Showing 13 items matching "mechanical advantage"

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Ship Rope Block, Russell & Co, Circa 1886

... mechanical advantage... for the mechanical advantage they provide for lifting, moving and re... are used for the mechanical advantage they provide for lifting ...This double-sheaved wooden ship’s block or pulley is a mechanical device used for lifting and moving heavy objects. It has two grooved wheels joined together, each with an axle between the cheeks or sides of the grooved wheel. Blocks and tackle are included in a ship’s rigging. These pulleys and ropes are used for the mechanical advantage they provide for lifting, moving and re-arranging the setting of the sails, which are very heavy work. Blocks are also used to load and unload the ship’s cargo. The FALLS of HALLADALE- The sailing ship Falls of Halladale was an iron-hulled, four-masted barque, used as a bulk carrier of general cargo. She left New York in August 1908 bound for Melbourne and Sydney. In her hold was general cargo consisting of roofing tiles, barbed wire, stoves, oil, and benzene as well as many other manufactured items. After three months at sea and close to her destination, a navigational error caused the Falls of Halladale to be wrecked on a reef off the Peterborough headland on the 15th of November, 1908. The captain and 29 crew members survived, but her cargo was largely lost, despite two salvage attempts in 1908-09 and 1910. The Court of Marine Inquiry in Melbourne ruled that the foundering of the ship was entirely due to Captain David Wood Thomson's navigational error, not too technical failure of the Clyde-built ship. The Falls of Halladale was built in1886 by Russell & Co., at Greenock shipyards on the River Clyde, Scotland for Wright, Breakenridge & Co of Glasgow. The ship had a sturdy construction built to carry maximum cargo and was able to maintain full sail in heavy gales, one of the last of the 'windjammers' that sailed the Trade Route. She and her sister ship, the Falls of Garry, were the first ships in the world to include fore and aft lifting bridges. The new, raised catwalk-type decking allowed the crew to move above the deck in stormy conditions.This artefact is important as it is an example of the materials and design of late-19th century ship’s rigging equipment. The object is also significant for its association with the historic sailing ship Falls of Halladale, wrecked in local waters in the early 20th century. The clipper ship Falls of Halladale shipwreck is of historical significance and is listed on the Victorian Heritage Register, No. S255. She was one of the last ships to sail the Trade Routes. She was one of the first vessels to have fore and aft lifting bridges. The vessel is an example of the remains of an international cargo ship and also represents aspects of Victoria’s shipping industry.Ship's block; a double-sheave wooden block with thick concretion on it. The rope block was recovered from the wreck of the sailing ship, Falls of Halladale.Noneflagstaff hill, maritime museum, maritime village, warrnambool, great ocean road, shipwreck coast, falls of halladale, shipwreck, peterborough, 1908 shipwreck, peterborough shipwreck, russell & co., greenock, wright breakenridge & co. glasgow, clipper ship, machine, mechanical advantage, block, wooden block, pulley, tackle, sheave, ship rigging, double-sheave, twin sheave, captain david wood thomson, iron ship, four-masted ship, sailing ship, windjammer, clyde, wright, breakenridge & co of glasgow, fore and aft lifting bridges -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Ship Rope Block, Russell & Co, Circa 1886

... mechanical advantage... for the mechanical advantage they provide for lifting, moving and re... are used for the mechanical advantage they provide for lifting ...This double-sheaved wooden ship’s block or pulley is a mechanical device used for lifting and moving heavy objects. It has two grooved wheels joined together, each with an axle between the cheeks or sides of the grooved wheel. Blocks and tackle are included in a ship’s rigging. These pulleys and ropes are used for the mechanical advantage they provide for lifting, moving and re-arranging the setting of the sails, which are very heavy work. Blocks are also used to load and unload the ship’s cargo. The FALLS of HALLADALE- The sailing ship Falls of Halladale was an iron-hulled, four-masted barque, used as a bulk carrier of general cargo. She left New York in August 1908 bound for Melbourne and Sydney. In her hold was general cargo consisting of roofing tiles, barbed wire, stoves, oil, and benzene as well as many other manufactured items. After three months at sea and close to her destination, a navigational error caused the Falls of Halladale to be wrecked on a reef off the Peterborough headland on the 15th of November, 1908. The captain and 29 crew members survived, but her cargo was largely lost, despite two salvage attempts in 1908-09 and 1910. The Court of Marine Inquiry in Melbourne ruled that the foundering of the ship was entirely due to Captain David Wood Thomson's navigational error, not too technical failure of the Clyde-built ship. The Falls of Halladale was built in1886 by Russell & Co., at Greenock shipyards on the River Clyde, Scotland for Wright, Breakenridge & Co of Glasgow. The ship had a sturdy construction built to carry maximum cargo and was able to maintain full sail in heavy gales, one of the last of the 'windjammers' that sailed the Trade Route. She and her sister ship, the Falls of Garry, were the first ships in the world to include fore and aft lifting bridges. The new, raised catwalk-type decking allowed the crew to move above the deck in stormy conditions.This artefact is important as it is an example of the materials and design of late-19th century ship’s rigging equipment. The object is also significant for its association with the historic sailing ship Falls of Halladale, wrecked in local waters in the early 20th century. The clipper ship Falls of Halladale shipwreck is of historical significance and is listed on the Victorian Heritage Register, No. S255. She was one of the last ships to sail the Trade Routes. She was one of the first vessels to have fore and aft lifting bridges. The vessel is an example of the remains of an international cargo ship and also represents aspects of Victoria’s shipping industry.Rope block, wooden double-sheave mechanical device with a short length of chain attached and remnants of the metal frame. It was recovered from the Falls of Halladale.Noneflagstaff hill, maritime museum, maritime village, warrnambool, great ocean road, shipwreck coast, falls of halladale, shipwreck, peterborough, 1908 shipwreck, peterborough shipwreck, russell & co., greenock, wright breakenridge & co. glasgow, clipper ship, block and rigging, ship’s block, iron ship, four-masted ship, sailing ship, windjammer, clyde, wright, breakenridge & co of glasgow, fore and aft lifting bridges, machine, mechanical advantage, block, wooden block, pulley, tackle, sheave, ship rigging, double-sheave, twin sheave, captain david wood thomson -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyWoodworking Tool - Adjustable Wrench

... and mechanical advantage in applying torque to turn objects eg. nuts.... This wrench is a tool used to provide grip and mechanical advantage ...Very old. The design of wrenches has varied over the years. This one has a screw/nut that moves the moving jaw towards the fixed jaw.Used by residents of the Kiewa ValleySolid steel. This wrench is a tool used to provide grip and mechanical advantage in applying torque to turn objects eg. nuts and bolts. This wrench is adjustable - by turning the 'nut' in the middle of the tool it allows the 'jaws' of the wrench to open to the required size.adjustable wrench, tool -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietySquare Headed Wrench

... ro provide grip and mechanical advantage in applying torque... which is used ro provide grip and mechanical advantage ...Used to tighten fasteners. This wrench is large so may have been used for fasteners on farm machinery or in the SECV workshop.Used by residents and workers in the Kiewa Valley.Cast iron or steel - 1 and three sixteenth of an inch embossed on one side and 8 and a quarter inches long on the other. This wrench has a square hollow (box ring) at one end which is used ro provide grip and mechanical advantage in applying torque to turn objects - usually rotary fasteners, such as nuts and bolts - or keep them from turning.embossed measurement on the handlewrench, tool -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Rope Block, Mid to Late 19th

... mechanical advantage. In general, the more sheaves in the blocks... of a tackle refers to its mechanical advantage. In general, the more ...A sailing block is single or multiple pulleys with one or more sheaves that are enclosed in an assembly between cheeks or chocks. In use, a block is fixed to the end of a line, to a spar, or a surface. A rope line is reeved through the sheaves, and maybe through one or more matching blocks at the far end, to make up what's known as a tackle. The purchase of a tackle refers to its mechanical advantage. In general, the more sheaves in the blocks that make up a tackle, the higher its mechanical advantage. The matter is slightly complicated by the fact that every tackle has a working end where the final run of rope leaves the last sheave. More mechanical advantage can be obtained if this end is attached to the moving load rather than the fixed end of the tackle. Various types of blocks are used in sailing. Some blocks are used to increase mechanical advantage and others are used simply to change the direction of a line. A ratchet block turns freely when a line is pulled in one direction but does not turn the other direction, although the line may slip past the sheave. This kind of block makes a loaded line easier to hold by hand, and is sometimes used on smaller boats for lines like main and jib sheets that are frequently adjusted. A single, large, sail-powered warship in the mid-19th century required more than 1,400 blocks of various kinds and sizes. An item from an old sailing vessel from the late 19th to early 20th century, unfortunately, the item cannot be identified as to what vessel it belonged to. It does however give an insight into a piece of sailing equipment that's design is still in use today on pleasure sailing craft. Wooden closed spelter double rope block with two pully's between sheaves, block has metal frame around outside of the sheaves and 4 metal pins, 2 each side of the frame at top and 2 at bottom, joining the sheaves together. The shaft between the sheaves is also wooden. Remnants of orange and black paint on outside of block. Shafts are chipped, wood has borer holes. (NOTE: Block was rediscovered after relocating objects to new storage area)Noneflagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, sailing ship, pulley, block, sheave, ship equipment, rope block, sail rigging -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Block, Late 19th to early 20th century

... mechanical advantage. In general, the more sheaves in the blocks... of a tackle refers to its mechanical advantage. In general, the more ...A sailing block is single or multiple pulleys with one or more sheaves that are enclosed in an assembly between cheeks or chocks. In use, a block is fixed to the end of a line, to a spar, or a surface. A rope line is reeved through the sheaves, and maybe through one or more matching blocks at the far end, to make up what's known as a tackle. The purchase of a tackle refers to its mechanical advantage. In general, the more sheaves in the blocks that make up a tackle, the higher its mechanical advantage. The matter is slightly complicated by the fact that every tackle has a working end where the final run of rope leaves the last sheave. More mechanical advantage can be obtained if this end is attached to the moving load rather than the fixed end of the tackle. Various types of blocks are used in sailing. Some blocks are used to increase mechanical advantage and others are used simply to change the direction of a line. A ratchet block turns freely when a line is pulled in one direction but does not turn in the other direction, although the line may slip past the sheave. This kind of block makes a loaded line easier to hold by hand and is sometimes used on smaller boats for lines like main and jib sheets that are frequently adjusted. A single, large, sail-powered warship in the mid-19th century required more than 1,400 blocks of various kinds and sizes.A historic item from an old sailing vessel from the late 19th to early 20th century, unfortunately. It represents part of the rigging required to set the sails on a wind-powered vessel.A two sheave wood sailing block with metal hook and becket. One sheave missing. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, block, sailing block, two-sheave block, 2 sheave wood block, marine technology, sailing equipment, rigging, rigging block -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Rope Block, Mid-20th century

... , the higher its mechanical advantage. Various types of blocks... a tackle, the higher its mechanical advantage. Various types ...A sailing or rope block has single or multiple pulleys with one or more sheaves enclosed in an assembly between cheeks or chocks. In use, a block is fixed to the end of the line, spar or load to be lifted such as at a transport dock. A rope line is reeved through the sheaves, and through one or more matching blocks at the far end, to make up what's known as a tackle. Generally, the more sheaves in the blocks that make up a tackle, the higher its mechanical advantage. Various types of blocks are used in sailing. Some blocks are used to increase mechanical advantage and others to change the direction of a line. A ratchet block turns freely when a line is pulled in one direction but does not turn in the other direction, although the line may slip past the sheave. This kind of block makes a loaded line easier to hold by hand.This rope block is an example of rope and tackle systems used in maritime settings to lift and move cargo and machinery, often with the help of a crane. It is also used on sailing vessels as part of the rigging, help to raise and lower the ropes and sails.Block; two sheave wooden rope block with ring and becket. It features a Closed Spelter Socket (CSS). Rings are galvanised metal. There is a compliance plate attached with an inscription. It was once owned by a government body, as indicated by the 'up-arrow" symbol.Compliance plate: stamped twice "CS" [Closed Spelter] and "↑"flagstaff hill, warrnambool, shipwreck coast, flagstaff hill maritime museum, flagstaff hill maritime village, lifting equipment, stevedoring, rope block, rigging block, sailing equipment, css, closed spelter socket -

Orbost & District Historical Society

Orbost & District Historical Societypulley

... for increasing mechanical advantage in a wire, chain or rope system... for increasing mechanical advantage in a wire, chain or rope system ...This pulley was found by Geoff Stevenson, on a beach near Cape Conran (east of Orbost). It probably came from a sailing ship which was wrecked there. Pulleys are simple devices for increasing mechanical advantage in a wire, chain or rope system. A pulley consists of a wheel with a specialized rim that rotates on an axle and carries some type of cable or chain. Ships used a variety of blocks (pulleys) for various tasks, such as stowing cargo or handling the sails. A large wooden pulley encased in iron. It was probably used on a sailing ship. pulley cape-conran sailing-ship maritime -

Flagstaff Hill Maritime Museum and Village

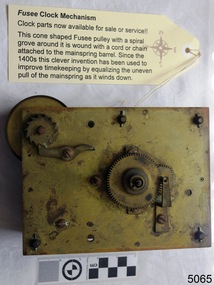

Flagstaff Hill Maritime Museum and VillageMachine - Fusee Clock Mechanism, early 20th Century

... pulley continuously changed the mechanical advantage of the pull... changed the mechanical advantage of the pull from the mainspring ...The origin of the fusee is not known. Many sources credit clockmaker Jacob Zech of Prague with inventing it around 1525. The earliest dated fusee clock was made by Zech in 1525, but the fusee appeared earlier, with the first spring-driven clocks in the 15th century. The idea probably did not originate with clockmakers, since the earliest known example is in a crossbow windlass shown in a 1405 military manuscript. Drawings from the 15th century by Filippo Brunelleschi and Leonardo da Vinci also show fusee mechanisms. The earliest existing clock with a fusee, also the earliest spring-powered clock, is the Burgunderuhr (Burgundy clock), a chamber clock whose iconography suggests that it was made for Phillipe the Good, Duke of Burgundy about 1430. Springs were first employed to power clocks in the 15th century, to make them smaller and portable.[1][5] These early spring-driven clocks were much less accurate than weight-driven clocks. Unlike a weight on a cord, which exerts a constant force to turn the clock's wheels, the force a spring exerts diminishes as the spring unwinds. The primitive verge and foliot timekeeping mechanism, used in all early clocks, was sensitive to changes in drive force. So early spring-driven clocks slowed down over their running period as the mainspring unwound. This problem is called lack of isochronism. Two solutions to this problem appeared with the first spring-driven clocks; the stack freed and the fusee. The stack freed, a crude cam compensator, added a lot of friction and was abandoned after less than a century. The fusee was a much more lasting idea. As the movement ran, the tapering shape of the fusee pulley continuously changed the mechanical advantage of the pull from the mainspring, compensating for the diminishing spring force. Clockmakers empirically discovered the correct shape for the fusee, which is not a simple cone but a hyperboloid. The first fusees were long and slender, but later ones have a squatter compact shape. Fusees became the standard method of getting constant force from a mainspring, used in most spring-wound clocks, and watches when they appeared in the 17th century. Around 1726 John Harrison added the maintaining power spring to the fusee to keep marine chronometers running during winding, and this was generally adopted. The fusee was a good mainspring compensator, but it was also expensive, difficult to adjust, and had other disadvantages: It was bulky and tall and made pocket watches unfashionably thick. If the mainspring broke and had to be replaced, a frequent occurrence with early mainsprings, the fusee had to be readjusted to the new spring. If the fusee chain broke, the force of the mainspring sent the end whipping about the inside of the clock, causing damage. The invention of the pendulum and the balance spring in the mid-17th century made clocks and watches much more isochronous, by making the timekeeping element a harmonic oscillator, with a natural "beat" resistant to change. The pendulum clock with an anchor escapement, invented in 1670, was sufficiently independent of drive force so that only a few had fusees. In pocketwatches, the verge escapement, which required a fusee, was gradually replaced by escapements which were less sensitive to changes in mainspring force: the cylinder and later the lever escapement. In 1760, Jean-Antoine Lépine dispensed with the fusee, inventing a going barrel to power the watch gear train directly. This contained a very long mainspring, of which only a few turns were used to power the watch. Accordingly, only a part of the mainspring's 'torque curve' was used, where the torque was approximately constant. In the 1780s, pursuing thinner watches, French watchmakers adopted the going barrel with the cylinder escapement. By 1850, the Swiss and American watchmaking industries employed the going barrel exclusively, aided by new methods of adjusting the balance spring so that it was isochronous. England continued to make the bulkier full plate fusee watches until about 1900. They were inexpensive models sold to the lower classes and were derisively called "turnips". After this, the only remaining use for the fusee was in marine chronometers, where the highest precision was needed, and bulk was less of a disadvantage until they became obsolete in the 1970s. Item is an example of clock mechanisms used until 1910 for many different styles of clocks and went out of fashion in the 1970s due to improvements in clock and watch making.Brass fusse clock movement, It has very heavy brass plates and wheels, high-count machined pinions, and a fusee. The mounting of the pendulum is missing and It has a recoil escapement. A fusee is a conical pulley driven through a chain by the spring barrel. As the spring runs down, the chain acts at a larger and larger radius on the conical pulley, equalising the driving torque. This keeps the rate of the clock more even over the whole run. It has motion work to drive an hour hand as well as a minute hand and the centre arbor is extended behind the back plate to drive some other mechanism.Inscription scratched on back"AM 40" flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, clock mechanism, fusee mechanism, horology -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionTool - Anvil, Bradford and Kendall, n.d

Port of Portland Collection Bradken, originally Bradford and Kendall, began as a steel foundry in Sydney in 1920 and produced BK anvils at its factories in Alexandria and Mascot NSW. Leslie Bradford (General Manager) and Jim Kendall (Chief Mechanical Engineer), two BHP steelworks employees, got lucky at the races one day in 1920 and pledged their £15,000 winnings to start a steel foundry business. The horse they backed, ‘Jack Findlay’ completed a remarkable sequence of five wins during 1919 and 1920. With each win Leslie Bradford, Jim Kendall and a group of friends rolled-over their bets. By January 24, 1920 they had won a small fortune. On April 28 1920, the group used their winnings to establish the Alloy Steel Syndicate and build a steel foundry in Alexandria, Sydney to take advantage of what they saw as an untapped potential for industrial growth. Bradford Kendall Ltd was incorporated on 20th March 1922.Metal blacksmiths anvil. An anvil is used by blacksmiths to forge and shape his work pieces. The conical horn is used for hammering curved work pieces. The anvil is a common tool of the blacksmiths (‘smithies’) and other metalworkers. There has been very little change in the basic design of the anvil since Greek and Roman times. Blacksmith anvil, 5CWT, iron BK Sydney Australia.Front: 'BK SYDNEY AUST. 5CWT' Back: -port of portland, anvil, blacksmith, industry, bk anvil, bradken, brandford and kendall -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Document, Prospectus Leahy's Electrical, 1951

This prospectus contains the history of Leahy's electrical . The objectives of this company were to allow expansion of the present business ( est,1946) , to take advantage of the excellent corner site and to modernise the building and carry all heavy duty electrical and mechanical lines for commercial users and farmers.Attached was a hire car services which operated as Leahy's Hire cars. The service of the the previous business commenced in 1946 at 82 Fairy Street and grew to employ up to 25 tradesmen. However the assets of the business were lost May1, 1950 when building stock and plant was destroyed by fire.In October 1950 Mr leahy purchased the freehold on the corner of Liebig and Koroit Streets Warrnambool The directors of the new company were John James Leahy, John Beynon Dwyer, William John Taggart Walter, William James Croft, Martin White and James Albert Affleck. They aimed to raise 50000 pounds with 100000 shares at ten shillings each. This document shows the beginnings of one of Warrnambool's most successful 20th century companies. It lists the people associated with it from its inception many of whom were and are well known in the district. It therefore has strong social and historical significance.Cream soft card cover with dark blue text. It is stapled together and contains 6 pages on cream paper with black text.back cover is plain.Prospectus of Leahy's Electrical Industries Ltd Warrnambool Vic, 19th April 1951.warrnambool, j j leahy, jim leahy, leahy's electrical industries, prospectus leahy's electrical industries 1951 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Dentist Drill, Late 19th century

The design of this and other similar treadle powered dental engine (or dentist drill) was in common use by dentists from the 1870’s into the 1920's. When electricity became accessible to most communities the electrically powered dental engines began to take over from the treadle power. Over the ages teeth were extracted using picks and scissors and other gouging instruments. Bow drills, hand drills and even a "bur thimble" drill were later used to prepare cavities for filling. Some drills were made bendable by attaching flexible shanks between the metal bur and the handle, giving access to the teeth at the back of the mouth. Other mechanical devices were introduced along the way, such as clockwork drills, but they were hard to handle and inefficient. Over the centuries “dentistry has been performed by priests, monks and other healers. This was followed by barbers; the barber’s chair may well have been the precursor to the dental chair. “(SA Medical Heritage Society Inc.) In 1871 James Morrison patented the first commercially manufactured 'foot treadle dental engine', the first practica dental engine although others had been introduced as early as 1790 (by John Greenwood). Handmade steel burs or drills were introduced for dental handpieces, taking advantage of the significant increase in the speed of the drill. In 1891 the first machine-made steel burs were in use. The treadle drill reduced the time to prepare a cavity from hours to less than ten minutes. In 1876 the Samuel S. White Catalogue of Dentist Instruments listed a 12 ½ inch wheel diameter dental engine, with 14 bright steel parts, for sale at US $55 In today’s market, this is the equivalent to US $1200 approx. The specifications of that dental engine are very similar to the this one in our Flagstaff Hill Maritime Village’s collection. It is interesting to note that workings of a similar treadle dentist drill were used and modified to power a treadle spinning wheel of one of the volunteer spinners at Flagstaff Hill Maritime Village. The foot treadle dental engine was a milestone in dental history. “Historic importance of treadle powered machines; they made use of human power in an optimal way” (Lowtech Magazine “Short history of early pedal powered machines”) The invention of a machine to speed up the process of excavation of a tooth lead to the invention of new burs and drills for the handpieces, improving speed and the surgical process of dentistry. They were the fore-runner of today’s electrically powered dental engines. This treadle-powered dentist drill, or dentist engine, is made of iron and steel and provides power for a mechanical dental hand-piece that would be fitted with a dental tool. The drill has a three footed cast iron base, one foot being longer than the other two. A vertical C shaped frame is joined into the centre of the base, holding an axle that has a driving-wheel (or flywheel) and connecting to a crank. A slender, shoulder height post, made from telescoping pipes, joins into the top of this frame and is height adjusted by a hand tightened screw with a round knob. On the post just above the frame is a short metal, horizontal bar (to hold the hand-piece when it is not in use). A narrow tubular arm is attached to the top of the stand at a right angle and can move up and down. At the end of the arm is a firmly fixed, flexible rubber hose protected for a short distance by a sheath of thin metal. At the end of the hose there is a fitting where the drill’s hand-piece would be attached; a small, silver coloured alligator clip is also at the end. A treadle, or foot pedal, is hinged to the heel to the long foot of the base, and joined at the toe to the crank that turns the driving-wheel. There is a spring under the toe of the treadle. The metal driving-wheel has a wide rim. Touching the inside of the rim are four tubular rings that bulge towards the outside of the driving-wheel, away from the pole, and all meet at the hub of the axle. The axle is bulbous between the inside of the driving-wheel and the frame then passes through the frame and is attached on the other side. The driving-wheel has a groove around which a belt would sit. The belt would also fit around a pulley on the arm, at the top of the post. The pulley is joined to a rod inside the arm and this spins the drill's hand-piece and dental tool holder. The two shorter feet of the base are made from a long metal bar that has been curved outwards, and its centre is bolted to the base of the pole. Under the ends of the curved legs of the base are wedge shaped feet. The driving-wheel is decorated in light coloured paint on both sides, each side having three sets of floral decals evenly spaced around them, and each about a sixth of the wheel's circumference. Similar decoration is along the sides of the frame. The foot pedal has decorative cutout patterns in the centre of the foot and at the toe. On the long foot of the stand is some lettering with a fine, light coloured border around it. The lettering is hard to read, being a dark colour and flaking off. There are also remnants of fine, light coloured flourishes. The foot pedal has lettering of the maker’s trade mark cast into the metal at the ball of the foot. Lettering on the base is peeling and difficult to read. The foot pedal has a trade mark cast into it that looks like a combination of ‘C’ , ‘S’ , ‘A’, ‘R’. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, dentist, teeth, dental drill, dental engine, treadle drill, foot powered drill, treadle engine, orthodontics, dental surgery, james morrison -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Dentist Drill, Late 19th century

The design of this and other similar treadle powered dental engine (or dentist drill) was in common use by dentists from the 1870’s into the 1920's. When electricity became accessible to most communities the electrically powered dental engines began to take over from the treadle power. Over the ages teeth were extracted using picks and scissors and other gouging instruments. Bow drills, hand drills and even a "bur thimble" drill were later used to prepare cavities for filling. Some drills were made bendable by attaching flexible shanks between the metal bur and the handle, giving access to the teeth at the back of the mouth. Other mechanical devices were introduced along the way, such as clockwork drills, but they were hard to handle and inefficient. Over the centuries “dentistry has been performed by priests, monks and other healers. This was followed by barbers; the barber’s chair may well have been the precursor to the dental chair. “(SA Medical Heritage Society Inc.) In 1871 James Morrison patented the first commercially manufactured 'foot treadle dental engine', the first practica dental engine although others had been introduced as early as 1790 (by John Greenwood). Handmade steel burs or drills were introduced for dental handpieces, taking advantage of the significant increase in the speed of the drill. In 1891 the first machine-made steel burs were in use. The treadle drill reduced the time to prepare a cavity from hours to less than ten minutes. In 1876 the Samuel S. White Catalogue of Dentist Instruments listed a 12 ½ inch wheel diameter dental engine, with 14 bright steel parts, for sale at US $55 In today’s market, this is the equivalent to US $1200 approx. The specifications of that dental engine are very similar to the this one in our Flagstaff Hill Maritime Village’s collection. It is interesting to note that workings of a similar treadle dentist drill were used and modified to power a treadle spinning wheel of one of the volunteer spinners at Flagstaff Hill Maritime Village. The foot treadle dental engine was a milestone in dental history. “Historic importance of treadle powered machines; they made use of human power in an optimal way” (Lowtech Magazine “Short history of early pedal powered machines”) The invention of a machine to speed up the process of excavation of a tooth lead to the invention of new burs and drills for the handpieces, improving speed and the surgical process of dentistry. They were the fore-runner of today’s electrically powered dental engines. This treadle-powered dentist drill, or dentist engine, is made of iron and steel and provides power for a mechanical dental handpiece that would be fitted with a dental tool. On the foot is painted lettering naming it "The Brentfield" and there is a fine line of light coloured paint creating a border around the name. The paint under the lettering is peeling off. The drill has a Y-shaped, three footed cast iron base, one foot being longer than the other two. A vertical frame is joined into the centre of the base, holding an axle that has a driving-wheel (or flywheel) and connecting to a crank. A slender, shoulder height post, made from adjustable telescoping pipes, joins into the top of this frame. On the post just above the frame is a short metal, horizontal bar (to hold the hand-piece when it is not in use). A narrow tubular arm is attached to the top of the stand at a right angle and can move up, down and around. There is a pulley each side of the joint of the arm and a short way along the arm is fitted a short metal pipe. A little further along the arm a frayed-ended cord hangs down from a hole. At the end of the arm is another pulley and a joint from which hangs a long, thin metal pipe with two pulleys and a fitting on the end. A treadle, or foot pedal, is joined to the long foot of the base, and joined at the toe to the crank that turns the driving-wheel. The metal driving-wheel has a wide rim. Touching the inside of the rim are four tubular rings that bulge towards the outside of the driving-wheel, away from the pole, and all meet at the hub of the axle. The axle fits between the inside of the driving-wheel and the frame then passes through the frame and is attached on the other side. The driving-wheel has a groove around which a belt would sit. The belt would also fit around a pulley on the arm, at the top of the post. The pulley is joined to a rod inside the arm and this spins the drill's hand-piece and dental tool holder. The foot pedal has a cross-hatch pattern on the heel and the ball of the foot has tread lines across it. The end of the toe and the instep areas have cut-out pattern in them. "The ____/ Brentfield / __ DE IN L___" (Made in London) painted on the long foot of the base. Marked on the drill connection is “Richter De Trey, Germany”flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, dentist, teeth, dental drill, dental engine, treadle drill, foot powered drill, treadle engine, orthodontics, dental surgery, james morrison, the brentfield, richter de trey, german dental fitting, london dental drill