Showing 211 items matching "plant processing"

-

Stawell Historical Society Inc

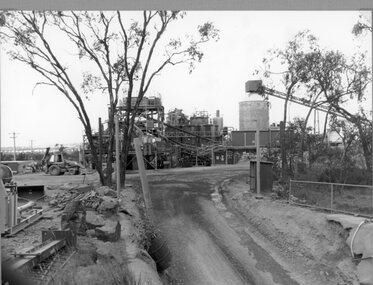

Stawell Historical Society IncPhotograph, Stawell Joint Venture, Magdala Gold Mining Processing Plant 1995

... Stawell Joint Venture, Magdala Gold Mining Processing Plant...Stawell Joint Venture. Processing plant 1995... grampians Stawell Joint Venture. Processing plant 1995 Stawell ...Stawell Joint Venture. Processing plant 1995stawell mining -

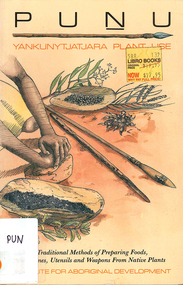

Victorian Aboriginal Corporation for Languages

Victorian Aboriginal Corporation for LanguagesBook, Pun?u : Yankunytjatjara plant use : traditional methods of preparing foods, medicines, utensils and weapons from native plants, 1988

... plant processing...Encyclopedia style entries for 27 plants with standard... mistletoes plant parts habitat plant processing Yankunytjatjara ...Encyclopedia style entries for 27 plants with standard scientific description plus description, science and stories in Yankunytjatjara with translations. Includes general and linguistic introduction, and extensive glossaries of botanical names, plant parts, processes etc, all Yankunytjatjara and English (and Latin as appropriate)B&w illustrations, colour illustrations, word listsclimate, landforms, vegetation, vegetable food (mai), fruits, seeds, roots, greens, galls, fungi, nectars, sweet secretions, gums, medicinal plants (punu ngangkari), language, stories, plant use, trees, shrubs, subshrubs, grasses, vines, succulents, mistletoes, plant parts, habitat, plant processing, yankunytjatjara, central australia -

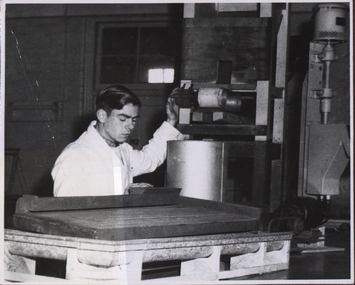

Federation University Historical Collection

Federation University Historical CollectionPhotograph - Black and White Photograph, Metallurgical Students

... ore processing plant....1 and .2) A male at a bench with pre processing model... ballarat school of mines metallurgy ore processing plant alf ....1 and .2) A male at a bench with pre processing model plant .3) a male at a metallurgical microscope .4) The original item ballarat school of mines, metallurgy, ore processing plant, alf mckenzie -

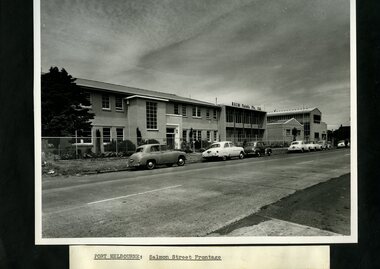

Port Melbourne Historical & Preservation Society

Port Melbourne Historical & Preservation SocietyPhotograph - CD-ROM, "BALM Paints", 1950s

... Melbourne. Images are from the 1950s and are of buildings, plant.... Images are from the 1950s and are of buildings, plant ...CD with 24 pictures of BALM Paints in Salmon St, Port Melbourne. Images are from the 1950s and are of buildings, plant and processes.industry - manufacturing, built environment - industrial, balm paints, dulux paints -

Stawell Historical Society Inc

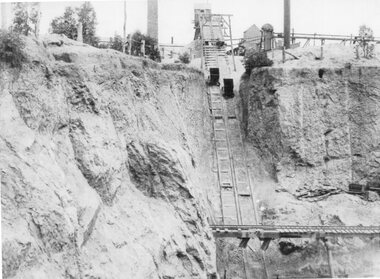

Stawell Historical Society IncPhotograph, Jubilee Open Cut - Wonga Company showing how ore is taken up an incline 1899

... incline to processing plant... pulled by cable moving up incline to processing plant Jubilee ...B/W photo Wonga Company 1899 showing how ore is taken up an incline in ore trucks..Rail tracks with ore trucks pulled by cable moving up incline to processing plantstawell mining -

Stawell Historical Society Inc

Stawell Historical Society IncPhotograph, Wonga Cyanide Gold Recovery Company Mining Operations 1899

... Cyanide gold processing plant infrastructure. Conveyor belt... gold processing plant infrastructure. Conveyor belt at centre ...B/W photo Wonga Company Plant 1899Cyanide gold processing plant infrastructure. Conveyor belt at centre of photo, cyanide vats in foreground.stawell mining -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - CENTRAL NELL GWYNNE MINE, 1960's

... image of poppet head with processing plants. Inscriptions:... of poppet head with processing plants. Inscriptions: Photograph ...Black and white photograph of Central Nell Gwynne. Side image of poppet head with processing plants. Inscriptions: 'Central Nell Gwynne Mine' written on bottom front of photographmining site, central nell gwynne gold mine, poppet head -

Rutherglen Historical Society

Rutherglen Historical SocietyImage, 2004

... of a gold processing cyanide plant at Christmastown. Photo... site of a gold processing cyanide plant at Christmastown. Photo ...Colour photograph of a story board marking former site of a gold processing cyanide plant at Christmastown. Photo is mounted on an album page.storyboards, working miners gold mining co, gold mining, cyanide plant -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - Kangaroo Flat Gold Mine Collection: Unity Mining employees

... clothing and wearing hard hats. In background, part of processing... and wearing hard hats. In background, part of processing plant ...A3 laminated sheet with colour photographs of mine personnel. Fourteen men and one woman dressed in orange high-vis clothing and wearing hard hats. In background, part of processing plant with 'Unity Mining Limited' on side of tank. Kangaroo Flat Gold mine site in far background. kangaroo flat gold mine, bendigo mining nl, new bendigo gold project, goldmining, personnel, doug buerger, colin burns, unity mining -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle - Ginger Beer, early to late 1900's

... to be easily moved within the ginger beer processing plants from... the ginger beer processing plants from the brewing vats/holding tanks ...This glass ginger beer bottle was manufactured and used early to late 1900's, until the time that cheaper containers were invented(plastic bottles). This bottle was so constructed to be easily moved within the ginger beer processing plants from the brewing vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1990s the bottle slowly became phased out of production however boutique suppliers still preferred thick glass to contain any explosive action. Two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co. were the main suppliers for the Victorian State. In the period when this bottle was manufactured and used the major ginger beer brewing plants for the whole of Victoria were located in Melbourne because this was where its greatest consumer base was there and most rural areas were supplied by domestic sources (mother brewing ginger beer for the children). The Kiewa Valley and its region was one rural area which until road invrastructure was enhance covered the ginger beer thirst by local family production. As the population expanded considerably in the late 1940's (SECV Hydro Scheme) with a greater demand for "soft" drinks" being established supplies from larger towns and cities were call for. Each bottle was "branded" during manufacturing to show the contents were from a reputable supplier (H Taylor) and where it originated from. These bottles were recyled by the manufacturer as a way to cut production costs. This method of recycling the bottles back to the specific manufacturer has (except for South Australia)been overtaken by a no cost recycling collection by councils (funded by their communities). This method by passes the user cost principle as the bottles are processed as non generic. The uneconomical "on cost" which was replaced by the "throw away" less costly plastic containers however did not provide the keen domestic brewer of the "beer" with a reusable bottle. This heavy gauged glass ginger beer bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the filling production line. The method of pouring ginger beer into the bottle has been part of the "production line". This bottle has a one and a half pint capacity and is made from "light green" coloured glass(a protection against light penetration). This thick glass bottle, to contain ginger beer, required its thickness because of the extensive handling (man and machine) before final consumption. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck. Ginger beer was a "soft drink" of great demand. On the middle portion of this bottle is a large elongated circle within it and following the spherical line is "H. TAYLOR" ans a star separates this from "MELBOURNE" rounding out the bottom curviture. Within these words are the large initials "T H" . The "T" superimposed onto the "H". On the base and covering the whole bottom is the letter "T". At the opposite side to the manufacturers logo is "THIS BOTTLE CANNOT BE SOLD OR USED BY ANY OTHER PERSON & IS NOT COMPLETE WITHOUT STOPPER" glass bottle, non alcoholic drink, taylor ginger beer bottle, reuseable bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Ginger Beer, circa mid to late 1900's

... to be easily moved within the ginger beer processing plants from... the ginger beer processing plants from the brewing vats/holding tanks ...This glass ginger beer bottle was manufactured and used early to late 1900's, until the time that cheaper containers were invented(plastic bottles). This bottle was so constructed to be easily moved within the ginger beer processing plants from the brewing vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1990s the bottle slowly became phased out of production however boutique suppliers still preferred thick glass to contain any explosive action. Two major glass bottle works companies, e.g. Australian Glass Manufacturers and the Melbourne Glass Bottle Works Co. were the main suppliers for the Victorian State.In the period when this bottle was manufactured and used the major ginger beer brewing plants for the whole of Victoria were located in Melbourne because this was where its greatest consumer base was there and most rural areas were supplied by domestic sources (mother brewing ginger beer for the children). The Kiewa Valley and its region was one rural area which until road invrastructure was enhance covered the ginger beer thirst by local family production. As the population expanded considerably in the late 1940's (SECV Hydro Scheme) with a greater demand for "soft" drinks" being established supplies from larger towns and cities were call for. Each bottle was "branded" during manufacturing to show the contents were from a reputable supplier (PHIBBS Bros) and where it originated from. These bottles were recycled by the manufacturer as a way to cut production costs. This method of recycling the bottles back to the specific manufacturer has (except for South Australia)been overtaken by a no cost recycling collection by councils (funded by their communities). This method by passes the user cost principle as the bottles are processed as non generic. The uneconomical "on cost" which was replaced by the "throw away" less costly plastic containers however did not provide the keen domestic brewer of the "beer" with a reusable bottle.This heavy gauged glass bottle (Ginger Beer) has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the production line. The method of pouring ginger beer into the bottle has been part of the "production line" process of automation. This bottle has a capacity to hold 250ml of ginger beer and is made from "clear" glass. The marority of ginger beer bottles produced in this time frame where made with a "green" tint in them.This tinting helped reduce the sunlight effecting the contentsAround the bottom side of the bottle and blown into the glass is "THIS BOTTLE IS THE PROPERTY OF PHIBBS BROS, ALBURY" above this, in "running script" and sloping up from left to right is "Phibbs Bros" and underneath parallel to it "ALBURY". On the base of the bottle is molded a big "L 289" underneath this "M" and below this "AGM".ginger beer bottle, soft drink bottles, cordial bottles -

Warrnambool and District Historical Society Inc.

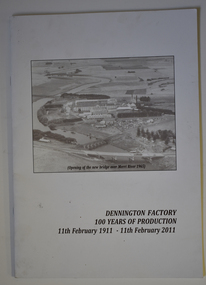

Warrnambool and District Historical Society Inc.Booklet - Centenary History of Dennington Factory, Dennington Factory 100 Years of Production, 2011

... to be a milk processing plant and in 2020 ProviCo, an animal nutrition... to be a milk processing plant and in 2020 ProviCo, an animal nutrition ...Centenary History of the Dennington FactoryThis is a booklet of 24 pages. The front cover has a black and white photograph and black printing and the back cover has a colour photograph, a logo and black printing. The pages contain printed text and black and white and colour photographs. The booklet is stapled.non-fictionCentenary History of the Dennington Factorynestles factory dennington, fonterra factory dennington -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - AUSTIN COLLECTION: Wattle Gully Gold Mine, Chewton, Not dated but possibly 1980's

... plant and a decline tunnel. The ore processing plant... plant and a decline tunnel. The ore processing plant ...Wattle Gully Mine holds a pivotal position in the history of the State's quartz mining industry. The rich strike at Wattle Gully mine in 1937 helped revive the State's gold mining industry that had been in the doldrums since the First World War. Wattle Gully, and a handful of other 'new' companies - the Maude and Yellow Girl, Morning Star, A 1, and North Deborah - were the flagships of the revived industry and sustained the State's gold production for some 30 years. Wattle Gully mine, with a yield of 350,000 ounces, was the richest mine of its era. By 1940, the Wattle Gully Company had paid out £207,000 in dividends to its shareholders. The company continued to mine profitably through the Second World War, though it struggled due to a shortage of manpower. After the war, the mine continued to develop - in the early 1950s new plant including a winding engine, steel poppet head, and twenty-head battery was added. The plant was obtained from the Central Nell Gwynne Company, Bendigo. On 13 March 1969, the Wattle Gully Company closed down the mine, laying off 62 men. Since 1970 Wattle Gully mine has worked intermittently. Recent additions to the mine's infrastructure has been a new ore processing plant and a decline tunnel. The ore processing plant was operated by Newmont mining from 1987 to 1990 and subsequently operated by Consolidated Victorian Mines and Duketon Goldfields. The mine site has retained evidence of its development since 1937 with its most recent periods of equipment upgrades in the 1950s and 1980s being documented by buildings, structures and intact and working machinery. Heritage Council Victoria: https://vhd.heritagecouncil.vic.gov.au/places/2380 Black and white photograph: view of engine room. Wattle Gully Gold Mine winding gear, two winding wheels in centre of image.gold mining, underground, wattle gully gold mine, chewton, winding gear -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - AUSTIN COLLECTION: Winding Gear, Wattle Gully Gold Mine, Chewton, 1982

... plant and a decline tunnel. The ore processing plant... plant and a decline tunnel. The ore processing plant ...Wattle Gully Mine holds a pivotal position in the history of the State's quartz mining industry. The rich strike at Wattle Gully mine in 1937 helped revive the State's gold mining industry that had been in the doldrums since the First World War. Wattle Gully, and a handful of other 'new' companies - the Maude and Yellow Girl, Morning Star, A 1, and North Deborah - were the flagships of the revived industry and sustained the State's gold production for some 30 years. Wattle Gully mine, with a yield of 350,000 ounces, was the richest mine of its era. By 1940, the Wattle Gully Company had paid out £207,000 in dividends to its shareholders. The company continued to mine profitably through the Second World War, though it struggled due to a shortage of manpower. After the war, the mine continued to develop - in the early 1950s new plant including a winding engine, steel poppet head, and twenty-head battery was added. The plant was obtained from the Central Nell Gwynne Company, Bendigo. On 13 March 1969, the Wattle Gully Company closed down the mine, laying off 62 men. Since 1970 Wattle Gully mine has worked intermittently. Recent additions to the mine's infrastructure has been a new ore processing plant and a decline tunnel. The ore processing plant was operated by Newmont mining from 1987 to 1990 and subsequently operated by Consolidated Victorian Mines and Duketon Goldfields. The mine site has retained evidence of its development since 1937 with its most recent periods of equipment upgrades in the 1950s and 1980s being documented by buildings, structures and intact and working machinery. Heritage Council Victoria: https://vhd.heritagecouncil.vic.gov.au/places/2380 Black and white photograph: view of engine room. Wattle Gully Gold Mine winding gear, two winding wheels in centre of image.gold mining, underground, wattle gully gold mine, chewton, winding gear -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - AUSTIN COLLECTION: Wattle Gully Gold Mine, Chewton, 1982

... plant and a decline tunnel. The ore processing plant... plant and a decline tunnel. The ore processing plant ...Wattle Gully Mine holds a pivotal position in the history of the State's quartz mining industry. The rich strike at Wattle Gully mine in 1937 helped revive the State's gold mining industry that had been in the doldrums since the First World War. Wattle Gully, and a handful of other 'new' companies - the Maude and Yellow Girl, Morning Star, A 1, and North Deborah - were the flagships of the revived industry and sustained the State's gold production for some 30 years. Wattle Gully mine, with a yield of 350,000 ounces, was the richest mine of its era. By 1940, the Wattle Gully Company had paid out £207,000 in dividends to its shareholders. The company continued to mine profitably through the Second World War, though it struggled due to a shortage of manpower. After the war, the mine continued to develop - in the early 1950s new plant including a winding engine, steel poppet head, and twenty-head battery was added. The plant was obtained from the Central Nell Gwynne Company, Bendigo. On 13 March 1969, the Wattle Gully Company closed down the mine, laying off 62 men. Since 1970 Wattle Gully mine has worked intermittently. Recent additions to the mine's infrastructure has been a new ore processing plant and a decline tunnel. The ore processing plant was operated by Newmont mining from 1987 to 1990 and subsequently operated by Consolidated Victorian Mines and Duketon Goldfields. The mine site has retained evidence of its development since 1937 with its most recent periods of equipment upgrades in the 1950s and 1980s being documented by buildings, structures and intact and working machinery. Heritage Council Victoria: https://vhd.heritagecouncil.vic.gov.au/places/2380 Black and white photograph: view of Wattle Gully mine site with ore bins, poppet head and mining sheds. Eucalypt trees in centre of image. gold mining, underground, wattle gully gold mine, chewton, ore bins, poppet head, mine sheds -

Bendigo Historical Society Inc.

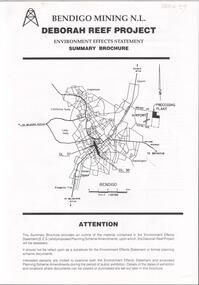

Bendigo Historical Society Inc.Document - DEBORAH REEF PROJECT ENVIRONMENT EFFECTS STATEMENT

... of the proposed processing plant near the Airport. Further maps on page 2... processing plant near the Airport. Further maps on page 2 and 3 show ...Two page document. On top, first page ' Bendigo Mining N.L., Deborah Reef Project, Environment Effects Statement, Summary Brochure'. Poppet head on top LH corner of document. A map of central Bendigo is drawn on page 1 and shows the location of the proposed processing plant near the Airport. Further maps on page 2 and 3 show the North Deborah Mine Site, the pipeline route and the airfield site. The summary brochure provides an outline of the material contained in the Environment Effects Statement and proposed planning scheme amendments upon which, the Deborah Reef Project will be assessed. Page four lists the issues that impact on this submission: planning and land use; socio economic environment; traffic; discharges to air; water management; explosives storage and handling; subsidence; heritage; flora and fauna and landscape and visual assessment. The 16th March, 1989, is the date given for submissions to be lodged in regard to this project.Bendigo Mining N.Lbendigo, mining, deborah reef project -

Federation University Historical Collection

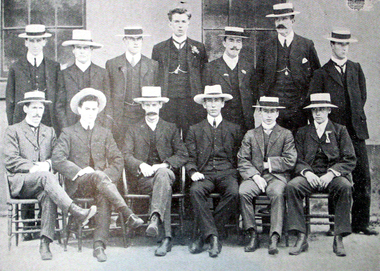

Federation University Historical CollectionBook, Ballarat School of Mines Students' Magazine, 1902-1906, 1902-1906

... junction mine plant or potter process... 10, Junction Mine plant or Potter Process, Broken Hill... mine plant or potter process broken hill propriety mill ...The Ballarat School of Mines is a predecessor institution of Federation University Ausgtralia.Five copies of the Ballarat School of Mines Students' Magazine bound in a blue hard cover and quart bound in calf. 1902 - Retirement of Herbert L. Krause 1905 - Mt Lyall Ore Deposits Images: Ballarat School of Mines Sports Association Committee and Officers, 1905 Standing left to right: W. Pearce, T. Williams, S. Hepburn, Seward, W. Figgis, J.R. Reid, P. Elliott Sitting left to right: P.A. Pratt, N. Buley, John Sutherland, H.R Murphy, J. Inglis, R. Nevett 1906 Excursion to Broken Hill, The Artistic Printing Process, Hints on Portraiture, Arizona, Cornish Mining Images Ballarat School of Mines and AusImm at the Central Mine, Broken Hill; At Iron Knob, Brown Boveri Turbo Generator at Block 10, Junction Mine plant or Potter Process, Broken Hill Propriety Mill, Carlyon's Hotel, Sam Jamieson, Electrical Labortory, Ballarat School of Mines Rowing Eight, Sports Committee,ballarat school of mines, magazines, sports committee, thomas williams, mount lyell, w. pearce, t. williams, s. hepburn, seward, w. figgis, j.r. reid, p. elliott, p.a. pratt, n. buley, john sutherland, h.r murphy, j. inglis, r. nevett, herbert l. krause, broken hill, artistic printing process, hints on portraiture, arizona, cornish mining, ausimm at the central mine, broken hill, iron knob, brown boveri turbo generator at block 10, junction mine plant or potter process, broken hill propriety mill, carlyon's hotel, sam jamieson, electrical labortory, ballarat school of mines rowing eight, sports committee,, rowing on lake wendouree, boat shed, h. valentine, l. seward, c. macgennis, d. don, m. gaunt, h. owne, l. nott, s. leathes, j.a. reid, h.r. murphy, alfred mica smith, r. hosking, zeehan, moonta, wallaroo, smelting silver, south africa, south australia excursion, sunnyside woollen mills, tasmanian excursion, swedish iron, mt jukes excurson, western australian gold ore, wynne-grant furnace, bhp sintering slimes, leggo furnace, mine ventilation, mount morgan mine, mount pani ltd, new zealand coal, adelaide school of mines, students' association, at iron knob, ausimm, excursions, visits, south australian excursion -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, early 1900's

... to be easily moved within the milk processing plants from the delivery... moved within the milk processing plants from the delivery vats ...This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) up to the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons) and produced. In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co. Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "clear" glass. There are other milk bottles that have a "green" tint in them.Around the bottom side of the bottle and blown into the glass "ONE PINT" and on the opposite side "MILK". Below these markings is "This BOTTLE BELONGS TO MILK BOTTLES RECOVERY LTD" below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION. On the base of the bottle is molded a big "M". An identification mark of "90" over "9" is beneath the "M". glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles, milk, dairy, farms, kiewa valley -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

... moved within the milk processing plants from the delivery vats... moved within the milk processing plants from the delivery vats ...This glass milk bottle was manufactured and used mid 1800's (1834 Victorian dairy industry was founded) to the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the large volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36"This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against sunlight penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle to contain milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle a circle within it 6/33 and next to this "ONE PINT" and under this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "4"glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, circa mid to late 1900's

... moved within the milk processing plants from the delivery vats... the milk processing plants from the delivery vats/holding tanks ...This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) up to the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under house at 1 Beauty Ave., Mt Beauty.This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head was manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against light penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle which contained milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle a circle within it "6/18" and next to this "MILK" and opposite "ONE PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "3"glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

... moved within the milk processing plants from the delivery vats... the milk processing plants from the delivery vats/holding tanks ...This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) until the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under house at 1 Beauty Ave., Mt Beauty.This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottle along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against light penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle to contain milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle a circle within it "6/36" and next to this "MILK" and opposite "ONE PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "15" glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

... moved within the milk processing plants from the delivery vats... moved within the milk processing plants from the delivery vats ...This glass milk bottle was manufactured and used mid to late1900's (1834 Victorian dairy industry was founded) up until the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under the house at 1 Beauty Ave., Mt BeautyThis heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against light penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle to contain milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle a circle within it "6/18" and next to this "MILK" and opposite "ONE PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "4"glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

... moved within the milk processing plants from the delivery vats... the milk processing plants from the delivery vats/holding tanks ...This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded), until the time that cheaper containers were invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under the house at 1 Beauty Ave., Mt BeautyThis heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against light penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle, to contain milk, required its thickness because of the extensive handling (man and machine) before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle is a circle within it "6/35" and next to this "MILK" and opposite "ONE PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "20"milk, dairy, glass bottle -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

... to be easily moved within the milk processing plants from the delivery... moved within the milk processing plants from the delivery vats ...This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) up until the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under the house at 1 Beauty Ave., Mt BeautyThis heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottle along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a half pint capacity and is made from "clear" glass. There are other milk bottles that have a "green" tint in them and this tint was to protect the contents from sun damage. This thick glass bottle to contain milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the top half of this bottle is "MILK" and opposite "HALF PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base is "2 M" underneath this "8/11" and underneath is "ISM -169"glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, Circa mid to late 1900's

... to be easily moved within the milk processing plants from the delivery... moved within the milk processing plants from the delivery vats ...This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) up to the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons) and produced. In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co. Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" This particular one has "7/14".This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one Imperial pint capacity and is made from "clear" glass. There are other milk bottles that have a "green" tint in them. Around the bottom side of the bottle and blown into the glass "ONE IMPERIAL PINT". Below these markings and stenciled is "KIEWA" (in freehand style and underlined) underneath is "PASTEURISED FULL CREAM MILK" underneath this ,in freehand stiyle is "USE" next to this in block style "KIEWA BUTTER, CREAM, AND ICE CREAM MIX" to the left of this ,and barely readable is stenciled "THIS BOTTLE ALWAYS REMAINS/ THE PROPERTY OF/ NORTH EASTERN DAIRY Co. Ltd". On the base of the bottle is molded a big "2". with a smaller "m". An identification mark of "7" over "14" is within a circled boundary. Below this is moulded "RM - 15". glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing Machine, 1903

... closed in 1935, becoming a Heinz food processing plant... closed in 1935, becoming a Heinz food processing plant ...Hugo Wertheim (1854-1919), was a merchant and manufacturer and was born on the 12th July 1854 at Lispenhausen, in the German electorate of Hesse-Kassel, son of Meyer Wertheim and his wife Minna, née Heinemann. Hugo reached Melbourne in October 1875. He soon began advertising, from premises at 39 Flinders Lane East, as agent for his father's cousin Joseph Wertheim, a well-established manufacturer of sewing machines. Hugo returned to Germany where he married Joseph Wertheim's daughter Sophie Emilie (1864-1953) on 30 August 1885 at Frankfurt. the couple then came to Melbourne. In a short time, with extensive advertising, Hugo established a substantial business, selling sewing machines, bicycles, pianos and other mechanical devices, under brands such as Wertheim, Electra, Planet, Griffin and Hapsburg. He also mounted elaborate displays at agricultural shows and in 1901 at the Pan American Exposition, Buffalo, United States of America. O. C. Beale worked with him before setting up his own piano business in New South Wales. Hugo continued to own 25 per cent of one of Beale's companies, which became Wertheim's Queensland business. In 1908 Wertheim opened a large, innovative piano factory at Richmond, Melbourne, intending to produce 2000 pianos and player pianos annually, predominantly using Australian materials. In laying the foundation stone, Prime Minister Alfred Deakin observed that “few men with such opportunities for a life of ease would have embarked on such an enterprise” Hugo died of chronic hepatitis on 11 July 1919 at his home at South Yarra, his wife, two daughters and three sons survived him; Herbert Joseph (1886-1972), the eldest, continued the business. Rupert became a share broker and went on to represent Victoria in inter-State tennis in 1913-27 and Australia in Davis Cup matches against Czechoslovakia in 1922. The piano factory closed in 1935, becoming a Heinz food processing plant and in 1955, GTV Channel 9 studios and offices.Early Australians had to be self-reliant in regards to making and mending their clothes and utensils. This sewing machine was one of many items used that exhibit the skill and craftsmanship of the women in these early families. A sewing machine was a necessary part of each home and this item demonstrates how women of the time managed had to become self-reliant in the repair and making of their families clothes to make their household budgets go further.Wertheim sewing machine in carry case, hand operated with two spindles, handle with locking pin, which turns lever between spokes of main handle, hand brake. The machine is table-mounted with a Turkish walnut base. The base can be attached to a cast iron table with a foot treadle as an optional extra. The walnut base has marquetry to the front set out as a measure for material. There is also an accessory box inside the carry case containing 20 additional items for use with the machine. Wertheim brass trademark badge riveted to the body of the machine of a crouching dwarf with a hammer with the name of the company Wertheim and Frankfurt. Gold filigree decoration in gold paint adorns the main body of the machine. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sewing machine, hand operated sewing machine, crank handle sewing machine, wertheim, dressmaking, taylor, domestic, clothing, hugo wertheim, joseph wertheim -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing Machine and case, Joseph Wertheim, late 19th century

... closed in 1935, becoming a Heinz food processing plant... closed in 1935, becoming a Heinz food processing plant ...Hugo Wertheim (1854-1919), was a merchant and manufacturer and was born on the 12th July 1854 at Lispenhausen, in the German electorate of Hesse-Kassel, son of Meyer Wertheim and his wife Minna, née Heinemann. Hugo reached Melbourne in October 1875. He soon began advertising, from premises at 39 Flinders Lane East, as agent for his father's cousin Joseph Wertheim, a well-established manufacturer of sewing machines. Hugo returned to Germany where he married Joseph Wertheim's daughter Sophie Emilie (1864-1953) on 30 August 1885 at Frankfurt. the couple then came to Melbourne. In a short time, with extensive advertising, Hugo established a substantial business, selling sewing machines, bicycles, pianos and other mechanical devices, under brands such as Wertheim, Electra, Planet, Griffin and Hapsburg. He also mounted elaborate displays at agricultural shows and in 1901 at the Pan American Exposition, Buffalo, United States of America. O. C. Beale worked with him before setting up his own piano business in New South Wales. Hugo continued to own 25 per cent of one of Beale's companies, which became Wertheim's Queensland business. In 1908 Wertheim opened a large, innovative piano factory at Richmond, Melbourne, intending to produce 2000 pianos and player pianos annually, predominantly using Australian materials. In laying the foundation stone, Prime Minister Alfred Deakin observed that “few men with such opportunities for a life of ease would have embarked on such an enterprise” Hugo died of chronic hepatitis on 11 July 1919 at his home at South Yarra, his wife, two daughters and three sons survived him; Herbert Joseph (1886-1972), the eldest, continued the business. Rupert became a share broker and went on to represent Victoria in inter-State tennis in 1913-27 and Australia in Davis Cup matches against Czechoslovakia in 1922. The piano factory closed in 1935, becoming a Heinz food processing plant and in 1955, GTV Channel 9 studios and offices.Early Australians had to be self-reliant in regards to making and mending their clothes and utensils. This sewing machine was one of many items used that exhibit the skill and craftsmanship of the women in these early families. A sewing machine was a necessary part of each home and this item demonstrates how women of the time managed had to become self-reliant in the repair and making of their families clothes to make their household budgets go further.Sewing machine, Wertheim brand “ Syst 182” hand crank operated machine with folding handle, timber case and carry handle. Metal machine is painted black, with remnants of gold, red and green scrolls and floral decoration. Machine has base with inlaid measuring rule across front and 2 holes drilled through the base (perhaps for mounting machine to a bench). Machine tilts open, hinged on one side, after thumb screw is unwound, revealing machine’s workings and serial number. Base has a fitted round, concave, silver metal pin holder with lid that hinges open, and symbol pressed into lid; several pins are inside. Body of machine has brand name transfer across front and oval metal trademark disc on front. Metal sliding covers over footplates have stamped lettering. Timber machine case or cover includes an accessory box with sliding cover and metal hook and eye latch, and inside the box are 23 metal sewing attachments, a disc and a stick of black crayon with maker’s trademark on it paper cover. Workings of machine have seized up. The crayon wrapper has printed on it “For the wonderful Wertheim new family machine made in Germany ‘Syst. 182’”, and the maker’s symbol with “Trademark” beside it. Made for Hugo Wertheim.“WERTHEIM” transfer across front and back of machine body. Cover of pin holder has symbol ‘Wings above a shield’. Maker’s trademark on gold oval disc, “WERTHEIM / FRANCFURT” and picture of a dwarf with a hammer. Left footplate has script “Syst 182”, right footplate has stamp in oval shape “MANUFACTURED IN - - /SPECIALLY FOR / HUGO WERTHEIM” Serial Number “7501”flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sewing machine, hand crank sewing machine, hugo wertheim, wertheim, clothing manufacturer, sewing, syst 182 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAccessory - Hemmer Foot, Joseph Wertheim, ca. 1891

... processing plant and in 1955, GTV Channel 9 studios and offices... processing plant and in 1955, GTV Channel 9 studios and offices ...This sewing machine accessory was donated with our collection's Wertheim sewing machine accessory box. The box contains twelve accessories, the instruction book and the receipt for the purchase of a Wertheim sewing machine. The receipt was written on July 23rd 1891 by the Wertheim distributor in Melbourne, Hugo Wertheim. His business was the Wertheim Sewing Machine and Hapsburg Piano Depot, trading at 173 Williams Street, Melbourne. The purchaser was Mrs Burrowes from Burrumbeet, Victoria, a district northwest of Ballarat. She paid £6-6 (six pounds and six shillings) in cash. The receipt was signed by H. Wertheim and the other signatory looks like John A. Cherry. Hugo Wertheim (1854-1919) was an agent for his father’s cousin Joseph Wertheim, a well-established sewing machine manufacturer in Germany. He was born in Lispenhausen, Germany, and migrated to Melbourne in October 1875, where he opened a merchandising business at 39 Flinders Lane East. He returned to Germany in 1885 to marry Joseph Wertheim's daughter Sophie Emilie. The couple came back to Melbourne, and Hugo quickly established a substantial business selling sewing machines, bicycles, pianos and other mechanical devices, under brands such as Wertheim, Electra, Planet, Griffin and Hapsburg. He exhibited at agricultural shows and in 1901 at the Pan American Exposition, Buffalo, United States of America. One of his staff was O. C. Beale, who later set up his own piano business in New South Wales. Hugo continued to own 25 per cent of one of Beale's companies, which became Wertheim's Queensland business. In 1908 Hugo Wertheim opened a piano factory in Richmond, Melbourne, aiming to produce 2000 pianos and player pianos a year, predominantly using Australian materials. In laying the foundation stone, Prime Minister Alfred Deakin observed that “few men with such opportunities for a life of ease would have embarked on such an enterprise” Hugo died of chronic hepatitis in 1919 at his home in South Yarra. His eldest son, Herbert Joseph (1886-1972), continued the business. The piano factory closed in 1935, becoming a Heinz food processing plant and in 1955, GTV Channel 9 studios and offices. The Wertheim Sewing Machine Company – Joseph Wertheim (1804–1899) founded the company in 1868 in Frankfurt, Germany. At this time Joseph was the Frankfurt city delegate for the Democratic Party. At its height, the Wertheim factory employed approximately 650 workers. The company used a trademark of a dwarf holding a hammer which is known to have been used until at least 1925, however in 1909 a Star of David was also registered. In 1870 a Wertheim subsidiary was formed in Barcelona, Spain. The business imported and sold complete machines, including the English Jones machine. Locals began calling the sewing machines “las rapidas”, and the business became known as “las casa de las rapidas”. In 1915 production began of a totally manufactured Spanish Wertheim machine. Wertheim in Germany continued manufacturing machines until 1932 when the Wertheim family fled to Spain. Despite converting to Christianity from Judaism, they feared the political unrest in Germany during that time. Wertheim Spain became Rapida SA and was then the sole manufacturer of the Wertheim machines. The factory was managed by Karl Wertheim under the alias Carlos Vallin. The sewing machine accessory is part of a donation that connected to domestic life in 1891 during the Victorian era. It is significant for connecting the Melbourne distributor of Wertheim sewing machines, Hugo Wertheim, to Victoria’s northwest district where the purchaser lived. It is also significant for connecting the Melbourne distributor to the importing of goods from the well-known German manufacturer of early domestic sewing machines, Joseph Wertheim. Broad Hemmer Foot for a Wertheim sewing machine. Joseph Wertheim manufacturer, Germany, distributed by Hugo Wertheim William Street Melbourne. Circa 1891flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, wertheim, sewing machine, victorian era, sewing machine accessory, wertheim sewing machine and hapsburg piano depot, wertheim sewing machines, sewing machine foot, domestic machines, dressmaking, home industry, fashion -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAccessory - Small Corder Foot, ca. 1891

... processing plant and in 1955, GTV Channel 9 studios and offices... processing plant and in 1955, GTV Channel 9 studios and offices ...This sewing machine accessory was donated with our collection's Wertheim sewing machine accessory box. The box contains twelve accessories, the instruction book and the receipt for the purchase of a Wertheim sewing machine. The receipt was written on July 23rd 1891 by the Wertheim distributor in Melbourne, Hugo Wertheim. His business was the Wertheim Sewing Machine and Hapsburg Piano Depot, trading at 173 Williams Street, Melbourne. The purchaser was Mrs Burrowes from Burrumbeet, Victoria, a district northwest of Ballarat. She paid £6-6 (six pounds and six shillings) in cash. The receipt was signed by H. Wertheim and the other signatory looks like John A. Cherry. Hugo Wertheim (1854-1919) was an agent for his father’s cousin Joseph Wertheim, a well-established sewing machine manufacturer in Germany. He was born in Lispenhausen, Germany, and migrated to Melbourne in October 1875, where he opened a merchandising business at 39 Flinders Lane East. He returned to Germany in 1885 to marry Joseph Wertheim's daughter Sophie Emilie. The couple came back to Melbourne, and Hugo quickly established a substantial business selling sewing machines, bicycles, pianos and other mechanical devices, under brands such as Wertheim, Electra, Planet, Griffin and Hapsburg. He exhibited at agricultural shows and in 1901 at the Pan American Exposition, Buffalo, United States of America. One of his staff was O. C. Beale, who later set up his own piano business in New South Wales. Hugo continued to own 25 per cent of one of Beale's companies, which became Wertheim's Queensland business. In 1908 Hugo Wertheim opened a piano factory in Richmond, Melbourne, aiming to produce 2000 pianos and player pianos a year, predominantly using Australian materials. In laying the foundation stone, Prime Minister Alfred Deakin observed that “few men with such opportunities for a life of ease would have embarked on such an enterprise” Hugo died of chronic hepatitis in 1919 at his home in South Yarra. His eldest son, Herbert Joseph (1886-1972), continued the business. The piano factory closed in 1935, becoming a Heinz food processing plant and in 1955, GTV Channel 9 studios and offices. The Wertheim Sewing Machine Company – Joseph Wertheim (1804–1899) founded the company in 1868 in Frankfurt, Germany. At this time Joseph was the Frankfurt city delegate for the Democratic Party. At its height, the Wertheim factory employed approximately 650 workers. The company used a trademark of a dwarf holding a hammer which is known to have been used until at least 1925, however in 1909 a Star of David was also registered. In 1870 a Wertheim subsidiary was formed in Barcelona, Spain. The business imported and sold complete machines, including the English Jones machine. Locals began calling the sewing machines “las rapidas”, and the business became known as “las casa de las rapidas”. In 1915 production began of a totally manufactured Spanish Wertheim machine. Wertheim in Germany continued manufacturing machines until 1932 when the Wertheim family fled to Spain. Despite converting to Christianity from Judaism, they feared the political unrest in Germany during that time. Wertheim Spain became Rapida SA and was then the sole manufacturer of the Wertheim machines. The factory was managed by Karl Wertheim under the alias Carlos Vallin.The sewing machine accessory is part of a donation that connected to domestic life in 1891 during the Victorian era. It is significant for connecting the Melbourne distributor of Wertheim sewing machines, Hugo Wertheim, to Victoria’s northwest district where the purchaser lived. It is also significant for connecting the Melbourne distributor to the importing of goods from the well-known German manufacturer of early domestic sewing machines, Joseph Wertheim. Small corder foot for a Wertheim sewing machine. Joseph Wertheim manufacturer, Germany, distributed by Hugo Wertheim William Street Melbourne. Circa 1891flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, wertheim, sewing machine, victorian era, sewing machine accessory, wertheim sewing machine and hapsburg piano depot, wertheim sewing machines, sewing machine foot, small corder foot, domestic machines, dressmaking, home industry, fashion -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAccessory - Seamer Foot, Joseph Wertheim, ca. 1891

... processing plant and in 1955, GTV Channel 9 studios and offices... processing plant and in 1955, GTV Channel 9 studios and offices ...This sewing machine accessory was donated with our collection's Wertheim sewing machine accessory box. The box contains twelve accessories, the instruction book and the receipt for the purchase of a Wertheim sewing machine. The receipt was written on July 23rd 1891 by the Wertheim distributor in Melbourne, Hugo Wertheim. His business was the Wertheim Sewing Machine and Hapsburg Piano Depot, trading at 173 Williams Street, Melbourne. The purchaser was Mrs Burrowes from Burrumbeet, Victoria, a district northwest of Ballarat. She paid £6-6 (six pounds and six shillings) in cash. The receipt was signed by H. Wertheim and the other signatory looks like John A. Cherry. Hugo Wertheim (1854-1919) was an agent for his father’s cousin Joseph Wertheim, a well-established sewing machine manufacturer in Germany. He was born in Lispenhausen, Germany, and migrated to Melbourne in October 1875, where he opened a merchandising business at 39 Flinders Lane East. He returned to Germany in 1885 to marry Joseph Wertheim's daughter Sophie Emilie. The couple came back to Melbourne, and Hugo quickly established a substantial business selling sewing machines, bicycles, pianos and other mechanical devices, under brands such as Wertheim, Electra, Planet, Griffin and Hapsburg. He exhibited at agricultural shows and in 1901 at the Pan American Exposition, Buffalo, United States of America. One of his staff was O. C. Beale, who later set up his own piano business in New South Wales. Hugo continued to own 25 per cent of one of Beale's companies, which became Wertheim's Queensland business. In 1908 Hugo Wertheim opened a piano factory in Richmond, Melbourne, aiming to produce 2000 pianos and player pianos a year, predominantly using Australian materials. In laying the foundation stone, Prime Minister Alfred Deakin observed that “few men with such opportunities for a life of ease would have embarked on such an enterprise” Hugo died of chronic hepatitis in 1919 at his home in South Yarra. His eldest son, Herbert Joseph (1886-1972), continued the business. The piano factory closed in 1935, becoming a Heinz food processing plant and in 1955, GTV Channel 9 studios and offices. The Wertheim Sewing Machine Company – Joseph Wertheim (1804–1899) founded the company in 1868 in Frankfurt, Germany. At this time Joseph was the Frankfurt city delegate for the Democratic Party. At its height, the Wertheim factory employed approximately 650 workers. The company used a trademark of a dwarf holding a hammer which is known to have been used until at least 1925, however in 1909 a Star of David was also registered. In 1870 a Wertheim subsidiary was formed in Barcelona, Spain. The business imported and sold complete machines, including the English Jones machine. Locals began calling the sewing machines “las rapidas”, and the business became known as “las casa de las rapidas”. In 1915 production began of a totally manufactured Spanish Wertheim machine. Wertheim in Germany continued manufacturing machines until 1932 when the Wertheim family fled to Spain. Despite converting to Christianity from Judaism, they feared the political unrest in Germany during that time. Wertheim Spain became Rapida SA and was then the sole manufacturer of the Wertheim machines. The factory was managed by Karl Wertheim under the alias Carlos Vallin. The sewing machine accessory is part of a donation that connected to domestic life in 1891 during the Victorian era. It is significant for connecting the Melbourne distributor of Wertheim sewing machines, Hugo Wertheim, to Victoria’s northwest district where the purchaser lived. It is also significant for connecting the Melbourne distributor to the importing of goods from the well-known German manufacturer of early domestic sewing machines, Joseph Wertheim. Seamer foot; feller single seamer for a Wertheim sewing machine. Made by Joseph Wertheim, Germany, and distributed by Hugo Wertheim, William Street Melbourne. Circa 1891flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, wertheim, sewing machine, victorian era, sewing machine accessory, wertheim sewing machine and hapsburg piano depot, wertheim sewing machines, sewing machine foot, seamer foot, domestic machines, dressmaking, home industry, fashion