Showing 75 items matching "solly"

-

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionPrint, Ti-Tree, 1984

... Maree Solly ...CEMA Art Collection. Part of "A Community View" 150 years in Portland Screenprint Exhibition. Part of Angela Gee Residency 1983 and 1984.Laminated screenprint of twig with flowers. The twig has green leaves, red buds, and red flowers with yellow centres. The work is printed on cream paper with torn edges.Front: 17/18 (lower left) MD Solly '84 (lower right) (pencil) Back: 40 -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionSlide - Slide - advertising Sol Segal, n.d

Sol Segal was a shop on Percy Street, Portland. It was advertised in the Portland Guardian in 1933.Glass slide, possibly used at Portland theatre advertising local business - Sol Segal; prestige hosiery. Image painted on one glass slide, then plain glass slide fixed over imagesol segal, womens clothing, mens clothing, portland business -

Clunes Museum

Clunes MuseumFunctional object - BATON

BATON BELONGED TO MR. ARTHUR BATSON [TOWN CLERK OF CLUNES BOROUGH COUNCIL 1874 - 1884] PRESENTED TO HIM BY MEMBERS OF HIS "TONIC SOL FA" CLASS.BATON BLACK WOODEN WITH DECORATIVE SILVER FERRULES AND INSCRIBED BAND."PRESENTED TO MR. ARTHUR BATSON BY THE MEMBERS OF HIS TONIC SOL FA CLASS. CLUNES JANUARY 1876"local history, musical instrument, accessories, batson arthur -

Warrnambool and District Historical Society Inc.

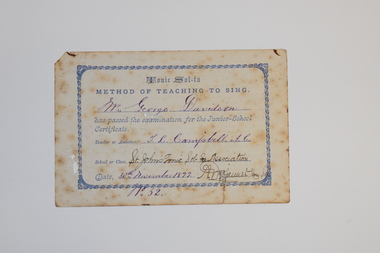

Warrnambool and District Historical Society Inc.Certificate - Singing certificate, St. John's Tonic Sol-Fa Association, 1877

This card was presented to George Davidson when he passed the Junior School examination held by St. John's Tonic Sol-Fa Association in 1877. The Tonic Sol-Fa was a technique used for teaching sight singing, invented in the 18th century and further developed, popularised and used extensively by singing teachers in the 19th century. The St. John's Tonic Sol-Fa Association was an extension of the choir of St. John's Presbyterian Church in Warrnambool and the conductor (and the teacher whose name is on this card) was T. L.Campbell. He was a well-known singing and music teacher in Warrnambool in the second half of the 19th century and specialized in the teaching of the viola, violin and violincello. George Davidson (1860-1941) was the son of John and Isobel Davidson, pioneer settlers in the Warrnambool district.This card is of some interest as a memento of the music scene in Warrnambool in the second half of the 19th century with references to T.L. Campbell, a music teacher, George Davidson, a pupil and a school of music, St. John's Tonic Sol-Fa AssociationThis is a small white card with a blue scroll border and blue printing on one side and printed information on the other side. The card has handwritten details in ink. It is stained, torn at one edge and has signs of silverfish damage.Tonic Sol-Fa Method of Teaching to Sing - Mr George Davidson has passed the examination for the Junior School Certificate. Teacher or Assistant: T.L. Campbell A.C. School or Class: St. John's Tonic Sol-Fa Association. Date: 30th November 1877 No. 52st john's warrnambool tonic sol-fa association, t.l.campbell warrnambool music teacher, george davidson warrnambool -

St Patrick's Old Collegians Association (SPOCA)

St Patrick's Old Collegians Association (SPOCA)Photograph - SPOCA, Presidents

-

National Wool Museum

National Wool MuseumMedicine bottle

Prepared by Martin Pleasance, Homeopathic Chemists, 180 Collins Street, Melbourne. Collection originally owned by Strauss family of Waverley Rainbow (on road to Lake Albaculya, 12 miles from Rainbow).MERCURIUS SOL. 6x. (label) MERCURIUS SOL. 6x. -

St Patrick's Old Collegians Association (SPOCA)

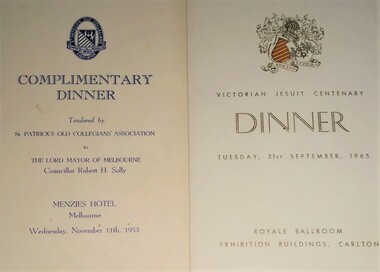

St Patrick's Old Collegians Association (SPOCA)Photograph - SPOCA, Annual Dinners

-

St Patrick's Old Collegians Association (SPOCA)

St Patrick's Old Collegians Association (SPOCA)Photograph - SPOCA, Annual Dinners

-

Clunes Museum

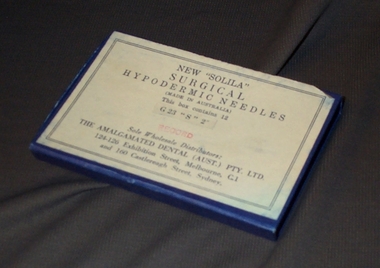

Clunes MuseumFunctional object - BOX CONTAINING 8 SURGICAL HYPODERMIC NEEDLES

BLUE CARDBOARD BOX CONTAINING HYPODERMIC NEEDLES. "NEW" "SOLILA" SURGICAL HYPODERMIC NEEDLES (MADE IN AUSTRALIA) THIS BOX CONTAINS 12 g23 "S 2" RECORD SOLE WHOLESALE DISTRIBUTERS : THE AMALGAMATED DENTAL (AUST) PTY LTD 124-126 EXHIBITION STREET, MELBOURNE C1 & 160 CASTLEREAGH STREET, SYDNEYON NEEDLES "23" & "SOL"local history, medical & surgery, medical, dental -

St Patrick's Old Collegians Association (SPOCA)

St Patrick's Old Collegians Association (SPOCA)Photograph - SPOCA, Annual Dinners

-

National Vietnam Veterans Museum (NVVM)

National Vietnam Veterans Museum (NVVM)Uniform - Uniform, Army, Belt

A yellow cotton drill gee belt.SOL PIO DO BOKbelt, clothing, mcphail collection -

National Wool Museum

National Wool MuseumMedicine bottle

Prepared by Martin Pleasance, Homeopathic Chemists, 180 Collins Street, Melbourne. Collection originally owned by Strauss family of Waverley Rainbow (on road to Lake Albaculya, 12 miles from Rainbow).MERCURIUS SOL. 6x. (label) -

St Patrick's Old Collegians Association (SPOCA)

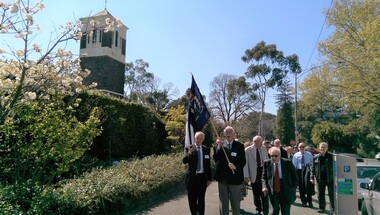

St Patrick's Old Collegians Association (SPOCA)Photograph - SPOCA, Anzac Mass & AGM 2023

-

St Patrick's Old Collegians Association (SPOCA)

St Patrick's Old Collegians Association (SPOCA)Photograph - SPOCA, Irish Jesuit 150-Years

-

St Patrick's Old Collegians Association (SPOCA)

St Patrick's Old Collegians Association (SPOCA)Photograph - SPOCA, Irish Jesuit 150-Years

-

St Patrick's Old Collegians Association (SPOCA)

St Patrick's Old Collegians Association (SPOCA)Photograph - SPOCA, Irish Jesuit 150-Years

-

St Patrick's Old Collegians Association (SPOCA)

St Patrick's Old Collegians Association (SPOCA)Photograph - History, Prizes & Documents

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, J & G Meakin, Late 19th or early 20th Century

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/This bowl was made by renowned pottery company J & G Meakin of England. The firm was established in the mid-1800's. The bowl is an example of kitchenware used in the 19th century and still in use today.Bowl; white ceramic, round and tapering inwards towards base. Made by J and G Meakin England.On base, 'Ironstone China Reg SOL 391413' with symbolflagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, mixing bowl, food preparation, j & g meakin, pottery, stoke-on-trent, kitchen equipment, ceramic -

Melbourne Tram Museum

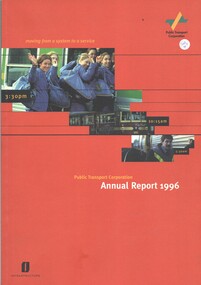

Melbourne Tram MuseumDocument - Report, Public Transport Corporation (PTC), "Public Transport Corporation - 1996 Annual Report", Oct. 1996

Book, centre stapled, 48 pages + card cover, printed on off-white paper full colour, titled "Public Transport Corporation - Annual Report 1996", providing a report to the Victorian Government on the performance of the PTC for the year 1995 - 1996. Includes a table of contents, Executive Review, attracting customers, changes and improvements, performance indicator, statutory information and Financial statements. Signed by Max Moore-Wilton as Chairman. PTC Chief Executive - Ian Dobbs. Alan Brown was the minister at the time. Has the theme "Moving from a system to a service".Has a white sticker on the front cover ""SOL T"trams, tramways, ptc, annual reports, melbourne -

St Patrick's Old Collegians Association (SPOCA)

St Patrick's Old Collegians Association (SPOCA)Photograph - SPOCA, Irish Jesuit 150-Years

-

Geoffrey Kaye Museum of Anaesthetic History

Geoffrey Kaye Museum of Anaesthetic HistoryContainer - Ampoule, Propanidid

Introduced by Bayer in 1963, Propanidid is an ultra short-acting general anaesthetic. It was withdrawn because of anaphylactic reactions.Set of three clear glass ampoules with product details printed in red ink. There is a clear liquid retained inside each of the ampoules.Printed in red ink: Eponotol / 0,5g Propanidid / in 10ml inj. sol.propanidid, anaesthetic, anaphylaxis, bayer -

Anglesea and District Historical Society

Anglesea and District Historical SocietyPlate, J & G Meakin, Eagle & Eastwood Pottery Works, 'LILAC' PLATE, 1912

Basically square with indented corners. "Lilac" trees and sprigs. Green edging.Regd. SOL - 391413 / J & G MEAKIN ENGLAND / (Unreadable bottom line)meakin, plate -

Clunes Museum

Clunes MuseumFunctional object - HYPODERMIC SYRINGE, ZENITH RECORD FIRETEX

USED IN THE CLUNES HOSPITAL.1 GLASS BARREL OF SYRINGE WITH CC MARKINGS .2 METAL PLUNGER. .3 METAL NEEDLE. .4 METAL CAPON NEEDLE : SOL, 18 ON BARREL "ZENITH" RECORD FIRETEX CC & M MARKINGlocal history, medical & surgery, medical -

Geoffrey Kaye Museum of Anaesthetic History

Geoffrey Kaye Museum of Anaesthetic HistoryTool - Needle

Blue cardboard box with lighter blue manufacturer's label and blue cardboard slide tray holding four (4) needles. The slide tray has allocation for twelve (12) needles.Stamped in red ink on manufacturer's label: RECORD Stamped into flat of needle: SOL / 24hypodermic, needle, syringe, amalgamated dental -

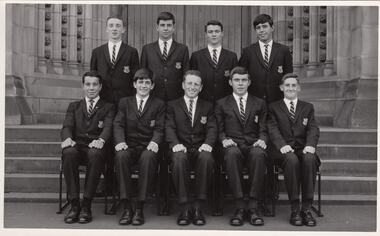

St Patrick's Old Collegians Association (SPOCA)

St Patrick's Old Collegians Association (SPOCA)Photograph - Students, 1960s

-

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncDomestic object - Ironstone China Wash bowl and jug

Ironstone china pieces were common domestic items during the 19th to mid 20th century in many Australian households. This kind of china is not porcelain but porous earthenware, made of clay mixed with feldspar. Patented in 1813 by Charles James Mason in Staffordshire, England, it was an immediate success and became widely produced by a range of Staffordshire potters. J & G Meakin Pottery dates back to 1845 when James Meakin started a pottery business at Lane End in Staffordshire.nIn 1848 he moved the business to Hanley in Staffordshire, before retiring in 1852 and handing the business over to his two sons James and George, who carried on with the pottery, trading as J & G Meakin. The "SOL" and sun face trademarks were registered in 1912. The firm was taken over by the Wedgwood Group in 1970. In 2000, production under the Meakin name ceased. W. H. Grindley was founded at the Newfield Pottery in 1880 by William Harry Grindley (principal partner). Mr Turner and Mr Alfred Meakin were also involved. Early advertisements stated that they produced Earthenware and Ironstone China - particularly for the Canadian, United States, South American and Australian markets. The mark on this jug was used from c1891 until 1925. W. H. Grindley China was manufactured until 1991, making it one of the last Stoke on Trent potteries.These items are representative of a common domestic item used by households in the Wodonga district and throughout Australia, many manufactured specifically for the Australian market.A white ironstone jug and bowl. The jug features a leaf design embossed on the surface. The bowl has a small circle pattern around the rim. They are not as set as the jug bears the mark W. H. Grindley and the bowl was made by J & G Meakin.Underneath Bowl: above and below image of the sun: "IRONSTONE CHINA/ REGD. SOL 391413/ J & G MEAKIN/ENGLAND Underneath jug: above and below the royal insignia: ROYAL IRONSTONE CHINA / W.H. GRINDLEY & CO. / ENGLAND"ironstone, domestic items, staffordshire pottery -

Kew Historical Society Inc

Kew Historical Society IncLeisure object - Hand-Held Puzzle, Sol's, Sol's 4 Ball Puzzle, Twentieth Century

Due to the generosity of a number of donors, the Kew Historical Society has a wide range of games and puzzles in its collection; typically designed for children's use. A number of the puzzles are European-made, generally of British origin, however there are a number that were made for the Australian market by Australian manufacturers. Metal and glass puzzle requiring the player to get a four metal balls into 4 channels."Sol's 4 Ball Puzzle / It can be done / Place four balls in containers / You have 2 seconds to do it."games, puzzles, toys -

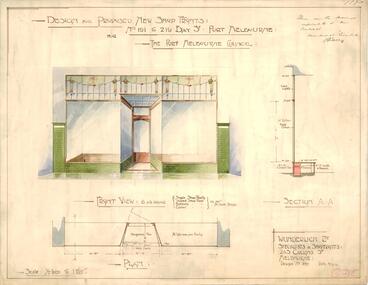

Port Melbourne Historical & Preservation Society

Port Melbourne Historical & Preservation SocietyPlan - Proposed renovation to shop fronts, Bay Street, Port Melbourne, Wunderlich Ltd, 14 Feb 1916

Plan of design for proposed renovation of shop fronts for nos. 191-219 Bay Street (market buildings) for Port Melbourne Council. Plus master copy for photocopies.Drawing endorsed by R.N. Solly representative of Wunderlich Ltd in top right hand corner: No. 695 in bottom right hand cornerbuilt environment - commercial, market reserve, wunderlich ltd, bay street -

Port Melbourne Historical & Preservation Society

Port Melbourne Historical & Preservation SocietyPlan - Alternative proposed renovation to shop fronts, Bay Street, Port Melbourne, Wunderlich Ltd, c. 1916

Alternative design for market shop front for no. 219 Bay Street for Port Melbourne Council c1916Drawing endorsed by R.N. Solly representative of Wunderlich Ltd in top right hand corner:No. 695 in bottom left hand cornerbuilt environment - commercial, market reserve, wunderlich ltd, bay street -

St Patrick's Old Collegians Association (SPOCA)

St Patrick's Old Collegians Association (SPOCA)Photograph - SPOCA, Communion Breakfast, 2018