Showing 12 items matching "metal lathe"

-

Tatura Irrigation & Wartime Camps Museum

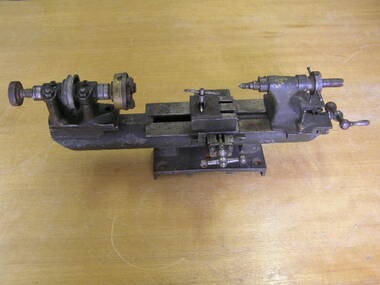

Tatura Irrigation & Wartime Camps MuseumTool - Lathe, Metal Lathe

... Metal Lathe...Handmade metal turning lathe, 600mls long and weighing 16... Kaltenbach Manuel Kaltenbach Handmade metal turning lathe, 600mls ...Made at a forge outside the camp 3 perimeter by Gotthilf Kaltenbach & Manuel Kaltenbach. It is made from British Army scrap metal. Used for fine metal turning. The Witworth gauges were not used in Central Europe after 1918. The motor that was on it was a small electric sewing machine motor which was discarded about ten years ago in Germany. Sent from Germany by Elfriede & Paul Faig.Handmade metal turning lathe, 600mls long and weighing 16 kg. Made at a forge site outside the camp perimeter. All dimensions are in imperial inches, all threads are Witworth gauges. Painted in British Army colours.tatura, camp 3, lathe, metalworking, paul faig, gotthilf kaltenbach, manuel kaltenbach -

Geoffrey Kaye Museum of Anaesthetic History

Geoffrey Kaye Museum of Anaesthetic HistoryPhotograph - Photograph, Geoffrey Kaye

... Metal lathe..., approximately late 1970s or early to mid 1980s. Geoffrey Kaye Metal ...Photograph has been taken in Geoffrey Kaye's later years, approximately late 1970s or early to mid 1980s.Large colour photograph of an elderly Dr Geoffrey Kaye wearing a white dustcoat and working on his lathe at his Cromwell Road, South Yarra home.geoffrey kaye, metal lathe, workshop -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncLathe

... Small metal lathe mounted on a metal stand. Driven by a 1/4... goldfields Trades Metal working None Small metal lathe mounted ...Small metal lathe mounted on a metal stand. Driven by a 1/4 HP 1425 RPM electric motor. Comes with a box of assorted chucks and fittings.Nonetrades, metal working -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Tools, George Panton & Sons, Jeweller Lathe, Early 20th century

This jewellery lathe (minus its rubber belt) came from the Warrnambool jewellery store of Michael Salamy and his son, Edward. The business was in two locations - in Timor Street, opposite the old Post Office, and at 179 Liebig Street. Michael Salamy erected two new buildings at 179 and 181 Liebig Street and the Salamy business was then headed by the son, Edward who was born in 1903 and died in 1977. The jewellery store was closed when Edward retired and Clancey Brothers men's store took over the building at 179 Liebig Street in 1966. Bill Clancey found the jewellery lathe in this building and donated it to the Historical Society. This lathe is of considerable interest as it comes from the prominent 20th century Warrnambool jewellery business of M.Salamy and Son. It is also an interesting memento of a 20th century industrial tool. This is a metal tool with several wheels connected with wing nuts. The large wheel has a wooden handle. A rubber belt connecting two of the wheels is missing. '0865 Panton Maker Glasgow'michael salamy and son, jewelers, warrnambool -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, Screwdriver large, c1900

A screwdriver is a tool, manual or powered, for turning (driving or removing) screws. A typical simple screwdriver has a handle and a shaft, and a tip that the user inserts into the screw head to turn it. The shaft is usually made of tough steel to resist bending or twisting. The tip may be hardened to resist wear, treated with a dark tip coating for improved visual contrast between tip and screw—or ridged or treated for additional 'grip'. Handle are typically wood, metal, or plastic and usually hexagonal, square, or oval in cross-section to improve grip and prevent the tool from rolling when set down. The handle and shaft of screwdrivers have changed considerably over time. The "Perfect Pattern Handle’ screwdriver was first manufactured by HD Smith & Company, which operated from 1850 to 1900. Screwdrivers were probably invented in the late 15th century, either in Germany or France when Screws were used to construct screw-cutting lathes, for securing breastplates, backplates, and helmets on medieval jousting armor—and eventually for multiple parts of the emerging firearms, particularly the matchlock. The jaws that hold the pyrites inside medieval guns were secured with screws, and the need to constantly replace the pyrites resulted in considerable refinement of the screwdriver. The screwdriver depended entirely on the screw, and it took several advances to make the screw easy enough to produce to become popular and widespread Canadian P.L. Robertson, though he was not the first person to patent the idea of socket-head screws, was the first to successfully commercialize them, starting in 1908. In Portland, Oregon, Henry F. Phillips patented his own invention, an improved version of a deep socket with a cruciform slot, today known as the Phillips Screw. Phillips offered his screw to the American Screw Company, and after a successful trial on the 1936 Cadillac, it quickly swept through the American auto industry. A main attraction for the screw was that conventional slotted screwdrivers could also be used on them, which was not possible with the Robertson Screw. A large steel screwdriver with worn wooden handlepioneers, early settlers, market gardeners, moorabbin, bentleigh, cheltenham, brighton, tools, craftsman, carpenters, , blacksmiths, builders, farmers, metalwork, woodwork, screws, philllips head screwdrivers, h.d.smith & co usa, p.l. robertson, henry f.phillips , oregon, canada, american screw company, -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Treadle Machine, Early 20th century

This foot-powered treadle machine could be used to manually operate many devices such as a sewing machine or spinning wheel. Treadle machines were used to power sewing machines, dental drills, lathes, spinning wheels and saws The machine is mounted on a board to demonstrate treadle operation.This mounted, smoothly working treadle machine demonstrates the treadle mechanism that was used in the early 20th century to power mechanical devices and in turn to save time, energy and money. The treadle was used in domestic and industrial environments. The Collection at Flagstaff Hill Maritime Museum and Village has two treadle-operated dentist's drills, a treadle sewing machine, a saw, a lathe and a treadle paper numbering machine.Treadle-powered machine; a black painted metal wheel with four curved spokes, connected to a wooden treadle. The height of the wheel is adjustable. The mechanical device is mounted on a thick rectangular wooden block. The working treadle mechanism turns smoothly. flagstaff hill, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, treadle machine, manual machine, foot treadle, display treadle, treadle, demonstration, education, working model -

The Ed Muirhead Physics Museum

The Ed Muirhead Physics MuseumResistance Ratio Bridge, J.L. William

Machine-made/cut, appears to be lathe turned. Electroplated, no apparent decorative elements. 14 rotatable, removable nuts. Surface finish: Brushed metal. “Ratio Resistance’ Handwritten pen on paper adhered with sticky tape on top circular face. Medallion screwed to top circular face: “J.L. WILLIAM/SCIENTIFIC INSTRUMENTS/ SERIAL NO. TYPE/ MELBOURNE - AUSTRALIA.” Machine-made manufacturer’s label, enamel on brass plate (unconfirmed) screw fixed, “Resistance/between/the knobs/as shown/Resistances (+0.05 at most). Handwritten pen on aged paper label attached with coated twine. -

Puffing Billy Railway

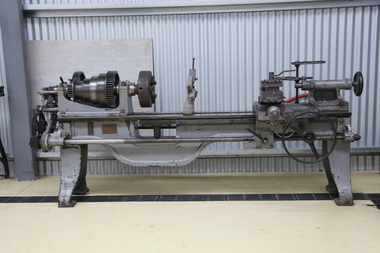

Puffing Billy RailwayLathe - Gap Bed, early 1900s

Possibly ex Victorian Railways Newport workshops Supplied by Bevan & Edwards Machinery Merchants, Melbourne Sebastian Lathes Described by its makers as the Utility School, Garage and Repair-shop Lathe, the machine immediately below, a Sebastian 15" (circa 1910 - 1926) was the Company's cheapest offering and, in its basic form, lacked a compound slide rest, the tailstock did not set over for taper turning and the bed lacked a gap. However, a friction-type countershaft unit was included in the price as well as a tool post, faceplate, drive plate, changewheels for screwcutting and a small tool kit. As with modern cars (especially BMW) everything worthwhile was on the options' list and by spending more it was possible to specify all those small but important extras. Although in its lowest-cost form this model was reduced to the fundamentals required for a useable, screwcutting centre (engine) lathe it was still reasonably specified and would certainly have fulfilled many requirements when installed in a school or training workshop. The true swing was 15.25", it was properly backgeared and screwcutting was through a conventional tumble-reverse mechanism that allowed both left and right-hand powered movement to the carriage by altering the position of just one lever. As standard it accepted 40" between centres, but any capacity could be ordered, in foot intervals, up to a maximum of 88" - when it is hoped that a central bed support might have been included …… The spindle, which ran in white-metal bearings, had a useful 15/8" hole and a No. 3 Morse taper centre. Some models appear to have had the leadscrew clasp-nut lever on the right-hand side of the apron, while on others it was positioned to the left.. Early Sebastian 13-inch lathe Typical of the Centre or "Engine" lathe made by many manufacturers from the late 1800s until the late 1930s, the basic flat-belt drive Sebastian, with separate countershaft, was eventually relegated to the economy end of the Company's range by the introduction of geared headstocks and self-contained motor-drive systems.Historic - Industrial Machinery - Gap Bed Lathe - Possibly ex Victorian Railways Newport workshops - Purchased and supplied from Bevan & Edwards Gap Bed Lathe - Grey with raw steel parts and a timber cupboard with gears and tools. Bevan & Edwards PTY,LTD Machinery Merchants Melbourne (possible government tag) 365bevan & edwards pty,ltd machinery merchants melbourne, puffing billy -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumTools, 1940's

... on lathe (no. 7955).|3. Metal thread cutting tool (originally... and possibly made on lathe (no. 7955).|3. Metal thread cutting tool ...Sent from Germany by Elfriede & Paul Faig.Tools belonging to W. Hermann / G. Kaltenbach - 1. Small metal handle|2. Drilling device, made of metal and possibly made on lathe (no. 7955).|3. Metal thread cutting tool (originally Australian).tatura, camp 3, faig, p, kaltenbach, g, hermann, w, trades, metalworking, handcrafts, woodturning -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumAbacus, Between 1939-1945

Camp 3 was one of the Tatura Group of civilian & prisoner of war internment camps during World War 2. Camp 3 was a civilian 'family' camp. The abacus was made by a German internee, for his son in the camp. It was made from scrap materials found in and around the camp & the beads & other wooden parts of the abacus were turned on a lathe also constructed by the internees. Wood & metal abacus with wooden base, sides & beads (100), & metal rails. Wood painted red & black. camp 3, tatura, internment camps, civilian internees -

Bendigo Historical Society Inc.

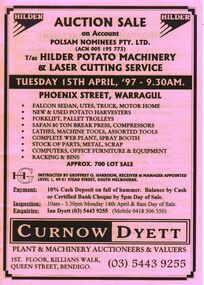

Bendigo Historical Society Inc.Document - IAN DYETT COLLECTION: AUCTION CATALOGUE - POLSAM NOMINEES PTY LTD

Pink paper catalogue with black printing for a sale on account of Polsam Nominees Pty. Ltd. T/as Hilder Potato Machinery & Laser Cutting Service on 15th April '97 at Warragul. For sale were vehicles, potato harvesters, forklift, pallet trolleys,80 ton press, compressors, lathes, machine tools, assorted tools, complete web plant, spray booth, parts, metal, scrap, computers, office furniture & equipment, racking and bins. Announcement printed in the front of catalogue mentions that J. H. Curnow & Son Pty. Ltd. Are combining their name with the Dyett family and trading as Curnow Dyett, Real Estate Agents, Auctioneers and Qualified Valuers.business, auctioneers, curnow dyett, ian dyett collection - auction catalogue - polsam nominees pty ltd, hilder potato machinery & laser cutting service, geoffrey o harrison, ian dyett, curnow dyett, j h curnow & son pty ltd, occupational health and safety act 1985, noel dyett, ian dyett, fred dyett -

Maldon Vintage Machinery Museum Inc

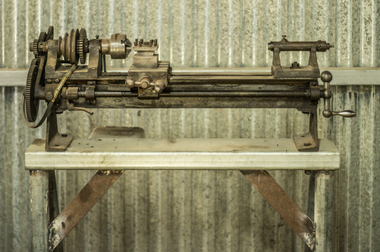

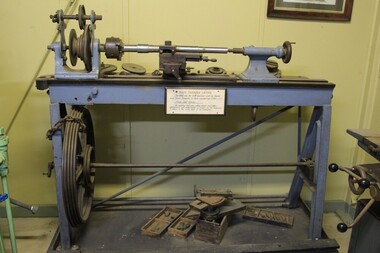

Maldon Vintage Machinery Museum IncTreadle Lathe, Post 1875

The first metal working machine used by David & James Thompson in 1878. Brought by ship by David Thompson who used it on the journey to make working models.The first machine used by David & James Thompson in their engineering section.Treadle lath for metal turning. Some brass accessories for metal working are laid out on a timber bench attached to the back of the lathe. Painted gunmetal grey and mounted on a black wooden platform for display purposes.Nonemachinery; tools; metalwork