Showing 36 items matching "sharpening steel"

-

Flagstaff Hill Maritime Museum and Village

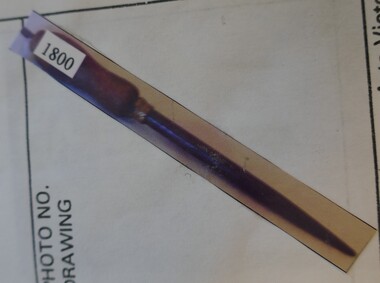

Flagstaff Hill Maritime Museum and VillageDomestic object - Sharpening Steel

... Sharpening Steel...Sharpening Steel...A honing steel, sometimes referred to as a sharpening steel... to as a sharpening steel, whet steel, sharpening stick, sharpening rod ...A honing steel, sometimes referred to as a sharpening steel, whet steel, sharpening stick, sharpening rod, butcher's steel, and chef's steel, is a rod of steel, ceramic or diamond-coated steel used to restore keenness to dulled blade edges. They are flat, oval, or round in cross-section and up to 30 centimetres (1 ft) long. The steel and ceramic honing steels may have longitudinal ridges, whereas the diamond-coated steels are smooth but embedded with abrasive diamond particles. Non-abrasive honing rods such as smooth ceramic or ribbed steel are able to remove small amounts of metal via adhesive wear. In normal use, the rod is applied to the blade at a slightly higher angle than that of the bevel, resulting in the formation of a micro-bevel. The term "hone" is associated with light maintenance performed on a blade without the effort and precision normally associated with sharpening, so the name "hone" was borrowed. In the 1980s, ceramic abrasives became increasingly popular and proved an equal, if not superior, method for accomplishing the same daily maintenance tasks; manufacturers replaced steels with ceramic (and later, manufactured diamond abrasive) sharpening "steels" that were actually hones. Use Honing steels are used by lightly placing the near edge of the blade against the base of the steel, then sliding the blade away from yourself along the steel while moving it down – the blade moves diagonally, while the steel remains stationary. This should be done with the blade held at an angle to the steel, usually about 20°, and repeating on the opposite side at the same angle. This is repeated five to ten times per side. Steeling It is often recommended that steeling be performed immediately before or after using a knife and can be done daily. By contrast, knives are generally sharpened much less frequently. A traditional smooth honing steel is of no use if the edge is blunt, because it removes no material; instead it fixes deformations along the edge of a sharp blade, technically known as burnishing. There has long been speculation about the efficacy of steeling (re-aligning the edge) vs honing (removing minor deformation with abrasives); studies tend to favour abrasives for daily maintenance, especially in high-carbide-volume "stainless" steels (such as the popular CPM S30V steel, which tends to "tear out" when steeled rather than re-forming an edge.) Small honing steel for outdoor activities Usage trends Steels have traditionally been used in the West, especially in heavy-use scenarios (e.g. butchering, where the edge deforms due to forceful contact with bone). These scenarios also lead Western trends toward blades tempered to a lower level of hardness (and thus lower brittleness). In East Asia, notably Japan, harder knives are preferred, so there is little need for steeling intra-day, as the edge does not deform as much. Instead, the blade is honed as needed on a waterstone. While tradition has kept the practice of steeling alive in Western kitchens, the majority of honing steels sold are abrasive rather than smooth, and knives are harder and more frequently made of stainless steel, which does not respond to traditional steeling techniques as well as high-carbon/low alloy tool steels.The sharpening steel is essential to maintain the sharpness of carving and other knives.Steel knife sharpener with bone handle. Part of a carving set.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sharpening steel, carving set, kitchen equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Knife Sharpener, Johann Friedrich Dick, 1873 to 1900

... sharpening steel... took over the company and began the production of sharpening...Sharpening Steel or Knife sharpener with bone handle... of sharpening steels, with the logo of “F Dick” on their products. One ...Johann Friedrich Dick founded the company in 1778 to manufacture files, the company continued in the manufacture of files as its main product line until 1873, when Paul Friedrich Dick took over the company and began the production of sharpening steels, with the logo of “F Dick” on their products. One hundred years after the founding of the company, a factory in Esslingen began construction. At that time the company had 20 employees. In 1881, company commissioned Germany's first file production machine. In 1889, Friedrich Dick built a new factory in Kollwitz/Fleischmannstrasse in Esslingen, employing 100 people and expanding the product line to include knives for butchers and chefs, cleavers and other specialized tools. Files manufactured ranged from the smallest watchmaker's file to the largest (over 45 cm in length) square file. In 1997, the F Dick company moved to a new headquarters in Deizisau, Germany. The old factory in Esslingen is now a class listed monument and the town's landmark.An item made by a world class manufacture of cutlery for chefs, the subject item is significant as its manufacture was probably early in the firms beginnings when Friedrich Dick took over in1873 when he specialised in making sharpening steels. The company is still producing these items today as well as other specialised knives for professionals. Early manufactured steels such as the subject item are sought after today by collectors and quite rare. Sharpening Steel or Knife sharpener with bone handle with ribbed pattern, brass knobs and ring at end of handleMarked F Dick Esslingenflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, sharpening steel, knife sharpener, kitchen tool, carving, kitchen utensil, cooking, f dick -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, Knife, curved, Sheffield c1900, 20thC

... continued to manufacture 'Cooks’ and palette knives and steels... crossed with a sharpening steel (and the letters ‘JO’). scratched... knife crossed with a sharpening steel (and the letters ‘JO ...John Oxley was a shoe and butchers’ knife manufacturer, who was listed in Whitecroft UK in 1822 . By 1825, he was based in Hollis Croft. John apparently died in about 1837. He had two sons – George (1808-1879) and James (1811-1881) who took over the business. George moved to Indianna, USA and in 1868 James continued to manufacture 'Cooks’ and palette knives and steels" Oxley’s trade mark was a butcher’s knife crossed with a sharpening steel (and the letters ‘JO’). The firm stayed in the family until 1960. Early settlers were self reliant and repaired their own equipment for kitchen,dairy, farm, horses, carts using various tools . This strong steel knife is typical of the type used by early settlers in Moorabbin Shire c1900Heavy duty curved steel knife with a wide blade encased in 2 thick leather straps secured with steel rivets Blade ; James Oxley with Trade Mark - a butcher’s knife crossed with a sharpening steel (and the letters ‘JO’). scratched into leather handle ; J EVANSknives, sheffield steel, oxley james ltd. , leatherworkers, saddles, horses, bootmakers, shoes, boots, builders, carpenters, early settlers, market gardeners, blacksmiths, tools, building equipment, hammers, moorabbin shire, bentleigh, mckinnon, highett, cheltenham,mcewan james pty ltd, melbourne, bunnings pty ltd, -

Stawell Historical Society Inc

Stawell Historical Society IncMemorabilia - Realia, 1910-1920

... Knife Sharpening Steel ... grampians Stawell Knife Sharpening Steel Memorabilia Realia ...Knife Sharpening Steel stawell -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Sickle

... Large curved sharpened steel blade with a wooden handle.... agriculture Austria Large curved sharpened steel blade with a wooden ...Type of sickle used by Mr. Slater at his property 'Mitcham Grove' North Blackburn. A lavender farm.Large curved sharpened steel blade with a wooden handle.Austriarural industry, agriculture -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Sickle

... Long curved sharpened steel blade with a wooden handle....rural industry agriculture 4 Long curved sharpened steel ...Long curved sharpened steel blade with a wooden handle.4rural industry, agriculture -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, whetstone , 'Bridestowe' with box, 20thC

... for sharpening steel blades , with the original box... A square block of grey abrasive material used for sharpening steel ...A Whetstone is a sharpening stone used for knives and other cutting tools. Sharpening stones, water stones or whetstones are used to grind and hone the edges of steel tools and implements e.g. scissors, scythes, knives, razors and tools such as chisels, hand scrapers and plane blades. Though it is sometimes mistaken as a reference to the water often used to lubricate such stones, the word "whetstone" is a compound word formed with the word "whet", which means to sharpen a blade, not the word "wet". The process of using a sharpening stone is called stoning.A square block of grey abrasive material used for sharpening steel blades , with the original boxBRIDESTOWE / Picture of ‘Kangaroo, Stag and Emu among radiating wheat stalks’ / TASMANIAwhetstones, sharpeners, steel blades, tools, cutlery, razors, moorabbin, bentleigh, cheltenham, early settlers, -

Mont De Lancey

Mont De LanceyTool - Grinding Stone, Unknown

... Equipment Sharpeners Sharpening stones Steel Wood A large sandstone ...Owned and used by the late Mr W.T. Sebire 1900. The frame was rebuilt by Russell Sebire.A large sandstone grinding stone disc with a pale blue wooden frame and metal turning handle/ It was used for sharpening tools such as axes in the late 19th or early 20th Century. grinding stones, sandstone, equipment, sharpeners, sharpening stones, steel, wood -

Geelong RSL Sub Branch

Geelong RSL Sub BranchMachete, There are no makers names, Mid 20th Century

... Steel blade machete with wooden double sided handle... a pocket on the front to hold a sharpening stone and has steel ...These machete's were issued to military personnel posted in jungle like conditions.The machete would have been used by military personnel during WW2 and during the 1950s.Steel blade machete with wooden double sided handle. The handle is attached to the wood with four steel rods. There is an olive green scabbard made of cotton material oil impregnated. The scabbard has a pocket on the front to hold a sharpening stone and has steel on the top opening to keep the opening firm, there is a steel catch for attachment to webbing and a cloth loop with press stud to hold the handle of the machete in place when in the scabbard. There is a cotton fabric loop through the handle.On the handle of the machete MA67. The item number on the scabbard is not readable.army, military, machete. -

Orbost & District Historical Society

Orbost & District Historical Societyaxe head

Inspected by Joanna Freslov, archaeologist 2/6/2008. Genuine Aboriginal axe head up to 2000 years old. Possibly came through trading from western district. Stone tools were used for a variety of purposes, in ways similar to those of the steel knives, axes, hammers and chisels. Ground-edge tools are made from fracture-resistant stone, such as basalt.This stone is able to withstand repeated impact, and and wqas generall used for stone axes. The stone was dug or found and then roughly shaped into a tool blank with blows from a hammerstone. The edges were then sharpened and refined by grinding the tool against a coarse, gritty rock. The necessary tools and equipment for hunting, fishing and warfare were one of the very few items that Aboriginals carried with them from place to place. Most were used for a multiplicity of purposes. Because many were made from raw natural materials, such as wood, generally only partial remains are found today. This axe head is an example of an early stone tool used by the Indigenous people of Victoria.Small grey oval-shaped axe head.axehead stone-artifact aboriginal tool -

Orbost & District Historical Society

Orbost & District Historical Societyaxe head

Inspected by archaeologist, Joanna Freslov on 2.6.2008. Stone tools were used for a variety of purposes, in ways similar to those of steel knives, axes, hammers and chisels. Ground-edge tools are made from fracture-resistant stone, such as basalt.This is able to withstand repeated impact, and and so was suitable for use in objects such as stone axes. The stone was quarried, and then roughly shaped into a tool blank with blows from a hammerstone. The edges were then sharpened and refined by grinding the tool against a coarse, gritty rock. The necessary tools and equipment for hunting, fishing and warfare were some of the very few items that Aboriginals carried with them from place to place. Most were used for a multiplicity of purposes. Because many were made from raw natural materials, such as wood, generally only partial remains are found today. This artefact is an exaample of the stone tools that Aboriginal people used.A dark stone handmade Aboriginal axe head.aboriginal axe-head stone-artefacts tool -

Orbost & District Historical Society

Orbost & District Historical Societyaxe head

Inspected by Joanna Freslov, archaeologist 2.6.2008. Ground-edged axes first appeared in south-eastern Australia about 4,000 years ago and were used either with handles or hand-held. Stone tools were used for a variety of purposes, in ways similar to those of steel knives, axes, hammers and chisels. Ground-edge tools are made from fracture-resistant stone, such as basalt. This is able to withstand repeated impact making it suitable for use in objects such as stone axes. The stone was quarried, and then roughly shaped into a tool blank with blows from a hammerstone. The edges were then sharpened and refined by grinding the tool against a coarse, gritty rock. The necessary tools and equipment for hunting, fishing and warfare were one of the very few items that Aboriginals carried with them from place to place. Most were used for a multiplicity of purposes. Because many were made from raw natural materials, such as wood, generally only partial remains are found today. This item is an example of a stone tool used by the early Indigenous people of Eastern australia.A handmade stone Aboriginal axe head.axe-head aboriginal tool stone-artefact -

Orbost & District Historical Society

Orbost & District Historical Societyaxe head

Inspected by Joanna Freslov, archaeologist 2.6.2008 Ground-edged axes first appeared in south-eastern Australia about 4,000 years ago and were used either with handles or hand-held. Stone tools were used for a variety of purposes, in ways similar to those of steel knives, axes, hammers and chisels. Ground-edge tools are made from fracture-resistant stone, such as basalt which is able to withstand repeated impact, and so is suitable for use in objects such as stone axes. The stone was quarried, and then roughly shaped into a tool blank with blows from a hammerstone. The edges were then sharpened and refined by grinding the tool against a coarse, gritty rockThe necessary tools and equipment for hunting, fishing and warfare were one of the very few items that Aboriginals carried with them from place to place. Most were used for a multiplicity of purposes. Because many were made from raw natural materials, such as wood, generally only partial remains are found today. This item is an example of an early axe head used by the Indigenous people of East Gippsland.A handmade stone Aboriginal axe head.aboriginal tool stone-artefact axe-head -

Orbost & District Historical Society

Orbost & District Historical Societyaxe head

Inspected by Joanna Freslov, archaeologist 2.6.2008. Stone tools were used for a variety of purposes, in ways similar to those of steel knives, axes, hammers and chisels. Ground-edge tools are made from fracture-resistant stone, such as basaltwhich is able to withstand repeated impact, and is suitable for use in objects such as stone axes. The stone was quarried, and then roughly shaped into a tool blank with blows from a hammerstone. The edges were then sharpened and refined by grinding the tool against a coarse, gritty rockThe necessary tools and equipment for hunting, fishing and warfare were one of the very few items that Aboriginals carried with them from place to place. Most were used for a multiplicity of purposes. Because many were made from raw natural materials, such as wood, generally only partial remains are found today. This axe head is an example of an early stone tool used by the Indigenous people of Eastern Australia.A handmade stone Aboriginal axe head.aboriginal tool stone-artefact axe-head -

Orbost & District Historical Society

Orbost & District Historical Societyaxe head

Inspected by Joonna Freslov, archaeologist 2.6.2008. Stone tools were used for a variety of purposes, in ways similar to those of steel knives, axes, hammers and chisels. Ground-edge tools are made from fracture-resistant stone, such as basalt which is able to withstand repeated impact, and is suitable for use in objects such as stone axes. The stone was quarried, and then roughly shaped into a tool blank with blows from a hammerstone. The edges were then sharpened and refined by grinding the tool against a coarse, gritty rock.The necessary tools and equipment for hunting, fishing and warfare were one of the very few items that Aboriginals carried with them from place to place. Most were used for a multiplicity of purposes. Because many were made from raw natural materials, such as wood, generally only partial remains are found today. This axe head is an example of an early stone tool used by the Indigenous people of Eastern Australia.A handmade stone Aboriginal axe head. Finger grips are clear.axehead aboriginal tool stone-artefact -

Bendigo Military Museum

Bendigo Military MuseumWeapon - MACHETE & SCABBARD, post 1960

.1) Machete, steel with wooden handle with loop hole. Australian issue. BEW 82. .2) Machete Scabbard, waterproof fine canvas with small pouch for sharpening stone, 2 attachments for fitting to web belt..2) 8465-65 - 5820 [up arrow] Cantas 89machete, weapons -

Frankston RSL Sub Branch

Frankston RSL Sub BranchSharpening Stone

A honing stone used for sharpening the cutting edge of steel bladed pocket knives or razor blades. The stone was issued to service personnel during World War 2. This stone was issued ca 1940. -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

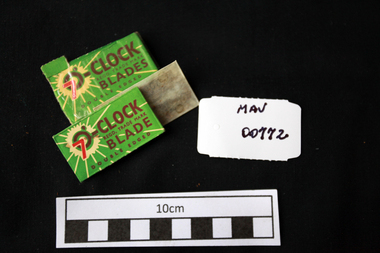

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Personal Effects, man's razor blade in box, 20thC

Safety razors had been developed in the mid-19th century, but still used a forged blade that dulled and rusted. In the 1870s, the Kampfe Brothers ( Germany) introduced a type of safety razor. Gillette improved these earlier safety-razor designs, and introduced the high-profit-margin stamped razor blade steel blade. Gillette's innovation was the thin, inexpensive, disposable blade of stamped steel. King Camp Gillette observed in 1902 that as existing, relatively expensive, razor blades dulled quickly and needed continuous sharpening, a razor whose blade could be thrown away when it dulled would meet a real need and likely be profitable. In 1918, when the U.S. entered World War I, the Gillette company provided all American soldiers with a field razor set, paid for by the government, and as they were allowed to take them at discharge they continued their use of this product thus ensuring future sales. An unused, wrapped, man's razor blade in a box. 7 O'clock brand '7 O'CLOCK / REGD. TRADE MARK / BLADES / DOUBLE EDGED shaving equipment. razorblades, safety razors, cheltenham, moorabbin, bentleigh, pioneers, early settlers -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietySpanner Small, 1920's

This spanner, part of a raker/jointer/guage set which is a sharpening tool for cross cut logging saws. The logging saws used in the early 1900's for the clearing of forests required constant sharpening of their "cutting teeth". The logging of forested areas during these times was very much a "hands on" method of either one or two men by the use of saw or hand axe. Chain saws, chain and ball(clearing) and bulldozing methods came in the mid 1900's.This particular spanner was part of a crosscut saw sharpening tool and method was used by surveyors laying down boundaries for the S.E.C. Victoria Hydro Electricity Scheme (1920's). This item was given to a local Kiewa Valley lad who accompanied the initial surveyors. The lad was responsible for the tendering and feeding of the surveyors "pack horses". Surveys during this period and in the dense mountainous terrain of the Victorian Alps was both exhausting and hazardous. Overnight accommodation at various log cabins was not always possible and swag/tent alternative was the "fall back"This small spanner is part of the Raker/Jointer Gauge saw set and is made from forged steel. The nut grip is of the two tightening nuts on the main construction frame. See KVHS 0090 (A &B) for the other items making up the sharpening tools.hand tool, saw, sharpening method, tree felling. -

Blacksmith's Cottage and Forge

Blacksmith's Cottage and ForgeSteel, Unknown

... Steels were used to sharpen knives.... Marsh goldfields Steels were used to sharpen knives. steel ...Steels were used to sharpen knives.Steel with an ivory handle - light yellow. Tapers at end. Grooves along length.Made in Englandsteel, cutlery, domestic item, ivory -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Saw Vice and Spanner, Henry Disston & Sons, Early 20th century

... . In 1855 Henry Disston cast a crucible saw sharpening steel ...Henry Disston (1819-1878) was born in England and later moved to America. He has been noted in a biography as a "Pioneer Industrialist Inventor". In 1840 he began making and selling his own saws in Philadelphia, USA, growing to become the world's largest saw manufacturer. Tools made by Henry Disston and his company have the reputation of being the finest tools money can buy.The saw sharpening vice and its shifting spanner are significant for their connection with Henry Distton & Sons, renowned for high quality hand saws and associated tools. In 1855 Henry Disston cast a crucible saw sharpening steel, the first person to ever do so in America. The hand tools are also important for their association with the early building industry. Saw sharpening vice with accompanying saw tooth shifting spanner. The vice has a ball and socket clamp. The top of the vice has a saw clamp with wide jaws. The metal surface has remnants of black paint. Inscription is cast into the jaws of the vice. It was made by Henry Disston & Sons"HENRY DISSTON & SONS"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, vice, saw sharpening vice, saw sharpening tool, saw tooth, shifting spanner, woodworking tool, henry disston, disston & co, hand saw, handsaw, hand tools, carpentry, boat building -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Bench Saw Vice, Henry Disston & Sons, 1910 -1925

The subject item is a saw blade sharpening clamp that attaches to a bench allowing the operator to sharpen the teeth on a saw with a file while keeping the saw blade in an upright position. Henry Disston (1819–1878) began his career as an American saw maker in Philadelphia. He emigrated from England in 1833 and started making saws and squares in 1840. In 1850, he founded the company that would become the largest saw maker in the world the ”Keystone Saw Works” on the Delaware River. Some five years later, Disston built a furnace possibly the first melting plant for steel in America and began producing the first crucible saw steel ever made in the United States. While his competitors were buying good steel from Britain, he was making his own, to his specification, for his own needs. Disston subsequently constructed a special rolling mill exclusively for saw blades. Over the following decade, the Disston company continued to grow, even while dedicating itself to the Union Army's war effort. In 1865, when his son Hamilton Disston rejoined the business after serving in the Civil War, Disston changed the company's name to Henry Disston & Son. Henry Disston and his sons set the standards for American saw makers, both in terms of producing high-quality saws and developing innovative manufacturing techniques. Disston also started making files in 1865. In September 1872, Henry Disston and two other men dug a part of the foundation for what was to become the largest saw manufacturing facility in the world: Disston Saw Works. This was in the Tacony section of Philadelphia. Having previously moved his expanding business from near Second and Market Streets to Front and Laurel Streets, Disston sought to establish his business away from this cramped area. It took over 25 years to move the entire facility to Tacony. This Philadelphia neighborhood seems to have been the only company town in the United States established within an existing city. At its peak of operations, Disston Saw Works employed 8,000 people and the factory covered 300 acres. The company, known as Henry Disston and Sons, Inc by the early 20th century, cast the first crucible steel in the nation from an electric furnace in 1906. The firm's Armour plate building near Princeton Avenue and Milnor Street contributed tremendously to the World War II effort. But the company's innovation and industriousness would not last forever. In 1955, with mounting cash-flow problems and waning interest on the family's part to run the firm, Henry Disston and Sons were sold to the H.K. Porter Company of Pittsburgh. Porter's Disston Division was sold in 1978 and became the Henry Disston Division of Sandvik Saw of Sweden. This division was then sold in 1984 to R.A.F. Industries of Philadelphia and became known as Disston Precision Incorporated, a maker of specialized flat steel products. In 2013, R.A.F. Industries sold Disston Precision Inc. in a private sale. Although the company has ceased making Disston handsaws, the Disston brand name still exists in this firm. A significant American company that pioneered the making of high-quality steel and saws along with other tools and accessories. The subject item is significant as it was made at a time when the company was in its hay day. Adjustable Ball & Socket Saw Sharpening vice, cast iron, with clamp to attach to a workbench. Made by Henry Disston & Co. No 1 painted greyflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, saw clamp, henry disston & sons, saw sharpening, tool accessories, wood saws -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Spokeshave, Sides & Skinner, First half of the 20th century

A spokeshave is a hand tool used to shape and smooth woods in woodworking jobs such as making cart wheel spokes, chair legs, paddles, bows, and arrows. The tool consists of a blade fixed into the body of the tool, which has a handle for each hand. Historically, a spokeshave was made with a wooden body and metal cutting blade. With industrialization metal bodies displaced wood in mass-produced tools. Being a small tool, spokeshaves are not suited to working large surfaces. The name spokeshave dates back to at least the 16th century, though the early history of the tool is not well documented. The name spokeshave reflects the early use of the tool by wheelwrights. The first spokeshaves were made of wood usually beech with steel blades, before being largely superseded by the development of metal-bodied spokeshaves in the latter half of the 19th century, though many woodworkers still use wooden spokeshaves. Due to their widespread use and versatility vintage wooden spokeshaves remain commonly available and relatively low in price. Spokeshaves consist of a blade or iron secured to the body or stock of the tool, which has two handles one for each hand. The bottom surface of the tool is called the sole. The blade can be removed for sharpening, and adjusted to vary the depth of the cut. An early design consisted of a metal blade with a pair of tangs to which the wooden handles were attached, as with a draw knife. Unlike a draw knife, but like a plane, spokeshaves typically have a sole plate that fixes the angle of the blade relative to the surface being worked. There are a wide variety of different types of spokeshave, suited to different trades and applications. A now vintage tool made by an Australian manufacture in NSW who specialised in making pruning shears, hacksaw frames and heel shaves under the Erskin brand name. This tool is now sought after by collectors even though it was probably made in the first quarter of the 20th century. It gives a snapshot of how carpenters work with wood by hand showcasing their craftsmanship. Hollow face Spokeshave, metal body with black enamel finish. Erskin stamped on frontflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, spokeshave, cabinet makers tools, wood working, cutting tool, shaping tool -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Awl, Mid to late 20th century

An Awl is used to make indentations in wood or other materials in order to ease the insertion of a nail or screw. The blade is placed across the fibers of the wood, cutting them when pressure is applied. The Awl is then twisted through 90 degrees which displaces the fibers creating a hole. This then gives a start to the nail or screw being inserted into the work piece. There is a difference between an Awl and a Bradawl, the Awl is a small hand-held tool with a sharpened point and a Bradawl is similar but is flattened at its tip to produce a sharp chisel edge.An everyday tool used in carpentry, the subject item at this time cannot be associated with an historical event, person or place, provenance is unknown, item assessed as believed to have been produced during the 20th century.Awl with wooden handle with brass ferrule & steel pointed shaftStamped on handle J McArthur (owner)flagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, awl, j mcarthur, carpenders tools, woodworking tools, nail starter -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Spokeshave, Mathieson and Son, 1860 to 1910

A spokeshave is a hand tool used to shape and smooth woods in woodworking jobs such as making cart wheel spokes, chair legs, paddles, bows, and arrows. The tool consists of a blade fixed into the body of the tool, which has a handle for each hand. Historically, a spokeshave was made with a wooden body and metal cutting blade. With industrialization metal bodies displaced wood in mass-produced tools. Being a small tool, spokeshaves are not suited to working large surfaces. The name spokeshave dates back to at least the 16th century, though the early history of the tool is not well documented. The name spokeshave reflects the early use of the tool by wheel wrights. The first spokeshaves were made of wood usually beech with steel blades, before being largely superseded by the development of metal-bodied spokeshaves in the latter half of the 19th century, though many woodworkers still use wooden spokeshaves. Due to their widespread use and versatility vintage wooden spokeshaves remain commonly available and relatively low in price. Spokeshaves consist of a blade or iron secured to the body or stock of the tool, which has two handles – one for each hand. The bottom surface of the tool is called the sole. The blade can be removed for sharpening, and adjusted to vary the depth of the cut. An early design consisted of a metal blade with a pair of tangs to which the wooden handles were attached, as with a draw knife. Unlike a draw knife, but like a plane, spokeshaves typically have a sole plate that fixes the angle of the blade relative to the surface being worked. There are a wide variety of different types of spokeshave, suited to different trades and applications. Company History: The firm of Alexander Mathieson & Sons was one of the leading makers of hand tools in Scotland. Its success went hand in hand with the growth of the shipbuilding industries on the Firth of Clyde in the nineteenth century and the emergence of Glasgow regarded as the "second city of the Empire". It also reflected the firm's skill in responding to an unprecedented demand for quality tools by shipyards, cooperage's and other industries, both locally and far and wide. The year 1792 was deemed by the firm to be that of its foundation it was in all likelihood the year in which John Manners had set up his plane-making workshop on Saracen Lane off the Gallowgate in the heart of Glasgow, not far from the Saracen's Head Inn, where Dr Johnson and James Boswell had stayed on their tour of Scotland in 1773. Alexander Mathieson (1797–1851) is recorded in 1822 as a plane-maker at 25 Gallowgate, but in the following year at 14 Saracen's Lane, presumably having taken over the premises of John Manners. The 1841 national census described Alexander Mathieson as a master plane-maker at 38 Saracen Lane with his son Thomas Adam working as a journeyman plane-maker. In 1849 the firm of James & William Stewart at 65 Nicolson Street, Edinburgh was taken over and Thomas was put in charge of the business, trading under the name Thomas A. Mathieson & Co. as plane and edge-tool makers. Thomas's company acquired the Edinburgh edge-tool makers Charles & Hugh McPherson and took over their premises in Gilmore Street. The Edinburgh directory of 1856/7 the business is recorded as being Alexander Mathieson & Son, plane and edge-tool makers at 48 Nicolson Street and Paul's Work, Gilmore Street. The 1851 census records indicate that Alexander was working as a tool and plane-maker employing eight men. Later that year Alexander died and his son Thomas took over the business. Under the heading of an edge-tool maker in the 1852/3 (Post-Office Glasgow Annual Directory) the firm is now listed as Alexander Mathieson & Son. By the early 1850s, the business had moved to 24 Saracen Lane. The directory for 1857/8 records that the firm had moved again only a few years later to East Campbell Street, also off the Gallowgate, and that through further diversification was also manufacturing coopers' and tin men's tools. The ten-yearly censuses log the firm's growth and in 1861 Thomas was a tool manufacturer employing 95 men and 30 boys; in 1871 he had 200 men working for him and in 1881 300 men. By 1899 the firm had been incorporated as Alexander Mathieson & Sons Ltd, even though only Alexander's son Thomas appears ever to have joined the firm.A vintage tool made by a well-known firm made for other firms and individuals that worked in wood. The tool was used to shape various items mainly in use by wheel wrights. A significant vintage item from the mid to late 19th century that today is quite sought after by collectors. It gives us a snapshot of how trade people predominately worked materials such as wood by hand and with tools that were themselves hand made shows the craftsman's art of the time. Spokeshave with blade 4 inches wide.Mathieson and Son Glasgow. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, spokeshave, mathieson and son, carpentry tools, wheel wright tools -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Saw gauge, Henry Disston, 1890-1920

Disston Saw Works of Philadelphia was one of the better known and highly regarded manufacturers of handsaws in the United States. During the Machine Age, the company was known as Henry Disston & Sons, Inc. a supplier of industrial saw blades. History: The story of handsaws in the United States mirrors the technical and development of steel in Sheffield, England, which was the center of handsaw production during the 18th century and through most of the 19th century. England's political and economic lock-on steel making in the colonies held American saw makers at bay until well after the Revolutionary War. American steel producers were unable to compete until the US government introduced import tariffs to level the playing field in 1861. Henry Disston: Henry Disston (1819–1878) began his career as an American saw maker in Philadelphia. He had emigrated from England in 1833 and started making saws and squares in 1840. In 1850, he founded the company that would become the largest saw maker in the world, the Keystone Saw Works. Some five years later, Disston built a furnace—perhaps the first melting plant for steel in America and began producing the first crucible saw steel ever made in the United States. While his competitors were buying good steel from Britain, he was making his own, to his specification, for his own needs. Disston subsequently constructed a special rolling mill exclusively for saw blades. Over the following decade, the Disston company continued to grow, even while dedicating itself to the Union Army's war effort. In 1865, when his son Hamilton Disston rejoined the business after serving in the Civil War, Disston changed the company's name to Henry Disston & Son. Henry Disston and his sons began to set the standards for American saw makers, both in terms of producing high-quality saws and files in 1865 through his development of innovative manufacturing techniques. In September 1872, Henry Disston and two other men dug a part of the foundation for what was to become the largest saw manufacturing facility in the world: Disston Saw Works. This was in the Tacony section of Philadelphia. Having previously moved his expanding business from near Second and Market Streets to Front and Laurel Streets. It took over 25 years to move the entire facility to Tacony. Henry Disston was renowned for having one of the first industries that exhibited environmental responsibility, as well as a paternalistic view towards his employees. For example, he had thousands of homes built in Tacony for his workmen. Funds to purchase these homes were made available through a building and loan association set up by the Disston firm. His caring influence on the community was evident in everyday life. To meet employees' cultural needs, a hall and a library were built with Henry Disston agreeing to pay a fixed sum towards its maintenance. The Tacony Music Hall was erected in 1885, also with the assistance of Disston money. Henry Disston had fallen ill by 1877 and never truly recovered; he suffered a stroke and died the next year. This came only one and a half years after seeing his products receive the highest honors at the great Philadelphia Centennial Exposition of 1876. His vision of a working-class community and the completion of the transfer of his enormous saw plant was carried out by his wife and his sons. The company, by the early 20th century, cast the first crucible steel in the nation from an electric furnace in 1906. The firm's armor-plate building near Princeton Avenue and Milnor Street contributed tremendously to the World War II effort. But the company's innovation and industriousness would not last forever. In 1955, with mounting cash-flow problems and waning interest on the family's part to run the firm, Henry Disston and Sons were sold to the H.K. Porter Company of Pittsburgh. Porter's Disston Division was sold in 1978 and became the Henry Disston Division of Sandvik Saw of Sweden. This division was then sold in 1984 to R.A.F. Industries of Philadelphia and became known as Disston Precision Incorporated, a maker of specialized flat steel products. In 2013, R.A.F. Industries sold Disston Precision Inc. in a private sale. Although the company has ceased making Disston handsaws, the Disston brand name still exists in this firm. A tool used to set and sharpen cross cut saws used to fell trees for building construction made by a well known American maker whos firm pioneered the making of saws and their related items including files.combination cross cut saw raker and gauge/jointerDisston USA in the castingflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Personal Effects, safety razor blade 'King Gillette'', 20thc

King Camp Gillette observed in 1902 that as existing, relatively expensive, razor blades dulled quickly and needed continuous sharpening, a razor whose blade could be thrown away when it dulled would meet a real need and likely be profitable. Safety razors had been developed in the mid-19th century, but still used a forged blade that dulled and rusted. In the 1870s, the Kampfe Brothers ( Germany) introduced a type of safety razor Gillette improved these earlier safety-razor designs, and introduced the high-profit-margin stamped razor blade steel blade. Gillette's innovation was the thin, inexpensive, disposable blade of stamped steel. Gillette's safety razor retailed for a substantial $5 half the average working man's weekly pay — yet sold by the millions. The most difficult part of development was engineering the blades, as thin, cheap steel was difficult to work and sharpen. This accounts for the delay between the initial idea and the product's introduction. To sell the product, Gillette founded the American Safety Razor Company on September 28, 1901 (changing the company's name to Gillette Safety Razor Company in July 1902). Gillette obtained a trademark registration (0056921) for his portrait and signature on the packaging. Production began in 1903, when he sold a total of 51 razors and 168 blades. The following year, he sold 90,884 razors and 123,648 blades, thanks in part to Gillette's low prices, automated manufacturing techniques and good advertising. By 1908, the corporation had established manufacturing facilities in the United States, Canada, England, France and Germany. Razor sales reached 450,000 units and blade sales exceeded 70 million units in 1915. In 1918, when the U.S. entered World War I, the company provided all American soldiers with a field razor set, paid for by the government, and as they were allowed to take them at discharge they continued their use of this product thus ensuring future sales. The company continues in the present day as the Gillette brand of Procter & Gamble, USA. Throughout the 20thC most men used this type of safety razor with disposable stainless steel razor blades to shave their beards prior to the introduction of affordable electric razors in 1960'sA blue packet of unused 'King Gillette' safety razor blades.on top of packet; Press with thumb / and snap end open / GILLETTE QUALITY THE / SAME THE WORLD OVER / FACTORIES IN / USA / CANADA , GREAT BRITAIN / MEXICO , FRANCE / COLUMBIA, GERMANY / BRAZIL, SPAIN / ARGENTINA, AUSTRALIA / GILLETTE TRADE MARK / KING C GILLETTE / RED. TRADE MARKS / GILLETTE (AUST.) PTY. LIMITED / MELBOURNE / DE 2023 / MADE IN AUSTRALIA / shaving equipment, safety razors, gillette king, proctor & gamble, moorabbin, bentleigh, cheltenham, -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Manufactured Object, stainless steel razor blade holder, c1950

King Camp Gillette observed in 1902 that as existing, relatively expensive, razor blades dulled quickly and needed continuous sharpening, a razor whose blade could be thrown away when it dulled would meet a real need and likely be profitable. Gillette's innovation was the thin, inexpensive, disposable blade of stamped steel. Safety razors had been developed in the mid-19th century, but still used a forged blade that dulled and rusted.. Gillette's safety razor was expensive but lasted many years and the convenience of inexpensive disposable sharp blades was very profitable for Gillette.Throughout the 20thC most men used a safety razor with disposable stainless steel razor blades to shave their beards prior to the introduction of affordable electric razors in 1960's.A two piece stainless steel razor blade holder. The base has a round hole to safely push blade with fingertip and the lid has side finger grooves to aid opening. Contains unused 'CLUB' razor blade in paper packet, 2 used Wilkinson Sword razor blades and 2 Gillette Blades on razor blade 'CLUB', WILKINSON SWORD ; GILLETTEshaving equipment, safety razors, gillette king, proctor & gamble, club razor blades pty ltd melbourne, wilkinson sword pty ltd england, moorabbin, bentleigh, cheltenham, -

Friends of Kurth Kiln

Friends of Kurth KilnFitting

Heavy Cast Steel Fitting for earth moving equipment. V shaped with sharpened edges, 2cm square holes for attachment to Machine. Red paint finish -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Domestic object - Knife Sharpener

... Tempered steel sharpener for sharpening knives.... Mitcham melbourne domestic items utensils cutlery Tempered steel ...Tempered steel sharpener for sharpening knives.domestic items, utensils, cutlery