Showing 53 items matching "raising machinery"

-

National Wool Museum

National Wool MuseumBooklet, Vee Raising Machinery

... Vee Raising Machinery...raising machinery..."Vee Raising Machinery" - Tomlinsons (Rochdale) Ltd, c.1953....Book / catalogue for raising machinery by Tomlinsons...-and-the-bellarine-peninsula "Vee Raising Machinery" - Tomlinsons (Rochdale ..."Vee Raising Machinery" - Tomlinsons (Rochdale) Ltd, c.1953.Book / catalogue for raising machinery by Tomlinsons (Rochdale) Ltd, 1953.textile finishing, tomlinsons (rochdale) ltd, raising machinery -

National Wool Museum

National Wool MuseumBook, Finishing Machinery

... Raising Machinery... and Sons Limited Cloth - woollen Cloth - worsted Raising Machinery ..."Finishing Machinery" by W.M. Whiteley and Sons Ltd, Oct. 1922. Catalogue of machinery for finishing woollen and worsted cloths.Catalogue of textile finishing machinery produced by William Whiteley and Sons Ltd, Huddersfield, Oct. 1922.textile machinery textile finishing, wm. whiteley and sons limited, cloth - woollen, cloth - worsted, raising machinery, milling, tentering, textile machinery, textile finishing -

National Wool Museum

National Wool MuseumBook, Cloth Raising Machines

... Raising Machinery... Finishing Tomlinsons (Rochdale) Ltd Raising Raising Machinery ..."Cloth Raising Machines" - Tomlinsons (Rochdale) Ltd, Rochdale, England, c.1930.Book: "Cloth Raising Machines" - Tomlinsons (Rochdale) Ltd, c.1930.textile machinery textile finishing, tomlinsons (rochdale) ltd, raising, raising machinery, textile machinery, textile finishing -

National Wool Museum

National Wool MuseumTeasel holder

... Raising Machinery... of a teasel gig. Raising Raising Machinery Teasel holders from ...Used to hold the teasels on the roller of a teasel gig.Teasel holders from the drum of a teasel gig. Teasel holders from the drum of a teasel gig.raising, raising machinery -

National Wool Museum

National Wool MuseumMachine - Teasel Gig, c1890

... raising machinery... the delicate work to raise the surface, or nap, the woollen cloth ...When the fabric is removed from the loom it is often stiff, rough and uneven. There are a number of finishing processes, both mechanical and chemical that give wool fabrics their special look and feel. The fabric is often scoured again to remove oils and dirt picked up during manufacture. It is then pressed. For a soft and fluffy surface, the fabric is brushed. For a smooth surface, it is shorn. For centuries, machines similar to this teasle gig were used to finish fabrics. It uses the prickly flower head off the teasle plant (Dispsacus Fullonum) to do the delicate work to raise the surface, or nap, the woollen cloth. At least 1,500 teasle heads are needed for one gig. The teasel is a thistle like plant whose dried heads are used on the teasel gig. They are fixed to frames around the drum, or gig. The gig turns in the opposite direction to the flow of the cloth until the nap is raised. Also spelled as Teazel Gig.Large metal machine with wooden rollers and teasel covered drum.textile finishing, raising, raising machinery, teasel gig, fabric, wool processing, plants, thistle, drum -

National Wool Museum

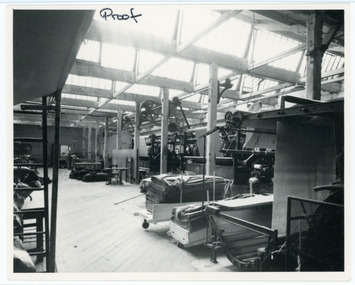

National Wool MuseumPhotograph

... raising machinery... finishing raising machinery Proof IAN HAWTHORNE / PHOTOGRAPHER ...Depicts the dry finishing room from one of the Godfrey Hirst mills in 1966. In 1966 McKendrick Consolidated Industries Ltd purchased Godfrey Hirst Ltd to operate a carpet manufacturing concern and this photo was taken at the time of the takeover.Proof IAN HAWTHORNE / PHOTOGRAPHER / Commercial, Portrait, Wedding, Colour Processor / Upstairs, 140 Moorabool St., Geelong Ph. 98096textile finishing, godfrey hirst and co. pty ltd, dry finishing, raising machinery -

National Wool Museum

National Wool MuseumBook - The Art of Napping

... raising machinery... by an American manufacturer of napping machinery. The napping (or raising.... raising raising machinery lustring tentering Book: "The Art ..."The Art of Napping", Woonsocket Napping Machinery Co., c.1924. Catalogue of napping machinery sent to Collins Bros by an American manufacturer of napping machinery. The napping (or raising) done by these machines is all done by wire, not teasels.Book: "The Art of Napping" Woonsocket Napping Machinery Co., c.1924. Letter from The Woonsocket Napping Machinery Company to Mr. Charles W. Ayling, 16 October 1924, page 1. Letter from Woonsocket Napping Machinery Company to Mr. Charles W. Ayling, 16 October 1924, page 2. Blueprint of Napping Machine, Woonsocket Napping Machinery Co. with speeds at which machines should run. Letter from Woonsocket Napping Machinery Co. to Collins Cros. Pty. Ltd., 17 April 1950textile finishing, cotton, woonsocket napping machinery co., raising, raising machinery, lustring, tentering -

National Wool Museum

National Wool MuseumBook, Finishing Machinery

... Carbonising Dyeing Raising Textile Machinery Textile Finishing ..."Finishing Machinery" - James Bailey, Textile Machine Maker, Huddersfield, c. 1926. Catalogue of machinery for fulling, scouring, carbonising, dyeing and finishing woollen and worsted and other types of textiles.Catalogue of textile finishing machinery from James Bailey, textile machine maker, Huddersfield, c.1926.textile machinery textile finishing, james bailey, textile machine maker, milling, scouring, carbonising, dyeing, raising, textile machinery, textile finishing -

Federation University Historical Collection

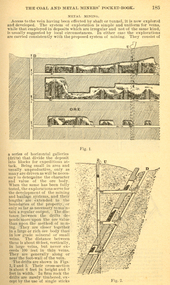

Federation University Historical CollectionBook, The Colliery Engineer Company, Coal and Metal Miners' Pocket Book, 1893, 1893

... , mine railways, Friction of mine cars, colliery machinery, steam..., mine railways, Friction of mine cars, colliery machinery, steam ...This book was specially compiled and prepared for the convenient use of mine officials, mining engineers, and students preparing themselves for certificates of competency as mine inspectors or mine foremen.Dark, hard covered book. Contents include arithmetic, weights and measures, Cylinders, Geometry, Mensuration, Surveying, strength and Weight of Materials, wire ropes, chains, Colliery management, precious metals, ventilation, hydrostatics, hydraulics, mine railways, Friction of mine cars, colliery machinery, steam raising, rules for engine drivers, faults, electricity, glossary of Mining terms.mining, coal, metal, colliery, definitions, brook, advertisements -

The Beechworth Burke Museum

The Beechworth Burke MuseumPhotograph - Photograph - Reproduction, c.1870s

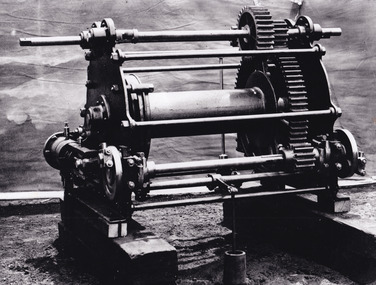

This photograph shows a piece of gold mining equipment identified as a mine winch, possibly an air winch cylinder of 1870s RG Ford's Patent design. Throughout the history of mining for gold and other precious materials, the windlass or winch (pictured) was used to bring up buckets full of soil from the bottom of a mine. This soil was then searched for gold/metals before being relocated to a different area. Due to the size and complexity of this particular piece of equipment, this winch may have been used to raise and lower mine carts to the entrance of the mine (often used in coal mining) and could have been used in raising cages up and down (acting as elevators) containing miners if the mine was particularly deep. The actual use of this particular item in the Beechworth locality is undocumented but these are some possibilities based on the use of these pieces of equipment in other mining locations. Mining can have a largely detrimental impact to the environment and therefore, the study of machinery like the one depicted in this photograph can help researches to reconstruct the methods and technologies used in the late 1800s and early 1900s. This particular item appears to have been removed from it's original site where it would have been used to assist with mining. It is possible that this photograph has been taken for recording purposes or as part of a machinery exhibition. Prior documentation records that this piece of equipment had connections to the Rocky Mountains Mining Company. Today, the Rocky Mountains Gold Mining company is famous in Beechworth for having been instrumental in the creation of the Rocky Mountain tunnel. Construction for this tunnel began in 1859 when a group of 12 men blasted a 400ft long tailrace though the rock beneath the town of Beechworth. Today, the 800ft tunnel, completed in 1871, is a popular tourist attraction but during the decades of gold mining, the purpose of this tunnel was to divert water away from the main sluicing operations so miners could better access gold and precious materials. The tunnel was used for this purpose for many years, later becoming useful for the Zwar Brother's tannery and currently as an outfall drain for Lake Sambell. This area continued to be mined until the early 1900s. The period when this item was in use is unclear but it is estimated to have been in the 1870s based on the design and appearance of the image. The gold works at the Rocky Mountain Tunnel closed in the early 1920s but the impact of mining remains in Beechworth today and therefore the study of photographs like this one which contain mining equipment can further understanding of mining in this region.This photograph has historic and research potential for study on the gold mining of the Beechworth region and types of equipment used to locate gold after the initial gold rush of 1853-1854 which resulted in the discovery of the surface gold and required miners to dig deeper to access precious metals. The clarity of the photo, and its good preserved condition, means it can continue to be used for research. This photo is part of a collection of six photos all within the Burke Museum Collection which depict mining equipment.Square black and white photograph on card.7793.1beechworth, mining, goldmining, goldmining equipment, beechworth burke museum -

Seaworks Maritime Museum

Seaworks Maritime MuseumShipbuilders model, Tri Ellis

... , machinery, rigging and superstructure, raised on a wooden base... painted in red, with detailed fittings, machinery, rigging ...Model ship was presented to the Melbourne Maritime Museum by the British Phosphate Commissioners. Built as Tri-Ellis (1958-74), Tryphena (1974-78), Man Tat (1978-80), 1980 broken up. DWT 13,756 SPEED 14 KNOTS.AT 112RPM. BOILERS LARKSON TRIMBLETUBE. FUEL CONSUMPTION 7 TPD. GENERATORS W.H.ALLEN - 4CYL.2SA290/470. 480B.H.P.320L.W.-220V 333RPM DAILY CONS - 1.5 TONS. EMERGENCY GEN R & H. 40 K.N. -220V. REFRIGERATING MACH: J & G HALL LTD. SUPERSTRUCTURE: FORECASTLE 62'..2 DECKS RIVETED AND WELDED. CARGO BATTONS NOT FITTED. 9 BULKHEADS. RISE OF FLOOR 6".WATER BALLAST 3,296 TONS INCLUDING TUNNEL TANKS 1,341 TONS. 'TWEEN- DECKS FORWARD 274 TONS. REFRIGERATED CARGO INSTALLATION - 6 HOLDS - 55.2',52',54',59.5',43' ,53'. GRAIN CAPACITY :621,640 CU. FT. BALE CAPACITY : 573,810 CU. FT. INSULATED CAPACITY : 5,050 CU.FT. 6 STEEL HATCHWAYS (27',30',30'* 30') (30'* 27.75') (27', 24' * 28' ). 12 WINCHES...DERRICKS 1 (25), 2 (10), 10 (5). MACHINERY: OIL 2SA 7CY.C20 * 1400MM EXHAUST 470MM. 6500 BHP. FUEL BUNKERS: 2135 TONS HIGH VISCOCITY FUEL. The main engine was an opposed piston type Harland & Wolff 6-620/ 1870 6 for the number of cylinders.. 620 for the cylinder bore and 1870 for the combined strokes of the main exhaust pistons in each cylinder. This engine was based no a Burmeister and Wain design but H & W gave these engines their own type designation. Sailed on board its maiden voyage to Australia via Casablanca Morocco where she collected her first load of phosphate. We sailed to Geelong via the Suez canal and the Port of Aden (Yemen) and Freemantle. The first load of phosphate was unloaded at Corio Bay (geelong) Formerly part of the collection of Melbourne shipping company, Howard Smith Ltd. Ship builder's model of the cargo ship Tri-Ellis IMO 5368196 - Body of moulded polyurethane painted in red, black and grey, the deck painted in red, with detailed fittings, machinery, rigging and superstructure, raised on a wooden base. Original ship built Clyde 1958, 11,761 gross tonnes, 531.5' x 68' x 31' (162.0 x 20.73 x 9.45m)plaque at foot of model "MV TRI ELLIS/ LENGTH B.P. 486'-3"- BREADTH MLD 68'0" - DEPTH MLD 40'6"/ TONNAGE GROSS 11,760/ Built by HARLAND & WOLFF LTD/ For BRITISH PHOSPHATE COMMISSIONERS" On model "TRI-ELLIS" painted black -

Seaworks Maritime Museum

Seaworks Maritime MuseumShipbuilders model, Express

... , machinery, rigging and superstructure, raised on a wooden base...., the deck painted grey, with detailed fittings, machinery, rigging ...The Express 11, was built in 1990, and is still in service as the Trimness. A self discharging bulk carrier she was built by Tsuneishi Zosen K. K. Numkauma for Howard Smith Industries Pty. Ltd. Length 150m Beam 24m Gross tons 17,309 speed 13 knots. Sold in 1996 to Trimnes Shipping, of Panama Sold 1996 to Trimnes Shipping Co, Panama and renamed Trimnes.Ship builder's model - Body of moulded polyurethane painted in maroon and black, the deck painted grey, with detailed fittings, machinery, rigging and superstructure, raised on a wooden base.on model: "EXPRESS/ EXPRESS HOBART" on base: PWO 2666.1/ 110/97 SI -

Seaworks Maritime Museum

Seaworks Maritime MuseumShipbuilders model, MT Salvageman

... with detailed fittings, machinery, rigging and superstructure, raised... in colours of green and cream with detailed fittings, machinery ...SALVAGEMAN of Hull (1980-) Owned by United Towing of Hull, she was the UK's largest and most powerful salvage tug for many years. In 1982 she saw service at the Falklands and played a part in the sinking and subsequent salvage of the Argentinian submarine Santa Fe. She was sold and renamed HISPANIA in 1991. Sold once again in 1996 and became the ANGLIAN PRINCE, a name that she still holds. 1977: Ordered and laid down as NOBLEMAN by "United Towing (Nobleman) Ltd", 1979 -12/07: Launched by "Chung Wah Shipbuilding & Engineering Co Ltd" at Hong Kong (HKG) (YN 160) 1980 -17/04: delivered to "UTC - United Towing Co (Howe) Ltd" at Hull (GBR) 1981 -16/03: mng "UTC - United Towing Co (Ocean Tugs) Ltd" at Hull (GBR), as SALVAGEMAN (GBR flag, regd Hull, ON 386484, c/s GXYN) 1987: taken over by "Howard Smith UK Ltd" at Hull (GBR) 1990 -24/04: To "Salvageman Ltd" at Douglas (IOM) 1991: To "COSMAR SA" (ESP), mng "Baluda Offshore" at Bilbao (ESP), renamed HISPANIA 1991 -25/7: British register closed and transferred to Spanish register (ESP flag, regd Bilbao, c/s EADY, 1597 GRT, 461 NRT) 1996: To "KTL - Klyne Tugs (Lowestoft) Ltd" at Lowestoft (GBR), renamed ANGLIAN PRINCEShip builder's model - Body of moulded polyurethane painted in maroon and black, the deck in colours of green and cream with detailed fittings, machinery, rigging and superstructure, raised on a wooden base. Ship was built by Chung Wah Shipbuilding & Engineering Co. on base of case: "M.T. SALVAGEMAN/BUILT 1979 BY/ CHUNG WAH SHIPBUILDING & ENGINEERING CO LTD HONG KONG/ FOR/ UNITED TOWING LTD/ LENGTH O/A 68.25M BREADTH MLD 14.20M DEPTH MLD. 6.80M" On model: "SALVAGEMAN/ SALVAGEMAN HULL/ SALVAGEMAN HULL" -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionPhotograph - Photograph - Machinery, n.d

Sourced from Casterton Town Hall (Former Shire of Glenelg)Black and white photo. Wooden raised platform over large boulder, machinery, 2 rainwater tanks on stand.Back: Round, purple, photographer's stamp -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Textile - Woollen Blanket, Warrnambool Woollen Mill, Circa 1949

The first Warrnambool to Melbourne cycling race was held in October 1895. 24 riders started with only 7 finishing the race. W. Nicol was the winner of the inaugural race. Two months later on 14/12/1895 the race was run in reverse. For the ensuing 43 years it was mainly Melbourne to Warrnambool. Since 1939 it has been run mainly Melbourne to Warrnambool. The prize of this blanket was 2nd prize to E. Ion of Tasmania in October 1949. The prize itself, A Warrnambool Blankets Tartan rug was made at the Warrnambool Woollen Mill in Harris St Warrnambool Early efforts to establish a woollen Mill in Warrnambool commenced with an early mill on the Merri at Woodford in 1874 but the site proved unsuitable and was financially struggling. The decision was made to move plant and and machinery to the old meat preserving factory in South Warrnambool The plant and equipment was sold to Mr Robert Hood of Sherwood on the Hopkins River East Warrnambool who carried on the venture until fire destroyed the building in 1882, The site lay idle until a group of local businessmen raised 40000 pounds to establish the mill in 1910. It continued to trade well through the early and mid 20th century. Dunlop brought the mill in 1968 and there was a slow downturn with numerous owners until it closed in 2000. The site passed into private hands in 2003.Both the Warrnambool Woollen Mill and the Melbourne to Warrnambool Road Race are a significant part of local history. The Melbourne to Warrnambool Cycling road race remains one of the premier sporting events in Australia. It commenced in 1895 Maroon and red block check with black and white check lines on front with plain maroon back. Fringed on two sides. Grey cotton label with The Warrnambool Woollen Mill Co Limited in top Left hand side of label, Victory Rug diagonally in blue Guaranteed All WOOL Made in Australia in bottom RH corner of label. Owner M bottom of label. 1949 Mr. Ernie Ion” handwritten in black pen.warrnambool, warrnambool woollen mill, marcus saltau, w. nicol -

Federation University Historical Collection

Federation University Historical CollectionModel, Model of the Munro Reaper, 1887

An example of good invention in an era of innovation in Australian manufacture and production. Levers raise the height of the cutter, disengaging the drive from the blades. The moveable blades under the fixed ‘fingers’. An eccentric rod changes circular motion to linear back and forth of the blades. Such a machine is now known as a mower for cutting grass for hay, and other grasses for storing as sheaves. 'Gift for Museum - The School of Mnes committee has accepted the offer from mr H.B. Munro, of Elsternwick, of a model reaping machine made in 1887 when the Munro machinery business was in operation in Alfredton. The model, which has won gold medals at various exhibitions, is to be placed in thr school museum. (Ballarat Courier 22 April 1932) Metal model with red paint detail in sectionsM263ballarat school of mines, ballarat school of mines museum, munro machinery, model, munro reaper -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Rope Block, Mid-20th century

A sailing or rope block has single or multiple pulleys with one or more sheaves enclosed in an assembly between cheeks or chocks. In use, a block is fixed to the end of the line, spar or load to be lifted such as at a transport dock. A rope line is reeved through the sheaves, and through one or more matching blocks at the far end, to make up what's known as a tackle. Generally, the more sheaves in the blocks that make up a tackle, the higher its mechanical advantage. Various types of blocks are used in sailing. Some blocks are used to increase mechanical advantage and others to change the direction of a line. A ratchet block turns freely when a line is pulled in one direction but does not turn in the other direction, although the line may slip past the sheave. This kind of block makes a loaded line easier to hold by hand.This rope block is an example of rope and tackle systems used in maritime settings to lift and move cargo and machinery, often with the help of a crane. It is also used on sailing vessels as part of the rigging, help to raise and lower the ropes and sails.Block; two sheave wooden rope block with ring and becket. It features a Closed Spelter Socket (CSS). Rings are galvanised metal. There is a compliance plate attached with an inscription. It was once owned by a government body, as indicated by the 'up-arrow" symbol.Compliance plate: stamped twice "CS" [Closed Spelter] and "↑"flagstaff hill, warrnambool, shipwreck coast, flagstaff hill maritime museum, flagstaff hill maritime village, lifting equipment, stevedoring, rope block, rigging block, sailing equipment, css, closed spelter socket -

Bendigo Historical Society Inc.

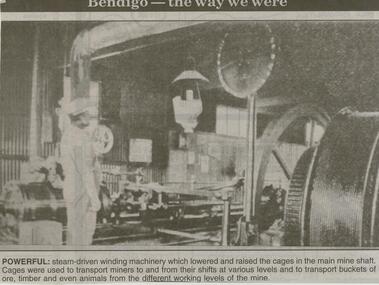

Bendigo Historical Society Inc.Newspaper - JENNY FOLEY COLLECTION: POWERFUL

... : steam-driven winding machinery which lowered and raised... machinery which lowered and raised the cages in the main mine shaft ...Bendigo Advertiser ''The way we were'' from 2000. Powerful: steam-driven winding machinery which lowered and raised the cages in the main mine shaft. Cages were used to transport miners to and from their shifts at various levels and to transport buckets of ore, timber and even animals from the different working levels of the mine. The clip is in a folder.newspaper, bendigo advertiser, the way we were -

National Wool Museum

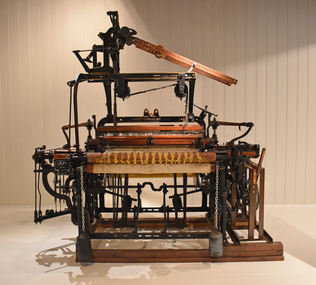

National Wool MuseumMachine - Loom, George Hattersley and Sons Ltd, 1920 - 1935

Weaving is the interlacing of two yarns, one at right angles to the other. Yarns that run the length of the fabric are called the warp. Yarns that run across the fabric are called the weft. Most woven fabrics are produced on a loom. The warp yarns are raised to form an opening - the shed. The weft carrier, usually the shuttle, shoots through the shed. Then the warp yarns change position up and down. Finally, the weft is pushed tight against the previous yarns, gradually building up the fabric. Hattersley dobby loom. In working order, black painted cast iron.weaving, george hattersley and sons ltd, weaving machinery, loom, wool processing, textile industry -

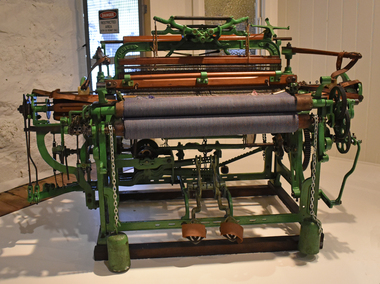

National Wool Museum

National Wool MuseumMachine - Loom, George Hattersley and Sons Ltd, 1920 - 1925

Weaving is the interlacing of two yarns, one at right angles to the other. Yarns that run the length of the fabric are called the warp. Yarns that run across the fabric are called the weft. Most woven fabrics are produced on a loom. The warp yarns are raised to form an opening - the shed. The weft carrier, usually the shuttle, shoots through the shed. Then the warp yarns change position up and down. Finally, the weft is pushed tight against the previous yarns, gradually building up the fabric. Hattersley treadle loom (revolving box hand loom). Beam of loom was removed and sent to Foster Valley Mill in 1989 to be returned via Tom Crocker. The National Wool Museum gratefully acknowledges the contribution of Mr Fred Murgatroyd & Mr Bernard Tolan in making this Hattersley Loom Operational. Green painted Hattersley treadle loom (revolving box hand loom).weaving, george hattersley and sons ltd, weaving machinery, wool processing, loom, restoration -

Rutherglen Historical Society

Rutherglen Historical SocietyImage, c1990

This photograph shows the workers' amenities at the Gold Battery. The building has a bedroom and kitchen. In front is a Baler Bucket and a cage. This particular cage was for raising and lowering the skips which brought the material to the surface. This is one of a series of photographs of the Rutherglen Gold Battery. The battery's purpose was to crush quartz from nearby quartz reefs and extract gold from within. The battery was erected in 1908 and consists of a five-head battery, Wilfrey table, Bergin pan, portable steam engine and shed. The battery was restored in 2011/12 and can be viewed daily between 9.00am and 5.00pm. See website for details.Colour photograph of a corrugated iron cottage, with several pieces of machinery around it.gold battery, gold processing -

Friends of Westgarthtown

Friends of WestgarthtownCog

Small iron cog with seven rounded cogs around edge. Raised circle in centre on both sides, square hole through centre.No visible markingsrural industry, farm machinery, cog, machine, iron -

Stawell Historical Society Inc

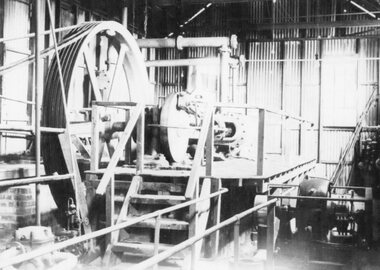

Stawell Historical Society IncPhotograph, Winding gear used to raise and lower the trucks up and down the Wonga open cut

B/W photo of winding gear used to raise and lower the trucks up and down the Wonga open cut.View of machinery inside winding shedstawell mining -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncPrinting Machine

Foot pedal operated platen machine patented by J. Wade, Halifax. Made of Metal and wood. Hand feed paper pickup.Patent plate and "ARAB" in raised letters on the base. -

Maldon Vintage Machinery Museum Inc

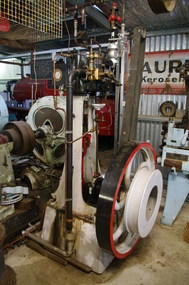

Maldon Vintage Machinery Museum IncSteam Engine, Estimated late 19th century

Large 4 wheeled single cylinder (horizontal) steam engine designed to be towed. Fire box painted black, boiler and steam cylinder green, wheels red. Boiler is not sound so engine is connected to an independent steam/air source to be operated for display purposes. 150 cm flywheel on LHS looking forward toward the front. Brass water drain tap on firebox. Also other brass fittings on firebox. Cast brass disc with red background fixed high on firebox :- "Marshal Sons & Co. / Made expressly / to the order / Shut, No. 45781, Open / of / Robison Bros / South Melbourne." "10017" raised in relief on firebox door. machinery; engines; steam power source -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncCar Jack, Possibly 1960s

Mechanical mobile car jack made by the TREWELLAH company of Trentham for APAC Industries Ltd. Known as a "Service Jack" used for servicing cars and light vehicles. Mounted on 4 wheels, two being castors. Painted red. On a brass plate fixed to top of body "APAC / Service Jack No. 247 / Range 4 5/8" to 19 3/4" / Capacity 5000 lb / Caution: Do not overload / This jack is guaranteed to raised 5000 lb / Overloading renders this guarantee null and void / lubricate jack thoroughly before using / always keep jack clean and well oiled / Manufactured in Australia / APAC Industries Limited. / South Australia"tools, automotive, servicing -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncSteam Engine

Vertical cylinder steam engine painted black, red and grey. In working order. Large flywheel and pulley on RHS and mounted on a raised concrete base. Belt drive overhead governor.No. "8532" is cast on the LHS of the frame.engines, steam, vertical -

National Wool Museum

National Wool MuseumTextile - Skirt, Tina Knitwear, 1980-2000

Part of a selection of garments knitted by ‘Tina Knitwear’. Tina Knitwear was a successful made to order knitwear business in Brighton from the mid-1960s to around 2010, run by Assunta and Franco Liburti. Daughter Melissa Persi writes: Our parents Assunta (Mum) and Franco (Dad) Liburti ran a successful made to order knitwear business in Brighton from the mid-1960s to around 2010. Assunta was affectionately known to her family as Assuntina, therefore the business was named "Tina Knitwear" after her. Assunta and Franco were born in the beautiful seaside town of Terracina in Italy in 1933 and 1930 respectively. As was so common in Italy in the 1950s, Assunta who was in her late teens and early twenties learnt the intricate skills of machine knitting, dressmaking and pattern making. Franco on the other hand, learnt the building trade with his 2 brothers and specialised in bricklaying and tiling. As was so common after the war, Assunta and Franco yearned for a better life so they decided that they would get engaged and then migrate to Australia to be married and raise their family in Australia, a land of much opportunity which they no longer felt their beloved Italy held for them. Assunta migrated to Australia first in 1957 and later Franco joined her in 1958 where they were married. For the first few years, Franco (also known as Frank) worked as bricklayer /tiler on buildings such as the Robert Menzies building at Monash University in Clayton and various buildings in the Melbourne CBD. Assunta on the other hand put her machine knitting skills to use working in factories doing piece machine knitting for various knitwear companies. The hours were long, the conditions were difficult, and travel was onerous without a car. After their 2 older children were born, it was decided that dad would leave the building trade and they would start their own made to order knitwear business. That way they could work from home and raise their family together. Mum taught dad everything he needed to know so he could operate the knitwear machinery. They purchased COPPO knitting machines from Italy and a Linking machine from Germany. Initially they had a knitwear shopfront in Bay Street Brighton where a store assistant would take the orders and client’s measurements and Assunta would then make the garments from a small workshop in their home. Unfortunately, the assistants were not skilled dressmakers and often measurements and orders were incorrectly taken. Assunta being the perfectionist and highly skilled machinist that she was, decided that she needed to oversee the entire process from meeting the client, to taking their order, right thru to the fittings and completion of the garment. It therefore made sense that they should close the shop front and run their business from their own home in Brighton and hence “Tina Knitwear” was born. Together, for more than 40 years they ran their very respected and successful business and were well known in the Bayside area. They specialised in made to order knitwear for both men and women using mainly pure wool (from Patons, Wangaratta Mills, Japan and Italy) but also lurex and estacel. Over those years, many of their clients became their close friends. It wasn't unusual for clients to come to order garments and then end up in the kitchen chatting over a cup of Italian espresso coffee and homemade biscuits. Some of their clients were especially memorable and became lifelong friends. Mrs Connell was a dear friend of mum’s, each year she would buy tickets for the “Gown of the Year” fashion show. She would insist on taking Assunta and her 2 daughters so that we could see the latest fashions. Then there was their dear friend Ms Griffiths. She had been a Matron nurse at the Queen Victoria Hospital when she met my parents in the 1970s. She returned to live in New Zealand in the 1980s but came back to Melbourne every year to stay for 2 weeks with the sole purpose of visiting my parents (she adored them) and order garments. For those 2 solid weeks, mum and dad would only knit for Ms Griffiths and she would go back to New Zealand with at least 5 or 6 new outfits. I actually think she enjoyed mum’s homemade pasta almost as much as her new clothes! Over the years, my parents learnt to speak English very well given that majority of their clients were not Italian speaking. Their oldest child John born in 1960 learnt to speak English with the help of those clients who were such a big part of our childhood. Mum and dad always went above and beyond to ensure their clients were satisfied. Mum was an absolute perfectionist and it showed in her attention to detail and the quality of their beautiful work. You only need to look at the garments that have stood the test of time or speak to their clients to know that this is true. Their clients would always comment on how well their clothes would last and much of their clients came via word of mouth and recommendations. Occasionally there would be disagreements because mum had found an error in dad's knitting (either a wrong stitch or a sizing mistake mainly) and would ask him to redo a piece, he would argue back saying that it was fine, but we always knew who would win the argument and that the piece would get remade! Similarly, we recall discussions where mum would ask dad to find a particular colour of wool in the garage where the stock was kept. He would try to convince her that they were out of stock of that colour and that the client should choose a different colour. She would insist they had it and then after hours of searching, he would return into the house sheepishly holding the wool! Our childhood is full of beautiful memories of mum and dad always being present, clients coming and going, mum humming her favourite songs as she worked often late into the night and sometimes, we even fell asleep to the hum of the machinery. They put their heart and soul into "Tina Knitwear" and took pride in providing only the best quality garments for their clients. In Italian there is a saying “lei ha le mani d’oro” which literally translated means “she has hands of gold”. Franco enjoyed his work but for Assunta, it was more than just work and there is no better way to describe her skills, passion and dedication to her machine knitting… she truly did have “hands of gold”. We will forever be grateful that our parents’ life journey gave us the opportunity to live in a home filled with creativity, dedication and passion, amazing work ethic and mutual respect, lifelong friendships and a lifetime of love. Red ribbed skirt with elastic waistband.knitwear, clothing, italy, migrants, brighton, knitting machine, linking machine, garments, business, family, community -

National Wool Museum

National Wool MuseumTextile - Skirt, Tina Knitwear, 1980-2000

Part of a selection of garments knitted by ‘Tina Knitwear’. Tina Knitwear was a successful made to order knitwear business in Brighton from the mid-1960s to around 2010, run by Assunta and Franco Liburti. Daughter Melissa Persi writes: Our parents Assunta (Mum) and Franco (Dad) Liburti ran a successful made to order knitwear business in Brighton from the mid-1960s to around 2010. Assunta was affectionately known to her family as Assuntina, therefore the business was named "Tina Knitwear" after her. Assunta and Franco were born in the beautiful seaside town of Terracina in Italy in 1933 and 1930 respectively. As was so common in Italy in the 1950s, Assunta who was in her late teens and early twenties learnt the intricate skills of machine knitting, dressmaking and pattern making. Franco on the other hand, learnt the building trade with his 2 brothers and specialised in bricklaying and tiling. As was so common after the war, Assunta and Franco yearned for a better life so they decided that they would get engaged and then migrate to Australia to be married and raise their family in Australia, a land of much opportunity which they no longer felt their beloved Italy held for them. Assunta migrated to Australia first in 1957 and later Franco joined her in 1958 where they were married. For the first few years, Franco (also known as Frank) worked as bricklayer /tiler on buildings such as the Robert Menzies building at Monash University in Clayton and various buildings in the Melbourne CBD. Assunta on the other hand put her machine knitting skills to use working in factories doing piece machine knitting for various knitwear companies. The hours were long, the conditions were difficult, and travel was onerous without a car. After their 2 older children were born, it was decided that dad would leave the building trade and they would start their own made to order knitwear business. That way they could work from home and raise their family together. Mum taught dad everything he needed to know so he could operate the knitwear machinery. They purchased COPPO knitting machines from Italy and a Linking machine from Germany. Initially they had a knitwear shopfront in Bay Street Brighton where a store assistant would take the orders and client’s measurements and Assunta would then make the garments from a small workshop in their home. Unfortunately, the assistants were not skilled dressmakers and often measurements and orders were incorrectly taken. Assunta being the perfectionist and highly skilled machinist that she was, decided that she needed to oversee the entire process from meeting the client, to taking their order, right thru to the fittings and completion of the garment. It therefore made sense that they should close the shop front and run their business from their own home in Brighton and hence “Tina Knitwear” was born. Together, for more than 40 years they ran their very respected and successful business and were well known in the Bayside area. They specialised in made to order knitwear for both men and women using mainly pure wool (from Patons, Wangaratta Mills, Japan and Italy) but also lurex and estacel. Over those years, many of their clients became their close friends. It wasn't unusual for clients to come to order garments and then end up in the kitchen chatting over a cup of Italian espresso coffee and homemade biscuits. Some of their clients were especially memorable and became lifelong friends. Mrs Connell was a dear friend of mum’s, each year she would buy tickets for the “Gown of the Year” fashion show. She would insist on taking Assunta and her 2 daughters so that we could see the latest fashions. Then there was their dear friend Ms Griffiths. She had been a Matron nurse at the Queen Victoria Hospital when she met my parents in the 1970s. She returned to live in New Zealand in the 1980s but came back to Melbourne every year to stay for 2 weeks with the sole purpose of visiting my parents (she adored them) and order garments. For those 2 solid weeks, mum and dad would only knit for Ms Griffiths and she would go back to New Zealand with at least 5 or 6 new outfits. I actually think she enjoyed mum’s homemade pasta almost as much as her new clothes! Over the years, my parents learnt to speak English very well given that majority of their clients were not Italian speaking. Their oldest child John born in 1960 learnt to speak English with the help of those clients who were such a big part of our childhood. Mum and dad always went above and beyond to ensure their clients were satisfied. Mum was an absolute perfectionist and it showed in her attention to detail and the quality of their beautiful work. You only need to look at the garments that have stood the test of time or speak to their clients to know that this is true. Their clients would always comment on how well their clothes would last and much of their clients came via word of mouth and recommendations. Occasionally there would be disagreements because mum had found an error in dad's knitting (either a wrong stitch or a sizing mistake mainly) and would ask him to redo a piece, he would argue back saying that it was fine, but we always knew who would win the argument and that the piece would get remade! Similarly, we recall discussions where mum would ask dad to find a particular colour of wool in the garage where the stock was kept. He would try to convince her that they were out of stock of that colour and that the client should choose a different colour. She would insist they had it and then after hours of searching, he would return into the house sheepishly holding the wool! Our childhood is full of beautiful memories of mum and dad always being present, clients coming and going, mum humming her favourite songs as she worked often late into the night and sometimes, we even fell asleep to the hum of the machinery. They put their heart and soul into "Tina Knitwear" and took pride in providing only the best quality garments for their clients. In Italian there is a saying “lei ha le mani d’oro” which literally translated means “she has hands of gold”. Franco enjoyed his work but for Assunta, it was more than just work and there is no better way to describe her skills, passion and dedication to her machine knitting… she truly did have “hands of gold”. We will forever be grateful that our parents’ life journey gave us the opportunity to live in a home filled with creativity, dedication and passion, amazing work ethic and mutual respect, lifelong friendships and a lifetime of love. Red wide ribbed pleated skirt with a plain yoke, navy blue band at bottom edge and elasticated waistband. A purple x is located inside to mark centre back of skirt.knitwear, clothing, italy, migrants, brighton, knitting machine, linking machine, garments, business, family, community -

National Wool Museum

National Wool MuseumTextile - Men's Coat, c1940s

Franco Liburti was wearing this coat when he farewelled his wife Assunta in Naples, Italy in 1957, the day she departed for Australia. Tina Knitwear was a successful made to order knitwear business in Brighton from the mid-1960s to around 2010, run by Assunta and Franco Liburti. Daughter Melissa Persi writes: Our parents Assunta (Mum) and Franco (Dad) Liburti ran a successful made to order knitwear business in Brighton from the mid-1960s to around 2010. Assunta was affectionately known to her family as Assuntina, therefore the business was named "Tina Knitwear" after her. Assunta and Franco were born in the beautiful seaside town of Terracina in Italy in 1933 and 1930 respectively. As was so common in Italy in the 1950s, Assunta who was in her late teens and early twenties learnt the intricate skills of machine knitting, dressmaking and pattern making. Franco on the other hand, learnt the building trade with his 2 brothers and specialised in bricklaying and tiling. As was so common after the war, Assunta and Franco yearned for a better life so they decided that they would get engaged and then migrate to Australia to be married and raise their family in Australia, a land of much opportunity which they no longer felt their beloved Italy held for them. Assunta migrated to Australia first in 1957 and later Franco joined her in 1958 where they were married. For the first few years, Franco (also known as Frank) worked as bricklayer /tiler on buildings such as the Robert Menzies building at Monash University in Clayton and various buildings in the Melbourne CBD. Assunta on the other hand put her machine knitting skills to use working in factories doing piece machine knitting for various knitwear companies. The hours were long, the conditions were difficult, and travel was onerous without a car. After their 2 older children were born, it was decided that dad would leave the building trade and they would start their own made to order knitwear business. That way they could work from home and raise their family together. Mum taught dad everything he needed to know so he could operate the knitwear machinery. They purchased COPPO knitting machines from Italy and a Linking machine from Germany. Initially they had a knitwear shopfront in Bay Street Brighton where a store assistant would take the orders and client’s measurements and Assunta would then make the garments from a small workshop in their home. Unfortunately, the assistants were not skilled dressmakers and often measurements and orders were incorrectly taken. Assunta being the perfectionist and highly skilled machinist that she was, decided that she needed to oversee the entire process from meeting the client, to taking their order, right thru to the fittings and completion of the garment. It therefore made sense that they should close the shop front and run their business from their own home in Brighton and hence “Tina Knitwear” was born. Together, for more than 40 years they ran their very respected and successful business and were well known in the Bayside area. They specialised in made to order knitwear for both men and women using mainly pure wool (from Patons, Wangaratta Mills, Japan and Italy) but also lurex and estacel. Over those years, many of their clients became their close friends. It wasn't unusual for clients to come to order garments and then end up in the kitchen chatting over a cup of Italian espresso coffee and homemade biscuits. Some of their clients were especially memorable and became lifelong friends. Mrs Connell was a dear friend of mum’s, each year she would buy tickets for the “Gown of the Year” fashion show. She would insist on taking Assunta and her 2 daughters so that we could see the latest fashions. Then there was their dear friend Ms Griffiths. She had been a Matron nurse at the Queen Victoria Hospital when she met my parents in the 1970s. She returned to live in New Zealand in the 1980s but came back to Melbourne every year to stay for 2 weeks with the sole purpose of visiting my parents (she adored them) and order garments. For those 2 solid weeks, mum and dad would only knit for Ms Griffiths and she would go back to New Zealand with at least 5 or 6 new outfits. I actually think she enjoyed mum’s homemade pasta almost as much as her new clothes! Over the years, my parents learnt to speak English very well given that majority of their clients were not Italian speaking. Their oldest child John born in 1960 learnt to speak English with the help of those clients who were such a big part of our childhood. Mum and dad always went above and beyond to ensure their clients were satisfied. Mum was an absolute perfectionist and it showed in her attention to detail and the quality of their beautiful work. You only need to look at the garments that have stood the test of time or speak to their clients to know that this is true. Their clients would always comment on how well their clothes would last and much of their clients came via word of mouth and recommendations. Occasionally there would be disagreements because mum had found an error in dad's knitting (either a wrong stitch or a sizing mistake mainly) and would ask him to redo a piece, he would argue back saying that it was fine, but we always knew who would win the argument and that the piece would get remade! Similarly, we recall discussions where mum would ask dad to find a particular colour of wool in the garage where the stock was kept. He would try to convince her that they were out of stock of that colour and that the client should choose a different colour. She would insist they had it and then after hours of searching, he would return into the house sheepishly holding the wool! Our childhood is full of beautiful memories of mum and dad always being present, clients coming and going, mum humming her favourite songs as she worked often late into the night and sometimes, we even fell asleep to the hum of the machinery. They put their heart and soul into "Tina Knitwear" and took pride in providing only the best quality garments for their clients. In Italian there is a saying “lei ha le mani d’oro” which literally translated means “she has hands of gold”. Franco enjoyed his work but for Assunta, it was more than just work and there is no better way to describe her skills, passion and dedication to her machine knitting… she truly did have “hands of gold”. We will forever be grateful that our parents’ life journey gave us the opportunity to live in a home filled with creativity, dedication and passion, amazing work ethic and mutual respect, lifelong friendships and a lifetime of love. Men's coat featuring a charcoal herringbone weave, with three buttons down the front and on each sleeve cuff.knitwear, clothing, italy, migrants, brighton, knitting machine, linking machine, garments, business, family, community, naples