Showing 8 items matching "saw clamp"

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Bench Saw Vice, Henry Disston & Sons, 1910 -1925

... Saw Clamp...The subject item is a saw blade sharpening clamp... shipwreck-coast flagstaff-hill-maritime-village Saw Clamp Henry ...The subject item is a saw blade sharpening clamp that attaches to a bench allowing the operator to sharpen the teeth on a saw with a file while keeping the saw blade in an upright position. Henry Disston (1819–1878) began his career as an American saw maker in Philadelphia. He emigrated from England in 1833 and started making saws and squares in 1840. In 1850, he founded the company that would become the largest saw maker in the world the ”Keystone Saw Works” on the Delaware River. Some five years later, Disston built a furnace possibly the first melting plant for steel in America and began producing the first crucible saw steel ever made in the United States. While his competitors were buying good steel from Britain, he was making his own, to his specification, for his own needs. Disston subsequently constructed a special rolling mill exclusively for saw blades. Over the following decade, the Disston company continued to grow, even while dedicating itself to the Union Army's war effort. In 1865, when his son Hamilton Disston rejoined the business after serving in the Civil War, Disston changed the company's name to Henry Disston & Son. Henry Disston and his sons set the standards for American saw makers, both in terms of producing high-quality saws and developing innovative manufacturing techniques. Disston also started making files in 1865. In September 1872, Henry Disston and two other men dug a part of the foundation for what was to become the largest saw manufacturing facility in the world: Disston Saw Works. This was in the Tacony section of Philadelphia. Having previously moved his expanding business from near Second and Market Streets to Front and Laurel Streets, Disston sought to establish his business away from this cramped area. It took over 25 years to move the entire facility to Tacony. This Philadelphia neighborhood seems to have been the only company town in the United States established within an existing city. At its peak of operations, Disston Saw Works employed 8,000 people and the factory covered 300 acres. The company, known as Henry Disston and Sons, Inc by the early 20th century, cast the first crucible steel in the nation from an electric furnace in 1906. The firm's Armour plate building near Princeton Avenue and Milnor Street contributed tremendously to the World War II effort. But the company's innovation and industriousness would not last forever. In 1955, with mounting cash-flow problems and waning interest on the family's part to run the firm, Henry Disston and Sons were sold to the H.K. Porter Company of Pittsburgh. Porter's Disston Division was sold in 1978 and became the Henry Disston Division of Sandvik Saw of Sweden. This division was then sold in 1984 to R.A.F. Industries of Philadelphia and became known as Disston Precision Incorporated, a maker of specialized flat steel products. In 2013, R.A.F. Industries sold Disston Precision Inc. in a private sale. Although the company has ceased making Disston handsaws, the Disston brand name still exists in this firm. A significant American company that pioneered the making of high-quality steel and saws along with other tools and accessories. The subject item is significant as it was made at a time when the company was in its hay day. Adjustable Ball & Socket Saw Sharpening vice, cast iron, with clamp to attach to a workbench. Made by Henry Disston & Co. No 1 painted greyflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, saw clamp, henry disston & sons, saw sharpening, tool accessories, wood saws -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Saw Vice and Spanner, Henry Disston & Sons, Early 20th century

... has a saw clamp with wide jaws. The metal surface has remnants... has a saw clamp with wide jaws. The metal surface has remnants ...Henry Disston (1819-1878) was born in England and later moved to America. He has been noted in a biography as a "Pioneer Industrialist Inventor". In 1840 he began making and selling his own saws in Philadelphia, USA, growing to become the world's largest saw manufacturer. Tools made by Henry Disston and his company have the reputation of being the finest tools money can buy.The saw sharpening vice and its shifting spanner are significant for their connection with Henry Distton & Sons, renowned for high quality hand saws and associated tools. In 1855 Henry Disston cast a crucible saw sharpening steel, the first person to ever do so in America. The hand tools are also important for their association with the early building industry. Saw sharpening vice with accompanying saw tooth shifting spanner. The vice has a ball and socket clamp. The top of the vice has a saw clamp with wide jaws. The metal surface has remnants of black paint. Inscription is cast into the jaws of the vice. It was made by Henry Disston & Sons"HENRY DISSTON & SONS"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, vice, saw sharpening vice, saw sharpening tool, saw tooth, shifting spanner, woodworking tool, henry disston, disston & co, hand saw, handsaw, hand tools, carpentry, boat building -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyTools - Vice and Clamp

... or sawing. Small steel clamp is a versatile tool that serves... vice. The clamp is 50 to 60 years old when they were made ...Very old vice. The clamp is 50 to 60 years old when they were made by Technical School students in metal work class.Used by carpenters, woodworkers, furniture makers, welders, construction and metal workers in the Kiewa ValleyMathieson's Hand Vice, the smallest at 3 inches. Ref. Page 74 Tools for all Trades Catalogue. Small steel vice consisting of two parallel jaws for holding a workpiece. One jaw is fixed and the other movable by a screw. The clamp is used for holding a workpiece during hand operations eg. filing, hammering or sawing. Small steel clamp is a versatile tool that serves to temporarily hold work securely in place by screwing each jaw together.vice/vise tool, clamp tool, hand tools -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionPhotograph, Swagging a band saw, n.d

... in a clamp. Swagging a band saw Photograph Photograph Ray Glyde Glyde ...Port of Portland Authority archiveFront: (no inscriptions) Back: Swagging a band saw (upper left, pencil). G2585 (upper left, pencil). Ray Glyde Creative Commercial & General Photography, 21 Prescott Terrace, Rose Park, South Australia. (Red stamp, lower right). G2585 (lower right, black pen).port of portland -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Suitcase/Trunk

The suitcase didn't catch on until the end of the 19th century, it was quite literally as a case for suits. A typical suitcase came equipped with an inner sleeve for storing shirts, and sometimes a little hatbox on the side. But even in the early 20th century, the "dress-suit case" was only one of countless styles of container travellers could buy, from steamer trunks to club bags. By the late 19th century a significant point was reached in the history of transportation, it was the beginning of mass tourism, rather than travel for travels sake made use of by the wealthy in society. Travel wasn't just for the wealthy any more but everyone. Suitcases began as an afterthought in the luggage and leather goods business, but they soon became the very symbol of travel. An 1897 wholesale price list included the words "suitcase" only twice in a 20-page list of luggage types. In America a 1907 T. Eaton & Co. Catalogue, trunks took up a full page while suitcases share a page with club bags and valises. In a 1911 a United Company catalogue, now displayed around 40 per cent of the advertisements were for suitcases. Early suitcases were lighter and more portable than trunks, but they were still bulky by today's standards. Leather, canvas, wicker or thick rubbery cloth was stretched over a rigid wood or steel frame. Corners were rounded out using brass or leather caps and some had wooden rails running around the case. Until steamship travel declined during the mid-20th century, many of these types of the case were advertised as waterproof with some lightweight models marketed specifically to women. The item gives us a snap-shot as to how people undertook travelling during a time when undertaking a journey for pleasure at the end of the 19th century was mainly only for the wealthy. This time saw the beginnings of change from the wealthy in society being able to travel, to the onset of mass tourism. Along with this change in societal norms saw many innervation's to the design of luggage as it became a fashionable item.Suitcase/trunk with inner tray, brown canvas covered with 2 hinge clamps and a central Eagle lock, four wooden lateral buffer railed slats running around the case, leather handles each end. noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, suitcase -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, Coping saw, c1900

... while continuing to cut steadily. tools, saws, steel , clamps ...A coping saw is a type of hand saw used to cut intricate external shapes and interior cutouts in woodworking or carpentry. It is widely used to cut mouldings to create coped rather than miter joints. It is occasionally used to create fretwork though it is not able to match a fretsaw in intricacy of cut, particularly in thin materials. Coping saw blades are always thicker and much coarser cutting than typical fretsaw blades. A coping saw consists of a thin, hardened steel blade, stretched between the ends of a square, c-shaped, springy-iron frame to which a handle is attached. The blade is easily removed from the frame so that the blade can be passed through a drilled hole in the middle of a piece of wood. The frame is then re-attached to the blade and the cut starts from the middle of the piece. Long cuts perpendicular to the edge of the material are possible but the shallow depth of the frame rather limits how far from the edge one may cut. The much deeper frame of the fretsaw is more useful for cutting well away from the edge but conversely cannot manage the thicker materials commonly cut by the coping saws. The coping saw blade is installed with the teeth pointing towards the handle. Unlike a hacksaw, which has the teeth pointed away from the handle, the coping saw cuts on the pull stroke. The coping saw blade is removable by partially unscrewing the handle. The blade is prevented from rotating by means of the short, steady bar provided where the blade is attached. Loosening the handle also allows the blade to be rotated relative to the frame as desired. Carefully aligning the finger steady bars at the top and bottom of the blade ensures that the thin blade is straight and not twisted along its length. Re-tightening the handle tensions the blade and locks it at the desired angle relative to the frame. The short steady bar nearest the handle is held securely between finger and thumb while the handle is tightened to ensure the blade remains at the desired angle. Unlike the fretsaw the coping saw blade has holding pins which lock securely into the angled slots of the rotatable blade holders. Gentle curves are achieved by slowly turning the whole frame by means of the handle while continuing to cut steadily. A coping saw with wooden handle but no bladetools, saws, steel , clamps, metalwork, woodwork, carpentry, early settlers, pioneers, market gardeners, moorabbin, bentleigh, cheltenham, fretsaw, coping saw, bowsaw, blacksmiths, -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncTool - Floor Board Clamp

A flooring clamp (or cramp) is used for holding tongue and groove floorboards in place whilst laying a new floor. The ratchet handle is used to apply horizontal pressure to hold boards firmly in place until they are secured. “The General and Commercial Directory of the Borough of Birmingham, and six miles round; including Wolverhampton, Bilston, Walsall, West Bromwich” published in 1858 lists William Bissell as an ironmonger in Union Street, Wolverhampton. In the catalogue for the 1862 London Exhibition, three items manufactured by William Bissell were listed, including:- “BISSELL'S PATENT FLOORING CRAMP. The force of this cramp is fully equal to 1 ton. It is adapted to joists from 2 to 4 in. and is the most expeditious and easy in working of any cramp in use.” In the 1864 edition of “Williams's Manufacturers' Directory, for London and Principal Market Towns in England”, page 445, in listings for Wolverhampton, W Bissell is listed as a Patentee of flooring cramps, lifting jacks and proprietor of mortise locks; mortising machines, bench and vertical saw-frames". By 1871 the business was operating as Messrs. J. G. Bissell and Co. and the trademark on this item in our Collection was phased out. This information assists in allocating the provenance of this item to the late 1860s.This item is significant because it is representative of housing construction tools used in the Wodonga District which have evolved into present day tools.A cast iron clamp used to install tongue and groove floorboards. Maker's mark on on side. W. B. BISSELL PATENTEE WOLVERHAMPTONcarpenters' tools, housing construction -

Royal Australian and New Zealand College of Obstetricians & Gynaecologists (RANZCOG)

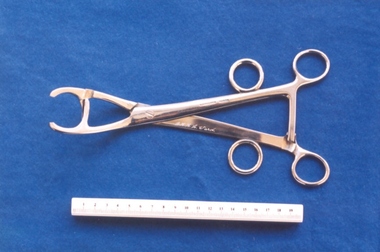

Royal Australian and New Zealand College of Obstetricians & Gynaecologists (RANZCOG)Tool - Bonney's myomectomy clamp used by Box Hill Hospital labour ward, Down Bros., London

Victor Bonney (1872- 1953) was a gifted and innovative surgeon. One of Bonney’s most notable achievements was his development of a successful procedure for myomectomy. After his wife developed fibroids and had her uterus removed early in their marriage, Bonney took a great interest in the practice of conservatism in surgery. Prior to Bonney, myomectomy “had fallen into disuse because of excessive blood loss during the operating and the infections that commonly followed” (Chamberlain, 'The master of myomectomy') , but Bonney saw an opportunity to revolutionise this practice. In his words: “I set myself to make myomectomy so feasible, successful and safe as to render it a fair alternative to hysterectomy in every case… Excepting only in a very few instances… I have succeeded, and now enter the operating theatre free of the trammels which at one time too often compelled my hand against my heart.” (Bonney, 'The fruits of conversatism') Bonney’s crucial innovation was the development of a new surgical clamp, an instrument which is now referred to as Bonney’s myomectomy clamp. The clamp was ingeniously designed to cut off blood supply to the uterus by compressing the uterine arteries, immediately reducing the excessive blood loss which had previously been associated with the procedure. Although technological advances mean that these are now seldom used, Bonney’s success with this procedure was such that his clamps were regularly used for myomectomy procedures for decades after his death. This instrument was included with other obstetric instruments, mostly destructive instruments, given to RANZCOG from Box Hill Hospital labour ward in February- March 1998. The maternity service at Box Hill Hospital combined with St George's Hospital in Kew to be known as Birralee Maternity Service. These instruments were collected by Julie Collette, Unit Manager, St George's Kew and given to RANZCOG Museum Curator, Susan Barnett. Stainless steel clamp. Scissor type instrument with two sets of finger grips and a locking ratchet mechanism. The blades close to form two apertures which can be selectively decreased in size."DOWN BROS LONDON STAINLESS" upper surface of RH handle; "B.H.H.L. WARD" inner surface of LH handle.surgery, obstetrics