Showing 12 items matching "mechanical saw"

-

University of Melbourne, Burnley Campus Archives

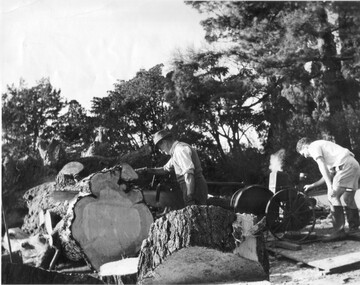

University of Melbourne, Burnley Campus ArchivesPhotograph - Black and white print, Removing the Cypress Tree, 1951

... mechanical saw... a mechanical saw on wheels to cut up the felled Cypress tree.. (b) Logs... Gardens. george manley andrew tylee staff mechanical saw cypress ...This tree was one of the earliest plantings in the Burnley Gardens.(a) George Manley and Andrew Tylee (staff) using a mechanical saw on wheels to cut up the felled Cypress tree.. (b) Logs on the lawn with the mechanical saw on wheels. Summer House behind. Also see B91.262-263.george manley, andrew tylee, staff, mechanical saw, cypress tree, summer house -

Puffing Billy Railway

Puffing Billy RailwayTool - Drag Saw, New Record Drag Saw, circa 1920s

... Large, mechanical saw mounted on a steel shaft connected... Saw puffing billy drag saw timber cutting early mechanical ...Circa 1920s petrol driven cross saw. It was mainly used cross cutting felled logs The Land on which the Menzies Creek railway station and Museum are built on was once apart of James Hermon's & his son William Hermon's property on which this Drag Saw was used. reference : Jinkers and Whims: A Pictorial History of Timber-Getting By Jack BradshawHistoric - Industrial Timber working petrol driven cross saw - Drag SawLarge, mechanical saw mounted on a steel shaft connected to tin fuel and water containers. The machine has two large spoked wheels, a rotating Crankshaft and an extended arm/rod attached to a crank and flywheel.New Record puffing billy, drag saw, timber cutting, early mechanical equipment, james hermon & sons, menzies creek, 1920s -

Orbost & District Historical Society

Orbost & District Historical Societypaling knife, c. late 19th, early 20th century

... by mechanical saws in timber mills.... by mechanical saws in timber mills. tool hand-tool paling-knife split ...Used for splitting wooden palings used in the construction of paling fences. Dates prior to palings being mass-produced by mechanical saws in timber mills.A rectangular iron blade attached to a wooden handle. The bottom of the blade is the sharp edge. tool hand-tool paling-knife split-timber -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionTool - Anvil, Bradford and Kendall, n.d

Port of Portland Collection Bradken, originally Bradford and Kendall, began as a steel foundry in Sydney in 1920 and produced BK anvils at its factories in Alexandria and Mascot NSW. Leslie Bradford (General Manager) and Jim Kendall (Chief Mechanical Engineer), two BHP steelworks employees, got lucky at the races one day in 1920 and pledged their £15,000 winnings to start a steel foundry business. The horse they backed, ‘Jack Findlay’ completed a remarkable sequence of five wins during 1919 and 1920. With each win Leslie Bradford, Jim Kendall and a group of friends rolled-over their bets. By January 24, 1920 they had won a small fortune. On April 28 1920, the group used their winnings to establish the Alloy Steel Syndicate and build a steel foundry in Alexandria, Sydney to take advantage of what they saw as an untapped potential for industrial growth. Bradford Kendall Ltd was incorporated on 20th March 1922.Metal blacksmiths anvil. An anvil is used by blacksmiths to forge and shape his work pieces. The conical horn is used for hammering curved work pieces. The anvil is a common tool of the blacksmiths (‘smithies’) and other metalworkers. There has been very little change in the basic design of the anvil since Greek and Roman times. Blacksmith anvil, 5CWT, iron BK Sydney Australia.Front: 'BK SYDNEY AUST. 5CWT' Back: -port of portland, anvil, blacksmith, industry, bk anvil, bradken, brandford and kendall -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Wringer/Mangle, Melvin Newton Lovell, 1898 -1900

Melvin Newton Lovell was born in Allegheny, Venango county, Pennsylvania, on 31 August 1844, to Darius T. Lovell (1815-1855) and Susan B. (Conover) Lovell (1827-1883). When Melvin Lovell was a boy, the family removed to Kerrtown, a village located in the vicinity of Titusville, PA. There Melvin served an apprenticeship at the carpenter's trade, and his natural mechanical talent enabled him to become a skilled workman. He followed his trade during the major portion of his term of residence in Kerrtown. In 1861, at seventeen years of age, Melvin Lovell left his home and, without parental authority, and entered the Union army soon after the outbreak of the Civil war. In August 1862, he was enlisted as a private in the 127th Pennsylvania Volunteer Infantry and saw active service until receiving his discharge at the end of May 1863. In 1865 he took up his residence in Erie, where he worked at the carpenter's trade for several years thereafter. In 1869 Melvin Lovell invented and patented several useful articles for household use, and in that year he began the manufacturing of certain of these inventions, in partnership with Franklin Farrar Adams, another inventor. Among the principal products of the original factory were washing machines and step-ladders. In 1881 Lovell individually began manufacturing other of his patents, including spring beds, and from modest inception, his Lovell Manufacturing Company grew to be one of the largest industrial concerns of its kind in the country and was recognized as being the most extensive manufacture of clothes-wringers in the entire world. In connection with his manufacture of domestic items, Lovell established sales agencies for his products in all parts of the country, and these branches were known as the Lovell stores. These goods were sold on the instalment plan and after his business had already been established becoming a substantial concern Lovell invented and patented the famous wringer which bears his name under the “Anchor” brand, and in later years he confined his operations largely to the manufacture of this very superior household invention. Lovell was also one of the organizers and stockholders of the Combination Roll & Rubber Manufacturing Co, of New York, which was formed to manufacture his patents, with headquarters in New York and a factory at Bloomfield, New Jersey.A significant household item used in the process of washing clothes by a man who had started in 1869, as a young carpenter and later he became a successful businessman and manufacturer of household items. Lovell was granted numerous patents for various devices during his career including several patents for adding machines (cash registers).Wringer (or mangle); portable wooden washing wringer with rubber rollers, manually driven by iron set of gears and handle. Includes iron clamps and adjusting screws for attaching. Marked on frame "382", "12 x 1 3/4" Anchor Brand "Made in USA" flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, mangle, clothes wringer, washing equipment, laundry, wringer, domestic, washing mangle -

Federation University Historical Collection

Federation University Historical CollectionBook, Mechanics' Magazine vol. 3, 1825 (exact)

Hardcovered book, half leather bound with marbled paper. Formerly book number 4040 from the Ballaarat East Public Library. Contents include: new pit-saw, self-moving carriage (car), Lord Worcestor's steam engine, extinction of fires, Cameron's Soda Water Apparatus, Newton's Lectures on Astronomy, coining at the Royal Mint, mechanical geometry, lifting ships by steam, voltaic-mechanic agent, steam navigation, portable hand-mill, Brown's pneumatic engine, Bell's invention for saving lives from shipwreck, triple pump, cycloidal chuck, potato-washer, sand clock, Galvanic electricity, perpetual motion, Hadley's Quadrent, Wollaston's Night-Bolt, rope bridges, boring machinery, locomotive steam-engines, new London Bridge, naval architecture, steam and water wheel, Spencer's Patent Forge, boat with wings, ivory profile portraits, Jenning's Gas burner, Ramage's Telescope, washing machine, tallow lamp, iron masts, self regulating pendulum, prismatic compass, simple blowpipe. Includes image of Henry Brougham, and many drawings of inventions.non-fictioncar, newton, fire, shipwreck, bell, naval architecture, locomotive, ballaarat east public library, ballarat east public library, ballarat east library, henry brougham, potassium, meridian lines, pit saw, self moving carriage, lord worcestor, steam engine, cameron s, soda water, astronomy, royal mint, mechanical geometry, lifting ships by steam, voltaic mechanic agent, steam navigation, hand mill, brown s pneumatic engine, triple pump, cycloidal chuck, potato washer, sand clock, galvanic electricity, perpetual motion, hadley s quadrent, wollaston s night bolt, rope bridges, boring machinery, steam engines, new london bridge, steam and water wheel, spencer s patent forge, boat with wings, ivory profile portraits, jenning s gas burner, ramage s telescope, washing machine, tallow lamp, iron masts, self regulating pendulum, prismatic compass, simple blowpipe, bookplate -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Wash trough, Melvin Newton Lovell, Mangle was Patented June 10, 1898 by Lovell Trough is possibly of later manufacture by a local unknown cabinet maker between 1900-1920

Melvin Newton Lovell was born in Allegheny, Venango county, Pennsylvania, on 31 August 1844, to Darius T. Lovell (1815-1855) and Susan B. (Conover) Lovell (1827-1883). When Melvin Lovell was a boy, the family removed to Kerrtown, a village located in the vicinity of Titusville, PA. There Melvin served an apprenticeship at the carpenter's trade, and his natural mechanical talent enabled him to become a skilled workman. He followed his trade during the major portion of his term of residence in Kerrtown. In 1861, at seventeen years of age, Melvin Lovell left his home and, without parental authority, and entered the Union army soon after the outbreak of the Civil war. In August 1862, he was enlisted as a private in the 127th Pennsylvania Volunteer Infantry and saw active service until receiving his discharge at the end of May 1863. In 1865 he took up his residence in Erie, where he worked at the carpenter's trade for several years thereafter. In 1869 Melvin Lovell invented and patented several useful articles for household use, and in that year he began the manufacturing of certain of these inventions, in partnership with Franklin Farrar Adams, another inventor. Among the principal products of the original factory were washing machines and step-ladders. In 1881 Lovell individually began manufacturing other of his patents, including spring beds, and from modest inception, his Lovell Manufacturing Company grew to be one of the largest industrial concerns of its kind in the country and was recognized as being the most extensive manufacture of clothes-wringers in the entire world. In connection with his manufacture of domestic items, Lovell established sales agencies for his products in all parts of the country, and these branches were known as the Lovell stores. These goods were sold on the instalment plan and after his business had already been established becoming a substantial concern Lovell invented and patented the famous wringer which bears his name under the “Anchor” brand, and in later years he confined his operations largely to the manufacture of this very superior household invention. Lovell was also one of the organizers and stockholders of the Combination Roll & Rubber Manufacturing Co, of New York, which was formed to manufacture his patents, with headquarters in New York and a factory at Bloomfield, New Jersey.A significant household item used in the process of washing clothes by a man who had started in 1869, as a young carpenter and later he became a successful businessman and manufacturer of household items. Lovell was granted numerous patents for various devices during his career including several patents for adding machines (cash registers). This item is now sought by collectors and is even rarer due to it's combination with a Lovell clothes wringer. Wooden wash trough with 2 troughs & attached a Lovell wringer (or mangle Anchor Brand) Hard to make out as worn off with useflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill-maritime-museum, flagstaff-hill-maritime-village, wash trough, wringer, mangle, laundry, cleaning, washing, housework, domestic, melvin newton lovell, wooden was trough -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Tilting Saw Bench, W F & John Barnes, 1874 to 1880

he subject item is a pedal-powered rip saw with a tilting table made in the USA by W.F. & John Barnes Co. of Rockford, Illinois, between 1874 and 1890. The saw's blade moves rapidly in a circular motion and is driven by a pedal that spins a heavy flywheel with a leather belt attached to a gear drive that in turn drives the circular saw blade. The operator holds a wood workpiece on the table and moves it forward so the blade cuts it to the desired width and length. Company History: WF & John Barnes Co. was established in 1869, by making a formal partnership between William F. Barnes and John Barnes in 1872, and then incorporating in 1884. This company was an early manufacturer of pedal-powered equipment. By 1881 they were also making powered machinery such as lathes and pedestal drills. Many companies were making lightweight foot-powered equipment, but Barnes and the Seneca Falls Co. were the only ones to also make professional-grade workshop machines. From the beginning of their existence, they focused on pedal-powered machinery and specialised in making scroll saws. By 1937 the company focus had completely shifted to automotive assembly machinery, and custom-built machinery, machine tools, electrical, hydraulic, and mechanical controls and systems, including nuclear hardware. their production of foot-powered machinery had ceased. In the intervening years, they have got out of manufacturing completely. After a series of ownership changes, their equipment parts and stock were purchased in 1998 by LeBlond Ltd. of Amelia, Ohio. An item that although incomplete gives a snapshot into the manufacture and use of early woodworking machinery before the introduction of electricity or electric motors to power machines.A Treadle powered tilting table saw benchWF & J Barnes, Rockford Ill USA flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Treadle Machine, Early 20th century

This foot-powered treadle machine could be used to manually operate many devices such as a sewing machine or spinning wheel. Treadle machines were used to power sewing machines, dental drills, lathes, spinning wheels and saws The machine is mounted on a board to demonstrate treadle operation.This mounted, smoothly working treadle machine demonstrates the treadle mechanism that was used in the early 20th century to power mechanical devices and in turn to save time, energy and money. The treadle was used in domestic and industrial environments. The Collection at Flagstaff Hill Maritime Museum and Village has two treadle-operated dentist's drills, a treadle sewing machine, a saw, a lathe and a treadle paper numbering machine.Treadle-powered machine; a black painted metal wheel with four curved spokes, connected to a wooden treadle. The height of the wheel is adjustable. The mechanical device is mounted on a thick rectangular wooden block. The working treadle mechanism turns smoothly. flagstaff hill, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, treadle machine, manual machine, foot treadle, display treadle, treadle, demonstration, education, working model -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Photograph - Washing Day at 'Law Muir Den' Mrs J L Smith c1910, c1910

Mrs J.L.Smith and Ada Smith in the backyard of the house Law Muir Den 510 Centre Rd Bentleigh c 1910. . The early settler women usually devoted a whole day to washing as it was very labourious. A fire was lit in a stone pit and a large tub of water boiled. Soap that had been made, usually in the previous Autumn, from fat drippings and caustic soda, was flaked into the tub to form suds. The clothes were moved around in the tub with a long wooden paddle that was also used to lift the clothes out of the tub into another tub of cold rinsing water..Stains were removed by scrubbing soap on the cloth against a scrubbing board. Clothes were wrung by hand or a mechanical wringer and hung on the clothes line to dry. Mary Ann Smith was married John Logan Smith 1860-1932 who at first rented a cottage 'Law Muir Den' & Shed from Mr Box and commenced business as a wood merchant - sawing logs into shorter pieces using one horse to power the saw. He purchased the property, added to the buildings , began trading in fuel and fodder as well and installed a chaff cutting mill powered by 10hp steam engine. The business prospered As Motor transport was increasing 1926 J L Smith built a small Garage on the opposite corner (Woolworths Supermarket 2005) , employed a good mechanic ( Reg Hunt ) and developed another successful business. J.L.Smith was an early settler in East Brighton now Bentleigh and established successful Wood cutting, Grain & Chaff cutting and Motor garage businesses in Centre Road . He was elected Councillor of the Shire of Moorabbin and, with Mary Ann, his family were involved with local Church, Red Cross, and other community organizations.Photograph, Black & White, showing 2 women washing clothes in a large tub, set over a fire in a stone pit, in the back yard. Clothes are hanging from a rope line strung between 2 trees and held up with a wooden 'prop' -

Trafalgar Holden Museum

Trafalgar Holden MuseumVehicle - VN Commodore, 1988

The VN Commodore was available in Executive, S, SS, Berlina and Calais specification levels, although a more basic SL model (opt. code A9K) was supposedly offered to government and fleet buyers, as it was not officially listed as part of the Commodore range. Changes in the relative values of the Australian dollar, the Japanese yen, and the US dollar made it impractical to continue with the well-regarded Nissan engine of the VL. Instead, Holden manufactured their own 90-degree V6 based on an old Buick design from the US, although initially it was imported. The 5.0-litre V8 remained optional and received a power boost to 165 kW (221 hp). Both these engines used multi point GM EFI and the V6 using 3 coil-packs for ignition. Holden and HSV developed this car as the basis for racing in Group A Confederation of Australian Motor Sport events. While the minimum number of cars built to qualify in Australian Touring car Championships, with modified body kit, brakes or engine is 500, only 302 VN were built but CAMS granted an exemption allowing them to compete.Holden and HSV had worked hard to develop this car to be a serious competitor to the Skyline, Ford Sierra and the BMW which had dominated in the previous years. This was to be the Holden’s answer and coincided with the return of Peter Brock back to the Holden team from 1987.Mechanically the cars were fitted with reworked version of Holden’s 4.9 litre V8. The engine block was cast for additional strength, modified cylinder heads roller rockers and high fuel flow fuel injection was applied. Output was 215 kw at 5200revs and, though at today’s standard, that is not that much it was very impressive at that time. The drive was through a six speed ZF gearbox with a heavy duty racing clutch and a limited slip differential.Under the Hawke government's Button car plan, which saw a reduction in the number of models manufactured locally, and the introduction of model sharing, the VN Commodore was rebadged as the Toyota Lexcen, named after the late America's Cup yacht designer, Ben Lexcen. Subsequently, the Toyota Corolla and Camry were, similarly, badged as the Holden Nova and Holden Apollo.Red executive 4 door sedanHolden Lion and stone emblem grille centre, Commodore boot LHS, Lion and stone emblem boot RHS.vehicle, vn commodore, holden, car -

Ringwood and District Historical Society

Ringwood and District Historical SocietyPhotograph, Boiler explosion at Ringwood station 20th June 1894 for engine 297R. "Heard in Box Hill"

Black and white photographs - 2 copiesTyped below photograph, "Boiler explosion at Ringwood station 20/6/1894. Heard in Box Hill". Article from newspapers:- Weekly Times (Melbourne, Vic. : 1869 - 1954), Saturday 27 January 1894, page 21 Official enquiry. The Board of Enquiry appointed by the Railway Commissioners to enquire into the causes of the boiler explosion which shattered the locomotive at Ringwood on Saturday night, assembled at the Railway department on Wednesday to commence its deliberations, The board consisted of Mr R. Fulton, engineer, C. W. McLean; engineer to the Marine Board, and Mr Mephan Ferguson, iron-founder. There is some difficulty at the outset about the constitution of the board; It was suggested that the Apt of Parliament contemplated that boards of experts, after the manner of the present one, needed, to have their appointments confirmed by the Governor-in-Council. The point, however, was not considered sufficiently important to prevent the board from proceeding with evidence. Robert Greyford, stationmaster at Ringwood, was the first witness. He said he saw the explosion on Saturday night at about twenty minutes to 8. There was a rush to the engine to see what had happened, and the driver and fireman were both found on the platform of the engine. The driver seemed badly hurt, but the fireman, to all appearances, was not so badly injured. They were both attended to and sent up to Melbourne by the last suburban train. Witness had a look at the engine and found the dome and all the plates round the boiler blown clean, away. The springs were also blown clean away. The Chairman (Mr Fulton) : Did you measure the distance ? Witness: Yes; one of the plates was 209 yards away. A piece from the top of the boiler 15 pounds in weight he found driven into the hard beaten track 410 yards away. Several pieces of boiler plate were found scattered at various distances. The buildings roundabout were injured. The Chairman; Did you notice anything peculiar about either of the driver or the fireman ? — No ; nothing wrong, with either of them. If the engine was blowing off at all, it must have been very light. In your opinion, were they perfectly sober ? — Perfectly. In approaching the station, is there a down or an up grade? — A very slight down grade. How is the road from Healesville ? — Up and down all the way. It is down, grade for about 200 yards coming into Ringwood station. They shut off ; steam about a quarter of a mile away, and come in at a good pace. They generally put on 15 pounds of steam while they are in the station. Mr Ferguson : Had the driver the usual load on ? — Yes ; about the usual load. Witness added that he had known the driver personally for about 10 years, and he had always been a careful, steady, sober man. He did not know the fireman so well. John Palmer, porter at Ringwood station, also saw the explosion. He was attending to the train on its arrival. He was knocked down by the force of the explosion. When he got up he saw the engine driver being carried into the office covered in blood. He noticed nothing peculiar about the driver and fireman, nor about the engine. Mr McLean : How far were you from the engine when you were knocked down ? — From ten to fifteen yards. William Paul, the guard of the train to which the injured locomotive Was attached, said he was looking at the engine at the very moment the explosion occurred. It seemed to come from exactly under the dome. The force of it took him off his feet. He was about 15 yards from the tender. When he rose he tried to reach the engine, but could not do so on account of the steam and coal dust. He called out to know whether any of the passengers were injured, and got no response, so that he concluded they were all right. All the lamps but about half dozen were extinguished by the force of the explosion, although the glass was not broken. He could testify most distinctly that the driver and fireman were both sober. The driver was a man who never drank. The steam started to blow off about a minute and a half before the explosion took place. The last place at which the engine took water was Healesville. The Chairman : Do yon know anything of the quality of the water there ? Is it creek water ? — Yes ; it comes from the Graceburn River. You never heard of its quality ?— No. How long have you known this engine on the road— About 13 months. Hew long have you known the driver on this line ? — About six weeks. I have known the fireman several years. The driver was a strict teetotaller, and I never saw the fireman take anything to drink in his life. Mr T. H, Woodroffe, chief mechanical engineer of the Victorian Railways, produced a report he had written to the secretary, about this explosion. The document gave facts concerning the engine and the explosion. It stated that the rapture seemed to have occurred at the rim of the plates adjoining the fire box. The engine was built at the Phoenix Foundry, Ballarat, in 1883. It was repaired at various times, the last time being in July of last year when it was sent to the Port Melbourne shops, and was then tested to a cold water pressure of 195 and found all right. It was the custom to overhaul all locomotives about every five years. The Chairman : There were no very heavy repairs in July, 1893; were there? — Not to the boilers. The shop manager's report says that the plug and safety tap holes were repaired, five new copper studs put in firebox, ash-pan door repaired, tender cleaned and overhauled, and studs re-rivetted, and boiler tested to pressure of 195, cold water. Mr Woodroffe read the report of the repairs effected to the boiler in December, 1888. That would be the time the plate was put in the boiler. On that occasion three new plates were put in the bottom and the boiler tested up to 195. The Chairman: Do you keep a record of the water used ?— Yes, the water in this case, I think, came from the Maroondah scheme. Mr Woodroffe said boilers were examined front time to time in the running sheds. In his opinion every possible care had been taken to keep the engine in proper care. There might, however, be lessons learnt from this. The Chairman: No doubt. From his examination of the plates [the] witness did not think the state of them could have been detected from the outside. There were no signs of leakage or sweating or anything of that sort. The next witness- was Walter Stinton, workshop manager at Newport and he said that the injured engine had been repeatedly repaired under his charge. He gave a technical account of the repairs effected on various occasions. The testing of locomotives was under his special notice. They had a high pressure pipe running; round the works, and a pump set at 2001b. When the boiler was pumped full of water the pressure when applied up to 1951b. The board appointed by the department to inquire into the Ringwood locomotive boiler explosion sat again at Spencer street on 25th inst. Mr R. Fulton presided and the other members of the board were. Mr Mephan Ferguson and Mr C. W. McLean. Charles Grubb, foreman of the boiler-makers at the Newport workshops, said he had inspected the pieces of plate that had been blown out of the engine, and after examining them, pointed out to the Chief Mechanical Engineer the portion where the plate had started to burst. It was under the lap, on the right hand side of the boiler. The grooving might be accounted for by bad water. During the past twenty years he had examined all the boilers that came into the Williamstown workshops, and while some were hardly marked at all, others were very badly eaten away. The practice was to cut out the defective portions. In this case the boiler was repaired in a similar manner. The Chairman : Can you suggest any other way of repairing so as to prevent accident ? — No, unless by taking out a plate on one side from the joint, and carrying it further up so as to avoid the joints meeting, or by taking out the plate altogether. What would.be the cost .of putting in a new " plate I—Perhaps about double the price; but I wouldn't recommend that course. It would be putting a new plate against plates that have been in use ten years or so and that would not be advisable. I think the present system better. I consider the present system of repairing the best. This is the first we have had so bad like that, to my knowledge. You attributed this to bad water. Is there no other probable cause ? — Well; unless the iron be bad. This was Lowmoor iron. I think this accident was caused by the eating away of plates. This one was the worst I have seen, for the short time it had been running. We use three classes of iron — Lowmoor, Monkbridge and Bowling. By Mr Woodroffe (Chief Mechanical Engineer) ; There are engines still running that were repaired at the same time as this one, in 1888, and. in the same way. These are engines 339 and 333. They have been recently examined and are in splendid order. What in your experience, is the age of a boiler on the Victorian railways? — From 17 to 20 years our earlier boilers stood. The later boilers don't stand so well. How is that? — There is difference in construction, and the material is lighter. The old boilers had thicker plates. Have you been asked in any way to curtail boiler affairs? — No, sir; nor in any way. You have never hesitated to carry out any necessary repairs? — Never. Our orders have been to exercise every care in examining, repairing and renewing boilers. Witness said that his practice was when an engine came into the workshop to find out how long she had been running. If over five years, he informed the workshop manager, and they thought it necessary the tubes were taken nut. If everything was in good order witness reported to the manager. The cost of taking out the tubes and putting them in again was about L20. Mr Woodroffe : Have you ever hesitated to repair a boiler on the score of expense ? — No, never. Mr McLean : Hew do yon ascertain whether a boiler requires repairs?— I keep a record of every boiler examined. From every boiler that comes in I have the dome covers taken off, and when it is practical I get inside. l can almost tell from the top of a boiler what the bottom is like. If there is any doubt about it I have the tubes taken out. If I have suspicion of defective plate I cause to have bored a triangle in the plate at the point where there is the most wear. There is a travelling inspector who visits all the running sheds of the colony except Port Melbourne and tests the boilers. He reports to us and we note what he points out. Alfred Thompson, locomotive inspector of the eastern section, said he knew this engine, 297R. He read a list of her repairs. He heard of the accident on Saturday night and went up to Ringwood. The Chairman : Did you ever notice anything peculiar about the engine? — No, I considered her A1 and would not have hesitated to have put on 140lb pressure owing to the repairs she had undergone. Witness considered that the explosion was caused by the expansion and contraction of the plates ; and, no doubt, the plate had been eaten away through bad water. The other side of the boiler showed: signs of corrosion: By Mr Woodroffe ; Is every care taken with the boilers ? — Yes, every possible care is taken for the safety of boilers, Weekly Times (Melbourne, Vic. : 1869 - 1954), Saturday 27 January 1894, page 7 EXPLOSION OF A LOCOMOTIVE BOILER, NARROW ESACPE FROM FATALITIES. THE DAMAGED ENGINE. [See drawing of loco – saved in “Railways” folder] The explosion of a locomotive boiler at Ringwood on Saturday evening, formed the subject of much discussion in railway circles on Monday. The Minister arrived at the office at an unusually early hour and immediately entered into a consultation with the acting chairman, Mr Kibble, and Mr Commissioner Murray. As the result of the interview it was resolved to ask three gentlemen of acknowledged engineering experience to sib as a board with the . object of inquiring into the cause of the accident and furnishing a report. Mr Richardson and the Commissioners are tally seized of the importance of having a searching investigation into the accident, and, with Mr Murray, the former went to Ringwood to inspect the scene of the disaster. They will he accompanied by Mr Woodroffe. During the morning no official report had come to hand from the driver or fireman of the engine in reference to the accident, but that is thought to be due to the circumstance that they have not sufficiently recovered to be able to give a circumstantial account of what occurred. The engine was one of the old R's, and, Mr Kibble pronounced them to be about the best class of engines used. So far nothing can be said as to the probable cause of the accident, as the broken plating of the engine has not been submitted to the inspection of experts. Weekly Times (Melbourne, Vic. : 1869 - 1954), Saturday 27 January 1894, page 7 STATEMENT BY THE FIREMAN. This morning Thomas Miles, fireman on the engine the boiler of which exploded on Saturday night, is suffering from an injury to the spine, as well as a very severe shaking to the system. He states that he was fireman on the engine attached to the train which left Healesville on Saturday evening, at ten minutes to 8. Everything went all right until Ringwood was reached, when, .just as the train was about to continue its journey, a load explosion took place and Miles remembers nothing more until he was picked np on the platform ; and found himself suffering from a pain in the back, and an injury to his arm. He cannot think of any reason which could have caused the explosion, as there was plenty of water in the boiler, and everything seemed working all right. Mr R. Fulton, consulting engineer, of Queen street; Mr McLean, a member of the Marine Board ; and Mr Mephan Ferguson, engineer, have consented to act as a board to inquire into the cause of the engine boiler explosion at Ringwood on Saturday evening. The board has been appointed under section 117 of Act 1135, which provides that the Governor-in-Council may direct the taking of a such a step. Mr1 Fulton will act as chairman of the board, which met for the first time at the railway offices, Spencer street, this forenoon. Before separating the members of the Board paid a visit to the Prince's Bridge locomotive sheds in company with Mr Woodroffe, the chief mechanical engineer, for the purpose of inspecting the shattered boiler. It has been stated that the explosion is known to have been caused by a flaw in a plate which was put on the boiler about four years ago, but enquiries have tailed to elicit anything in support of that view. The engineers connected with the department are not inclined to say anything on the subject. Weekly Times (Melbourne, Vic. : 1869 - 1954), Saturday 14 April 1894, page 20 The Ringwood Boiler Explosion, The Minister of Railways has received the supplementary report of the board appointed by him to investigate the circumstances connected with the explosion of a locomotive boiler at Ringwood. In their first report the board did not attach blame to anyone. Mr Richardson felt satisfied that the responsibility of having the engines properly inspected and overhauled periodically could be fixed if the inquiry were extended. He therefore referred the matter again to the Board, who took further evidence. In the report now furnished, the Board hold Loco. Inspector Thompson blameable, but point out as a mitigating circumstance that he had not received "written instructions" respecting inspections and overhauls. Weekly Times (Melbourne, Vic. : 1869 - 1954), Saturday 7 July 1894, page 32 The Ringwood Boiler Explosion. The Minister of Railways takes exception to the tone of a paragraph appearing in a morning contemporary respecting the Ringwood boiler explosion. It makes it appear that Mr Richardson has referred the report of the board which considered the facts connected with the explosion to the Crown solicitor simply because he differed from the finding of the board. The Minister explains that when he received the report he found that the responsibility for having boilers properly inspected and overhauled had not been clearly fixed. He personally obtained farther evidence on that point, and arrived at a conclusion, from which the commissioners differed. As he did not like to take upon himself the responsibility of deciding upon the effect of the evidence, he submitted the matter to the Crown Solicitor, but that officer did not furnish him with the information sought. He has, therefore, referred the question to the Attorney-General, together with the draft of a regulation respecting boiler inspections and overhauls in the future. Mr Richardson says that his whole aim is to have the responsibility positively fixed. Weekly Times (Melbourne, Vic. : 1869 - 1954), Saturday 28 April 1894, page 23 The Minister of Railways has completed his consideration of the supplementary report received by him from the Ringwood Boiler Explosion Board. The report, it will be remembered, held Loco-Inspector Thompson blameable for the non-inspection of the boiler, but considered there was extenuating circumstances. There was a certain amount of doubt as to the absolute instructions given for overhauling engines periodically. Mr. Richardson is sending the report on to the Commissioners with instructions that the responsibility respecting inspection of boilers shall be made clear for the future.