Showing 15 items matching "rock blasting"

-

Federation University Historical Collection

Federation University Historical CollectionBook, K.H. Fraenkel, Manual on Rock Blasting Vol 2, 1953, 1953

... Manual on Rock Blasting Vol 2, 1953...rock blasting... example of the information taught at the school. rock blasting ...School of Mines and Industries is a predecessor of Federation UniversityThe School of Mines and Industry Ballarat was established as a school to teach about mining in 1870, this book would have been a good example of the information taught at the school.Manual in a hard covered ring binder. The manual is written in English and Swedish. Includes illustrations.rock blasting, mining, compressed air supply, compressor plants, rock drills, explosives, electrical firing, short delay blasting, ventilation -

Clunes Museum

Clunes MuseumTool - METAL SCOOP, UNKNOWN

... BLASTING ROCK DURING CONSTRUCTION OF SHEEP DIP. IT WAS THOUGHT...TOOL USED TO CLEAN OUT HOLE FOR DYNAMITE WHEN BLASTING ROCK... BLASTING ROCK DURING CONSTRUCTION OF SHEEP DIP. IT WAS THOUGHT ...THIS TOOL CAME FROM WALTER COOK'S FARM AND WAS USED WHEN BLASTING ROCK DURING CONSTRUCTION OF SHEEP DIP. IT WAS THOUGHT TO BE USED MUCH EARLIER IN THE HISTORY OF THE FARM TO BLAST THE WELL WHICH IS THE MAIN WATER SUPPLY FOR STOCKTOOL USED TO CLEAN OUT HOLE FOR DYNAMITE WHEN BLASTING ROCKlocal history, trades, tools, cook family -

The Beechworth Burke Museum

The Beechworth Burke MuseumPhotograph - Photograph - Reproduction

... for rock blasting or to make holes for plug and feather quarrying... for rock blasting or to make holes for plug and feather quarrying ...This photo depicts a man standing next to a large piece of mining equipment identified as a hydraulic chisel (alternative name: drifter dill or power rock drill). This piece of machinery was used in mining to place holes in the walls of a mine which were then filled with dynamite or other explosives for rock blasting or to make holes for plug and feather quarrying. The additional tools to the right of the photograph and in front of the machinery can be identified as either picks or as feather and wedges, the latter of which were used to split stone drilled by the hydraulic or power chisel. Depending on the date of the photograph, which is not provided, this chisel was either powered by electricity or by hydraulics. The following is written on the drill "R.C. FORD'S PATENT No91 / MELBOURNE VICTORIA 1879". The man depicted in this photograph wears a wide brim hat, a loose fitting white shirt and loose pants. He wears boots and has a medium sized dark beard. This attire, along with his locality in the mine and proficiency with the mining equipment, identifies this man as a miner working in this particular, but unidentified, mine. It depicts an instance of hydraulic chiseling which makes this photograph valuable for the study of mining techniques from a date c1880.The search for gold is ingrained into the history of Victoria and therefore, images like this one which portray the types of machinery used in mining can reveal important information for technology and highlight the methods used to break apart the earth in order to obtain access to gold and other precious materials during the period this photograph was captured. Further research into RC Ford can potentially reveal even further information pertaining to this photograph. This image is of important historical significance for its ability to convey information about the methods and machinery used to access gold or mine more in general. It also highlights the size of machinery at the time and allows us to compare this to the size of the person standing besides the machinery to better understand the manpower which would have been required to use and set-up this macinery.A black and white rectangular reproduced photograph printed on matte photographic paper.Reverse: 7816/ copy 1/3gold, sluicing, gold sluicing, hydraulic sluicing, gold and tin mine, mining, gold mining, beechworth, burke museum, melbourne, victoria, hat, mining machinery, machinery, r. c. ford -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietySketch Rock Core Display, circa mid to late 1900's

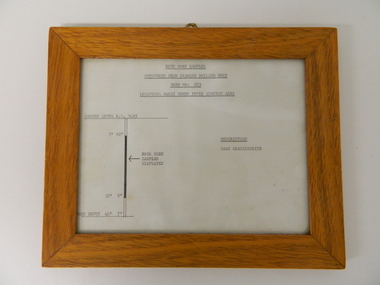

... drill and blast techniques(rock characteristics play an import... size of the plant. This would have included drill and blast ...This framed sketch details, in graphic form, where the core samples in the display cabinet were removed. The drilling was a precursor to the decision where to locate, in this case, the McKay Creek Power Station. The information gained by structural engineers from the core samples would be used also for the placements of underground tunnels entry and exit points and the overall effective size of the plant. This would have included drill and blast techniques(rock characteristics play an import part of explosion control), requirements for support structures and reinforcing cement/steel forms. The use and replenishment of diamond drill bits(the strongest available, see KVHS 0280) was dependent on the "type" of rock found. Support beams for reinforced ceilings and floors was also a necessity.The visual derails of where the rock core samples were removed is very significant in the formulation and placement of the underground Power Stations and their maze of tunnels(in and out) for a successful implementation of the Hydro Scheme. The amount of pre-planning and scientific studies required for such a large scheme must be undertaken to ensure that a "white elephant" was not the result.This framed and glass front rock core display sketch has type written information of the rock samples displayed in KVHS 0279 (A). It has a softwood stained and glossed frame with a fixed(nailed) back board and a brass fixture for mounting onto a wall.The paper and type are slighted faded (sunlight affected). The sign heading "ROCK CORE SAMPLES RECOVERED FROM DIAMOND DRILLED BORE" underneath this "BORE NO: 883" and below this "LOCATION: McKAY CREEK POWER STATION AREA" to the left a sketch incorporating the ground level point "GROUND LEVEL R.L.3493", and the core depth point "CORE DEPTH 40' 7". In between and representing( in visual form) the core location areain question.alternate energy supplies, alpine feasibility studies temperature, rainfall, sec, kiewa hydro scheme, electricity -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyCore Rock Samples

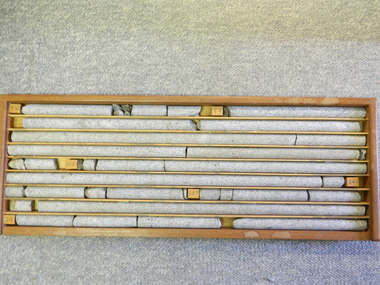

... included drill and blast techniques (rock characteristics play... and blast techniques (rock characteristics play an import part ...The core samples in the display cabinet were obtained from the various sites at which drilling into the rock surface was carried out (under the control of design and structural engineers of the SEC Kiewa Hydro Scheme - late 1940's). This function was a precursor to the decision where to locate, in this case, the McKay Creek Power Station. The information gained by structural engineers from the core samples would be used also for the placements of underground tunnels entry and exit points and the overall effective size of the generator plant. This would have included drill and blast techniques (rock characteristics play an import part of explosion control), requirements for support structures and reinforcing cement/steel forms. The use and replenishment of diamond drill bits(the strongest available, see KVHS 0280) was dependent on the "type" of rock found (harder rock required greater numbers of drill bits). Support beams for reinforced ceilings and floors was also a necessity.These rock core samples are very significant in the formulation and placement of the underground Power Stations and their maze of tunnels (in and out) for a successful implementation of the Hydro Scheme. The amount of pre-planning and engineering studies required for such a large scheme must be undertaken to ensure that a "white elephant" was not the result.There are nine columns of rock cores, each 30mm in diameter, set in a wooden display rack. A clear plastic (slide out) protective panel is installed to the front section. Within each column are block details of the depth from which that section was brought from. See KVHS for the appropriate sketch details.Depth levels (retrieved from) are shown for each section on wooden Blocks: 1st Block: "7'10" (seven feet, ten inches), 2nd Block:"9'4" (nine feet, four inches), 3rd Block: "19'3" (nineteen feet, three inches), 4th Block: "24'2" (twenty four feet, two inches), 5th Block: "25'7"( twenty five feet, seven inches) and last block: "30' (thirty feet)"alternate energy supplies, alpine feasibility studies temperature, rainfall, sec, kiewa hydro scheme, electricity -

The Beechworth Burke Museum

The Beechworth Burke MuseumGeological specimen - Brown coal

This particular specimen was recovered from the Lal Lal Coal and Iron Mine in Victoria, 19km from Ballarat. Brown Coal was discovered here in 1857, just alongside the Geelong to Ballarat Railway line. This discovery of lignite (brown coal) was the first in Victoria, which would bring important benefits to the region and state, both of which had previously been reliant on coal imports. In the 1860s, iron ore was found just 5km from Lal Lal, and the area was converted into an Iron Ore Mine. The Lal Lal Iron Mining Company took over operations in 1874, who then peaked iron production in 1884. This mine continued operations until June 1884, when the blast furnace was extinguished and never recommenced. The blast furnace at Lal Lal is considered one of the most important and highly significant sites ion early industrial history in Australia, as it is the only remaining best furnace from the nineteenth century in the Southern Hemisphere. The furnace ruins are 17 metres high, and are clearly visible today on Iron Mine Road, Lal Lal, near the Bungal Dam. This specimen of Lignite (brown coal) is significant, as it was mined from the area where brown coal was first discovered in Victoria, leading to an important and controversial future of the mining and use of brown coal in this State. The Victorian Heritage Database has listed the Lal Lal Coal Mine with local significance, with their Statement of Significance stating: "The Lal Lal coal mine is historically significant as the site of the first discovery of lignite (brown coal) in Victoria, and one that promised important benefits to regional and state industries that were reliant on coal imports at the time. The significance of the stie is reduced by the poor state of preservation of the coal mining and processing fabric". This specimen is part of a larger collection of geological and mineral specimens collected from around Australia (and some parts of the world) and donated to the Burke Museum between 1868-1880. A large percentage of these specimens were collected in Victoria as part of the Geological Survey of Victoria that begun in 1852 (in response to the Gold Rush) to study and map the geology of Victoria. Collecting geological specimens was an important part of mapping and understanding the scientific makeup of the earth. Many of these specimens were sent to research and collecting organisations across Australia, including the Burke Museum, to educate and encourage further study.A hand-sized light-weight, soft and combustable sedimentary rock specimen, that is dark brown in colour. The specimen has jagged edges, as though parts of the rock have crumbled away. Brown coal, or Lignite, is formed naturally from compressed peat, and is typically found in natural basins. The stages to the formation of coal ('coalification') begin with plant material and wood, which will decay if it is not subjected to deep burial or heating, and turn into Peat. Peat, when sufficiently compressed naturally, will turn into Brown Coal (Lignite), and finally into Black Coal (sub-bituminous, bituminous and anthracite). Each successive stage has a higher energy content and lower water content. It is brownish-black in colour. Brown Coal has a high moisture content, between 50 and 75 percent, and a low carbon content. Some Brown Coals may be stratified, with layers of plant matter, which means little coalification has occurred beyond the peat natural processing stage. When Brown Coal is submerged in dilute nitric acid or boiling potassium hydroxide solution, it reacts to produce a reddish solution, of which higher-ranked coals do not. When brown coal is pulverised and burned in boilers, the steam is used to drive turbines, which generates electricity. It is the lowest rank of coal, as when burned, it creates a relatively low heat content, which in turn does not create a great output of steam. burke museum, beechworth, indigo shire, beechworth museum, geological, geological specimen, mineralogy, brown coal, brown coal specimen, lignite, lal lal, lal lal coal mine, lal lal iron mine, ballarat, blast furnace -

The Beechworth Burke Museum

The Beechworth Burke MuseumPhotograph, c1900

A black and white photograph depicting seven men and four women surrounded by tunnel boring machinery. A tunnel boring machine (TBM), also known as a "mole", is a machine used to excavate tunnels with a circular cross section through a variety of soil and rock strata. They may also be used for microtunneling. They can be designed to bore through anything from hard rock to sand. Tunnel boring machines are used as an alternative to drilling and blasting (D&B) methods in rock and conventional "hand mining" in soil. TBMs have the advantages of limiting the disturbance to the surrounding ground and producing a smooth tunnel wall. This significantly reduces the cost of lining the tunnel, and makes them suitable to use in heavily urbanised areas. The major disadvantage is the upfront cost. TBMs are expensive to construct, and can be difficult to transport. The longer the tunnel, the less the relative cost of tunnel boring machines versus drill and blast methods. This is because tunneling with TBMs is much more efficient and results in shortened completion times, assuming they operate successfully. Drilling and blasting however remains the preferred method when working through heavily fractured and sheared rock layers.This photograph is significant as it shows the machinery used and attire worn by men and women during the gold rush era. Black and white rectangular photograph printed on photographic paperburke museum, mining, beechworth, boring machinery, excavate, gold, gold fields, gold rush, miners -

The Beechworth Burke Museum

The Beechworth Burke MuseumPhotograph, 1920-1950

This image taken between 1920-1930 depicts open-cut hydraulic sluicing at the Three Mile Mine, located about five kilometres south of Beechworth. Alluvial, or surface, mining began on this site in the 1850s, but was soon replaced by hydraulic sluicing methods. By the start of 1880 it is estimated that nine hundred miles of water races had been cut though soil and rock in the Beechworth district. Hydraulic sluicing employs high pressure jets of water to blast away large areas of earth and wash it down to be run through a sluice box. Gold gets caught in the sluice and the remaining slurry is washed away. Large water quantities were required for hydraulic sluicing, and the long water races and deep tailraces that were constructed were considered great engineering feats. This method of mining is extremely effective, but causes significant environmental damage and impacts to waterways and agricultural operations. Miners at Beechworth built extensive networks of races and dams to secure reliable supplies of water on a scale far greater than elsewhere in Victoria. By the 1880s Beechworth's water barons continued to hold more than half of all the water right licences on issue and undertook sluicing operations on a massive scale. The manipulation of surface and ground water via race networks was well planned and recorded in detail by local mining surveyors. The maps that were created, combined with modern geo-spatial technologies, provide a vital key in understanding the great lengths to which miners went to capture and control critical water resources. Today, Three Mile mine is called Baarmutha. The Three Mile Mine was unproductive until 1865 when John Pund and three other miners secured a fifteen year license and constructed a water race from Upper Nine Mile Creek to Three Mile Creek. In the early twentieth century Pund & Co. averaged over one thousand ounces of gold per year from the mine. After Pund's death in 1915, GSG Amalgamated Co operated the site, continuing sluicing until 1950. This image of hydraulic sluicing methods shows the extent of water-works engineering in the landscape. This photograph has historic and research potential for understanding changes to the landscape, the evolution of mining methods, and the extensive construction, manipulation and management of water networks in the Beechworth district. Black and white rectangular photograph on matte paperReverse: 7597-1 / Sluice Mining / Copied from original on loan from Webb (Qld) / Donated Nov 2009 / Baarmutha Three Mile Mine c1920-1950 / Managed by the Plain Bros then Parkinsons / Current Location is: Beechworth Animal Shelter / used for Baarmuthaburke museum, beechworth museum, beechworth, gold fields, gold rush, victorian gold rush, hydraulic sluicing, spring creek, netwown falls, mining tunnels, water races, tailraces, gold ming history, colonial australia, australian gold rushes, mining technology, beechworth historic district, indigo gold trail, indigo shire, john pund, water manipulation, water engineering, three mile creek, three mile mine, water race, large-scale mining methods, historical mining construction, alluvial mining, mining environmental impacts, baarmutha, water barons -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionPhotograph - Photograph - Blacknose Quarry, 21/10/1952

Port of Portland Authority ArchivesFront: 'BLACKNOSE QUARRY FACE 21.10.52 LOOKING NORTH SHOWING ROCK BROUGHT DOWN BY TRIAL BLAST' Printed in bottom frame Back: Purple PHT stamp 5/2 crossed out - ink top leftport of portland archives, blacknose quarry -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyDrill Bit, Circa 1950

This is the cutting bit on the end of a drilling rod. It would have been used to drill holes into rock for placing explosives, for installing steel rock anchors, etc. In hard rock the bits need to be replaced regularly. Compressed air is blown through the holes near the tip of the bit to blow rock fragments out of the drill hole. The main drilling unit would have been powered by compressed air (Pneumatic). Rotary Air Blast Drilling. This drill bit was used by workers in the SEC Vic. Kiewa Hydro Electricity Scheme. This type of bit although strong needed replacing frequently when the rock composition (type of rock) was extremely compact. The configuration of the tip bit (four star like pattern) was to provide the "teeth" to tear into the rock. This bit was manufactured in 1949 however drilling for rock cores, in the Kiewa Valley and the Victorian Alps, was carried out from the late 1920's.This particular drill bit would have been used by construction workers to drill holes into rock for either explosives or for installing steel anchor points into the rock. The use of compressed air was not only for waste extraction but also for running the main drilling unit.This four star rotary air balst (RAB) drill bit has a central "blow" hole (compressed air outlet to remove the ground rock particles through four extraction holes). There are four raised cutting/grinding lugs which allows the air compression hole(incoming) to always have a clear unblock opening. Extracted ground material is "blown" out from the drill head via the larger hole created by the steel bit.Stamped on the bottom outside shank "FAGERSTA SECO SWEDEN" and below this "102 7041 01 05 049".sec vic kiewa hydro scheme, alternate energy supplies, drilling into rocks in alpine regions -

Federation University Historical Collection

Federation University Historical CollectionBook, Machinery for Metalliferous Mines, 1894, 1894

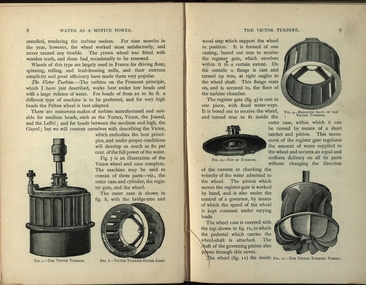

The 1st edition of this famous work, giving an excellent account of the machinery used in late 19th century metal mining in the UK and overseas is very rare. It covers a wide range of equipment - pumps, steam engines, drills, winding engines, stamps & concentration mills, aerial ropeways, tramways and early uses of electricity etc. Brown hard cloth covered book. xvi 564 pages with additional advertisements, with over 300 illustrations and drawings, some fold out. Chapters include Water as a motive power, Wind engines and ventilating machinery, Steam boilers/engines and oil engines, hoisting machinery, draining of Mines, pumping engines, rock drilling machinery, boring machinery, concentration machinery, sizing and classifications trommels, joggers and jigging, fine concentration, milling of gold ores, milling of silver ores, amalgamation plates and machinery, dry and roasting machinery, chlorination and cyandide processes for the extraction of gold, electricity as a motive power for mining, electric lighting and blasting, aerial wire ropeways, transport by rail and road. There a a number of lovely line illustrations in the book including: Poncelot's undershot waterwheel; Fromont furnace;Victor turbine; Pelton waterwheel; Root's positive blower;Cross section and front elevation of Lancashire boiler; Robey's Compound Mill Engine; Portable Winding Plant; Iron Pit Head Gear ; Loading Arrangement in an Incline Shaft; kibble; Worthington Pump; California Pump; Scram's Air Compressor; Rock drill Bits; Special Sharpening tools; Boring tools;Rotating Picking table; Ore Feeder; roller crusher; stamp battery; round buddle; slime table; vanner; amalgamating plant; belt elevator;roasting furnace;splicing wire rope; capel; tipping waggon;mining, cornish pump, linkenbach table, water wheel, ventilation, oil engine, california, america, water, steam boilers, steam engines, oil engines, pumpimg, rock drilling, boring, jiggers, milling, silver, gold, drying and roasting, chlorination, cyaniding, lead, zinc, copper, electricity, electric lighting, wire ropes, transport, wind engine, poppet head -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionPhotograph - Photograph - Blacknose Quarry Portland, 21/10/1952

Port of Portland Authority ArchivesFront: Front- Blacknose Quarry face 21/10/52 looking south showing rock brought down by trial blast'- Printed in bottom frame Back- Purple PHT Stamp 5/3- Ink, top leftport of portland -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionPhotograph - Photograph - Cape Grant Quarry, Quarry, Cape Grant, 01/11/1956

Port of Portland Authority ArchivesFront: Back- Border ruled around in pencil. Cape Grant Quarry 1/11/56 'View to south east showing excavtor on limestone level, quarry master on 70ft level and box blast result on 40ft level in foreground. Note rock fave obscured by over burden material' - Pencil '5 x 3/4 approx' - pencilport of portland archives -

Southern Sherbrooke Historical Society Inc.

Southern Sherbrooke Historical Society Inc.Photograph - Colour photograph, Cardinia Reservoir construction

Colour photograph of blasting works during the construction of the Cardinia Reservoir, Narre Warren East, in the 1970s. Plumes of dust rise from the orange sand and rock. In the distance low treed hills are visible. -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph - Digital Photograph, Marguerite Marshall, One Tree Hill Mine, Smiths Gully, 8 June 2006

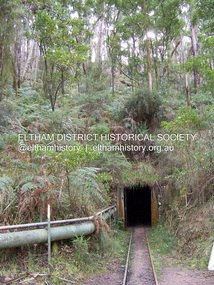

... , The Golden Crown in Yarrambat. These days, after blasting the gold..., The Golden Crown in Yarrambat. These days, after blasting the gold ...Gold was discovered on One Tree Hill in 1854. The site has been worked intermittently until fairly recent times. Published: Nillumbik Now and Then / Marguerite Marshall 2008; photographs Alan King with Marguerite Marshall.; p53 Though still a working mine, One Tree Hill Mine at Smiths Gully, now stands in a tranquil reserve surrounded by bush and native animals - in contrast to its heyday. In the mid 19th century, when the mine was part of the Caledonia Goldfields, hundreds of men in search of their fortune worked the alluvial gold in the Yarra River, its tributaries and the reefs that made up the goldfields. Miner Stan Bone, assisted by Wilfred Haywood, is the last of the independent gold miners in the area and still uses the quartz crushing battery as miners did when gold was first discovered in the area in 1851.1 Stan, who is the last of six generations of miners in his family, was aged 17 when he began mining on his father Alex’ mine, The Golden Crown in Yarrambat. These days, after blasting the gold-bearing rock in Mystery Reef, one of the four reefs at One Tree Hill, Stan transports it around five kilometres by tip truck to the Black Cameron Mine for crushing. There he uses water from the waterlogged mine, (which still contains gold), as the Happy Valley Creek at One Tree Hill is usually dry.2 The One Tree Hill Mine has been worked for close to a century since it opened around the late 1850s.3 The Swedish Reef was its most productive reef and one of the largest in the area. Around 1859, extractions included 204 ounces (5.8kg) of gold, won from 57 pounds (26kg) of stone.4 Then during World War Two, Stan’s uncle, Bill Wallace, and Alex Bone, closed the mine. In 1973, Stan, with his Uncle Bill, reopened the Black Cameron Mine and worked there until 1988. Stan resumed mining One Tree Hill in 1998. As late as the 1920s gold was picked up by chance! When crossing a gully on his way to vote at the St Andrews Primary School, Bill Joyce picked up some quartz containing gold. This site was to become the Black Cameron Mine. The Caledonia Diggings, named after Scotland’s ancient name by local Scots, began around Market Square (now Smiths Gully) and included Queenstown (St Andrews), Kingstown (Panton Hill) and Diamond Creek. There were also poorer bearing fields in Kangaroo Ground and Swipers Gully (now Research). * None of these compared in riches to the Ballarat and Bendigo fields5, but the Caledonia Diggings continued intermittently for close to 100 years. Gold was discovered in Victoria following a bid to stem the disappearance of much needed workmen to the New South Wales diggings. Several businessmen offered a reward of £200, for the discovery of gold within 200 miles (322 km) of Melbourne. Late in June 1851, gold was first discovered at Andersons Creek, Warrandyte. Then in 1854, George Boston and two other men discovered gold at Smiths Gully. Gold transformed the quiet districts, with a constant flow of families and vehicles on the dirt tracks en route to the Caledonia Diggings. Three thousand people worked the gullies in Market Square, including about 1000 Chinese miners. The square established its own police, mining warden, gold battery, school, shops and cemetery and grog flowed. Market Square flourished until the middle 1860s. Bullocks transported quartz from the Caledonia Goldfields to the crushing machinery at the Queenstown/St Andrews Battery, near Smiths Gully Cemetery. It was destroyed by bushfire in 1962. By the late 1850s, most early alluvial fields were in decline, but minor rushes continued until around 1900 and some until the early 1940s. Some miners did well, although most earned little from their hard labour in the harsh and primitive conditions.6 But according to historian, Mick Woiwod, the gold fields helped to democratise society, as individuals from all walks of life were forced to share experiences, and the ability to succeed, depended less on inherited wealth or social rank.This collection of almost 130 photos about places and people within the Shire of Nillumbik, an urban and rural municipality in Melbourne's north, contributes to an understanding of the history of the Shire. Published in 2008 immediately prior to the Black Saturday bushfires of February 7, 2009, it documents sites that were impacted, and in some cases destroyed by the fires. It includes photographs taken especially for the publication, creating a unique time capsule representing the Shire in the early 21st century. It remains the most recent comprehenesive publication devoted to the Shire's history connecting local residents to the past. nillumbik now and then (marshall-king) collection, gold mining, one tree hill mine, smiths gully