Showing 5 items matching "sheet metal fabrication"

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Fuller, Grooving iron

... sheet metal fabrication... vintage tool sheet metal fabrication groover seamer hand tool ...This hand groover is sometimes called a seamer, grooving iron, punch or fuller. It would have been used by a metal smith, such as a blacksmith, tinsmith or sheet metal worker. It is used to join two edges of metal. The smith overlaps the edges of the metal, then places the tool on top and beats it with a hammer on the top, forcing the metal into the tool's groove, which joins the metal. The device would be moved along the edges to complete the seam. The same tool could give a decorative finish to an artisan's work.This hand groover is sometimes called a seamer, grooving iron, punch or fuller. It would have been used by a metal smith, such as a blacksmith, tinsmith or sheet metal worker. It is used to join two edges of metal. The smith overlaps the edges of the metal, then places the tool on top and beats it with a hammer on the top, forcing the metal into the tool's groove, which joins the metal. The device would be moved along the edges to complete the seam. The same tool could give a decorative finish to an artisan's work.Tool: a fuller, used to form a groove in heated iron. It is also referred to as a groover, seamer or fuller punch. Hand tool with round handle, flat round top and indented rectangular base. Base has grooves on long edges. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, blacksmith tool, vintage tool, sheet metal fabrication, groover, seamer, hand tool, tinsmth, metalsmith, seaming tool, sheet metal worker, manual tool, smith's tool, fuller, grooving iron, punch -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Fuller, Grooving iron

... sheet metal fabrication... purpose of joining sheets of metal together. The metal formed ...This hand groover is sometimes called a seamer, grooving iron, punch or fuller. It would have been used by a metal smith, such as a blacksmith, tinsmith or sheet metal worker. It is used to join two edges of metal. The smith overlaps the edges of the metal, then places the tool on top and beats it with a hammer on the top, forcing the metal into the tool's groove, which joins the metal. The device would be moved along the edges to complete the seam. The same tool could give a decorative finish to an artisan's work.This handmade tool was made for the particular purpose of joining sheets of metal together. The metal formed in this way could be used for water tanks, boilers and other similar items. It is an example of the equipment made and used in the trades of a metalsmith and blacksmith in the 19th and early 20th centuries.Tool: a fuller, used to form a groove in heated iron. It is also referred to as a groover, seamer or fuller punch. Hand tool with round handle, flat round top and indented rectangular base. Base has grooves on long edges. flagstaff hill maritime museum, maritime museum, shipwreck coast, great ocean road, blacksmith tool, vintage tool, sheet metal fabrication, groover, seamer, hand tool, tinsmth, metalsmith, seaming tool, sheet metal worker, manual tool, smith's tool, fuller, grooving iron, punch -

Federation University Historical Collection

Federation University Historical CollectionReports, Ballarat Technical School Reports: John Bainbridge, 1974, 1974

John Bainbridge's report indicate that he was in Form 4G1. The "G" indicates that he was doing general subjects. These included English, Social Studies, Mathematics 1, Science 1, as well as Graphics, metal fabrication, Auto Practices and Electical Practices. His reports indicate he had a good degree of understanding and ability. There were reports written at the end of each term. At this time there were only three terms each year. The four term year was introduced into Victorian schools in 1987.Printed subject sheets for teachers to complete on appropriate sections. Section for level of ability to be marked, space for individual comments. Separate sheets stapled together in folder.School name. Subject teacher's signature on each page -

Moorabbin Air Museum

Moorabbin Air MuseumManual (item) - Handbook on the Fabrication of Sheet Metal - Ministry Aircraft Prodn

... Handbook on the Fabrication of Sheet Metal - Ministry...Handbook on the Fabrication of Sheet Metal - Ministry... Moorabbin melbourne Handbook on the Fabrication of Sheet Metal ... -

Federation University Historical Collection

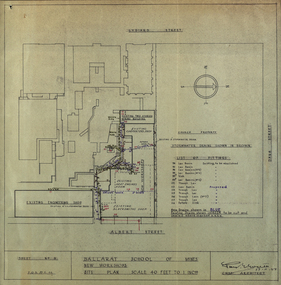

Federation University Historical CollectionPlan - Plans, Ballarat School of Mines New Workshops, 1944, 17/11/1944

This building has been demolished to make way for new buildings along Albert Street. According to E.J. Barker this was Metal Fabrication.Plans (dyeline) for new building along the Ballarat School of Mines Albert Street frontage .1) Ballarat School of Mines New Workshops .2) as above Scale 1:480 WGS 84 37 degrees 33 feet 54 inches south 143 degrees 50 feet 30 inches eastSheet No 3 F.G.B.ballarat school of mines, metal fabrication, albert street, buildings, plan, heat engines room, model mine, blacksmiths shop, blacksmithing, carpenters shop, engineering shope, percy everett