Showing 26 items matching "mechanical loader"

-

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - AUSTIN COLLECTION: mechanical loader, Williams United Gold Mine, Eaglehawk, 1987

... AUSTIN COLLECTION: mechanical loader, Williams United...mechanical loader..., Mick Lovell, operations, standing beside a mechanical loader... Western Mining GMC mine drive mechanical loader bogger Black ...Black and white photograph: underground mine photograph, Mick Lovell, operations, standing beside a mechanical loader (bogger) in drive of Williams United Gold Mine, Eaglehawk. Loader is tipping ore into a truck. gold mining, underground, williams united gold mine, eaglehawk, western mining gmc, mine drive, mechanical loader, bogger -

Glenelg Shire Council Cultural Collection

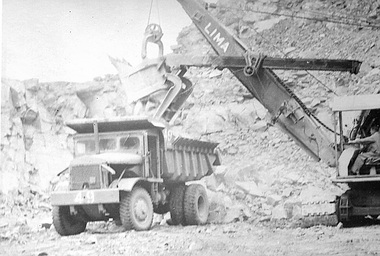

Glenelg Shire Council Cultural CollectionPhotograph - Photograph - Shovel loading truck with rocks, c. 1962

... Black and white photograph of mechanical shovel, shovel... of mechanical shovel, shovel loading truck with rocks. Photograph ...Port of Portland Authority archivesFront: (no inscriptions) Back: equ18 (pencil, lower right)port of portland -

Federation University Historical Collection

Federation University Historical CollectionDocument - Document - Design, E J Barker: University of Melbourne: Bachelor of Mechanical Engineering; Civil Engineering 1 and 1A; Design of Welded Plate Girder, 1946

Assessment No 2 Project was to design a welded plate girder required in a building to span between two steel columns which have to be spaced 60 feet centre to centre. It needs to carry its own weight plus specified loads. This was part of Civil Engineering 1A . Jack chose to do Engineering while still at Footscray Technical School as it gave access to Diploma Courses and tertiary studies. This enabled him to enter the University of Melbourne and do a Bachelor in Mechanical Engineering - 1945, 1946, and 1947. In 1948 he did a Diploma in Education at Melbourne University. From this path he was able to follow a career in teaching and his first appointment was at the School of Mines in Ballarat, (SMB) 1949. He became the first Vice Principal of SMB in 1960 and then Principal in 1964 to 1976. From 1976 to his retirement in 1987, he was the Foundation Director of Ballarat College of Advanced Education (BCAE). The Library building at Mount Helen Campus is named after him.Manila folder with design assessment. Written descriptions and detailed drawings.e j barker, jack barker, melbourne university, engineering, diploma of mechanical engineering, diploma of electrical engineering, school of mines ballarat, smb, diploma in education, vice principal, principal, foundation director, ballarat college of advanced education, bcae, bachelor of mechanical engineering, library, mount helen campus, engineering drawing, design, specifications, manufacture, civil engineering, welded plate girder, 60 feet, steel columns -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Rope Block, Mid to Late 19th

A sailing block is single or multiple pulleys with one or more sheaves that are enclosed in an assembly between cheeks or chocks. In use, a block is fixed to the end of a line, to a spar, or a surface. A rope line is reeved through the sheaves, and maybe through one or more matching blocks at the far end, to make up what's known as a tackle. The purchase of a tackle refers to its mechanical advantage. In general, the more sheaves in the blocks that make up a tackle, the higher its mechanical advantage. The matter is slightly complicated by the fact that every tackle has a working end where the final run of rope leaves the last sheave. More mechanical advantage can be obtained if this end is attached to the moving load rather than the fixed end of the tackle. Various types of blocks are used in sailing. Some blocks are used to increase mechanical advantage and others are used simply to change the direction of a line. A ratchet block turns freely when a line is pulled in one direction but does not turn the other direction, although the line may slip past the sheave. This kind of block makes a loaded line easier to hold by hand, and is sometimes used on smaller boats for lines like main and jib sheets that are frequently adjusted. A single, large, sail-powered warship in the mid-19th century required more than 1,400 blocks of various kinds and sizes. An item from an old sailing vessel from the late 19th to early 20th century, unfortunately, the item cannot be identified as to what vessel it belonged to. It does however give an insight into a piece of sailing equipment that's design is still in use today on pleasure sailing craft. Wooden closed spelter double rope block with two pully's between sheaves, block has metal frame around outside of the sheaves and 4 metal pins, 2 each side of the frame at top and 2 at bottom, joining the sheaves together. The shaft between the sheaves is also wooden. Remnants of orange and black paint on outside of block. Shafts are chipped, wood has borer holes. (NOTE: Block was rediscovered after relocating objects to new storage area)Noneflagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, sailing ship, pulley, block, sheave, ship equipment, rope block, sail rigging -

Federation University Historical Collection

Federation University Historical CollectionPhotograph, Black and White, Australian Porcelain Insulator Co. Ltd Factory, 1939, 1939

Australian Porcelain Insulator Co. Ltd Factory, 1939 Four black and white photographs relating to the Australian Porcelain Insulator Co. Ltd Factory .1) exterior view .2) view of a 22kv line pin .3) mechanical test m/c pulsating load 0-35,000 .4) electrical test room 120kv - 20kva test transformer test capacity. 2 tables approximately 40 feet to 10 inches per table.australian porcelain insulator company, industrial heritage, insulators, electricity, graham beanland -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined

Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070.Whale bone was an important commodity, used in corsets, collar stays, buggy whips, and toys.Whale bone in two pieces. Advanced stage of calcification as indicated by deep pitting. Off white to grey.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whale bones, whale skeleton, whales, whale bone, corsets, toys, whips -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Block, Late 19th to early 20th century

A sailing block is single or multiple pulleys with one or more sheaves that are enclosed in an assembly between cheeks or chocks. In use, a block is fixed to the end of a line, to a spar, or a surface. A rope line is reeved through the sheaves, and maybe through one or more matching blocks at the far end, to make up what's known as a tackle. The purchase of a tackle refers to its mechanical advantage. In general, the more sheaves in the blocks that make up a tackle, the higher its mechanical advantage. The matter is slightly complicated by the fact that every tackle has a working end where the final run of rope leaves the last sheave. More mechanical advantage can be obtained if this end is attached to the moving load rather than the fixed end of the tackle. Various types of blocks are used in sailing. Some blocks are used to increase mechanical advantage and others are used simply to change the direction of a line. A ratchet block turns freely when a line is pulled in one direction but does not turn in the other direction, although the line may slip past the sheave. This kind of block makes a loaded line easier to hold by hand and is sometimes used on smaller boats for lines like main and jib sheets that are frequently adjusted. A single, large, sail-powered warship in the mid-19th century required more than 1,400 blocks of various kinds and sizes.A historic item from an old sailing vessel from the late 19th to early 20th century, unfortunately. It represents part of the rigging required to set the sails on a wind-powered vessel.A two sheave wood sailing block with metal hook and becket. One sheave missing. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, block, sailing block, two-sheave block, 2 sheave wood block, marine technology, sailing equipment, rigging, rigging block -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined

Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070.Whale bone was an important commodity, used in corsets, collar stays, buggy whips, and toys.Whale bone piece. Advanced stage of calcification as indicated by deep pitting. Off white to grey.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whales, whale bone, corsets, toys, whips -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined

Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070. Whale bone was an important commodity, used in corsets, collar stays, buggy whips, and toys.Whale bone vertebrae. Advanced stage of calcification as indicated by deep pitting. Off white to grey.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whales, whale bone, corsets, toys, whips -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Ship Rope Block, Russell & Co, Circa 1886

This double-sheaved wooden ship’s block or pulley is a mechanical device used for lifting and moving heavy objects. It has two grooved wheels joined together, each with an axle between the cheeks or sides of the grooved wheel. Blocks and tackle are included in a ship’s rigging. These pulleys and ropes are used for the mechanical advantage they provide for lifting, moving and re-arranging the setting of the sails, which are very heavy work. Blocks are also used to load and unload the ship’s cargo. The FALLS of HALLADALE- The sailing ship Falls of Halladale was an iron-hulled, four-masted barque, used as a bulk carrier of general cargo. She left New York in August 1908 bound for Melbourne and Sydney. In her hold was general cargo consisting of roofing tiles, barbed wire, stoves, oil, and benzene as well as many other manufactured items. After three months at sea and close to her destination, a navigational error caused the Falls of Halladale to be wrecked on a reef off the Peterborough headland on the 15th of November, 1908. The captain and 29 crew members survived, but her cargo was largely lost, despite two salvage attempts in 1908-09 and 1910. The Court of Marine Inquiry in Melbourne ruled that the foundering of the ship was entirely due to Captain David Wood Thomson's navigational error, not too technical failure of the Clyde-built ship. The Falls of Halladale was built in1886 by Russell & Co., at Greenock shipyards on the River Clyde, Scotland for Wright, Breakenridge & Co of Glasgow. The ship had a sturdy construction built to carry maximum cargo and was able to maintain full sail in heavy gales, one of the last of the 'windjammers' that sailed the Trade Route. She and her sister ship, the Falls of Garry, were the first ships in the world to include fore and aft lifting bridges. The new, raised catwalk-type decking allowed the crew to move above the deck in stormy conditions.This artefact is important as it is an example of the materials and design of late-19th century ship’s rigging equipment. The object is also significant for its association with the historic sailing ship Falls of Halladale, wrecked in local waters in the early 20th century. The clipper ship Falls of Halladale shipwreck is of historical significance and is listed on the Victorian Heritage Register, No. S255. She was one of the last ships to sail the Trade Routes. She was one of the first vessels to have fore and aft lifting bridges. The vessel is an example of the remains of an international cargo ship and also represents aspects of Victoria’s shipping industry.Ship's block; a double-sheave wooden block with thick concretion on it. The rope block was recovered from the wreck of the sailing ship, Falls of Halladale.Noneflagstaff hill, maritime museum, maritime village, warrnambool, great ocean road, shipwreck coast, falls of halladale, shipwreck, peterborough, 1908 shipwreck, peterborough shipwreck, russell & co., greenock, wright breakenridge & co. glasgow, clipper ship, machine, mechanical advantage, block, wooden block, pulley, tackle, sheave, ship rigging, double-sheave, twin sheave, captain david wood thomson, iron ship, four-masted ship, sailing ship, windjammer, clyde, wright, breakenridge & co of glasgow, fore and aft lifting bridges -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Photograph, Black & White Horse drawn scoops earthwork in Moorabbin Shire c1900, c1900

The, horse drawn metal scoop ,guided by a man, was used to clear earth for road making. Well before the introduction of motorised, mechanical graders and trucks the painstaking, labour-intensive work was undertaken by large teams of sturdy men using strong horses such as the draught horse. Roads were needed by the market gardeners to transport their produce to market. Later as the heavy wagon loads continually caused ruts and general degradation of the roadways a Plateway system was installed so that the wagon wheels could roll along the rails thus protecting the roadways. August 31st 2021 Ron Nash, from WA, informs us "The men and horses pulling earth scoops in the photo are not moving earth for road making - they are excavating an "earth tank", or dam, as described in common nomenclature today. This skill was known as "tank sinking", and tank sinkers were active in many rural and remote areas in the 1800's and early 1900's, establishing sizeable dams for important water reserves for community and farm and railway use. With the advent of mechanised equipment such as bulldozers, the trade of tank sinking was still carried out, but on a faster basis. I am a former tank sinker and earth moving contractor, now long retired." Early settlers in Moorabbin Shire had to build the roads, plateways, drains, as the settlement of the land, in Dendy's Special Survey 1841 Brighton, spread and market gardeners need to transport their produce to market. Their most valuable possession was the draught horse that was used for ploughing, drawing carts and these scoops.Black & White photograph showing many horses pulling metal scoops guided by men to move earth for road making in Moorabbin Shire c 1900Back Handwritten Informationplateway, roadworks moorabbin shire, draught horses, metal scoops, paviers, box alonzo, smith j l; chaff cutter, horse drawn carts, toll gates brighton, motor cars 1900, steam engines, early settlers, bentleigh, mckinnon, parish of moorabbin, city of moorabbin, county of bourke, moorabbin roads board, shire of moorabbin, henry dendy's special survey 1841, were j.b.; bent thomas, o'shannassy john, king richard, charman stephen, highett william, ormond francis, maynard dennis, market gardeners, vineyards, orchards -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Ship Rope Block, Russell & Co, Circa 1886

This double-sheaved wooden ship’s block or pulley is a mechanical device used for lifting and moving heavy objects. It has two grooved wheels joined together, each with an axle between the cheeks or sides of the grooved wheel. Blocks and tackle are included in a ship’s rigging. These pulleys and ropes are used for the mechanical advantage they provide for lifting, moving and re-arranging the setting of the sails, which are very heavy work. Blocks are also used to load and unload the ship’s cargo. The FALLS of HALLADALE- The sailing ship Falls of Halladale was an iron-hulled, four-masted barque, used as a bulk carrier of general cargo. She left New York in August 1908 bound for Melbourne and Sydney. In her hold was general cargo consisting of roofing tiles, barbed wire, stoves, oil, and benzene as well as many other manufactured items. After three months at sea and close to her destination, a navigational error caused the Falls of Halladale to be wrecked on a reef off the Peterborough headland on the 15th of November, 1908. The captain and 29 crew members survived, but her cargo was largely lost, despite two salvage attempts in 1908-09 and 1910. The Court of Marine Inquiry in Melbourne ruled that the foundering of the ship was entirely due to Captain David Wood Thomson's navigational error, not too technical failure of the Clyde-built ship. The Falls of Halladale was built in1886 by Russell & Co., at Greenock shipyards on the River Clyde, Scotland for Wright, Breakenridge & Co of Glasgow. The ship had a sturdy construction built to carry maximum cargo and was able to maintain full sail in heavy gales, one of the last of the 'windjammers' that sailed the Trade Route. She and her sister ship, the Falls of Garry, were the first ships in the world to include fore and aft lifting bridges. The new, raised catwalk-type decking allowed the crew to move above the deck in stormy conditions.This artefact is important as it is an example of the materials and design of late-19th century ship’s rigging equipment. The object is also significant for its association with the historic sailing ship Falls of Halladale, wrecked in local waters in the early 20th century. The clipper ship Falls of Halladale shipwreck is of historical significance and is listed on the Victorian Heritage Register, No. S255. She was one of the last ships to sail the Trade Routes. She was one of the first vessels to have fore and aft lifting bridges. The vessel is an example of the remains of an international cargo ship and also represents aspects of Victoria’s shipping industry.Rope block, wooden double-sheave mechanical device with a short length of chain attached and remnants of the metal frame. It was recovered from the Falls of Halladale.Noneflagstaff hill, maritime museum, maritime village, warrnambool, great ocean road, shipwreck coast, falls of halladale, shipwreck, peterborough, 1908 shipwreck, peterborough shipwreck, russell & co., greenock, wright breakenridge & co. glasgow, clipper ship, block and rigging, ship’s block, iron ship, four-masted ship, sailing ship, windjammer, clyde, wright, breakenridge & co of glasgow, fore and aft lifting bridges, machine, mechanical advantage, block, wooden block, pulley, tackle, sheave, ship rigging, double-sheave, twin sheave, captain david wood thomson -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Rope Block, Mid-20th century

A sailing or rope block has single or multiple pulleys with one or more sheaves enclosed in an assembly between cheeks or chocks. In use, a block is fixed to the end of the line, spar or load to be lifted such as at a transport dock. A rope line is reeved through the sheaves, and through one or more matching blocks at the far end, to make up what's known as a tackle. Generally, the more sheaves in the blocks that make up a tackle, the higher its mechanical advantage. Various types of blocks are used in sailing. Some blocks are used to increase mechanical advantage and others to change the direction of a line. A ratchet block turns freely when a line is pulled in one direction but does not turn in the other direction, although the line may slip past the sheave. This kind of block makes a loaded line easier to hold by hand.This rope block is an example of rope and tackle systems used in maritime settings to lift and move cargo and machinery, often with the help of a crane. It is also used on sailing vessels as part of the rigging, help to raise and lower the ropes and sails.Block; two sheave wooden rope block with ring and becket. It features a Closed Spelter Socket (CSS). Rings are galvanised metal. There is a compliance plate attached with an inscription. It was once owned by a government body, as indicated by the 'up-arrow" symbol.Compliance plate: stamped twice "CS" [Closed Spelter] and "↑"flagstaff hill, warrnambool, shipwreck coast, flagstaff hill maritime museum, flagstaff hill maritime village, lifting equipment, stevedoring, rope block, rigging block, sailing equipment, css, closed spelter socket -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined

Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070.Whale bone was an important commodity, used in corsets, collar stays, buggy whips, and toys.Whale bone piece. Advanced stage of calcification as indicated by deep pitting. Off white to grey.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whales, whale bone, corsets, toys, whips -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined

Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070.Whale bone was an important commodity, used in corsets, collar stays, buggy whips, and toys.Whale bone piece. Advanced stage of calcification as indicated by deep pitting. Off white to grey.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whales, whale bone, corsets, toys, whips -

Puffing Billy Railway

Puffing Billy RailwayD21 - Diesel Mechanical locomotive, 1968

D21 - Diesel Mechanical locomotive Date built - 1968 Original owner - TGR Original gauge - 1067mm Withdrawn - 1983 Built to 3'6" gauge in 1968 by the Tasmanian Government Railways and numbered V12, ownership of this Diesel Mechanical locomotive was transferred to Australian National Railways (Tas.) in 1978. It was withdrawn and sold to the E.T.R.B. in 1983 1968 - D21 ex-Tasmanian Government Railways (TGR) V class No.12, built by the TGR Launceston Workshops in 1968 to a design of Vulcan-Drewry (England). Tasmanian Government Railways V class The V class were the first diesel locomotives operated by the Tasmanian Government Railways (TGR) with four delivered by the Vulcan Foundry in 1948 to a design by the Drewry Car Co. They were a narrow gauge version of the British Rail Class 04. In 1951 a fellow two were delivered followed by another two in 1955. Between 1959 and 1968 the TGR built a further four at its Launceston Workshops. Two identical locomotives were purchased by the Mount Lyell Mining and Railway Company in 1953. When it closed in 1963, 2405 was sold to the Emu Bay Railway as number 22, while 2406 went to the TGR as V13. All the TGR units were withdrawn between 1983 and 1987 while the Emu Bay unit remained in service until 2000. Ten have been preserved: V1 by the Bellarine Peninsula Railway, Victoria V2 by the Don River Railway V4 by the Hotham Valley Railway, Western Australia V5 by the Hotham Valley Railway, Western Australia V7 by the Derwent Valley Railway V8 by the Bellarine Peninsula Railway, Victoria V9 by the West Coast Wilderness Railway V12 by the Puffing Billy Railway, Victoria (regauged to 760 mm gauge and numbered D21) V13 by the Zig Zag Railway, New South Wales, sold to the West Coast Wilderness Railway, renumbered D2 22 by the West Coast Wilderness Railway, renumbered D1 Tasmanian Government Railways V class Manufacturer Vulcan Foundry Tasmanian Government Railways Entered service 1948 Number built 14 Number preserved 10 Fleet numbers TGR: V1-V13 Emu Bay: 22 Power: 152kW (204hp) or 114kW (153hp) Motor: Gardner 8L3 (V) or Gardner 6L3 (VA) Wheel Arrangement: - C - Weight: 25.6t Allowable load on 1:40 grade: 170t Length over headstocks: 6.8m (22ft 6in) Introduced: 1948 Built By: Vulcan Foundry, England; TGR Workshops, Launceston; Using parts supplied by Drewry Car Co (UK) Number Preserved: 10 Number In Service: 0 Total Number Built: 14Historic - Tasmanian Government Railways - Diesel Mechanical locomotive - V12 / Puffing Billy Railway Diesel Mechanical locomotive D21D21 - Diesel Mechanical locomotive made of steel D21diesel mechanical locomotive, puffing billy, d21, v12 diesel mechanical locomotive, d21 diesel mechanical locomotive, tasmanian government railways -

Puffing Billy Railway

Puffing Billy RailwayNRT1, Ruston & Hornsby Diesel Locomotive, 1951

NRT1 - Ruston & Hornsby Diesel Locomotive Built in 1951 to a gauge of 3', this Ruston diesel locomotive or rail tractor operated on the State Electricity Commission of Victoria’s Kiewa scheme. Some years later, it was regauged to 2'6" and was operated by the Melbourne & Metropolitan Board of Works. NRT1 is a Ruston & Hornsby diesel locomotive, built in England in 1951 to a gauge of 3 feet, and was initially employed by the State Electricity Commission of Victoria. It was later re-gauged to 2' 6" and ended it's working life in 1977 when it was transferred to Puffing Billy. In 1977, it was taken to the P.B.P.S. Steam Museum and stored until 1978 when it was taken to the Emerald Carriage Workshops. Later in 1983 it was returned to service as NRT1 following the V.R. classification procedure as a narrow-gauge rail tractor, but it had number plates installed and was painted Hawthorn green. It will eventually be painted the red of V.R. rail tractors with the number & class painted on in black. This type of locomotive was popular in many industrial locations, with their unique clutch-less 3 speed gearbox meaning the driver could control them whilst walking alongside, a bonus when shunting. Adjustable tie rods meant that as the axles moved on the springs, they followed the radius of the drive chains, reducing the chances of chain snatch LOCOMOTIVE DETAILS NRT class No. originally constructed : No. in service : 1 No. stored: Wheel arrangement : 0-4-0DM Roadworthy weight : 9T 3cwt. Maximum axle load : 4T 15cwt. Tractive effort (85%) : Length overall: 15' 6" Height overall: 10' Driving wheel diameter: 18" Date of manufacture: 1950 Manufacturer : Ruston Hornsby Place of manufacture: Lincoln, England Locomotive type : Diesel Mechanical Manufacturers classification : 48 DL Historic - Industrial narrow Gauge Railway - Ruston & Hornsby diesel locomotive used by State Electricity Commission of Victoria - NRT1 - Ruston & Hornsby Diesel Locomotive NRT1 - Ruston & Hornsby Diesel Locomotive made of steel NRT1 ruston & hornsby diesel locomotive, nrt1 diesel locomotive, nrt1, puffing billy -

Melton City Libraries

Melton City LibrariesDocument, Service of Celebration and Thanksgiving for the life of Ernest Wesley Barrie (Bon) 1909-1985, 1985

SUMMARY - Ernest W (Bon) Barrie, 1909 – 1985 Profile Melton Mechanics Institute Member 1935 - 1982i Trustee 1952 - 1982 Life Member 1968 Years of service – 47 years He constructed and provided a public address system which was used at Melton and district halls and sports grounds for a wide variety of community events including school sports, gymkhanas, theatrical productions and processions. Fire Brigade Melton Fire Brigade (and predecessor Bush Fire Brigade) Apparatus Officer, 1945 - 1953 Captain, 1951 - 1965 Mt Cotterill Fire Brigades’ Group Elected Group Officer, on the formation of the Group, 1967. As Group Communications Officer he operated the VL3 LY base radio station from home on a 24 hour basis for fire brigades of Melton, Rockbank, Sydenham, Diggers Rest, Toolern Vale, Truganina and Werribee. With his brother Edgar, he built the first Melton Fire Truck. It was housed on the family property until a fire station was constructed in the Melton township. Recipient of the Queens Medal, 1979 Recognised for 44 years of service on the Melton Fire Brigade Memorial Wall Plaque, dedicated May 2013 Melton State School, no 430 Committee – School Correspondent (secretarial and financial role) 34 years of Service Provided his Amplifier Equipment for events and the annual district School Sports from 1939-1973. Donated the House Athletic Shield Melton and District Historical Society 1968 – 1985 President and foundation member Willows Historical Park – supported the establishment of the park and contributed many volunteers hours in the construction and landscaping of the precinct Member, Western Metropolitan Groups of Historical Societies, 1980s Shire of Melton Councillor South Riding, 1969-1971 Member of the Water Trust Melton Uniting Church Melton Uniting Church (and its predecessors the Methodist, Methodist-Presbyterian churches). A lifetime association which extended from childhood when he attended Sunday school until his death in 1985. Member of the Presbyterian Board of Management for more than 25 years in which he held positions of Honorary Secretary and Treasurer, Board member of the Parish Council and Member of the Committee of Management. He was a Sunday school teacher 1933. Community development With Mr RC Butler met with Shire Council in 1937 to canvass residents to ascertain prospective Electric consumers in the district. Electricity was subsequently turned on at dusk on 20th December 1939. Melton Progress Association, including Melton Musical, Elocutionary and Vocal Competitions, Vice President 1939 1940 Melton Development Association, 1960s Volunteer Air Observers Corps (VAOC)ii Carried out plane spotting at Shire Office and spotting tower in Melton and later from home until 1944/45. Agriculture and farming Progress and Better Farming Association, Melton. Honorary Secretary, 1935 Member, Agricultural Engineering Society Australia c1960-1985 A successful grower of wheat, oats and barley, he planted experiment plots and held Field Days on the “Darlingsford” property. He later diversified into other grains and sheep (wool and meat). He took a enthusiastic interest in agricultural engineering and was keen to introduce innovative ideas that improved the productivity of farms and farming practices. In the mid 1950 he conducted trials during harvest on the family property of the original mechanical hay fork built on a British Bedford truck by Bill Gillespie. This design was further refined in collaboration with the Gillespie brothers and resulted in the construction the hydraulically operated tractor mounted hay fork. The innovative design of the hay fork created interest from far and wide and was quickly taken up by farmers because it significantly reduced hand labouring of loading sheaves of hay with a pitch fork. His father established chaff mills in Melton, Rockbank, Parwan, Diggers Rest in the first decade of 1900 and in 1915 went into partnership with JR Schutt to establish the Schutt & Barrie Pty. Ltd. Chaff Cutting and Flour Mill in West Footscray. When it ceased trading in 1968 the directors were: Ernest W Barrie and Thomas L Barrie, R, A, and M Schutt. Awards Queens Medal, 1979 Rotary Award for Community Service, 1980 Victoria 150th Anniversary Celebrations contributions, 1985 Service held at Melton Uniting Church local identities -

Melton City Libraries

Melton City LibrariesPhotograph, Bon Barrie, c.1940, Unknown

SUMMARY - Ernest W (Bon) Barrie, 1909 – 1985 Profile Melton Mechanics Institute Member 1935 - 1982i Trustee 1952 - 1982 Life Member 1968 Years of service – 47 years He constructed and provided a public address system which was used at Melton and district halls and sports grounds for a wide variety of community events including school sports, gymkhanas, theatrical productions and processions. Fire Brigade Melton Fire Brigade (and predecessor Bush Fire Brigade) Apparatus Officer, 1945 - 1953 Captain, 1951 - 1965 Mt Cotterill Fire Brigades’ Group Elected Group Officer, on the formation of the Group, 1967. As Group Communications Officer he operated the VL3 LY base radio station from home on a 24 hour basis for fire brigades of Melton, Rockbank, Sydenham, Diggers Rest, Toolern Vale, Truganina and Werribee. With his brother Edgar, he built the first Melton Fire Truck. It was housed on the family property until a fire station was constructed in the Melton township. Recipient of the Queens Medal, 1979 Recognised for 44 years of service on the Melton Fire Brigade Memorial Wall Plaque, dedicated May 2013 Melton State School, no 430 Committee – School Correspondent (secretarial and financial role) 34 years of Service Provided his Amplifier Equipment for events and the annual district School Sports from 1939-1973. Donated the House Athletic Shield Melton and District Historical Society 1968 – 1985 President and foundation member Willows Historical Park – supported the establishment of the park and contributed many volunteers hours in the construction and landscaping of the precinct Member, Western Metropolitan Groups of Historical Societies, 1980s Shire of Melton Councillor South Riding, 1969-1971 Member of the Water Trust Melton Uniting Church Melton Uniting Church (and its predecessors the Methodist, Methodist-Presbyterian churches). A lifetime association which extended from childhood when he attended Sunday school until his death in 1985. Member of the Presbyterian Board of Management for more than 25 years in which he held positions of Honorary Secretary and Treasurer, Board member of the Parish Council and Member of the Committee of Management. He was a Sunday school teacher 1933. Community development With Mr RC Butler met with Shire Council in 1937 to canvass residents to ascertain prospective Electric consumers in the district. Electricity was subsequently turned on at dusk on 20th December 1939. Melton Progress Association, including Melton Musical, Elocutionary and Vocal Competitions, Vice President 1939 1940 Melton Development Association, 1960s Volunteer Air Observers Corps (VAOC)ii Carried out plane spotting at Shire Office and spotting tower in Melton and later from home until 1944/45. Agriculture and farming Progress and Better Farming Association, Melton. Honorary Secretary, 1935 Member, Agricultural Engineering Society Australia c1960-1985 A successful grower of wheat, oats and barley, he planted experiment plots and held Field Days on the “Darlingsford” property. He later diversified into other grains and sheep (wool and meat). He took a enthusiastic interest in agricultural engineering and was keen to introduce innovative ideas that improved the productivity of farms and farming practices. In the mid 1950 he conducted trials during harvest on the family property of the original mechanical hay fork built on a British Bedford truck by Bill Gillespie. This design was further refined in collaboration with the Gillespie brothers and resulted in the construction the hydraulically operated tractor mounted hay fork. The innovative design of the hay fork created interest from far and wide and was quickly taken up by farmers because it significantly reduced hand labouring of loading sheaves of hay with a pitch fork. His father established chaff mills in Melton, Rockbank, Parwan, Diggers Rest in the first decade of 1900 and in 1915 went into partnership with JR Schutt to establish the Schutt & Barrie Pty. Ltd. Chaff Cutting and Flour Mill in West Footscray. When it ceased trading in 1968 the directors were: Ernest W Barrie and Thomas L Barrie, R, A, and M Schutt. Awards Queens Medal, 1979 Rotary Award for Community Service, 1980 Victoria 150th Anniversary Celebrations contributions, 1985 Photographs of Bon Barrielocal identities, pioneer families -

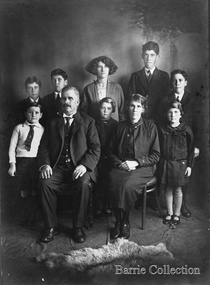

Melton City Libraries

Melton City LibrariesPhotograph, Charles Ernest and Jessie Barrie with family, Unknown