Showing 10 items matching "roller drum"

-

National Vietnam Veterans Museum (NVVM)

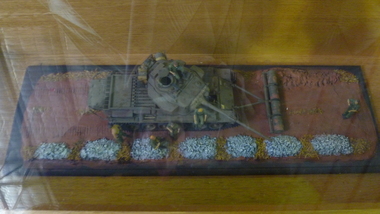

National Vietnam Veterans Museum (NVVM)Model - Diorama

... Roller drum... with roller drum configuration. Four x forty-four gallon drums filled... tank Roller drum Diorama A diorama of a Centurion MBT mine ...A diorama of a Centurion MBT mine clearance tank with roller drum configuration. Four x forty-four gallon drums filled with concrete and set on frame of water pipes. These were rolled along in front of the tank to bulldoze soil.mine clearing, centurion tank, roller drum, diorama -

National Wool Museum

National Wool MuseumMachine - Teasel Gig, c1890

... Large metal machine with wooden rollers and teasel covered... Large metal machine with wooden rollers and teasel covered drum ...When the fabric is removed from the loom it is often stiff, rough and uneven. There are a number of finishing processes, both mechanical and chemical that give wool fabrics their special look and feel. The fabric is often scoured again to remove oils and dirt picked up during manufacture. It is then pressed. For a soft and fluffy surface, the fabric is brushed. For a smooth surface, it is shorn. For centuries, machines similar to this teasle gig were used to finish fabrics. It uses the prickly flower head off the teasle plant (Dispsacus Fullonum) to do the delicate work to raise the surface, or nap, the woollen cloth. At least 1,500 teasle heads are needed for one gig. The teasel is a thistle like plant whose dried heads are used on the teasel gig. They are fixed to frames around the drum, or gig. The gig turns in the opposite direction to the flow of the cloth until the nap is raised. Also spelled as Teazel Gig.Large metal machine with wooden rollers and teasel covered drum.textile finishing, raising, raising machinery, teasel gig, fabric, wool processing, plants, thistle, drum -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncCarder, Not known

... . Large spikes on drum. Wooden roller to feed fleece.... meshing gearwheels. Large spikes on drum. Wooden roller to feed ...Green painted, hand operated, floor standing drum carder. Metal guard badly corroded. Four legs. Three meshing gearwheels. Large spikes on drum. Wooden roller to feed fleece.Ruben Sutcliffe / Maker / Manchester. In relief on topside of frame.textile machinery; spinning; wool carding; metalcraft; cast iron -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageGestetner Machine, c. 1922 - 1929

... , a stencil-method duplicating machine with two rotating drums plus... between rollers and pressed against the drum. The process ...This Gestetner Cyclostyle duplicating machine was invented and manufactured by David Gestetner. He claimed in 1922, once he had released several models, that if a Gestetner Durotype stencil was used together with his Cyclostyle machine, then 10,000 copies could be made from the one Durotype stencil, an amazing claim for office technology of that era. David Gestetner (1854-1939), was born in Csoma, Hungary. He has been called the “founder of the worldwide office copying and duplicator industry.). He moved to London and in 1879 filed his first copying patent. In 1881 he patented the Cyclostyle stylus (or pen), which was used in conjunction with his Cyclograph device for copying text and images, He established the Gestetner Cyclograph Company in England at this time (1881) to protect his inventions and to produce his products; stencils, stylos (stylus or pen) and ink rollers. HIs inventions included nail-clipper and the ball-point pen (although the latter is more commonly associated with Laszlo Biro). Gestetner’s patented Cyclograph duplicator was used with his Cyclostyle Stylus or pen to write or draw on special thin wax-coated stencil paper (originally used for kite making paper) in the following way; 1. The Cyclostyle stencil was placed on a lower, framed metal plate of the Cyclograph 2. An upper frame was clipped over the top 3. The Cyclostyle pen, with its tip being a small metal-spiked or toothed wheel, was used to write or draw on the stencil, punched small holes into the paper and removed the wax coating in those places 4. The upper frame and stencil was then removed and a piece of blank paper was placed onto the metal plate in the lower frame and the upper frame with stencil was replaced 5. A roller was given an even distribution of Cyclostyle ink and rolled by hand over the stencil in the frame. This forced the ink through the holes in the stencil to and made a copy of the stencil on the paper 6. The upper frame was raised, the printed paper removed and another blank sheet was put into place. The whole process was repeated until enough copies were made. Gestetner’s invention developed further in 1894, with a stencil that could be placed on a screen on a revolving drum. The drum was manually rotated, the stencil then wrapped around another drum and was fed between cloth-covered rollers on which ink was evenly spread. Each revolution of the drum forced ink through the holes in the stencil and transferred the ink onto paper that had been fed between rollers and pressed against the drum. The process was repeated for each page. The paper was still fed and removed manually in this earlier invention but became more automatic in later models. In 1902 Gestetner duplicator model 6 was put onto the market. This model included the improvement of an automatic paper feed that synchronised with the rotation of the stencil. The Gestetner machine was the first office printing machine. It was easily installed and it made exact copies of the sane document quickly, effectively and inexpensively. This changed the way offices operated, making information easily available to many more users. The machines were commonly used in small businesses, schools, churches, clubs and other organisations for the wide distribution of a wide variety of information in the form of worksheets, newsletters and more. In 1906 the Gestetner Works were opened in Tottenham Hale, North London, and thousands of people were employed there up until the 1970’s. Due to the fast growing success of the Gestetner Duplicator machines many international branches for sales and service centres were established. David Gestetner was succeeded by his son Sigmund, followed by his grandson’s David and Jonathan. Further advancement was made by using a manual typewriter with specifically designed stencils. The end product was a printed, typewritten copy similar to the print from newspapers and booklets. In the next few years there were further developments of this revolutionary invention. The Gestetner Cyclostyle duplicator in our Collection is dated c.1922 - 1929 and it uses Gestetner Durotype stencils The 1922 British Industries Fair’s catalogue contained advertising for the Gestetner Rotary Cyclostyle “The World’s Premier Duplicator”, demonstrated at Stand K 86.” A Notice at the foot of the advertisement’s page boasts "Important - D Gestetner's latest invention, the "Durotype" Stencil, enables you to obtain 10,000 copies from one original if desired. It contains no wax of any description, is indestructible, can be stored indefinitely and printed from as required” In 1929 the look of the Gestetner machines changed; American designer Raymond Loewy was invited by Gestetner to improve the look of his duplicators, resulting in a very streamlined appearance. Eventually, around 1960’s, offices replaced their Gestetner with small photocopying machines and printers. Gestetner took over ownership of other office machine companies over time, including Nashua, Rex Rotary, Hanimex and Savin and eventually all came under the holding company name of NRG (Nashuatech, Rex Rotary and Gestetner). In 1996 Ricoh acquired the Gestetner Company, and it was renamed the NRG Group. REFERENCES Cyclostyle, Stencil Duplicating Machines, antique Copying Machines, Early Office Museum, http://www.officemuseum.com/copy_machines.htm Duplicating machines, Wikipedia Duplicator, Collection online, Canada Science and Technology Museums Corporation http://techno-science.ca/en/collection-research/collection-item.php?id=1989.0229.001 Gestetner duplicators, Totterham-Summerhillroad.com http://tottenham-summerhillroad.com/gestetner_duplicators_tottenham.htm Gestetner Duplicator, V&A Museum http://collections.vam.ac.uk/item/O322014/gestetner-duplicator-duplicator-loewy-raymond-fernand/ Gestetner, Grace’s Guide to British Industrial History, http://www.gracesguide.co.uk/Gestetner Duplicating machines such as this one revolutionalised access to copies of printed material, changing the way that educational bodies, offices, small businesses and community clubs and charities operated.Duplicating machine, Gestetner Cyclostyle Durotype, a stencil-method duplicating machine with two rotating drums plus rollers. Hand operated, tabletop office machine. Front has folding Bakelite handle, oil filling hole, calibrating gauge with scale, and copy counting meter. Right side has printed manufacturer’s plate that slides out as a paper output tray. Left side has metal plate with protrusions and perforations, plus another similar plate that is detached. It also has a metal frame attached [that would have been used to hold a paper input board, adjusted for various sizes of paper]. Cover, metal, with folding wooden handle on top, attaches to base with metal clips. Inscriptions printed on machine, mostly in gold-coloured paint. Round metal manufacturing plate is stamped with Serial Number 95759. Made by D. Gestetner, London, c.1922-1929Maker’s plate “MANUFACTURED / BY / D. GESTETNER LTD, / No. 95759 / CYCLOSTYLE WORKS / TOTTENHAM HALE / LONDON, N” Copy counting meter shows “1 4 6 4 8 [space]“ copies. Calibrating gauge has divisions with numbers “0 1 2“, labelled “← [left arrow] “TO PRINT LOWER” and “→ [right arrow], TO PRINT HIGHER”. “The Gestetner”, “Cyclostyle”, “Gestetner” (Trade Mark), Right side print of manufacturing details includes “The / Gestetner / TRADE MARK” And “THE FOLLOWING TRAFE MARKS / - - - OF INK, STENCILS / - - - AND GUARANTEE OF PERFECT / - - - BOTH - - - AND MACHINE” and “CYCLOSTYLE / DUROTYPE / GESTETNER” and “D. Gestetner” flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, office machine, copying machine, gestetner machine, duplicating machine, duplicator, stencil machine, gestetner cyclograph company, cyclograph, cyclostyle, d. gestetner ltd, gestetner durotype stencils, gestetner cyclostyle, printing machine, office technology, durotype stencils, david gestetner, raymond loewy, roneo, rotary duplicatorten, mimeo, mimeograph machine, roneograph copier -

The Beechworth Burke Museum

The Beechworth Burke MuseumPhotograph

This photograph depicts two members of the Beechworth Band at a 'Liedertafel' concert in the main hall at the Burke Museum in 1999. The concert related to an exhibition titled, 'From the Liedertafel to the Skating Rink: Entertainment in Beechworth 1852 - early 1900s', which celebrated the rich and diverse entertainments that were a part of Beechworth life in the nineteenth and early twentieth centuries. 'Liedertafel' is a German tradition that accompanied European settlers to Australia. It refers to a friendly society of men united by an enthusiasm for singing. The Beechworth Liedertafel was established 14 March 1894 at the London Tavern, Camp Street, Beechworth, by president, Mr. A.A. Billson, and a visiting conductor, Mr. H. Fielder. The Beechworth Brass Band was formed by Mr. H. Vandenberg in 1887. Marching bands, choirs, processions, circus acts, theatrical performances, races, fancy dress and roller skating carnivals, were among the vibrant and diverse entertainments offered in Beechworth during the gold rush period. Race meetings were revived with a gala atmosphere at Baarmutha on New Year's Day and Easter Monday in the early 1880s. 'Spiller's Skating Rink', which premiered at St. Georges Hall in August 1869, was accompanied by the 'Beechworth Fire and Drum band'. In 1888, Beechworth had two skating rinks in operation, the Columbia Elite at Oddfellow's Hall, and the Beechworth Skating Rink, corner Camp and Last Streets, Beechworth. Vandenberg's Beechworth Brass Band was reported to have provided musical entertainment for patrons at both venues.This photograph of the Beechworth Band playing at the Burke Museum is historically significant for the information it conveys about an exhibition at the Burke Museum between September and November 1999. The use of the contemporary Beechworth Band in a 'Liedertafel' performance provides insight into curatorial approaches at the turn of the twenty-first century and improves our understanding of how exhibitions use objects in the Burke Museum's Collection to tell stories about the past in the present. The story of Liedertafel's and Beechworth Brass Band is historically and socially significant for understanding the role played by German immigrants in building Victorian communities. In settler communities, cultural associations centred on artistic, recreational and sporting activities not only provided a popular means of entertainment, but fostered social cohesion among settlers from diverse ethnic backgrounds.Rectangular colour photograph printed on matte photographic paper. Obverse (On keyboard): Technics / Reverse: 7028 / Label: Liedertafel / exh. / Beechworth / Band / 1999/2000 /liedertafel, beechworth band, burke museum, from the liedertafel to the skating rink, entertainment in beechworth 1852 - early 1900s, gold rush, immigration, beechworth's german heritage, london tavern beechworth, beechworth's first brick tavern, spiller's skating rink, vandenberg's beechworth brass band, protestantism, teetotallism, skating carnivals, beechworth german association, yma's, beechworth skating rink, progress societies, billson's brewery, german-australians, roller skating history -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionSlide - Slide - Construction Portland/Cashmore Airport, c. 1980

Coloured slide. Excavation in centre, with water in bottom. Concrete retaining wall in foreground. Roller on left edge of excavation. Pump and drum on ground near top of retaining wall. -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Pulley, Ca 1889

Wooden pulley wheel section from the wreck “Newfield”. The Newfield was a three-masted iron and steel barque, built in Dundee, Scotland, in 1889 by Alexander Stephen and Sons. It was owned by the Newfield Ship Company in 1890 and later that year It was registered in Liverpool to owners Brownells and Co. The Newfield left Sharpness, Scotland, on 28th May 1892 with a crew of 25 under the command of Captain George Scott and on 1st June left Liverpool. She was bound for Brisbane, Australia, with a cargo of 1850 tons of fine rock salt, the main export product of Sharpness. At about 9pm on 28th August 1892, in heavy weather, Captain Scott sighted, between heavy squalls, the Cape Otway light on the mainland of Victoria but, due to a navigational error (the ship’s chronometers were wrong), he assumed it to be the Cape Wickham light on King Island, some 40 miles south. He altered his course to the north, expecting to enter Bass Strait. The ship was now heading straight for the south west Victorian coast and at about 1:30am ran aground on a reef about 100 yards from shore and one mile east of Curdie’s Inlet, Peterborough. The ship struck heavily three times before grounding on an inner shoal with 6 feet of water in the holds. Rough sea made the job of launching lifeboats very difficult. The first two lifeboats launched by the crew were smashed against the side of the ship and some men were crushed or swept away. The third lifeboat brought eight men to shore. It capsized when the crew tried to return it to the ship for further rescue The Port Campbell rocket crew arrived and fired four rocket lines, none of which connected with the ship. A local man, Peter Carmody, volunteered to swim one mile to the ship with a line to guide the fourth and final lifeboat safely to shore. Seventeen men survived the shipwreck but the captain and eight of his crew perished. The Newfield remained upright on the reef with sails set for a considerable time as the wind slowly ripped the canvas to shreds and the sea battered the hull to pieces. The Marine Board inquiry found the wreck was caused by a "one man style of navigation" and that the Captain had not heeded the advice of his crew. According to Jack Loney ‘… when the drama was over . . the Newfield was deserted except for the Captain’s dog and two pigs.’ Flagstaff Hill Maritime Museum has several artefacts that have been salvaged from the wreck. See also other items in the Flagstaff Hill Newfield Collection.The report from SHP documented the following in regards to the Newfield collection: Flagstaff Hill’s collection of artefacts from the Newfield is of historical and archaeological significance at a State level, because of its association with the shipwreck, which is on the Victorian Heritage Register. The collection is significant because of its relationship between the objects. The Newfield collection is archaeologically significant as it is the remains of an international cargo ship. The Newfield collection is historically significant for representing aspects of Victoria’s shipping history and its potential to interpret sub-theme 1.5 (Living with natural processes). The collection is also historically significant for its association with the shipwreck. The Newfield collection meets the following criteria for assessment: Criteria A: Importance to the course, or pattern, of Victoria’s cultural history Criteria B: Possession of uncommon, rare or endangered aspects of Victoria’s cultural history Criteria C: Potential to yield information that will contribute to an understanding of Victoria’s cultural history This item is an oval-shaped brown and orange wooden shell from a ship’s pulley. The original wooden material is now petrified but the lighter coloured concentric rings of the wood's grain are still visible. A metal sheave or drum is fitted into the centre hole and some of the edge of its sheave’s collar has corroded and broken away. The collar has three holes of equal size that are evenly spaced around it. The bearing ring is now detached but still connected to the pulley with a string on which a label is attached. Most of the six cylindrical metal roller bearings are sand encrusted but some are still visible. Recovered from the wreck of the ship NEWFIELD.The pulley has a string through it that attaches it to the bearing. The label on the string bears the handwritten words “PULLEY WHEEL / NEWFIELD / PETER ROLAND”.block, flagstaff hill, maritime museum, shipwreck coast, warrnambool, peter carmody, carmody, newfield, shipwreck, pulley, wheel, pulley block, sheave, drum, peterborough, south west victoria, rocket, rocket crew, shipwreck artefact, flagstaff hil maritime museum -

National Wool Museum

National Wool MuseumPicker

Wool picking machine designed to separate locks of wool before it is carded and spun. The picker opens the wool’s locks which makes it easier to send the fleece through a carding machine. It does this by teasing the fibres (which can also be done by hand just by pulling the lock structure apart), but a picker does this in bulk and much quicker than what can be done by hand. It is possible to spin fibres directly after the picking stage; however, it is usually more desirable to card and blend them with other fibres. Typically, at a textile mill, a picking machine can separate enough lengths of fibre for a full day’s work after just a single hour. It will also help to remove any vegetation matter or other any unwanted elements that may be present in the wool. The quality of the casting on this machine suggest that it was made locally, either in Australia or New Zealand. Mike Leggett, the donor of the machine, acquired it from New Zealand where the seller said it had been used by his father to pick wool to make hand stuffed horse saddles. Mike attempted to used it a couple of times to pick alpaca hair, but the speed of the attached motor caused damage to the fibres. The motor is thought to be an added attachment, sometime around the 1960s judging by its age, while the machine itself is thought to be dated around the 1920s. The machine works by inserting wool through the rollers. Initially there was a conveyor belt feeder system which was powered by the handle on the side. This conveyor belt has been removed however, most likely due to age and deterioration. Wool is now fed through the initial teeth and is met by a spiked rotating drum which works to separate the fibres. The separated fibres would then complete a loop of the drum before being dispatched somewhere below, around where the motor presently sits, at a rapid rate of speed. Typically this wool will be collected in a closet or large catchment area, as can be seen from the 8:47 minute marker in the linked video (link - https://www.youtube.com/watch?v=kMjx-t3tH3A). It is not apparent how the wool is collected with this machine. Red and green machine with four green legs currently attached to a wooden pallet with wheels for easy movement. The green legs lead up to a red central circular barrel from which many attachments are present. Also present on the wooden pallet is a small black motor which is attached by a rubber belt to the central drum inside the red barrel. The belt spins the wooden drum via a dark red circular plate attached to the side of the drum. On the other side of the red barrel, a green handle extends for turning the picker’s conveyor belt feeder system. Two green walls extend forward from the central red barrel, guarding either side of where the conveyor belt would have been. At the start of these walls is a wooden cylinder, which the conveyor belt would have wrapped around, followed by two interlocking gears which rotate and accept the fed wool. The red roof extends over the central cylinder from here, securing the wool inside and protecting hands from the heavily spiked internal wooden cylinder which rotates and separates (picks) the wool. Extending over the top of this red roof is a green handle which reaches to the back of the machine (not pictured). Here it accepts a weight to ensure pressure is always present for the initial feeder interlocked gear teeth. There are two large gear cogs on the rubber belt side of the machine and 3 small gear cogs on the handle side of the machine, all coloured green. A green handle is also present at the rear of the machine, below the location from which the weight is hanging. A power cable extends from the motor and there are two adjustable metal rods on the top of the machine, the purpose of these rods is presently unknown. Black texter. On top of drum. Wording: HG3707 Wording. Imprint: BRACEWIND BLYN On motor. Wording AEIwool picking, textile manufacturing, wool processing -

National Wool Museum

National Wool MuseumTool - Drum Carder, Kacoonda, c.1980

This drum carder was purchase by Gill Stange at the Whittlesea Show in the late 1980s. The carder allowed Gill to spin fleece from her own Merino sheep. Merino is a difficult wool to spin when compared to other popular varieties, such as Corriedale or crossbred wool. The carder helped her to tease out the fleece, slightly separating the fibres before spinning. It also allowed for easier removal of foreign matters, such as seeds and mud. Little is known about the Kacoonda brand who produced the carder. They were Australian based and appear to have only operated throughout the 1980s.The carder has one large central roller with two smaller rollers on either side. The larger roller rotates in the inverse direction of the two smaller rollers. The carding cloth is a mint green in which closely spaced wire pins are embedded. The shape, length, diameter, and spacing of these wire pins is that of a standard carder. On one side of the carder a handle is found that is used to spin the three rollers. Additionally on this side is a sticker which reads “The Kacoonda Carder. Subject to Patent Action”. A Silver grip for the easy movement of the carder can also be found high on this side. On the opposite side of the carder, many nuts and plates can be found which hold the rollers in place. This is opposed to the other side of the carder, which has a brown plastic cover plate attached underneath the handle. The walls providing a path for the carded wool to follow when being carded, are made of wood. The carder comes complete with a teasing tool. This tool has the same mint green carding cloth as the carder’s rollers. It is attached to a simple wood handle for ease of use.Wording, green, printed. Sticker on side of carder. “The Kacoonda Carder / SUBJECT TO PATENT ACTION”whittlesea show, drum carder, textile production, carding wool, kacoonda -

National Wool Museum

National Wool MuseumTeasel holder

Used to hold the teasels on the roller of a teasel gig.Teasel holders from the drum of a teasel gig. Teasel holders from the drum of a teasel gig.raising, raising machinery