Showing 24 items matching "specialist tool"

-

Clunes Museum

Clunes MuseumFunctional object - TOBACCO CUTTER

... SPECIALIST TOOL...Clunes Museum 36 Fraser Street Clunes goldfields SPECIALIST ...Wooden Base, Metal Blade, Wooden Handle. specialist tool, commercial tool -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, George Coop, Steam locomotive J-502 hauling a specialist plant track repair and goods recovery train departing Echuca, Aug. 1963

... containing all the specialist tools for re-railing the train... containing all the specialist tools for re-railing the train ...A special plant track repair and goods recovery train proceeding to a cattle train derailment on the Balranald (NSW) line from which sheep had also escaped. The train composition was made up of J-Class steam locomtive J-502, a water gin carrying extra water for the train given doubtful supplies en-route, a wagon to reload the surviving sheep, a wagon containing track tools and equipment, a carriage for the work crew, a bogie wagon containing all the specialist tools for re-railing the train, followed lastly by the Guard's van. The specialist wagons and their equipment were based at the Bendigo Depot (see painted markings on van side) in a state of readiness for immediate use as the need arose The train is viewed approaching the Iron Bridge grade out of the Echuca rail yard. The Gatekeepers hut is visible on the right. The gatekeeper would be notified of the approaching train at which time he would open the gate to allow the train to pass through the Packenham Street level crossing.Digital TIFF file Scan of black and white print Enlargement prints on textured paper (15.5 x 20.5 cm)george coop collection, echuca, j-502, j-class steam locomotive (vulcan foundry) -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, George Coop, Steam locomotive J-502 hauling a specialist plant track repair and goods recovery train departing Echuca, Aug. 1963

... containing all the specialist tools for re-railing the train... containing all the specialist tools for re-railing the train ...A special plant track repair and goods recovery train proceeding to a cattle train derailment on the Balranald (NSW) line from which sheep had also escaped. The train composition was made up of J-Class steam locomtive J-502, a water gin carrying extra water for the train given doubtful supplies en-route, a wagon to reload the surviving sheep, a wagon containing track tools and equipment, a carriage for the work crew, a bogie wagon containing all the specialist tools for re-railing the train, followed lastly by the Guard's van. The specialist wagons and their equipment were based at the Bendigo Depot (see painted markings on van side) in a state of readiness for immediate use as the need arose The train is viewed approaching the Iron Bridge grade out of the Echuca rail yard. The Gatekeepers hut is visible on the right. The gatekeeper would be notified of the approaching train at which time he would open the gate to allow the train to pass through the Packenham Street level crossing.Digital TIFF file Scan of black and white print Enlargement prints on textured paper (15.5 x 20.5 cm)george coop collection, echuca, j-502, j-class steam locomotive (vulcan foundry) -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Tools, Saws, Early 20th century

... of the world’s premier manufacturers of specialist woodworking tools. ... of the world’s premier manufacturers of specialist woodworking tools ...These handsaws belonged to a Warrnambool furniture maker and dealer, Ernest Brighton Phillips (1875-1924). He learned cabinet making at the Warrnambool Box Works and established a furniture warehouse at the corner of Liebig and Koroit Streets in the late 1890s. By the early 20th century he had the largest furniture warehouse and factory in Victoria outside Melbourne and his furniture was sold all over Australia. He and his family lived at ‘Heatherlie’ in Koroit Street and today the site of this family home houses the retirement village complex known as ‘Heatherlie’. The makers of these saws was Robert Sorby of the Kangaroo Works in Sheffield, England. This business was established in 1928 and is one of the world’s premier manufacturers of specialist woodworking tools. These two tools are of some significance as they belonged to Ernest Phillips, a prominent businessman in Warrnambool at the end of the 19th and the beginning of the 20th centuries. These are also a good example of the type of tools used in the woodworking trade 100 years ago. These are two handsaws which belonged to Ernest Phillips. They have wooden handles attached to the blade by metal screws. One screw is missing on the larger saw. The blades are made of steel with serrated edges and they are inserted into a fold of steel along the top edge. The handles are well-worn and the blades are a little rusty. ‘Robt. Sorby Sheffield Cast Steel’ ‘E. Phillips’ ernest phillips, robert sorby, history of warrnambool -

Orbost & District Historical Society

Orbost & District Historical Societymortising axe, late 19th - early 20th century

A mortise axe is a specialist axe designed for hewing sills and notches in joints. The axe has a long, narrow head, making it easier to work on large logs. The shape enables the user to hew a long way down into the notch, where otherwise a chisel would be used. This tool has one blade, which may be pushed, swung or struck with a mallet. Others, have two, one of which is used for separating the fibres, and the other for levering out the waste.This is an example of a common woodworking tool used by the early settlers in the Orbost district.A long wooden handled axe used to cut mortises in posts for post and rail fences. The blade is made of iron and is quite long.axe mortise-axe fencing timber farm-tool -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Leg Vice, Mid 19th Century

The blacksmith leg vise is also called the "solid box vise" and is one of the most important tools in the blacksmith's shop. It firmly holds hot iron while it is hammered, chiseled, or twisted. These are the only vises that are designed to take this kind of use day in and day out. A small 30-pound blacksmith's vise can survive pounding that would wreck a much heavier cast iron bench model. Three things make a blacksmith's vice special. One is that they are forgings, not cast iron or ductile iron. The second is the leg that provides support to the floor or from a sunken post. The last is the hinge, while not a perfect way to construct a vice the pin joint is durable and can take a considerable beating. If sheared it is easy to replace. These things all combine into a tool that can take decades of heavy use and abuse. Most in use is one to two hundred years old.Some of these vises were made by specialists such as Atwood of Stourbridge England, Steel City and Columbian in the U.S. and others were made in anvil manufacturing plants such as "Mousehole Forge" and "Peter Wright" in England and "Fisher-Norris" and others in North America. The design of these vises right down to the last chamfer seems to have been perfected in the 1600s and remained more or less the same until the 20th century. The bodies are forged wrought iron or mild steel and they have hard steel surfaces welded into the jaws. The jaws have little or very shallow serrations which are generally worn off.Around the turn of the 20th Century during the hey-day of the blacksmith shop in North America, these tools were considered so standard a commodity that they were sold without reference to the manufacturer. Very few were even marked with the maker's name. Size is best defined by weight as there is some variation in jaw size from manufacturer to manufacturer. They were sold by the pound and are still best judged by the pound.A vintage tool used in a Blacksmiths shop during the early 19th century to the beginning of the 20th century. Regarded as a significant into social history of the time.Leg Vice attached with screws to bench via a block of wood. Has large metal pole which practically reaches the floor. Also has a metal device to either tighten or slacken vice.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Ararat & District Historical Society (operating the Langi Morgala Museum)

Ararat & District Historical Society (operating the Langi Morgala Museum)Tool - Nurses Lamp

The lamp helps contextualise the nursing history of our region. This item was owned by Sister Hebe Graham, who was born in 1890 and trained at Stawell Hospital before WW1. She became a specialist nurse and received a commendation from Lord Duggan, Governor of Victoria.Flat, rectangular lamp with light fixed at top centre and activated by small spring-loaded button on top of lamp. Case is primarily stainless steel and partially covered in a leather case."T E C BRITISH MADE" stamped on top of lamp.sister hebe graham, nurses lamp, stawell hospital, ww1, 1890, lord duggan -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Razor Strop, circa 1922

A razor strop such as this one was used to sharpen and polish straight-edged razors. This particular design has a swivel hook with a locking clip that allows for movement as the strop is being used. This strop is branded "Sherlite". On May 5th, 1922 the Commonwealth officially accepted and advertised the Trade Mark Application of Thomas Sherry of Victoria, for the Trade Mark of "Sherlite" to be used under the heading of "Leather, Skins unwrought and Wrought”. Thomas Sherry’s application was to use the word “Sherlite” for detachable soles made of rubberised leather. Straight razors and cut-throat razors were the major tools for shaving before the safety razor was invented in the 1880s and even today specialist shaving shops still sell straight razors. Along with the razor, the process of shaving would commonly involve lathering up shaving soap with a shaving brush that had boar bristles. Men could own several razors and rotate them through the week and some shops sold the razors in a set, a razor for each day of the week. Straight razors could require stropping more than once during the shaving of a heavy beard, and stropping would also be performed at the end of each shave. Honing would only be performed two or three times a year, preserving the blade's edge. A lot of skill was needed to hone and strop the blades of these early razors and the methods to do so were a large part of the curriculum in Barber colleges. The razor would be sharpened on a grinding wheel then honed on sharpening stone and finally finished using a strop. Straight edge razors would usually be sold unfinished and that process would be completed by the customer. A razor strop, usually made from leather, thick canvas, or light timber, would be used to straighten and polish the straight razor for shaving. Strops could also be used to polish other blades such as knives, small metal tools, and chisels. Sometimes an abrasive polishing compound is also used to give a mirror finish. Some strops, such as this one in our Collection, are designed to be used while hanging from a nail or peg, while others are handheld. The person using the strop would draw the spine of the blade down along the strop with the blade following, without putting any pressure on the blade. At the end of the stroke, rotate the blade over its spine then draw the spine along the strop again so that the edge moves away from the top. The finer grade of leather strap is used to give the final finish.Razor strop, leather, and metal. Sherlite brand, double straps: two straps of different grade leather joined at ends with metal fittings. Stropping faces; sharpening surface is stained red and finishing surface is stained black. One end has a padded, bulbous-shaped leather grip handle, the other end has a metal, swivel hook hanger. Inscriptions painted in gold on leather at the hook end.Razor strop, leather and metal. Sherlite brand, double straps: two straps of different grade leather joined at ends with metal fittings. Stropping faces; sharpening surface is stained red and finishing surface is stained black. One end has padded, bulbous shaped leather grip handle, the other end has metal, swivel hook hanger. Inscriptions printed in gold on leather at hook end.Printed gold lettering stamped “Sherlite”flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, shaving leather, shaving accessory, barber’s equipment, barber shop razor strop, razor strop, straight razor, razor and knife sharpener, sherlite razor strop, personal effects, toiletries, thomas sherry -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Spirit Level, 1937-1955

Initially Elvicta was known as Elliot Lucas (hand tools)Ltd, and was established around 1937 based at 38 Summer Row, Birmingham. Around 1950 the firm relocated to Cannock, Staffordshire and by 1965 had moved again to their Church bridge Works also at Cannock. The Elliot Lucas Ltd Elvicta Cabinet and Tool factory as it was known employed over a hundred people and operated from the company's satellite works in Crickhowell southeastern Powys, Wales, near Abergavenny, in the county of Brecknockshire during the 1950s. The company manufactured a range of specialist pliers, nippers and pincers including the brands Elvicta, Electoy and Elect.A tool that is now regarded today as vintage, is collectable and highlights a time when tools were made by hand and how wood was predominately used to manufacture such items. It gives a snapshot of the time before the use of plastics and other synthetic materials which are now used to produce every day objects and tools such as this spirit level.Elvicta brand wooden spirit level made by Elliott-Lucas Ltd England. Level has two levels one vertical one horizontal . Has 2 brass corner protectors Has 530 marked on plate denotes model No and an original label 610 mm long x 60 mm x 30 mmflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

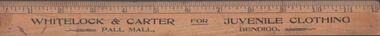

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Tool - BENDIGO BUSINESSES COLLECTION: WHITELOCK & CARTER

... . The lane no rent showroom - Specialists in children's wear. Tool ...Wooden ruler 12 inches. Whitelock & Carter for Juvenile clothing, Pall Mall, Bendigo. The lane no rent showroom - Specialists in children's wear.bendigo, business, whitelock & carter -

Forests Commission Retired Personnel Association (FCRPA)

Forests Commission Retired Personnel Association (FCRPA)Mortising Tool, Axe

... A mortising tool is a specialist axe designed for hewing... Ford Street Beechworth, Victoria high-country A mortising tool ...A mortising tool is a specialist axe designed for hewing sills and cutting notches in timber. It has a long, narrow head, making it easier to work on large logs. The shape enables the user to cut a long way down into the notch, where otherwise a chisel would be used. Example of a common bush woodworking tool used before the advent of chainsaws and power equipmentMortising Tooltimber tools -

Forests Commission Retired Personnel Association (FCRPA)

Forests Commission Retired Personnel Association (FCRPA)Mortising Tool, Axe

... A mortising tool is a specialist axe designed for hewing... Ford Street Beechworth, Victoria high-country A mortising tool ...A mortising tool is a specialist axe designed for hewing sills and cutting notches in timber. It has a long, narrow head, making it easier to work on large logs. The shape enables the user to cut a long way down into the notch, where otherwise a chisel would be used.Example of a common bush woodworking tool used before the advent of chainsaws and power equipmentMortising Tool, AxePrades Co Solid Steeltimber tools -

Australian Army Museum of Western Australia

Australian Army Museum of Western AustraliaDiorama, 2015

This diorama is the introductory feature in the World War 1 Gallery - 1918 experience. The figure shows details of the Lewis gun and webbing including the documented but irregular positioning of the entrenching tool.The diorama text discusses the transition from manpower to firepower with the restructure of infantry battalions to incorporate more light machine guns and to give the platoon an all round versus specialist capability. The increase in firepower and the reduction to three from four battalions in an infantry regiment in part offset the decline in voluntary recruitment. The offensive capabilities of an infantry battalion was therefore generally maintained but with 700 men instead of 1100 when fully manned .1:1 scale diorama showing a Lewis gunner of 44th Battalion, 11th Brigade, 3rd Division, Australian Imperial Force in May 1918amiens, last 100 days, lewis gun, spring offensive -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern was possibly made for casting a part for Craftman Marine, makers of engines for boats and other machines. It is part of a set that is stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; rectangular wooden block with a corner cut diagonally. A five-sided shape has been carved into the centre, with one side curved inwards and slightly shallower than the other sides. The cut-out area is painted black. Three holes are drilled in the cut-out side to align the pattern with another piece of work. A wooden slat is fixed across the diagonal side. The back of the pattern has a handwritten inscription, possibly by two writers. The pattern is part of a set of foundry patterns from Briggs Brass Foundry and is connected to Craftman Marine.In black handwriting: "1 # H AL" Handwritten in a different hand: "CRAFTMAN MARINE" Written the the first hand: BRIGGS" (or "BRICK")flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912, craftman marine, craftsman marine -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. It may fit together with one of the other patterns with a similar outline. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century.Pattern; thick square mostly unopainted wooden block with a solid half-cylinder added to the top, which has rounded shoulders. A disc is added to the front, aligned with the curve at the top. The top curve has orange paint and the dial is pink. Three holes are drilled in the back, in a triangular configuration. It is similar in shape to a mantle clock or an early-style radio. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that is stored in a strong wooden crate and may be part of another similar pattern. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; unpainted, square wooden block with a semi-circle of dowel added to the centre of the side with rounded corners. Three short dowel pegs are inserted on one flat side; one below the semi-circle and one near the lower corners in an overall triangle configuration. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; rectangular wooden block made from laminated sections of wood painted black. A half-cylinder shape was carved into the long side, and a dowel shape was placed at the lower side. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; pair of U-shaped carved blocks, unpainted. The blocks have opposing metal pins and holes to hold them together. One block has a disc shape carved into the base. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century.Pattern; hexagonal wooden shape painted orange. The thick carved wooden shape is in halves forming a hole when locked together with the dowel pegs and opposing drilled holes. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; round wooden shape with a wide concave centre and a round flat handle in the middle, painted dark brown. The underside has a large wooden disc added to the centre. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; an unpainted, rectangular wooden frame with a top and sides, similar to a small rectangular stool. A solid half-cylinder shape was added under the horizontal 'seat' with another smaller half-cylinder attached to it, end-to-end. A string is tied between two metal loops attached to the back. There are two X marks stamped into the back. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.Stamped: "X" "X"flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden patterns are part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. It may fit together with one of the other patterns with a similar outline. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; a pair of blocks that form a rectangle with a carved centre hole and disc shape inside. The block is made from laminated pieces of wood with cut corners. Both sides have four drilled holes in a square configuration but in different positions. The cut faces and the space carved into them are painted red; one piece has two dowel pins that fit into two drilled holes on the other. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

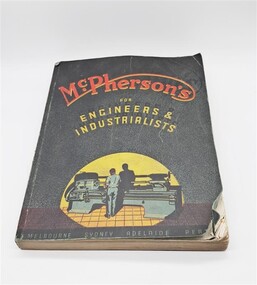

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionBook - Tool Catalogue, McPherson's Limited, McPherson's FOR ENGINEERS & INDUSTRIALISTS, 1949

... , tool specialists, suppliers of engineers' requisites ...This book is a catalogue issued for machinery merchants, tool specialists, suppliers of engineers' requisites, manufacturers of pumps, bolts, nuts, rivets, makers of high grade machine tools.Book is covered by green card and printed on the front with the title and a cartoon sketch/picture of a man standing facing away from viewer at a large industrial piece of machinery. Appears to be working. Picture includes an orange tiled floor and yellow wall. The book has 448 pages. Front cover: McPherson's FOR ENGINEERS & INDUSTRIALISTS MELBOURNE SYDNEY ADELAIDE PERTH Back Cover- McPherson's Ltd. 546-566 COLLINS STREET MELBOURNE * Telephone: MY270 * Telegraphic Address: "MERCHANT" MELBOURNEnon-fictionThis book is a catalogue issued for machinery merchants, tool specialists, suppliers of engineers' requisites, manufacturers of pumps, bolts, nuts, rivets, makers of high grade machine tools. -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood Moulding Plane, George Hathersich, 1797-1851

George Hathersich made wood moulding planes at 30 Shade Hill Street, Manchester, England, from 1797 to 1851. After his death, his wife, Elizabeth, carried on making planes. Moulding planes are used to create decorative edges on timber for doors, tables, cabinets and elaborate cabinetry.The maker, Hathersich, was a very early plane maker from Manchester, England. Hathersich's early 19th-century hand-operated planes are rare examples of crafted woodworking tools. Similar tools are still made today and used by specialists in cabinet and woodcraft trades.Plane; hand-operated mounding plane, round type. A narrow rectangular plane with a wooden wedge and an iron blade inserted in the bed. The wooden surface is stained and varnished. It has inscriptions. Made by George Hathersich of Manchester, UK. Also marked C S Schofield. "Hathersich" "C S Schofield"flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, wood work, builder, carpenter, wood worker, woodworking, plane, moulding plane, tool, woodworking tool, george hathersich, shudehill, manchester, england, c s schofield