, unlike grass, tend to retain heat and smoulder. Early tools were whatever happened to be close at hand. They were simple and primitive and included shovels, slashers, axes, hoes, beaters and rakes. A cut branch to beat the flames was often the only thing available. Farming and logging tools, developed over centuries of manual labour, and readily available at local hardware stores came into use, but little thought was given to size, weight, and balance. This leather beater was based on a century-old stockman's design which used green cow hide leather lashed to a broom handle. It's recommend that users lift no more than above knee height to conserve energy and let the beater to the work. For years foresters experimented with combination tools. In about 1952 fire beaters and other implements were being replaced with Rakuts and later RakehoesEarly firefighting toolBushfire beater - Leather with wooden handlebushfire, forests commission victoria (fcv) -

Melbourne Legacy

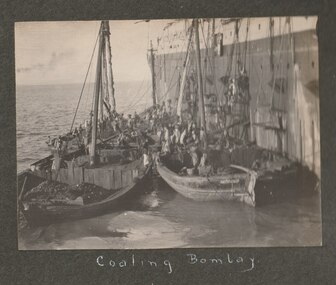

Melbourne LegacyPhotograph, Bombay, 1920

... and the type of manual labour it required with the men lifting it up... and the type of manual labour it required with the men lifting it up ...Three photos from an album belonging to JB McLean, of his voyage home from World War 1 in 1920 on the Ceramic. The photos are of small boats providing coal to the Ceramic in Bombay, India and the type of manual labour it required with the men lifting it up the side of the ship. The visit to Bombay was a stop over point for the Ceramic on its way to Australia. The Ceramic departed Tillbury, UK 12th March and docked in Freemantle on 27th April 1920 and then went onto Adelaide, Melbourne and Sydney. The Ceramic was a transport vessel built in Belfast in 1913 for the White Star Line to transport frozen produce and apples from Australia to UK. It was taken over by the Australian Government for troop transport in October 1914 and could carry over 3,000 troops. This trip in 1920 there were 1467 on board, there were women and children as well as 439 soldiers returning home, one of whom was John 'Basil' McLean. Was with other World War 1 memorabilia that has come from Private John Basil McLean, 2nd Reinforcements, 37th Battalion, A.I.F. There was a large collection of postcards so he may have been collecting them as souvenirs. J.B. McLean (Service No. 13824) was from near Maffra, Victoria and enlisted on 22 January 1916. He embarked on 16 December 1916 for Europe. His full war record is available from AWM. He spent time with the Australian Field Artillery (Pack Section). At the end of the war he worked for a year at the A.I.F. Headquarters in London before returning to Australia on the 'Ceramic', arriving Portsea in 1920.A collection of items from John Basil McLean is in the archive. Kept as an indication of what founding legatees experienced in World War One and what they saw on the way home.Sepia photo x 2 of Indians providing coal to the Ceramic in Bombay glued to black cardboard in an album of photos from 1920.Handwritten caption 'Coaling Bombay' in white ink.souvenir, world war one, jb mclean, ceramic, bombay -

Mission to Seafarers Victoria

Mission to Seafarers VictoriaPoster, Art, Labour and Working Life, 2018

... the layers of manual, emotional and intellectual labour involved... the layers of manual, emotional and intellectual labour involved ...A poster printed by the RMIT in 2018, to promote an exhibition of works at the MTSV about the interelationships between labour, working life and artistic practice. BACKGROUND The Work of Art was an exhibition about labour, working life and artistic practice. The exhibition explored three aspects of art's relationship to work: (1) artworks about contemporary labour, (2) the labour of art-making itself and (3) the often precarious aspects of life as a working artist. Throughout the exhibition, different artists "worked" from the space of the gallery, revealing the layers of manual, emotional and intellectual labour involved in the work of art. CONTRIBUTION I was invited to develop the exhibition by the "Murphy Group", a group of researchers at RMIT. As the lead co-curator for the exhibition, I researched the history of artistic responses to working conditions. Through this process I identified a gap - while many artists have explored the conditions of labour and working life in their artworks, fewer have drawn attention to the working conditions of artists themselves. This became a key theme in the exhibition. The exhibition presented the work of nine contemporary Australian artists, including high profile and mid-career artists like Bindi Cole and Bek Conroy, alongside the work of emerging artists. In addition to the display of artworks throughout the space, five artists worked performatively, bringing to life the processes and manual labour involved in artmaking. A public forum extended the complex discussion on the relationship between art, work and labour. SIGNIFICANCE The works were presented in the context of a public space that has a strong relationship to contemporary labour - the Mission to Seafarers in Docklands. The Mission to Seafarers is a working mission that provides support to ship-workers. Presenting the works in this space created a real connection between the artworks and the lived experience of precarious labour. The exhibition reached a large audience including over 1000+ visitors in 10 days. It fostered a high engagement on social media and attracted media coverage including a feature in ArtsHub.A record of the ongoing involvement of the MTSV in art, and working with the art community by providing a suitable venue and display space.A3 size yellow paper promotional poster, double-sided. Three-quarters of the front of the poster is covered with the repeated line "Art, Labour & Working Life" in large font, to form ten rows. These rows are in outline form except for picked out words which are in entirely black characters and these cascade down, a row at a time, a word at a time, to form the same line ("Art, Labour & Working Life"). rmit, 2018, events, labour, working life, artistic practice, hiring event, cultural events, multimedia, nicholas walton-healey -

Forests Commission Retired Personnel Association (FCRPA)

Forests Commission Retired Personnel Association (FCRPA)Fire Beater - Canvas, c 1930s

... , developed over centuries of manual labour, and readily available..., developed over centuries of manual labour, and readily available ...Bushfire perimeter rather than bushfire area is the main control problem for firefighters on the ground. A conundrum rapidly compounded by spot fires. A small 5 ha fire can be nearly 1 km around the perimeter. That's a long way to build a control line by hand in rough bush. Dry firefighting techniques by hand were mostly confined to “knocking down” or “beating out” the flames, as well as "digging out". Digging or raking a “mineral earth” trail down to bare dirt proved most effective in forest fuels which, unlike grass, tend to retain heat and smoulder. Early tools were whatever happened to be close at hand. They were simple and primitive and included shovels, slashers, axes, hoes, beaters and rakes. A cut branch to beat the flames was often the only thing available. Farming and logging tools, developed over centuries of manual labour, and readily available at local hardware stores came into use, but little thought was given to size, weight, and balance. This canvas hose beater was based on a century-old design which used lengths of canvas fire hose rivetted together and lashed with wire to a broom handle. The hose was be soaked in water to improve its effectiveness. If the flames were more than a metre or so the user was generally not able to get close enough to extinguish the fire It's recommend that users lift no more than above knee height to conserve energy and let the beater to the work. For years foresters experimented with combination tools. In about 1952 fire beaters and other implements were being replaced with Rakuts and later RakehoesEarly firefighting toolBushfire beater - Canvas with wooden handleR P PWD (Public Works Department) The handle has painted markings which indicate which FCV District it belonged to.bushfire, forests commission victoria (fcv) -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionRakehoe (McLeod Tool)

... , developed over centuries of manual labour, and readily available..., developed over centuries of manual labour, and readily available ...Bushfire perimeter rather than bushfire area is the main control problem for firefighters on the ground. A conundrum rapidly compounded by spot fires. A small 5 ha fire can be nearly 1 km around the perimeter. That's a long way to build a control line by hand in rough bush. Dry firefighting techniques by hand were mostly confined to “knocking down” or “beating out” the flames, as well as "digging out". Digging or raking a “mineral earth” trail down to bare dirt proved most effective in forest fuels which, unlike grass, tend to retain heat and smoulder. Early tools were whatever happened to be close at hand. They were simple and primitive and included shovels, slashers, axes, hoes, beaters and rakes. A cut branch to beat the flames was often the only thing available. Farming and logging tools, developed over centuries of manual labour, and readily available at local hardware stores came into use, but little thought was given to size, weight, and balance. For years foresters experimented with combination tools. In about 1952 fire beaters and other implements were being replaced with Rakuts. However, its believed the now common Rakehoe is an Australian variation of the American McLeod Tool which was developed in 1905 by forest ranger Malcolm McLeod of the Sierra National Forest. The late Athol Hodgson advised that predecessors, Reg Torbet who had been the Chief Fire Officer for the Forests Commission from 1948-1956, along with his QLD counterpart Clive Price, went in late 1951 as Australian delegates on a 10 week fire study tour of Nth America organised by the United Nations. They came back with a couple of McLeod tools from Canada. Cam MacLeod (different spelling) had been the Head of Fire Research for the Canadian Forest Service at the time and had supplied them. The tools were ideal for deciduous forests in the eastern provinces and Clive arranged to have them manufactured in QLD. The Rakho, as it was then spelled, was first issued to FCV crews 65 years ago in 1955-56. The American Pulaski had been trialled, but never found favour with Australian firefighters.Rakhoeforests commission victoria (fcv), hand tools, forest harvesting, bushfire -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionFire beater (canvas)

... , developed over centuries of manual labour, and readily available..., developed over centuries of manual labour, and readily available ...Bushfire perimeter rather than bushfire area is the main control problem for firefighters on the ground. A conundrum rapidly compounded by spot fires. A small 5 ha fire can be nearly 1 km around the perimeter. That's a long way to build a control line by hand in rough bush. Dry firefighting techniques by hand were mostly confined to “knocking down” or “beating out” the flames, as well as "digging out". Digging or raking a “mineral earth” trail down to bare dirt proved most effective in forest fuels which, unlike grass, tend to retain heat and smoulder. Early tools were whatever happened to be close at hand. They were simple and primitive and included shovels, slashers, axes, hoes, beaters and rakes. A cut branch to beat the flames was often the only thing available. Farming and logging tools, developed over centuries of manual labour, and readily available at local hardware stores came into use, but little thought was given to size, weight, and balance. For years foresters experimented with combination tools. In about 1952 fire beaters and other implements were being replaced with Rakuts. However, its believed the now common Rakehoe is an Australian variation of the American McLeod Tool which was developed in 1905 by forest ranger Malcolm McLeod of the Sierra National Forest. The late Athol Hodgson advised that predecessors, Reg Torbet who had been the Chief Fire Officer for the Forests Commission from 1948-1956, along with his QLD counterpart Clive Price, went in late 1951 as Australian delegates on a 10 week fire study tour of Nth America organised by the United Nations. They came back with a couple of McLeod tools from Canada. Cam MacLeod (different spelling) had been the Head of Fire Research for the Canadian Forest Service at the time and had supplied them. The tools were ideal for deciduous forests in the eastern provinces and Clive arranged to have them manufactured in QLD. The Rakho, as it was then spelled, was first issued to FCV crews 65 years ago in 1955-56. The American Pulaski had been trialled, but never found favour with Australian firefighters.Fire Beater (canvas) 1930s designforests commission victoria (fcv), hand tools, forest harvesting, bushfire -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionPulaski

... , developed over centuries of manual labour, and readily available..., developed over centuries of manual labour, and readily available ...Bushfire perimeter rather than bushfire area is the main control problem for firefighters on the ground. A conundrum rapidly compounded by spot fires. A small 5 ha fire can be nearly 1 km around the perimeter. That's a long way to build a control line by hand in rough bush. Dry firefighting techniques by hand were mostly confined to “knocking down” or “beating out” the flames, as well as "digging out". Digging or raking a “mineral earth” trail down to bare dirt proved most effective in forest fuels which, unlike grass, tend to retain heat and smoulder. Early tools were whatever happened to be close at hand. They were simple and primitive and included shovels, slashers, axes, hoes, beaters and rakes. A cut branch to beat the flames was often the only thing available. Farming and logging tools, developed over centuries of manual labour, and readily available at local hardware stores came into use, but little thought was given to size, weight, and balance. For years foresters experimented with combination tools. In about 1952 fire beaters and other implements were being replaced with Rakuts. However, its believed the now common Rakehoe is an Australian variation of the American McLeod Tool which was developed in 1905 by forest ranger Malcolm McLeod of the Sierra National Forest. The late Athol Hodgson advised that predecessors, Reg Torbet who had been the Chief Fire Officer for the Forests Commission from 1948-1956, along with his QLD counterpart Clive Price, went in late 1951 as Australian delegates on a 10 week fire study tour of Nth America organised by the United Nations. They came back with a couple of McLeod tools from Canada. Cam MacLeod (different spelling) had been the Head of Fire Research for the Canadian Forest Service at the time and had supplied them. The tools were ideal for deciduous forests in the eastern provinces and Clive arranged to have them manufactured in QLD. The Rakho, as it was then spelled, was first issued to FCV crews 65 years ago in 1955-56. The American Pulaski had been trialled, but never found favour with Australian firefighters.Pulaski Fire Tool Combines an axe and a grubbing hoe. Digging end and cutting end with short wooden handleforests commission victoria (fcv), hand tools, forest harvesting, bushfire -

Forests Commission Retired Personnel Association (FCRPA)

Forests Commission Retired Personnel Association (FCRPA)Rakehoe, McLeod Tool (American)

... , developed over centuries of manual labour, and readily available..., developed over centuries of manual labour, and readily available ...Bushfire perimeter rather than bushfire area is the main control problem for firefighters on the ground. A conundrum rapidly compounded by spot fires. A small 5 ha fire can be nearly 1 km around the perimeter. That's a long way to build a control line by hand in rough bush. Dry firefighting techniques by hand were mostly confined to “knocking down” or “beating out” the flames, as well as "digging out". Digging or raking a “mineral earth” trail down to bare dirt proved most effective in forest fuels which, unlike grass, tend to retain heat and smoulder. Early tools were whatever happened to be close at hand. They were simple and primitive and included shovels, slashers, axes, hoes, beaters and rakes. A cut branch to beat the flames was often the only thing available. Farming and logging tools, developed over centuries of manual labour, and readily available at local hardware stores came into use, but little thought was given to size, weight, and balance. For years foresters experimented with combination tools. In about 1952 fire beaters and other implements were being replaced with Rakuts. However, its believed the now common Rakehoe is an Australian variation of the American McLeod Tool which was developed in 1905 by forest ranger Malcolm McLeod of the Sierra National Forest. The late Athol Hodgson advised that predecessors, Reg Torbet who had been the Chief Fire Officer for the Forests Commission from 1948-1956, along with his QLD counterpart Clive Price, went in late 1951 as Australian delegates on a 10 week fire study tour of Nth America organised by the United Nations. They came back with a couple of McLeod tools from Canada. Cam MacLeod (different spelling) had been the Head of Fire Research for the Canadian Forest Service at the time and had supplied them. The tools were ideal for deciduous forests in the eastern provinces and Clive arranged to have them manufactured in QLD. The Rakho, as it was then spelled, was first issued to FCV crews 65 years ago in 1955-56. The American Pulaski had been trialled, but never found favour with Australian firefighters.First used in 1955Rakehoe Combination of a heavy-duty six-toothed (each 9cm long) rake with a large, sturdy (25cm) hoe.bushfire, forests commission victoria (fcv) -

Orbost & District Historical Society

Orbost & District Historical Societyscythe blade, late 19th - early 20th century

Scythes were used to manually mow wheat or grass. Scythes were used with a long sweeping movement which made them much less tiring for labourers to use than reaping hooks or sickles though they still involved great physical labour and considerable skill to perfect. Both hands were in use and the operator did not have to bend his back to reach down to the crop. On farms scythes were sharpened on a sandstone wheel mounted on an axle with a crank handle on one side. This was hand powered and used with water. Scythes were not used as often on farms after the mechanisation of harvesting. They were still used for cutting awkward shaped small plots and for opening a path for the tractors. This item is an example of a tool used by the early settlers of the Orbost district. An iron scythe blade, curved and tapered. There is no handle and the blade is rusted and pitted."ROSE"scythe tool agriculture rural -

Kiewa Valley Historical Society

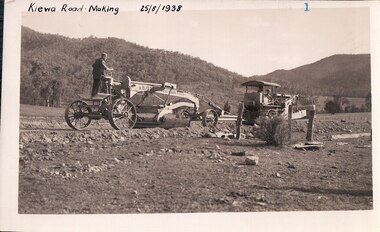

Kiewa Valley Historical SocietyBlack and White photograph of Road Making Machinery, Kiewa Road Making, 25/08/1938

... months of hard manual labour saved, but a very significant amount ...Construction of the main road from South Tawonga to the Bogong High Plains, to provide access to the construction sites for the new Kiewa Hydro Electric Scheme, was commenced early in 1938, the work being undertaken on behalf of the Commission by the Country Roads Board. For the construction work, the Commission purchased three Caterpillar - model R07 - diesel crawler tractors equipped with Kay Brunerei (Brunner) hydraulically operated trailbuilders (angle dozers). This acquisition resulted from a visit to the United States of America in May, 1937 by the Construction Engineer ( Mr. C.H. Kernot) and Assistant Civil Engineer (Mr. J.F. Douglas) where they saw this relatively new type of equipment in use. With the co-operation of the CRB, the Commission demonstrated the operation of these machines at Fishermen's Bend on 6th April, 1938. They were then sent to Kiewa where they commenced operation towards the end of the month. From South Tawonga, the route led immediately across the Western Branch of the Kiewa River necessitating the construction of a bridge 100 feet long. By the end of 1939, the excavation had been 'opened up' for a distance of 19 1/2 miles (approx. 31 km) and of this length, 10 miles (approx. 16 km) had been surfaced.The purchase and use of this type of mechanical equipment in road making was a huge investment, as prior to this most of the work would have been done manually with the use of picks and shovels. Not only were many months of hard manual labour saved, but a very significant amount of time in providing access to the proposed work sites for the new Kiewa Hydro Scheme. This photo is an excellent reminder of how primitive the early machinery was compared to the present but also represents the forward thinking of the State Electricity Commissions engineers in purchasing such innovative equipment . A black and white photograph showing the type of machinery used for road making in the 1930's. It shows a grader being towed by a caterpillar tractor.On the top left hand corner of the photograph , hand written in black ink is the words 'Kiewa Road Making 25/8/1938'. On the right hand side of the photo has been stamped in blue the Number 1. It has been developed on Velox paper (marked on back of photo) with a gloss finish.road making, state electricity commission, caterpillar tractor, kiewa -

Kiewa Valley Historical Society

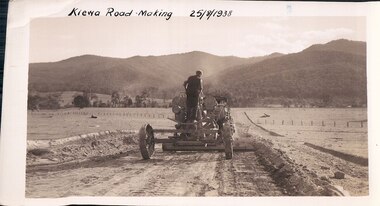

Kiewa Valley Historical SocietyBlack and White photograph of Road Making Machinery, Kiewa Road Making 25/08/1938 No. 2, 25/08/1938

... were many months of hard manual labour saved, but a very ...Construction of the main road from South Tawonga to the Bogong High Plains, to provide access to the construction sites for the new Kiewa Hydro Electric Scheme, was commenced early in 1938, the work being undertaken on behalf of the commission by the Country Roads Board. For the construction work, the Commission purchased three Caterpillar - model R07 - diesel crawler tractors equipped with Kay Brunerei (Brunner) hydraulically operated trailbuilders (angle dozers). This acquisition resulted from a visit to the United States of America in May, 1937 by the Construction Engineer ( Mr. C.H. Kernot) and Assistant Civil Engineer ( Mr. J.F. Douglas) where they saw this relatively new type of equipment in use. With the co-operation of the CRB, the Commission demonstrated the operation of these machines at Fishermen's Bend on 6th April, 1938. They were then sent to Kiewa where they commenced operation towards the end of the month. From South Tawonga, the route let immediately across the Western Branch of the Kiewa River necessitating the construction of a bridge 100 feet long. By the end of 1939, the excavation had been 'opened up' for a distance of 19 1/2 miles (approx. 31 km.) and of this length, 10 miles (approx. 16 km.) had been surfaced. (see KVHS 0328)The purchase of this type of mechanical equipment in road making was a huge investment, as prior to this most of the work would have been done manually with the use of picks and shovels. Not only were many months of hard manual labour saved, but a very significant amount of time in providing access to the proposed work sites for the new Kiewa Hydro Scheme. This photo is an excellent reminder of how primitive the early machinery was compared to the present but also represents the forward thinking of the State Electricity Commissions engineers in purchasing such innovative equipment.A black and white photograph of road making near Mt. Beauty in 1938. Mount Beauty hills can be seen in the background with cleared land for grazing in the fore ground.Hand printed in black ink at the top of the photograph is 'Kiewa Road Making 25/8/1938'. On the right hand corner has been printed the number 2. It has been printed on gloss Velox paper.road making, state electricity commission, caterpillar tractor, kiewa, secv -

Kiewa Valley Historical Society

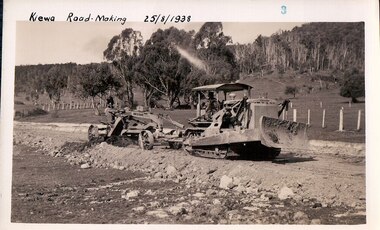

Kiewa Valley Historical SocietyBlack and White photograph of Road Making Machinery, Kiewa Road Making 25/8/1938(No. 3 in a series of 8), 25/08/1938

... months of hard manual labour saved, but a very significant amount ...Construction of the main road from South Tawonga to the Bogong High Plains, to provide access to the construction sites for the new Kiewa Hydro Electric Scheme, was commenced early in 1938, the work being undertaken on behalf of the Commission by the Country Roads Board. For the construction work, the Commission purchased three Caterpillar - model R07 - diesel crawler tractors equipped with Kay Brunerei (Brunner) hydraulically operated trail builders (angle dozers)). This acquisition resulted from a visit to the United States of America in May, 1937 by the Construction Engineer ( Mr. C.H. Kernot) and Assistant Civil Engineer (Mr. J.F. Douglas) where they saw this relatively new type of equipment in use. With the co-operation of the CRB, the Commission demonstrated the operation of these machines at Fishermen's Bend on 6th April, 1938. They were then sent to Kiewa where they commenced operation towards the end of the month. From South Tawonga, the route led immediately across the Western Branch of the Kiewa River necessitating the construction of a bridge 100 feet long. By the end of 1939,the excavation had been 'opened up' for a distance of 19 1/2 miles (approx. 31 km.) and of this length, 10 miles (approx. 16 km) had been surfaced.The purchase and use of this type of mechanical equipment in road making was a huge investment, as prior to this most of the work would have been done manually with the use of picks and shovels. Not only were many months of hard manual labour saved, but a very significant amount of time in providing access to the proposed work sites for the new Kiewa Hydro Scheme. This photo is an excellent reminder of how primitive the early machinery was compared to the present but also represents the forward thinking of the State Electricity Commission's Engineers in purchasing such new and innovative equipment.A black and white photograph of a Caterpillar diesel crawler tractor and a hydraulically operated trailbuilder (angle dozer) making a road in the Mt. Beauty area.Hand written in black ink in the top left hand corner are the words "Kiewa Road Making 25/8/1938". On the upper right hand of the photograph has been stamped the number 3. On the back is stamped the word 'Velox' severaly times, which is the make of the photograhic paper. roadmaking, caterpillar tractor, kiewa, state electricity commission -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBook - Instruction Manual, Illustrated Directions for using the New High Arm Davis Vertical Feed Sewing Machine, 1883-1885

This book of Illustrated Directions was produced for use with the Davis New High Arm Vertical Feed (VF) Sewing Machine. The first model of the High Arm was produced in 1881, and the ‘New’ model, Model 2 VF, was introduced from 1883 and continued at least until 1885, when the Model 3 VF was manufactured. Job Davis, an inventor, showed his Davis Sewing Machine to two brothers in Watertown. The brothers, John and Joseph Shaldon, who founded the Davis Sewing Machine Company in February 1868 in Watertown, New York. The firm moved to Ohio in the 1890. Its early sewing machines were known as the Vertical Feed machines. These machines differed from others, in that there were two presser feet that moved and held the cloth as the needle went in and out of it. This type of action was also called ‘walking foot’ by makers of similar machines. Other machines used a feed dog below the machine’s bed to move the fabric. The Davis Company was awarded a Patents for its improvement to sewing machines. London offices were set up at 54, Queen Victoria Street, London in 1982. It was known as the Vertical Feed Sewing Machine Company. An article published in March 1885 states that the London Manager of the Vertical Feed Sewing Machine Company has 300,000 machines world-wide, including 4,000 in England alone. It claimed that the Auxiliary Forces Uniform and Equipment Company in Limerick, Ireland, was running its machines with steam power and could produce first-class work at the rate of 1,500 stitches per minute. The hand stitched binding of the manual is an example of early book binding processes. The is significant for its relationship to the Davis New High Arm Vertical Feed sewing machine, which was invented in 1866 and became popular in the domestic market. It was also used in industrial conditions as a labour-saving machine, one of the many machines that were part of the Industrial Revolution when steam power replaced manual power in many factories. Paper book with stitched binding. Printed text and illustrations contained within the 42-page booklet. The manual includes drawn diagrams and instructions for use of the Davis New High Arm Vertical Feed Sewing Machine, a foot treadle machine made in the 1880s. Front cover: "ILLUSTRATED DIRECTIIONS for the NEW HIGH ARM DAVIS Vertical Feed Sewing Machine and its Accessories and Attachments"flagstaff hill maritime museum and village, great ocean road, shipwreck coast, sewing machine manual, davis sewing machine, new high arm sewing machine, model 2 vf, vertical feed, sewing machine instructions, sewing machine directions, job davis, john sheldon, joseph sheldon, high arm sewing machine, watertown, new york, vertical feed sewing machine company, treadle, steam sewing machine, auxiliary forces uniform and equipment company, limerick, ireland -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTimer, 1940s

Australia's first telephone exchange was opened in Melbourne in August 1880. It was operated by the Melbourne Telephone Exchange Company. Owned by W. H. Masters and T. T. Draper, the Manager of the Company was H. Byron Moore. This was only two years after the world's first exchange in the United States, and just four years after Bell first spoke on a telephone. The exchange was located in the old Stock Exchange building at 367 Collins Street, a site now occupied by the Commonwealth Bank. In 1884, the operations of the Company, by then known as the Victorian Telephone Exchange Company, had grown considerably and were transferred to Wills Street, Melbourne. Private ownership of this company continued until 1887 when it was bought out by the Victorian Colonial Government. Other colonial governments followed this example. By 1910, the growth in telephone services made additional accommodation necessary. This could not be provided in the existing building in Wills Street and arrangements were made for a new exchange in Lonsdale Street. Alexander Graham Bell visited Australia in 1910 to advise the Federal Government's Postal Commission. Telephone exchanges were established in Adelaide with (48 subscribers), Hobart (10 subscribers) and Launceston (35 subscribers). The first exchange in Western Australia was established in 1887 and located in a small three-room cottage in Wellington Street, Perth with 17 subscribers. The year 1888 marked the opening of the Fremantle exchange in a small room at the rear of the Town Hall. There were nine subscribers. Australia's first automatic exchange was installed in the GPO in Sydney, in 1911, for internal use. But the first automatic exchange for public use was opened at Geelong in Victoria in the next year July 1912 with 800 subscribers. Melbourne's first automatic exchange was opened in the suburb of Brighton in 1914; the first public automatic exchange in NSW began operating at Newtown, Sydney in 1915; and Queensland's first was installed at South Brisbane in 1925. 1929 saw the opening of Tasmania's first automatic exchange in Hobart. an automatic telephone service. In June 1977, the manual telephone exchange at Swansea was replaced with an automatic service and made Tasmania the first State in Australia to have a fully automatic net work. The half-century following Federation saw the growth of the automatic operation; a great extension of trunk line services; The automatic telephone contributed greatly to the early popularity of telephones in Australia. It was a quicker and more convenient way of communicating with another person on the same exchange — instead of having to go through tedious processes with the operator. From its introduction, the number of automatic telephones in operation grew to a remarkable extent. In 1886, the first trunk link of 16 km was connected to the exchanges of Adelaide and Port Adelaide in South Australia. Then, in 1907, the first inter-capital telephone trunk line was opened between Sydney and Melbourne. It was followed by a line between Melbourne and Adelaide in 1914. Sydney and Brisbane were linked in 1923, and Perth and Adelaide in 1930. In 1930, the first overseas calls from Australia came possible with the introduction of a radio telephone service to England, and through there to Europe and America. A similar service opened to New Zealand in the same year. Initially, trunk channels linked different manual trunk exchanges. It was necessary for a succession of trunk operators to connect the appropriate channels, one after the other until the connection was made. As trunk traffic grew. the system became increasingly unsuitable. More trunk operators had to be employed and so labour costs increased. It was a tedious and slow way of making a long-distance call, and it was sometimes hard to hear, particularly when several exchanges were linked With technical advances, trunk switching moved from manual operation through a partly automatic phase. Automatic transit switching equipment was used and only a single operator was required to connect a trunk call to a wanted automatic subscriber. Until well beyond the middle of this century, the majority of trunk traffic went through this single telephonist control. In 1953, the number of telephones in use in Australia passed the one million mark. By then, the need for improvement in the automatic exchanges was be coming well recognised. The need was for a telephone switching system which would do a better job more economically than the conventional step-by-step ex-change. This led to the adoption of the Crossbar system as the standard in automatic telephone exchanges in 1960. The introduction of Crossbar switching was a big step forward in the automation of trunk calls. It substituted automatic switching and charging equipment for the originating trunk operator, and improved the quality of the system radically. Before the introduction of the Crossbar system there were often very long delays in obtaining a booked trunk call, and the quality of sound was often very poor. With Crossbar, Subscriber Trunk Dialing (STD) became a reality. A trunk call by STD was as easy to make and almost as fast to connect as a local call.The item was made around the 1940s and used up until the 1970s in manual cord telephone exchanges as a way to time and charge users for trunk calls made over the telecom system of the time. Post Master General dept. - Trunk Call Timer.Inscribed PMG, C. of A, 37. Bell chimes at 3 min increments.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, timer, trunk call, telephone, cord exchange -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Rope machine, Continental Trading Corporation Ltd, ca. 1911

This rope-making machine, called The New Era Rope Machine, was patented in the USA on July 18th 1911. It was made by the Continental Trading Corporation Ltd. in Chicago, USA. The ends of the rope would be threaded through the matching and hooked onto the machine's claws on the other side. The machine's handle would be rotated manually, which would twist the rope ends together, entwining them to make one thick rope.This manually operated rope-making machine is a labour saving devise used particularly by sailmakers in their rigging and ropework tasks. Rope-making machine, metal. The model is "The New Era Rope Machine". The manually operated machine has three claws through which roping material is threaded. Internal wheels have cogs around their perimeter. The two pieces that make up the machine's case are bolted together. Made by Continental Trading corporation Ltd Chicago USA. The machine was patented on 18th July 1911."The New Era Rope Machine" " Continental Trading Corporation Ltd Chicago USA" "Patd july 18 1911" "Made in USA" "Keep oiled"flagstaff hill, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, ropework, the new era rope machine, patented, 1911, textile machine, continental trading corporation ltd., chicago, rope-making machine, textile industry -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

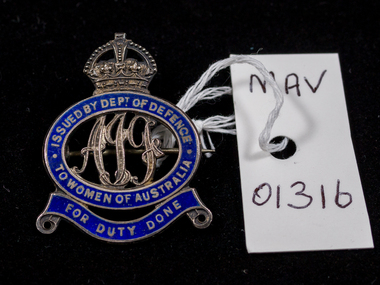

City of Moorabbin Historical Society (Operating the Box Cottage Museum)WW1 Medal for Women relatives of serving soldiers, c1914 - 1918

... families especially due to the heavy manual labour that the Women ...Female Relative Badges were issued to the nearest female relative (usually wives or mothers) of those who engaged in active service overseas during the First and Second World Wars. Two Female Relative Badges were issued during the First World War. One was issued to the nearest female relative of soldiers, airmen, nurses, and masseuses who left Australia for active service abroad; the other to the nearest female relative of members of the Royal Australian Navy (RAN) who had enlisted for general naval sea service for at least a period of the war, and who performed service outside Australian waters. A bar was suspended below the badge to indicate additional relatives involved in the war effort. The Female Relatives Badge was promulgated under Military Order 280 of 1917 and superseded by Military Order 1818 of 1918. (Australian War Memorial )So many Moorabbin Shire young men volunteered to serve in 1st AIF during WW1 . This caused great hardship for farming families especially due to the heavy manual labour that the Women had to undertake to maintain food production for Australia and overseas . This medal may be associated with Alonzo Sheldrake Box who served at Gallipoli and France Circular Silver medal with Crown , Blue engraving and pin clasp on back . A silver bar is attached Around edge ; Issued by Dept. of Defence to Women of Australia Centre cut out : A I F On Bar : For Duty Done On Back : Stokes & Sons 57691world war 1914-18, moorabbin shire, early settlers, pioneers, box alonzo, box william, australian military medals, anzac, gallipoli, sheldrake martha, box elizabeth, box mary louisa, closter mary, war memorials, a -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Food Mill, 1950s+

The Moulin Legumes No. 3 food mill is a useful manual kitchen utensil for milling, sieving, grating and pureeing various food types (legumes, vegetables, fruit and herbs). The food is placed in the chamber and the handle is turned to push the food through the holes in the blades and into a bowl placed below it. The various blades allow choice of consistency as they have different sized holes. It was in use before electric food processors were invented and is still used in modern times. The vegetable mill was invented by the French inventor and industrialist, Jean Mantelet, in 1932. Inspired by his wife, he invented the mill, which simply and quickly made cooked food into puree or mash. He said "My greatest pride is to rid women of a daily chore." The business started using the brand Moulinex in 1956 and today is it a household name linked to useful and good quality kitchen utensils and aids. The name comes from combining the words Moulin Express, which was an electric coffee mill. The embossed text "BREVETE S G D G" was a type of French patent without a government guarantee. It stopped being used in 1968. This Moulin is an example of a kitchen utensil used before electric food processors were invented, and had gained popularity to process foods such as vegetable's, fruit, nuts and herbs in a domestic or commercial kitchen. The first model of the Moulin Legunes was invented in 1932 by French industrialist Jean Mantelet to meet the reduce labour for housewives in the kitchen. Millions of this labour saving device have since been sold. Food mill, metal, for manually processing food. Conical-shaped food chamber, two U-shaped handles on opposite sides, two clips inside. Three interchangeable twelve-sided cutting blades, each with different sized holes. Made in France. Model is Moulin Legumes No. 3. Impressed into the side, within a circle "MADE IN FRANCE - BREVETE S G D C -" and in centre "2" (Brevete is French word for Patent)flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, made in france, french kitchen utensils, moulin, food preparation, kitchen utensil, food mill, food processor, sieve, moule, mouli, grater, puree, hand operated, moulin legumes no. 3, vingage, kitchen gadget, moulineux, jean mantelet -

Unions Ballarat

Unions BallaratIs it safe? Dead workers don't work, 1990s?

This is an OH&S manual targeted at construction industry workers. Includes issues such as asbestos, chemicals and use of tools. This is the third edition of the manual. The most recent copy of the manual is available from the CFMEU.Relevance to workplace health and safety and trade unions' stance on pertinent issues.Paperback book. Front cover: black background; green, white and red lettering.btlc, ballarat trades regional trades and labour council, ballarat trades hall, oh&s, workplace safety, construction industry, asbestos -

Unions Ballarat

Unions BallaratAFMEU Occupational Health and Safety Manual 1994, 1994

Automotive, Food, Metal & Engineering Union (AFMEU). The AFMEU has existed under various names over time. After many amalgamations, it is currently under the Australian Manufacturing Workers Union (AMWU). An historical timeline for the union(s) can be found at http://www.vicunions.org.au/affiliatesHistorical document. Significant to occupational health and safety, particularly for members of the AFMEU and people working in the automobile industry.Paperback book.Front cover: title and year. Back cover: advertising.btlc, ballarat trades and labour council, ballarat regional trades and labour council, unions, automotive, food, metal & engineering union, afmeu, oh&s, occupational health and safety, automobile industry -

Unions Ballarat

Unions BallaratDiagnostic & Statistical Manual (DSM) - Psychiatry's Deadliest Scam, Citizens Commission on Human Rights International, 2011

The film is an exposé alleging that the DSM is used to justify psychiatric fraudulence and quackery. The DSM is portrayed as a highly contentious manual used by psychiatrists for diagnostic purposes. ALLEGATIONS are made in relation to how the guide may be used to unnecessarily medicate and manipulate patients. Also available online at: http://www.cchr.org/videos/diagnostic-statistical-manual.htmlRelevant to civil liberties, patient rights and the profession of psychiatry.DVDbtlc, ballarat trades hall, ballarat trades and labour council, dsm, diagnostic & statistical manual, psychiatry, psychiatrists, psychiatric diagnoses and treatment, patients - rights, mental illness, pharmaceutical companies, civil liberties -

Unions Ballarat

Unions BallaratBook - Trade Unions, Jackson, Michael P

Introduction to trade unions in the Western world, with a focus upon the British experience. Chapter titles: 1. Introduction 2. Trade union growth and development 3. White collar and non-manual trade unionism 4. Internal democracy 5. The challenge from the shop floor 6. Collective bargaining and economic objectives 7. Trade unions: conflict or compromise 8. Trade unions and governments: new directions? 9. Conclusions: trade unions as mature organisationsRelevant to trade unionism in Western countries.Book; paper.Front cover: Author's name and title. btlc, ballarat trades and labour council, trade unions, economics, governments -

Falls Creek Historical Society

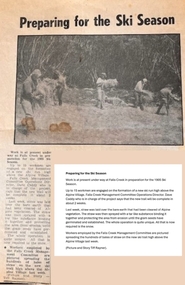

Falls Creek Historical SocietyArticle - Newspaper article "Last Hoot" development - Summer of 1984/85

Over the summer of 1984/85 extensive regeneration work was carried out to establish the “Last Hoot”. It was a big job and took all summer to complete the work which included throwing rocks of the run, digging in cross drains and spreading the area with hay. All work was done manually. Though difficult physical work, those who dedicated their time and labour to the task have interesting memories of that time, including arriving to load up hay bales only to find the cattle from the high plains had walked across the dam wall to come and enjoy a fabulous feast! The Hoot Ski Trail has two sections. Fast Hoot is a 341 metre blue downhill run located near Falls Creek. The Last Hoot is a one km blue ski run (piste) trail which can be used in both directions. It finishes at Slalom Plaza in Falls Creek Village. Snowlands Lodge is near the bottom of the trail in Slalom Street. One of its most popular features is “The Last Hoot” Restaurant.This article is significant because it documents the work carried out to establish a popular ski trail at Falls Creek, VictoriaThis newspaper article reports on the work carried out to prepare for a new ski trail the "Last Hoot" at Falls Creek over the summer of 1984/85.In image L to R Debbie Howie, Larraine Boulton, Nina Frueauf, Rob McEwan, Eric Napierthe last hoot, deb howie -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Boiler, T & F Johnson, boilermakers, late 19th century

... manual labour. The makers were one of many boilermaker ...A steam boiler like this late 18th century boiler, is often called a colonial boiler. Steam boilers were used in factories throughout Australia, mounted over similar designs of brick furnaces. This heat from the fire travels through the tubes in this fire tube boiler and the water heats as it circulates around them. Another kind of boiler is a water tube boiler, in which the water is inside the tubes and the heat of the combustion surrounds the tubes. The boiler in our collection burned wood as fuel but others of this design could also burn coal, coke, gas and liquid fuels. The boiler was made by T & F Johnson, boilermakers. In 1922 their factory was located at Coventry Street, South Melbourne. They were still advertising their 'Colonial, multi, vertical boilers, all sizes' at the same address in 1934. The connected pressure gauge, made in London by Dewrance, measures 0 to 400 pounds per square inch. John Dewrance is renowned as a pioneer of the steam locomotive in the early 19th century. He founded John Dewrance & Co. in South London in 1844. His son Sir John Dewrance took over in 1879. In 1939 the company became a subsidiary of Babcock & Wilcox, and was eventually owned by Emerson. How the boiler works: - A boiler is about two-thirds filled with water and heat is applied, in this case in the form of burning wood. The heat is transferred through the metal of the boiler to the water. When the water boils the steam rises to the top, and as it escapes from the boiler the steam pressure builds up in the steam space to later be released to do work; drive machinery such as ship and train engines, turbines, presses, wheels, and driving belts to operate looms and saws. The heat associated with the boiler can be used for preserving food, sterilising, factory manufacturing processes, and steaming wood for shipbuilding. Every boiler has several components fitted for safe operation: - - Safety valves - Gauge glass - Pressure gauge - Main steam stop valve - Water check valve - Blowdown valve - Manhole doorThe boiler is a significant item that gives us a snapshot of early Melbourne's industrial history. It is an example of the technological advancement during the Industrial Revolution where steam-driven machinery and motors could perform tasks more efficiently than manual labour. The makers were one of many boilermaker businesses in Melbourne during the early late-19th andearly 20th centuries. The maritime trade and skills of boilermaking are still learned and applied today. The Dewrance steam pressure gauge connected to the boiler was made by the London firms foundered by John Dewrance. He was renowned for developing the steam locomotive in the early 19th century.Boiler; a horizontal cylindrical underfired steam boiler. It is a multi-tubular design and is timber plank-clad, with brass fittings and pressure gauges. The boiler has an iron door at one end with a metal chimney above it. It is installed over a brick-enclosed solid fuel furnace. Two large, wood-mounted pressure gauges are connected to the boiler and have inscriptions. An inscription is on a red, cast iron plaque above the boiler door. The boiler's maker is T & F Johnson, South Melbourne. One of the pressure gauges was made by Dewrance, London..Maker's plate: "T & F JOHNSON / BOILERMAKERS / SOUTH MELBOURNE" Pressure gauge: "POUNDS PRESSURE / PER [square] INCH / DEWRANCE LONDON"flagstaff hill, warrnambool, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, boiler, multi tube boiler, steam boiler, steam technology, underfired boiler, horizontal boiler, timber clad boiler, steam power, industrialisation, boilermakers, south melbourne, dewrance, john dewrance, pressure gauge, dewrance pressure gauge, t & f johnson, london, steam engine, steam locomotive, pounds per square inch, 19th century, steam machine, johnson tyne foundry, colonial boiler, fire tube boiler