Showing 131 items matching "manual tool"

-

Moorabbin Air Museum

Moorabbin Air MuseumManual (Item) - CAC Tool Engineering Manual, Tool Engineering Manual Commonwealth Aircraft Corporation Pty Ltd

... CAC Tool Engineering Manual ...Tool Engineering Manual Commonwealth Aircraft Corporation... CAC Tool Engineering Manual ...Commonwealth Aircraft Corporation -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Fuller, Grooving iron

... manual tool... tinsmth metalsmith seaming tool sheet metal worker manual tool ...This hand groover is sometimes called a seamer, grooving iron, punch or fuller. It would have been used by a metal smith, such as a blacksmith, tinsmith or sheet metal worker. It is used to join two edges of metal. The smith overlaps the edges of the metal, then places the tool on top and beats it with a hammer on the top, forcing the metal into the tool's groove, which joins the metal. The device would be moved along the edges to complete the seam. The same tool could give a decorative finish to an artisan's work.This hand groover is sometimes called a seamer, grooving iron, punch or fuller. It would have been used by a metal smith, such as a blacksmith, tinsmith or sheet metal worker. It is used to join two edges of metal. The smith overlaps the edges of the metal, then places the tool on top and beats it with a hammer on the top, forcing the metal into the tool's groove, which joins the metal. The device would be moved along the edges to complete the seam. The same tool could give a decorative finish to an artisan's work.Tool: a fuller, used to form a groove in heated iron. It is also referred to as a groover, seamer or fuller punch. Hand tool with round handle, flat round top and indented rectangular base. Base has grooves on long edges. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, blacksmith tool, vintage tool, sheet metal fabrication, groover, seamer, hand tool, tinsmth, metalsmith, seaming tool, sheet metal worker, manual tool, smith's tool, fuller, grooving iron, punch -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Fuller, Grooving iron

... manual tool... sheet metal worker manual tool smith's tool fuller grooving iron ...This hand groover is sometimes called a seamer, grooving iron, punch or fuller. It would have been used by a metal smith, such as a blacksmith, tinsmith or sheet metal worker. It is used to join two edges of metal. The smith overlaps the edges of the metal, then places the tool on top and beats it with a hammer on the top, forcing the metal into the tool's groove, which joins the metal. The device would be moved along the edges to complete the seam. The same tool could give a decorative finish to an artisan's work.This handmade tool was made for the particular purpose of joining sheets of metal together. The metal formed in this way could be used for water tanks, boilers and other similar items. It is an example of the equipment made and used in the trades of a metalsmith and blacksmith in the 19th and early 20th centuries.Tool: a fuller, used to form a groove in heated iron. It is also referred to as a groover, seamer or fuller punch. Hand tool with round handle, flat round top and indented rectangular base. Base has grooves on long edges. flagstaff hill maritime museum, maritime museum, shipwreck coast, great ocean road, blacksmith tool, vintage tool, sheet metal fabrication, groover, seamer, hand tool, tinsmth, metalsmith, seaming tool, sheet metal worker, manual tool, smith's tool, fuller, grooving iron, punch -

Moorabbin Air Museum

Moorabbin Air MuseumDocument (item) - Drafting practice threads springs, CAC Tool engineering manual

... CAC Tool engineering manual... Moorabbin melbourne CAC Tool engineering manual Document Drafting ... -

B-24 Liberator Memorial Restoration Australia Inc

B-24 Liberator Memorial Restoration Australia IncService Maunuals Case, Service Manuals in officially supplied Case, C. 1930s 1940s

... in gold circle. Service Manuals. 01618 i tooled into base of case.... Farm Rd & Princes Highway Werribee melbourne Service manuals ...Service manuals for the B-24D Liberator aircraft.These instruction mauals were officially issued from the Consolidated Aircraft Corporation, San Diego, California USASquare leather case with 2 handles and metal clasp, with gold inscriptions.E. Duplex SUMITON, ALA. CONSOLIDATED VULTEE with an eagle in gold circle. Service Manuals. 01618 i tooled into base of case. -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, Screwdriver large, c1900

... A screwdriver is a tool, manual or powered, for turning... A screwdriver is a tool, manual or powered, for turning (driving ...A screwdriver is a tool, manual or powered, for turning (driving or removing) screws. A typical simple screwdriver has a handle and a shaft, and a tip that the user inserts into the screw head to turn it. The shaft is usually made of tough steel to resist bending or twisting. The tip may be hardened to resist wear, treated with a dark tip coating for improved visual contrast between tip and screw—or ridged or treated for additional 'grip'. Handle are typically wood, metal, or plastic and usually hexagonal, square, or oval in cross-section to improve grip and prevent the tool from rolling when set down. The handle and shaft of screwdrivers have changed considerably over time. The "Perfect Pattern Handle’ screwdriver was first manufactured by HD Smith & Company, which operated from 1850 to 1900. Screwdrivers were probably invented in the late 15th century, either in Germany or France when Screws were used to construct screw-cutting lathes, for securing breastplates, backplates, and helmets on medieval jousting armor—and eventually for multiple parts of the emerging firearms, particularly the matchlock. The jaws that hold the pyrites inside medieval guns were secured with screws, and the need to constantly replace the pyrites resulted in considerable refinement of the screwdriver. The screwdriver depended entirely on the screw, and it took several advances to make the screw easy enough to produce to become popular and widespread Canadian P.L. Robertson, though he was not the first person to patent the idea of socket-head screws, was the first to successfully commercialize them, starting in 1908. In Portland, Oregon, Henry F. Phillips patented his own invention, an improved version of a deep socket with a cruciform slot, today known as the Phillips Screw. Phillips offered his screw to the American Screw Company, and after a successful trial on the 1936 Cadillac, it quickly swept through the American auto industry. A main attraction for the screw was that conventional slotted screwdrivers could also be used on them, which was not possible with the Robertson Screw. A large steel screwdriver with worn wooden handlepioneers, early settlers, market gardeners, moorabbin, bentleigh, cheltenham, brighton, tools, craftsman, carpenters, , blacksmiths, builders, farmers, metalwork, woodwork, screws, philllips head screwdrivers, h.d.smith & co usa, p.l. robertson, henry f.phillips , oregon, canada, american screw company, -

The Beechworth Burke Museum

The Beechworth Burke MuseumTool - Propelling Pencil

A propelling pencil is a type of mechanical pencil.The lead is manually pushed down a tube of matching diameter, and is friction-fit. A small rod inside the pencil pushes the lead forward, as needed, usually with a twist an action mechanism.The social history objects held in the Burke Museum's collection help to tell the stories of Beechworth's past by showing the social, cultural, and economic aspects of the town's history.A small propelling pencil that features a stone handle.writing equipment, pencil, mechanical pencil -

The Beechworth Burke Museum

The Beechworth Burke MuseumTool - Propelling Pencil

A propelling pencil is a type of mechanical pencil.The lead is manually pushed down a tube of matching diameter, and is friction-fit. A small rod inside the pencil pushes the lead forward, as needed, usually with a twist an action mechanism.The social history objects held in the Burke Museum's collection help to tell the stories of Beechworth's past by showing the social, cultural, and economic aspects of the town's history.A small silver propelling pencil with a diamond patterned handle.England/ V. S. Lead/mechanical pencil, writing equipment, pencil -

Orbost & District Historical Society

Orbost & District Historical Societybook, Automatic Electric Company, Principles of Automatic Telephony, Circuits and Trunking, 1925

The Strowger switch is the first commercially successful electro-mechanical stepping switch telephone exchange system. It was developed by the Strowger Automatic Telephone Exchange Company founded in 1891 by Almon Brown Strowger. In 1912 Australia's first automatic telephone exchange was installed at Geelong. Victoria. The exchange equipment was Strowger Automatic telephone apparatus, manufactured by the Automatic Electric Company, Chicago USA. This is a useful research tool for the history of telephony.A 96 pp bound book with a dark brown cover. On the front cover inside a narrow black ruled frame is the title, "Principles of Automatic Telephony Circuits and Trunking" Below that is the logo for the Strowger Automatic telephone manufactured by the Automatic Electric company, Chicago.telephony communication manual-automatic-telephony -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Cabinet Scraper, 1945-1955

A cabinet scraper (sometimes called a ‘card scraper’) is a woodworking tool used for shaping and finishing furniture. The name ‘cabinet’ is used because scrapers are versatile and important tools for cabinet makers to provide a smooth surface to a finished cabinet. The body and the cutting edges of most cabinet scrapers are formed from a single piece of material. The blades are created on each edge of the body. Also, a scraper can have adjustable blades and a wooden handle these are two-handled cabinet scrapers. Cabinet scrapers are used manually to scrape small amounts of material from the surface of the wood to smooth it, shape it, or remove an old finish such as varnish from its surface. They are commonly used on furniture and musical instruments such as guitars and violins. The tools can be used on hardwood or softwood but when using a cabinet scraper on any wood, you should generally work along the grain.A tool used to finish timber to give a smooth finish and a important tool for a cabinet maker that has been in use for many hundreds of years in different design formsBox scraper adjustable with long wooden handle.Noneflagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, box scraper, scraper, woodwork tool, cabinet scraper, furniture finishing -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDrill Press, early to mid-20th century

This post drill press has been made by Melbourne business, Dawn Manufacturing Company. It can be operated manually or by a pulley driven flywheel, with the aid of an engine connected to a power supply. In the late 1800s early 1900s a drill press like this would have been driven by steam from a boiler, the main power source for manufacturer’s power at that time. Dawn’s Golden Anniversary 1917-1967 Catalogue describes this model 611 drill as … “Ruggedly constructed with accurately reamed bearings. The coupling between the main spindle and feed screw engages the full circumference of the spindle, and embraces a ball-bearing thrust race. The pillar, as in all “Dawn Drilling Machines” is a solid bright steel bar, in place of the usual light tubing. Adjustable automatic feed.” And “F. & l. Pulleys extra, if required”. DAWN MANUFACTURING CO. The Dawn Manufacturing Co. was founded in Coburg, Melbourne, in 1917 by the four Blake brothers, who were all engineers. After World War I Dawn was supplying drills Australia wide and the company was growing at a healthy rate. During the depression they remained busy, with employees working 60-80 hour weeks. Dawn was contracted to supply vices and clamps to the Australian Defence Department and munitions factory during the World War II. - 1959 the company was taken over by G.N. Raymond Group. - 1967 the Dawn Manufacturing Co. had distributors in Australia and overseas, including USA, Canada, New Zealand, Asia and the Middle East. - 1973 the Siddons Ramset Limited acquired Dawn. - December 1991, Dawn became a unit of the United States owned Stanley Works Pty. Ltd. - November 1998 Dawn became 100 per cent Australian owned. The drill is a typical tool of a blacksmith, cart wright, wheelwright and garage business. It is an example of the tools of the blacksmiths’ trade in Victoria in the early to mid-20th century.Post type drill press machine with gear driven flywheel. Drill press is attached to a post and is fitted with a pulley belt and will run at a speed of maxim 200 r.p.m. The machine can also be manually operated. It has an aperture in the centre, a chuck, for the drill bit and has two metal handles at the centre, on the right hand side. Gear ratio 2:1 main drive, 6" diam, 3:1 reduction gear. Made by Dawn of Melbourne, Australia. Model No. 611, Code No. 9157"DAWN MFG COY”, “MELB. AUSTRALIA", " 611"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, blacksmiths, blacksmith’s drill, blacksmith tools, dawn drill model no. 611, dawn drill code no. 9157, dawn manufacturing coy melbourne, dawn manufacturing coy coburg, dawn post drill, drilling machine, drill with gear driven flywheel, forging tool, metal working tool, post drill, steam powered drill, trade tool, warrnambool district 1900s -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyGrinder/Mincer - Meat

Old farm kitchen tool used for mincing meat manually.Used at Tawonga, in the Kiewa Valley, by resident Des WartonCast iron with dull smooth surface consisting of a tap to screw it onto a table, a barrel enclosing the auger that turns when the handle is wound around and forces the meat to spill out of a circular grinder. The hand crank is curved with a wooden knob . The outlet is oval shaped.Embossed on barrel: "Universal" Embossed on outlet "2" Embossed on handle "L.F. & c - New Britain Conn U.S.A."household tool, kitchen, meat mincer, grinder, universal no. 2 -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Tool - Hedgetrimmer, 1949

This is a manual hedge trimmer which has a push pull action. It is not a very common garden tool possibly a lot slower to use than clippers. It dates from mid 20th century.This is quite a rare tool.This tool is consists of a metal bar with a row of prongs attached . A blade on one end is moved along the length of the metal bar thereby trimming the bush. There is a wooden handle attached to the metal bar and a wooden ball and spring on the righthand side.Code Half Time. Made in England Pat App No 16418/49warrnambool, tool, hedgetrimmer, code halftime -

Bendigo Military Museum

Bendigo Military Museumphotograph - Cartographic Squadron Production – Army Survey Regiment, Fortuna, c1980

This collection of 12 photos was most likely taken in 1980. The photos were most likely taken in Cartographic Squadron’s Ante Room, the Attic and small offices on the top floor of Fortuna Villa. The computer based Editwriter typesetting system was introduced in 1975 as a replacement to the aging Fotosetter machine. It was operated by a specialised technician, who generated a large variety of map type styles and sizes quickly and reliably, as well as text panels. CPL Richards performed this task for several years and in photo .1P and .2P is reading off a type order next to the computer monitor. Output on Copy proof adhesive backed stripping type film replaced messy wax and spray adhesives in 1978. The Editwriter capability supported all RASvy units and contractor type setting requirements. Scribing was the cartographic process of drafting features such as drainage, relief, vegetation, roads and culture on specially coated map reproduction material. The cartographic technician scribed out the map feature such as a contour to a specified line width on the map sheet, using a tool affixed with a sapphire tipped cutter. The quality control edit (Proving) stage of map production was the first opportunity to inspect a proof of the map independently and systematically. Proving tasks were carried out by technicians conversant of the map product specification and task requirement, however, was not involved in its production. Corrections were identified, marked up and sent to back to the correcting section or contractors. Terrain Embossing was a manual map production technique to produce hill shading on medium to small scale graphics and air charts. SPR John Martin is seen in photos .8P to.10P using a fine embossing metal stylus to push down on the drainage impression on a thin malleable opaque plastic material (AK Poligraphy). Ridge lines were then pushed down using the contour impression as a guide, on the opposing side of the AK Poligraphy to create a 3D plastic model terrain effect. The map impression was sprayed with white paint and photographed to create a contone tone hill shade. SPR Gina (Coore) Neilson is seen in photo .11P washing a contone positive of a land mass in a solution. The contone components were registered to the map sheet, as shown in photo .12P and masked using an air brush and a halftone negative was then created. The terrain embossing method of producing hill shading was more efficient to produce than previous specialised artistic methods such pencil/eraser and air brush. Furthermore, a more consistent enhancement of terrain on charts was achieved between technicians.This is a set of 12 photographs of Cartographic Squadron performing four map production tasks at the Army Survey Regiment, Fortuna, Bendigo c1980. The first ten photographs were on 35mm negative film and were scanned at 96 dpi. Photos .11P and .12P were on photographic paper and scanned at 300 dpi. They are part of the Army Survey Regiment’s Collection. .1) - Photo, black & white, c1980, Editwriter typesetter, CPL Paul Richards. .2) - Photo, black & white, c1980, Editwriter typesetter, CPL Paul Richards. .3) - Photo, black & white, c1980, Scribing contours on a RAAF Chart, SPR Megan (McBurney) Reynolds. .4) - Photo, black & white, c1980, Scribing contours on a RAAF Chart, SPR Megan (McBurney) Reynolds. .5) - Photo, black & white, c1980, Scribing contours on a RAAF Chart, SPR Rod Skidmore. .6) - Photo, black & white, c1980, Scribing contours on a RAAF Chart, SPR Rod Skidmore. .7) - Photo, black & white, c1980, Formal quality control edit (Proving), CPL Ian Belmont. .8) - Photo, black & white, c1980, Hill Shade Terrain Embossing, SPR John Martin. .9) - Photo, black & white, c1980, Hill Shade Terrain Embossing, SPR John Martin. .10) - Photo, black & white, c1980, Hill Shade Terrain Embossing, SPR John Martin. .11) - Photo, black & white, c1980, Hill Shade Terrain Embossing, SPR Gina (Coore) Neilson. .12) - Photo, black & white, c1980, Hill Shade Terrain Embossing, unidentified..1P to .10P No personnel are identified. .11P and .12P annotated ‘Terrain Embossing’royal australian survey corps, rasvy, army survey regiment, army svy regt, fortuna, asr, carto -

Greensborough Historical Society

Greensborough Historical SocietyBooklet, Foley Automatic Power Setter

... manuals saws power tools tools 6 pages, some colour Foley ...Foley Automatic power setter. model 352. was used to set (cut) the teeth on saw blades6 pages, some colourowners manuals, saws, power tools, tools -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Churn, small domestic butter, c1880

A butter churn is a device used to convert cream into butter. This is done through a mechanical process, via a crank used to manually turn a rotating device inside the barrel shaped churn. The agitation of the cream, caused by the mechanical motion of the device, disrupts the milk fat. The membranes that surround the fats are broken down, subsequently forming clumps known as butter grains. These butter grains, during the process of churning, fuse with each other and form larger fat globules. Air bubbles are introduced into these fat globules via the continued mechanical action of the churn. The butter grains become more dense as fat globules attach to them while the air is forced out of the mixture. This process creates a liquid known as buttermilk. With constant churning, the fat globules eventually form solid butter and separate from the buttermilk. The buttermilk is then drained off and the butter is squeezed to eliminate excess liquid and to form it into a solid mass. Then rinsing could be done simply by washing in water, followed by draining, salting and working or "kneading" the butter with a pair of wooden butter pats, or with bare hands. This is a paddle churn, a barrel that contains a paddle, which is operated by a handle. The paddle churned the butter inside the container when the handle was turned. Early settlers had to be self sufficient, growing their own vegetables, making tools and clothing and usually had a house cow to produce their milk supplyThis domestic butter churn is an example of the skill of the pioneer craftsman, carpenters and tool makers c1900. As pioneers and early settlers had to be self sufficient they usually kept a dairy cow or 'house cow' to provide milk for drinking and for butter and cheese to made by the family.A small wooden, domestic butter churn with a lid and a crank that manually rotated the paddle inside. E. CHERRY / MAKER / GISBORNE / VICTORIA / Apioneers, early settlers, market gardeners, moorabbin, brighton, cheltenham, dairy products. dairy farmers, milk, butter, dairies -

4th/19th Prince of Wales's Light Horse Regiment Unit History Room

4th/19th Prince of Wales's Light Horse Regiment Unit History RoomBook, US Army AG Publications Center, Operator's & Organizational Maintenance Manual for AN/VRC radios & ancilliary equipment, Sept 1972

Soft covered book detailing operator's & organizational maintenance, spare parts, special tools for radio sets: AN/VRC12, AN/VRC43, 44, 45, 46, 47, 48, 49,54, & 55, mounting MT-1029/VRC and MT-1898/VRC, antenna AT-912/VRC, control frequency selector C-2742/VRC and control radio set C-2299/VRC. TM 11-5820-401-12 -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyDrill Auger, Circa early 1900s

This item wasused before diesel, electric and battery drilling apparatus were used by farmers, and other trades requiring a portable yet reliable method of drilling holes. As this item is a 3/4 inch hole drill it would be suitable for fencing and providing holes for structural studs. As with all outdoor farm equipment, man power was required (be it the farmer or farm hands). Fitness of the operator was at a high standard but protective gloves were not highly thought of as it was before occupational, health and safety regulations became mandatory over all manual handling activities, be they on rural properties or town/city factories. This period was one where the male ego was at its pinnacle i.e. the harder the tasks the more of a man was required. Hard manual work was not only the "way to go" but also a necessity. Evolution of cheap portable electric/battery powered tools opened up a more efficient method available, especially to those with less muscle strength. This item personifies the rugged environment of the rural workplace. The Kiewa Valley with its main emphasis on farming and grazing provided ample opportunity to use this construction implement. The manufacturer being a Scottish tool company is very significant in the era when this hole maker was in high demand. British steel products were of high grade and had a good record of reliability. The reliability of any tool was a solid factor for farmers and tradesmen in this semi-isolated region (Circa early 1900s) within the Kiewa Valley and its regional area. This factor,although not as crucial, post 1960s, when Asian manufacturers entered the market place and produced cheaper tools and transportation and supplies was more frequent and reliable, the need for the more expensive British made tools diminished considerably. After the influx of tradesmen from war torn Europe (post 1945) and the increased availability of tradesmen in the Kiewa Valley and its region the price of tools was and still is not as crucial and the cost of all required tools has become a minimal part of the equation. It is only with the emerging younger trades person, farmer and grazier, who have more, "one eye on production costs" and no "old ties to the motherland" inert mind set that quality tools such as this auger and other hand tools "must be made to last a life time" is no longer part of the modern work environment.This cast iron, hand operated Auger has a short barrel shaped cylinder at one end (known as the "Eye") and at the other end a Helical screw blade (screws the cutting edge into wooden material, thereby creating a hole 3/4 inch diameter in the wood) . The barrel section at the top permits a metal or wooden leverage plank to be inserted. The main rod has a 180mm long cutting/screw blade running from the bottom up towards the "eye" end. From the end of the screw blade to the handle is 380mm and cylindrical, but this changes at 550mm from the "eye" end to a 14mm x 10mm rectangular shape shaft.This shaft end is welded to the "Eye".On the shaft below the "eye" is stamped " MATHESON GLASGOW" on the front side and a spade (cards) symbol on the back.auger, hand drill, fencing, tool, rural trades, brace & bit -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyDrill Auger, Circa early 1900's

This item was before diesel, electric and battery drilling apparatus were used by farmers, and other trades requiring a portable yet reliable method of drilling holes. As this item is a 3/4 inch hole drill it would be suitable for fencing and providing holes for structural studs. As with all outdoor farm equipment, man power was required (be it the farmer or farm hands). Fitness of the operator was at a high standard but protective gloves were not highly thought of as it was before occupational, health and safety regulations became mandatory over all manual handling activities, be they on rural properties or town/city factories. This period was one where the male ego was at its pinnacle i.e. the harder the tasks the more of a man was required. Hard manual work was not only the "way to go" but also a necessity. Evolution of cheap portable electric/battery powered tools opened up a more efficient method available, especially to those with less muscle strength.This item personifies the rugged environment of the rural workplace. The Kiewa Valley with its main emphasis on farming and grazing provided ample opportunity to use this construction implement. The manufacturer being a Scottish tool company is very significant in the era when this hole maker was in high demand. British steel products were of high grade and had a good record of reliability. The reliability of any tool was a solid factor for farmers and tradesmen in this semi-isolated region (Circa early 1900s) of the Kiewa Valley and its regional area. This factor,although not as crucial, post 1960s, when Asian manufacturers entered the market place and produced cheaper tools and transportation and supplies was more frequent and reliable, the need for the more expensive British made tools diminished considerably. After the influx of tradesmen from war torn Europe (post 1945) and the increased availability of tradesmen in the Kiewa Valley and its region the price of tools is not as crucial and the cost of all required tools has become a minimal part of the equation. It is only with the emerging younger trades person, farmer and grazier, who have more, "one eye on production costs" and no "old ties to the motherland" inert mind set that quality tools such as this auger and other hand tools "must be made to last a life time" is no longer part of the modern work environment.This cast iron hand operated drill, has a short barrel-shaped cylinder, known as "the eye" welded across the main rod and is 30mm in circumference. It also has a hole drilled to allow a screw to be fastened onto the hand stock ( not available).The main rod is solid for 400mm and then has been flattened and coiled (Helical screw blade) for another 200mm. At the end of the larger screw blade there is a smaller gauged starter blade with a pointer thread 15mm long. This Auger produces a 1/8th inch hole (metric measurement not used at time of manufacture) See KVHS 0469 for 3/4 inch hole and KVHS 0471 for another 1/8th inch hole.A number 5 stamped on the flat sideauger, hand drill, fencing, tool, rural trades, brace & bit -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyDrill Auger, Circa early 1900's

This item was before diesel, electric and battery drilling apparatus were used by farmers, and other trades requiring a portable yet reliable method of drilling holes. As this item is a 3/4 inch hole drill it would be suitable for fencing and providing holes for structural studs. As with all outdoor farm equipment, man power was required (be it the farmer or farm hands). Fitness of the operator was at a high standard but protective gloves were not highly thought of as it was before occupational, health and safety regulations became mandatory over all manual handling activities, be they on rural properties or town/city factories. This period was one where the male ego was at its pinnacle i.e. the harder the tasks the more of a man was required. Hard manual work was not only the "way to go" but also a necessity. Evolution of cheap portable electric/battery powered tools opened up a more efficient method available, especially to those with less muscle strength.This item personifies the rugged environment of the rural workplace. The Kiewa Valley with its main emphasis on farming and grazing provided ample opportunity to use this construction implement. The manufacturer being a Scottish tool company is very significant in the era when this hole maker was in high demand. British steel products were of high grade and had a good record of reliability. The reliability of any tool was a solid factor for farmers and tradesmen in this semi-isolated region (Circa early 1900s) of the Kiewa Valley and its regional area. This factor,although not as crucial, post 1960s, when Asian manufacturers entered the market place and produced cheaper tools and transportation and supplies was more frequent and reliable, the need for the more expensive British made tools diminished considerably. After the influx of tradesmen from war torn Europe (post 1945) and the increased availability of tradesmen in the Kiewa Valley and its region the price of tools is not as crucial and the cost of all required tools has become a minimal part of the equation. It is only with the emerging younger trades person, farmer and grazier, who have more, "one eye on production costs" and no "old ties to the motherland" inert mind set that quality tools such as this auger and other hand tools "must be made to last a life time" is no longer part of the modern work environment.This cast iron hand operated drill, has a short barrel-shaped cylinder, known as "the eye" welded across the main rod and is 30mm in circumference. It also has a hole drilled to allow a screw to be fastened onto the hand stock ( not available).The main rod is solid for 400mm and then has been flattened and coiled (Helical screw blade) for another 200mm. At the end of the larger screw blade there is a smaller gauged starter blade with a pointer thread 15mm long. This Auger produces a 1/8th inch hole (metric measurement not used at time of manufacture) See KVHS 0469 for 3/4 inch hole and KVHS 0470 for another 1/8th inch hole.auger, hand drill, fencing, tool, rural trades, brace & bit -

Orbost & District Historical Society

Orbost & District Historical Societytextbooks, 1948 - 1982

These reference books were used in the Orbost pharmacy by various chemists. . Chemists who worked in Orbost included Henry Cottman; James Alfred Dubois Williams; Harry Arthur Murray; Miss P.E .Mason (Phyllis Estelle?); Miss Sybil Monica Buzza; Thomas James Frayer; Australia Shaw; James David Torley; John William Zimmer; Dalkeith William Steele; William Thomas Hollingsworth; E.E. Cohen; R.S. Anderson; Frances John Perry Faith Everard Pardew and Charles Anthony Wurf. "n Britain, the Medical Act of 1858 charged the General Medical Council with the "production of a book containing the list of medicines and compounds, and the manner of preparing them together with the true weights and measures by which they are to be mixed and prepared". The British Pharmacopoeia thus became the official reference book and superseded other previous manuals" (from .South Australian Medical Heritage Society Inc" These reference books have an association with Orbost. Historical works in pharmacy show the evolution of therapeutics and the development of diverse treatment and are therefore a useful research tool. Five heavy reference books. They contain detailed information on drugs and other pharmaceutical materials with standards for substances. Details of each book are in the catalogue folder.pharmacies-orbost reference-books-pharmacy medicine drugs -

Orbost & District Historical Society

Orbost & District Historical Societycalendar, E-Gee Printers, Old Views of East Gippsland 2018, 2017

This is one a series of calendars compiled annually by East Gippsland Historical Society.This is a useful pictorial reference tool.A 2018stapled calendar, titled "Old Views of East Gippsland". On the purple coloured front is a black/white photograph of a punt on the Tambo River. It has a manual winding winch, three men on a small wharf, one man is fishing. It contains early photographs of East Gippsland, one for each month. There is a hole for hanging. The title is at the top and the year at the bottom in black print. calendar-old-views-of-east-gippsland photographs-historic-east-gippsland -

Orbost & District Historical Society

Orbost & District Historical Societybook, first half 20th century

In the early 20th century, smocking appears in women’s magazines and sewing manuals on garments, domestic textiles and children’s wear. The 1930s and 1940s were the heyday of patterns and innovative stitch development. Embroidery has always had a great appeal to women, as it needs few tools. Historically the skills were taught within the family or in primary schools. Articles to make or embroider had been available in kits since the 1850s. Fancy work, the opposite of plain sewing, enjoyed great popularity in the 19th and 20th centuries. Companies which manufactured threads often produced instruction guides and patterns. This instruction book has been well-used. A small 30pp book with no cover. It contains instructions for embroidery stitches, including smocking.book-embroidery smocking handcraft needlework -

Federation University Historical Collection

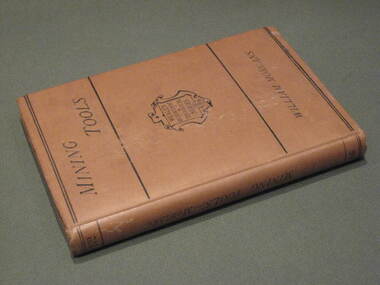

Federation University Historical CollectionBook, Manual of Mining Tools, 1871, 1871

... . Manual of Mining Tools, 1871 Book Book William Morgans Lockwood ...The author, William Morgans, was a lecturer on mining at the Bristol School of Mines. The owner of the book, William Baragwanath, was a former student of the Ballarat School of Mines who held the following positions: Department of Mines (1897-1922); director of the geological survey (1922-24); chief mining surveyor (1924-32); secretary for mines (1932-34); chief mining surveyor (1934-43); consultant to the Department of Mines (1943-50); President, Royal Society of Victoria (1943-44), councillor of the Ballarat School of Mines (1916-50).Hard cover book of 207 pages with buff cloth cover. The books covers materials andf processes used in the manufacture of tools, special uses, qualities and efficiciency. It includes 235 wood engravings of mining tools drawn to scale. Tools include borers, hammers, sledges, picks, shovels, spades, saws, helves and handles.Title page handwritten in ink 'W.B.' [William Baragwanath]mining, tools, ballarat school of mines, geology, bristol school of mines, government geologist, william baragwanath -

Federation University Historical Collection

Federation University Historical CollectionBook, Owen Jones, The Grammar of Ornament, 1868

Book featuring coloured plates of examples of historic ornamentRed cloth hard covered book of 112 plates bookplatenon-fictionBook featuring coloured plates of examples of historic ornamentornament, grammar, plates -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Equipment - Barbers’ Equipment, hair clippers steel 'Brown & Sharpe", c1940

1833 Brown & Sharpe was founded in Providence, Rhode Island by David Brown and his son Joseph R. Brown. David Brown retired in 1841 and Joseph Brown formed a partnership with Lucian Sharpe in 1853. During the 19th and 20th centuries, Brown & Sharpe was one of the best-known and most influential machine tool builders and was a leading manufacturer of instruments for machinists (such as micrometers and indicators ) and helped establish: The American wire gauge (AWG) standards for wire; The Brown & Sharpe taper in machine tool spindle tapers; and The Brown & Sharpe worm threadform for worm gears. .Like most machine tool builders, Brown & Sharpe rode a business cycle roller coaster during 1920- 40. After being kept very busy during World War I, builders suffered a slump in the post–World War I recession and depression of 1920–21. The Roaring Twenties brought renewed sales, but then the Great Depression slashed them. The armament-build-up period of 1936 to 1940 again renewed machine tool activity, and then the World War II materiel effort exploded demand, pushing it to record heights and employed 11,000 workers. Brown and Sharpe machine tools were a mainstay of American metal manufacturing until the late 20th Century and could be found in most machine shops and factories that worked with metal. Brown and Sharpe made callipers and micrometers that were essential to products built to fine tolerances. Shortly after World War II, Henry D. Sharpe, Jr. succeeded his father as president of Brown & Sharpe Manufacturing Company, at which point it evolved into a new and modern company built, or at least designed, to last. The firm stopped producing its old stalwarts: sewing machines, hair clippers, and certain categories of machine tools and employment dropped to 3,500 in 1976. Due to industrial disputes in the 1980’s B&S started focusing more on developing Coordinate-Measuring Machines. The company began to lose money as it shifted production away from machine tools and toward advanced metrology equipment, losing $14.6 million in 1990 and employed only 700. In 1994 Brown & Sharpe acquired DEA of Italy, an established manufacturer of CMMs. In 2001, substantially all of the assets of the Brown & Sharpe Manufacturing Company, including the intellectual property, designs, trademarks, facilities and inventory, were acquired by Hexagon AB, Switzerland, without the acquisition of the Brown & Sharpe Manufacturing Company itself. A set of manual barbers’ hair clippers with an adjustable wing screw, from Brown and Sharpe, Manufacturing Company Ltd., Providence, Rhode Island, USA. Chrome plated, in fair condition, c1940on Right handle; MADE BY BROWN & SHARPE MFG. CO. POV. R.I. / PAT'D IN GREAT BRITAIN, EN FRANCE, S.G.D.G. / U.S.A. PATENTS JULY 1-79, JUNE 3-84, AUG 23- 92 on top blade ; BRESSANT / TRADEMARK on base of lower blade ; No. 2* barbers, hairdressers, hair clippers, brown and sharpe manufacturing company, providence rhode island, hexagon ab, switzerland, great britain, france, ww1 1914-1918, ww11 1939-1945, great depression 1930, micrometers, tools, precision instruments, brown david, brown joseph r , sharpe lucian, sharpe henry d jnr, american wire gauge standard, sewing machines, metrological tools, worm gears, spindle tapers, screw machines, moorabbin, bentleigh, cheltenham, city of moorabbin industries, -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Machine - Dairy, Milk Separator manual, c1900

A separator is a centrifugal device that separates milk into cream and skimmed milk. Separation was commonly performed on farms in the past where farmers milked a few cows, usually by hand, and separated by letting milk sit in a container until the cream floated to the top when it could be skimmed off by hand. Some of the skimmed milk was consumed while the rest was used to feed calves and pigs. Enough cream was saved to make butter, and the excess was sold. Manual rotation of the separator handle turns a mechanism which causes the separator bowl to spin at thousands of revolutions per minute. When spun, the heavier milk is pulled outward against the walls of the separator and the cream, which is lighter, collects in the middle. The cream and milk then flow out of separate spouts. Montgomery Ward was founded by Aaron Montgomery Ward in 1872.as a mail-order business in Chicago, Illinois USA. Rural customers were attracted by the wide selection of items that were unavailable to them locally and were also inspired by the innovative company policy of "satisfaction guaranteed or your money back".This milk separator is typical of the type used by early settlers in Moorabbin Shire where every family owned a 'house cow' to supply their dairy needs. Households also kept a few chickens for eggs and developed a vegetable garden with additional fruit trees. A 'primrose' manual milk separator 'Montgomery Ward', Chicago USA c1900'primrose ' / SATTLEY / MONTGOMERY WARD/ CHICAGOearly settlers, dairy farmers, milk products, dairies, market gardeners, blacksmiths, tools, moorabbin shire, bentleigh, mckinnon, highett, cheltenham, moorabbin -

National Vietnam Veterans Museum (NVVM)

National Vietnam Veterans Museum (NVVM)Manual, United States Army, Organizational, Direct Support and General Support Maintenance Repair Parts and Special Tools List For Howitzer, Light, Towed: 105 mm Soft Cecoil XM 204, 1976

A cream coloured manual with black writing on the front cover. In the middle there is a scetch of a Howitzer. On the top right hand someone has written RAA Trails Unit Lab. At the bottom of the cover reads Janualy 1976. them manual is held together by four stapleshowitzers, military weapons -

National Vietnam Veterans Museum (NVVM)

National Vietnam Veterans Museum (NVVM)Manual, United States Army, Operator And Organisational Maintenance Repair Parts and Special Tool List for Submachine Guns, Caliber .45, M3 and M3A1 (2 copies), 1957

A cream coloured manual with black writing. There are three punch holes down the left hand side of the manual. There is a heading "Department of the Army Technical Manual at the top of the manual. the manual is stored in a plastic folder.military weapons, submachine guns -

Moorabbin Air Museum

Moorabbin Air MuseumManual (collection) - Rolls Royce turbojet tool kits, Service Tool Kits For Rolls Royce Turbo Jet Engines

... Engines Manual Rolls Royce turbojet tool kits ...List and description of tools for maintenance of R & R turbo jet engines