Showing 9 items matching "ship water boiler"

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Water Boiler, Jackson Boilers Ltd, 1920s

... ship water boiler... water boilers for their ships. The firm applied for a USA patent... water boilers for their ships. The firm applied for a USA patent ...Jackson Boilers Ltd., brass founders, electro platers and sheet metal works made this tube water boiler. It was a fitting in the vessel Reginald M, a small cargo ship built at Port Adelaide in 1922 and named after her builder and first owner, John Murch. The Reginald M was launched at Largs Bay, South Australia, in 1922 to carry cargo around South Australia that included guano, barley, wool, horses, cattle, timber, explosives, potatoes, shell grit, and gypsum. It passed through numerous owners over the years and primarily maintained its purpose as a cargo vessel. In 1975, the decommissioned Reginald M was purchased by Flagstaff Hill Maritime Museum as an attraction. Although restoration efforts were undertaken and maintained for the craft above the water line, deterioration occurred below the surface and resulted in the ship being unsafe for visitors to board. It was broken up and removed from Flagstaff Hill in 2018, but items such as the historical boiler remain in Flagstaff Hill’s Collection. JACKSON BOILERS LTD.: - In 1911, Henry Jackson was the Managing Director at Jackson Boilers Ltd. He had gained around 30 years’ experience as a tin plate worker, plumber and gas fitter at Ilkey in 1881, then at Leeds by 1901. By 1921, he had changed employment from Jackson Boilers to Managing Director of Patent Water Boilers. During World War I, Jackson Boilers Ltd of Leeds performed war work like many other manufacturers at that time. The firm made cases for the explosive picric acid and electroplated fuse hole plugs. In 1918, the firm employed 15 males and 19 females. Jacksons Boilers became very successful throughout the first half of the twentieth century with showrooms and sales offices in Scotland, the Midlands and Southern England. It also had an office in Dublin, Ireland. In the post-war 1920s, the firm’s production included instantaneous water boilers and coffee machines for cafes, restaurants and canteens. Jackson Boilers also began to supply shipping lines with catering water boilers for their ships. The firm applied for a USA patent for the tube boiler in 1930, for the design which appears to have been invented in 1926. A 1971 advertisement adds the credentials, Members of the Catering Equipment Manufacturers’ Association. The tube water boiler was designed specifically for use in a ship's restaurant or dining area and patented by Jackson Boilers Ltd. of Leeds. The boiler is significant as a patented design, illustrating the evolution of maritime, commercial and domestic water boilers that have led to many innervations and improvements in today's boilers that are used in heating and in producing hot water for domestic and catering use. It is also significant as it is one of the earlier boilers the Jackson company made in the early 1920s before they applied for a US patent on their revised design in 1926.Water boiler, free standing Jackson's Tube boiler. A tall metal cylindrical stand with a metal sphere on top and several pipe fittings on the sides. A brass tap with a lever handle is connected to the front. A plaque with maker's details is attached under the tap. Details are also impressed into the cylinder above the tap.Jackson Boilers Leeds Ltd. "JACKSON'S PATENT" . Other details indecipherable. flagstaff hill maritime museum and village, flagstaff hill maritime museum, flagstaff hill, maritime museum, maritime village, warrnambool, great ocean road, leeds, jackson boilers ltd, jackson boilers, henry jackson, brass founders, electro platers, sheet metal works, patent water boilers, leeds manufacturer, tube water boiler, domestic boiler, tube domestic boiler, tube boiler, water heaters, water boilers, self-feeding water boilers, sheet metal work instantaneous water heaters, engineering, allied trades, metal workers, metal trade, food machinery, hospitality equipment, ship equipment, ship water boiler, ship heater, catering boilers, café boiler, restaurant boiler, canteen boiler, catering equipment manufacturers’ association, cema, kitchen equipment, kitchen appliance, war work, world war i, wwi, picric acid, picric acid cases, fuse hole plugs, electro plated fuse hole plugs, reginald m, cargo ship, port adelaide, 1922, john murch -

Seaworks Maritime Museum

Seaworks Maritime MuseumShipbuilders model, Tri Ellis

Model ship was presented to the Melbourne Maritime Museum by the British Phosphate Commissioners. Built as Tri-Ellis (1958-74), Tryphena (1974-78), Man Tat (1978-80), 1980 broken up. DWT 13,756 SPEED 14 KNOTS.AT 112RPM. BOILERS LARKSON TRIMBLETUBE. FUEL CONSUMPTION 7 TPD. GENERATORS W.H.ALLEN - 4CYL.2SA290/470. 480B.H.P.320L.W.-220V 333RPM DAILY CONS - 1.5 TONS. EMERGENCY GEN R & H. 40 K.N. -220V. REFRIGERATING MACH: J & G HALL LTD. SUPERSTRUCTURE: FORECASTLE 62'..2 DECKS RIVETED AND WELDED. CARGO BATTONS NOT FITTED. 9 BULKHEADS. RISE OF FLOOR 6".WATER BALLAST 3,296 TONS INCLUDING TUNNEL TANKS 1,341 TONS. 'TWEEN- DECKS FORWARD 274 TONS. REFRIGERATED CARGO INSTALLATION - 6 HOLDS - 55.2',52',54',59.5',43' ,53'. GRAIN CAPACITY :621,640 CU. FT. BALE CAPACITY : 573,810 CU. FT. INSULATED CAPACITY : 5,050 CU.FT. 6 STEEL HATCHWAYS (27',30',30'* 30') (30'* 27.75') (27', 24' * 28' ). 12 WINCHES...DERRICKS 1 (25), 2 (10), 10 (5). MACHINERY: OIL 2SA 7CY.C20 * 1400MM EXHAUST 470MM. 6500 BHP. FUEL BUNKERS: 2135 TONS HIGH VISCOCITY FUEL. The main engine was an opposed piston type Harland & Wolff 6-620/ 1870 6 for the number of cylinders.. 620 for the cylinder bore and 1870 for the combined strokes of the main exhaust pistons in each cylinder. This engine was based no a Burmeister and Wain design but H & W gave these engines their own type designation. Sailed on board its maiden voyage to Australia via Casablanca Morocco where she collected her first load of phosphate. We sailed to Geelong via the Suez canal and the Port of Aden (Yemen) and Freemantle. The first load of phosphate was unloaded at Corio Bay (geelong) Formerly part of the collection of Melbourne shipping company, Howard Smith Ltd. Ship builder's model of the cargo ship Tri-Ellis IMO 5368196 - Body of moulded polyurethane painted in red, black and grey, the deck painted in red, with detailed fittings, machinery, rigging and superstructure, raised on a wooden base. Original ship built Clyde 1958, 11,761 gross tonnes, 531.5' x 68' x 31' (162.0 x 20.73 x 9.45m)plaque at foot of model "MV TRI ELLIS/ LENGTH B.P. 486'-3"- BREADTH MLD 68'0" - DEPTH MLD 40'6"/ TONNAGE GROSS 11,760/ Built by HARLAND & WOLFF LTD/ For BRITISH PHOSPHATE COMMISSIONERS" On model "TRI-ELLIS" painted black -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageSteel Sample, ca. 1876

The sample of steel from which the S.S. Julia Percy’s boiler was made has been tested, according to the attached label. The test involved heating the steel to blood red temperature (or dark red colour) then dipping it into water and bending it when it was cold. A “very severe test for quality” was written on the ticket by T.H. Osborne. (Mr Thomas Hamilton Osborne was the secretary for the Western Steam Navigation Co, established in Warrnambool in 1886. The company’s office was on the corner of Timor and Liebig Streets in Warrnambool and its north-western wall is now part of the current Warrnambool Regional Art Gallery. ) Cold bending of steel in a press or through rollers is the typical method of curving steel for construction. The steel needs to be manufactured in such a way that it is strong enough yet still flexible enough not to crack when bent or rolled. The boiler on the Julia Percy could have been a Scotch Boiler, a design introduced in the 1870’s and still being used today. This design was more robust that previous boilers, generating higher working steam pressures. The design incorporate greater ability to roll iron plates, leading to greater strength, thicker plating and fewer riveted joints. They were originally made of iron then later incorporated steel sections until they were entirely constructed of steel. Many examples of this type of boiler can be found on wreck sites. Shipping was the cheapest and most practical means of carrying produce and goods during the period 1840-1890. Regular domestic steamer services commenced in the Warrnambool district in the late 1850’s and by 1870 the passenger trade was booming. Produce was loaded from the jetty into ‘lighters’ (small boats), which took it to the ships at anchorage in the bay. Passengers were taken to the ship’s side then climbed aboard up ladders or gangways. The coming of the railway in October 1889 meant the gradual decline and end of the steam shipping era. Originally the ship was known as the SS Julia Percy and was later renamed as the Leeuwin. She was an iron passenger-cargo steam ship built in Glasgow by Thomas Wingate for the Warrnambool Steam Packet Company, which commissioned the ship for the steamship trade in Victoria’s western district. She was first registered in Warrnambool, Victoria in 1876. At one point in time the Julia Percy would sail from Warrnambool to Melbourne every Friday and return from Melbourne to Warrnambool every Tuesday. The cost of a return ticket for a Saloon Fare was £1.0.0. She would sail “if practical and weather permitting”. The Julia Percy changed hands several times. Her next owner was the Western Steam Navigaiton Co of Melbourne (1887). It was the manager of this company, Mr. T.H. Osborne, who tagged ths steel sample above. Melbourne Steamship Co became the next owners (1890), followed by William Howard Smith and Sons (1901) for use in Queensland coastal trades, then she was bought by George Turnbull in 1903 and used for local mail contract in Western Australia. She was sold to the Melbourne Steamship Company Ltd. (1906) and re-named the Leeuwi but continued in her Western Australian coastal run. She was converted into a coal hulk in Melbourne in 1910 as a result of damaged caused when she was driven against the jetty at Dongara during a gale. The ship was eventually dismantled and scuttled in Bass Strait on 28 December 1934. The steel sample is significant for its association with the wreck of the Leeuwin (Julia Percy), which is on the Victorian Heritage Register. It is historically significant for being a rare artefact that has potential to interpret aspects of western Victoria’s 19th century steamship trade and Victorian cultural history, including the testing and manufacturing process associated with steam power. Leeuwin is listed on the Victorian heritage Register as being historically significant ‘as one of only four wrecks of steamships in Victorian waters associated with the western district of Victoria’s coastal steamship trade. Her registered number is VHR S413. A sample of the steel from which the boiler of the "SS Julia Percy" (later named Leeuwin) was made. The piece of steel is a ‘C’ shape with the ends almost meeting. A luggage ticket is tied onto the steel and has an inscription on it. The steel is rusty.Ticket with typed information “Steel of which the Boiler of the “Julia Percy” (Warrnambool Steam Navigation Co) was made. TEST: Made Blood hot or Dark Red then dipped into water and bent cold. A very severe test for quality T.H. Osborne. Below these words is the hand written inscription in black “FM 151 / 9.75” julia percy, leeuwin, steel, boiler, steam ship, metal testing, western steam navigation co., flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, t.h. osborne -

Puffing Billy Railway

Puffing Billy RailwaySteam Driven Weir Pump, 1900s

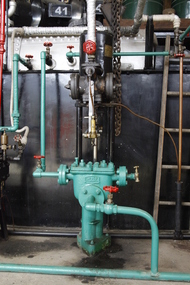

Weir Pumps - these types of vertical pumps were used extensively with both land and marine steam pumps. The pumps were also used for various duties from pumping oil fuel and feed water for boilers, to draining bilges on steam ship[s They are a single cylinder, double acting vertical pumps used by G. & J. Weir Ltd. , of Cathcart, Glasgow Historic - Weir Vertical PumpSteam Driven Weir Pump Green and Black with metal parts.No. B49717puffing billy, weir, steam pump -

Puffing Billy Railway

Puffing Billy RailwayVertical Pump, Weir, 1948

Weir Pumps - these types of vertical pumps were used extensively with both land and marine steam pumps. The pumps were also used for various duties from pumping oil fuel and feed water for boilers, to draining bilges on steam ship[s They are a single cylinder, double acting vertical pumps used by G. & J. Weir Ltd. , of Cathcart, Glasgow The large pump serial number 231703 was built in 1948 and worked at the old Victoria Brewery in East Melbourne before coming to the Museum in 1985. Historic - Weir Vertical Pump used at the old Victoria Brewery in East Melbourne The large pump serial number 231703 was built in 1948 and worked at the old Victoria Brewery in East Melbourne before coming to the Museum in 1985.Weir Vertical Pump - Large Steel PumpWeir puffing billy, weir vertical pump, victoria brewery -

Puffing Billy Railway

Puffing Billy RailwayWeir Pump ( no. 2 ), Vertical ( no. 2 )

Weir Vertical Pump Weir Pumps - these types of vertical pumps were used extensively with both land and marine steam pumps. The pumps were also used for various duties from pumping oil fuel and feed water for boilers, to draining bilges on steam ship[s single cylinder, double acting vertical pumps used by G. & J. Weir Ltd. , of Cathcart, Glasgow .Weir Vertical Pump ( no. 2 ) - Steel vertical pumpWeirpuffing billy, fluid pump, weir, vetical pump -

Geelong Naval and Maritime Museum

Geelong Naval and Maritime MuseumTeacup

The Orungal was originally built in Glasgow in 1923 for the Khedival Mail Steamship & Graving Dock Company of Egypt and named the S.S. Fezara. Due to the effects on steamship companies of the Great Depression including the steep costs of building new ships and increases in running costs and port charges, no new passenger ships had been ordered in Australia since before World War One. To meet demand for passenger berths, the Fezara (5826 tons) along with its sister ship the Famaka (5856 tons, renamed Ormiston), were chartered by the Australasian United Steam Navigation Company Ltd (A.U.S.N.Co.) in 1927. Both the A.U.S.N.Co and the Khedival Mail Steamship Co. were part of the P&O Group. The Orungal operated in this role as an interstate passenger and mail steamer between 1927 and 1940, being used mainly on the Melbourne to Queensland and Western Australian runs, with 240 single class berths. Following the outbreak of World War Two six of the nine large passenger liners servicing mainland Australian passenger and mail trades were requisitioned by the Government to ferry equipment, troops and supplies. Some of them were converted to armed merchant cruisers and used for patrol work and escort duties in the Indian and Pacific Oceans. The Orungal had originally been requisitioned by the government along with the Zealandia on 25 June 1940, to transport troops to Darwin, but was returned to commercial service because "of her unsuitability", perhaps too slow for the demands of the work. Despite being rejected for patrol and convoy duties the Orungal still had a vital role as one of only three passenger liners left to service the mainland Australian trade. Following its requisitioning by the Government shortly after war broke out, it had been fitted out with defensive armament. On its final voyage arriving at Port Phillip Heads from Sydney, Captain Gilling was attempting to enter the Heads ahead of a worsening south-westerly storm and, with a minefield known to have been laid in the area, had been warned by the Navy not to deviate from the swept channel. The captain and crew held fears that in the stormy seas a mine may have been carried away. In the worsening weather a blur of lights at Barwon Heads was mistaken for Port Lonsdale, and the Orungal steamed ashore onto Formby Reef, just east of the entrance of the Barwon River - instead of passing safely through the middle of the Rip. At the Marine Board Inquiry Capt. Gilling - who had been master of the Orungal since 1926 - stated that after becoming uneasy about his position and changing course to starboard one point: " At 10.21 pm I ordered the engine room to stand by and gave instructions for the patent log to be hauled in and for the sounding-gear to be got ready. Approximately two minutes later, in a flash of lightning, I saw land off the port beam. I immediately recognised it as Barwon Heads, and ordered the helm to be put hard to starboard, but the vessel struck before she had time to answer the helm" Barwon Heads and Ocean Grove residents were startled to hear the shrill blast of the ship's whistle, followed by the bright flares and explosions of signal rockets. The Queenscliff lifeboat crew, who had responded to the tragic collision between the Goorangai and another passenger liner the Duntroon in Port Phillip Bay less than 24 hours earlier, were later praised for their efforts in safely taking off all the passengers and crew. Most of the passengers were asleep at the time of the wreck, and were woken up by the commotion, the ship shaking "from stem to stern" and stewards ordering them to lifeboat stations in driving rain. It was a dramatic time with the ship siren wailing and distress rockets being fired. It was reported that "When it was found the ship was safe, the passengers all went to the music room. There they sang and danced for several hours. The ship's orchestra played merrily, and amateur performers among the passengers clowned, danced and sang to keep the laughter going. In the early hours of the morning passengers went to their cabins, most of them to sleep soundly while the keel grated on the rocks". At dawn the Queenscliff lifeboat arrived at the scene having been launched at 2.30am, and cautiously approached the ship which was being "battered by mountainous seas". By 5am oil from a burst oil line was helping to calm seas around the Orungal sufficiently enough for the lifeboat to approach, and all the passengers and crew were taken off in several trips by the lifeboat. A Court of Inquiry later found that the wreck was caused by an abnormal set of current to the north-west and cleared the officers and crew of neglect of duty. The sight of a huge liner almost on the beach saw an unprecedented amount of traffic as people drove an estimated 10,000 cars, using some 60,000 gallons of fuel in a time of strict petrol rationing, to see the spectacle. Salvage operations began in an attempt to refloat the vessel, scheduled for the high tide on 15 December 1940. However, during these operations, at 2.30 am on 13 December 1940, a major fire broke out, believed to have been caused by spontaneous combustion in the boiler room. The ship was soon ablaze, with smoke pouring from its hatches and ventilators, and at mid-morning the magazine exploded fiercely. Of the 60 men working aboard the vessel two were severely burned and had to be taken to Geelong Hospital. The gathered spectators witnessed the eerie sight of the ship's hull glowing red when night fell. The well-known building demolition contractor Whelan the Wrecker bought the salvage rights, and methodically proceeded to dismantle the ship and its fittings. The drama was not yet over for the wreckers when - without warning - the burnt-out hulk was 'attacked' by RAAF for strafing practice. Salvage rights were transferred to another private owner in 1963. By 1945 the combined effects of the exposed location, fire and salvage had seen what was left of the wreck disappear beneath the waves. The site today is marked by two of the four Scotch type boilers sitting upright and exposed at low tide, just north-east of the small boats channel at the entrance to Barwon Heads. Large sections of steel hull plating and framing, and impressively large pieces of ships structure and machinery including masts, booms, deck winches, propeller shaft, flywheel, and a thrust block lie scattered about and make the site an interesting shallow dive. It is interesting to compare the site of the Orungal with the intact remains of similar large passenger ships scuttled in deep water in the Ships' Graveyard, such as the Milora and Malaita. The site is subject to waves and surge, and is best dived on flat calm days The teacup originated from the SS Orungal and was likely used heavily in the ship's life as a passenger, mail and cargo carrier around Australia. The teacup is significant for its connections to SS Orungal and of this ships connected story of being sunk in extraordinary circumstances in the local region. A.U.S.N. Co. Ltd. Teacup salvaged from SS Orungal ss orungal, fezara, world war two, barwon heads, ocean grove -

Mission to Seafarers Victoria

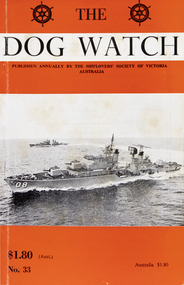

Mission to Seafarers VictoriaJournal (item) - Periodicals-Annual, Shiplovers' Society of Victoria, The Annual Dog Watch

This journal provides the reader with glimpses of the adventures and hardships of a seaman's life. Many of the stories are of sailing ships.Contributes to our knowledge of the importance of shipping and places on record those stories of the sea which would otherwise be lost.Contents Foreword - 5 Editorial - 7 'Sunbeam' and 'Sunbeam 2' - 11 Queer Convoy of the Pacific - 19 Port Phillip Mutinies of the 1850s - 24 Boiler-Room Bedlam - 26 The Nautical Chart - 30 The Challenge of the Sea - 32 Flagstaff Hill Maritime Village - 33 A Wonderful Gift - 34 The Dhow Sailors - 35 My Second Ship - 45 We Star our Voyage - 53 Peril in Ice - 58 L ' Avenir Apprentice - 61 Of Sharks and Such - 71 Submarine Duty 1918 - 75 The 'Samuel Plimosll' - 84 The 'Marco Polo's' Voyage - 85 Tarry Barry -- Keep-Water Man - 95 The Albatross - 99 At Quiet Moorings I Recall - 100 "Oh, But I'm Longing for me Ain Folk" - 104 Remedy for Stowaways - 105 The Little Ship - 106 Comments on 'My First Ship' - 109 Not a Soft Answer - 110 Just a Little Too Much of a Good Thing - 111 Early History of the 'Regina Maris' - 113 The Development of Lakes Entrance - 115 Book Reviews - 119sailing ships, steamships, shipping, seafaring life, shiplovers' society of victoria, dog watch -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Boiler, T & F Johnson, boilermakers, late 19th century

A steam boiler like this late 18th century boiler, is often called a colonial boiler. Steam boilers were used in factories throughout Australia, mounted over similar designs of brick furnaces. This heat from the fire travels through the tubes in this fire tube boiler and the water heats as it circulates around them. Another kind of boiler is a water tube boiler, in which the water is inside the tubes and the heat of the combustion surrounds the tubes. The boiler in our collection burned wood as fuel but others of this design could also burn coal, coke, gas and liquid fuels. The boiler was made by T & F Johnson, boilermakers. In 1922 their factory was located at Coventry Street, South Melbourne. They were still advertising their 'Colonial, multi, vertical boilers, all sizes' at the same address in 1934. The connected pressure gauge, made in London by Dewrance, measures 0 to 400 pounds per square inch. John Dewrance is renowned as a pioneer of the steam locomotive in the early 19th century. He founded John Dewrance & Co. in South London in 1844. His son Sir John Dewrance took over in 1879. In 1939 the company became a subsidiary of Babcock & Wilcox, and was eventually owned by Emerson. How the boiler works: - A boiler is about two-thirds filled with water and heat is applied, in this case in the form of burning wood. The heat is transferred through the metal of the boiler to the water. When the water boils the steam rises to the top, and as it escapes from the boiler the steam pressure builds up in the steam space to later be released to do work; drive machinery such as ship and train engines, turbines, presses, wheels, and driving belts to operate looms and saws. The heat associated with the boiler can be used for preserving food, sterilising, factory manufacturing processes, and steaming wood for shipbuilding. Every boiler has several components fitted for safe operation: - - Safety valves - Gauge glass - Pressure gauge - Main steam stop valve - Water check valve - Blowdown valve - Manhole doorThe boiler is a significant item that gives us a snapshot of early Melbourne's industrial history. It is an example of the technological advancement during the Industrial Revolution where steam-driven machinery and motors could perform tasks more efficiently than manual labour. The makers were one of many boilermaker businesses in Melbourne during the early late-19th andearly 20th centuries. The maritime trade and skills of boilermaking are still learned and applied today. The Dewrance steam pressure gauge connected to the boiler was made by the London firms foundered by John Dewrance. He was renowned for developing the steam locomotive in the early 19th century.Boiler; a horizontal cylindrical underfired steam boiler. It is a multi-tubular design and is timber plank-clad, with brass fittings and pressure gauges. The boiler has an iron door at one end with a metal chimney above it. It is installed over a brick-enclosed solid fuel furnace. Two large, wood-mounted pressure gauges are connected to the boiler and have inscriptions. An inscription is on a red, cast iron plaque above the boiler door. The boiler's maker is T & F Johnson, South Melbourne. One of the pressure gauges was made by Dewrance, London..Maker's plate: "T & F JOHNSON / BOILERMAKERS / SOUTH MELBOURNE" Pressure gauge: "POUNDS PRESSURE / PER [square] INCH / DEWRANCE LONDON"flagstaff hill, warrnambool, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, boiler, multi tube boiler, steam boiler, steam technology, underfired boiler, horizontal boiler, timber clad boiler, steam power, industrialisation, boilermakers, south melbourne, dewrance, john dewrance, pressure gauge, dewrance pressure gauge, t & f johnson, london, steam engine, steam locomotive, pounds per square inch, 19th century, steam machine, johnson tyne foundry, colonial boiler, fire tube boiler