Showing 302 items matching "spout"

-

Puffing Billy Railway

Puffing Billy Railwaybucket, with spout

Hand made metal bucket with spout leade soldered Bucket marked “ 10 - Not for Mineraleol” Metal bucket with spout 10 - Not for Mineraleolpuffing billy, metal bucket with funnel, tinsmith -

Greensborough Historical Society

Greensborough Historical SocietyTile and teapot spout, Tile fragment, and teapot spout, 1940s

The house at 113 Mountain View Road Briar Hill, formerly the home of Bob Barling, scoutmaster in the 1950s, was totally destroyed by fire. These items were salvaged from the site.Two items salvaged from house fire: Tile fragment & teapot spouttile, teapot -

Hume City Civic Collection

Hume City Civic CollectionMetal Jug

Thought to be used for measuring liquids in retail premises by Council Inspectors, Weights and Measures. Used by Shire of Bulla and donated by Hume City Council when amalgmation took place.Tapered metal container with spout and handle used for measuring liquids.on spout "crown/16/91..."shire of bulla, george evans collection -

Hume City Civic Collection

Hume City Civic CollectionMetal Jug

Thought to be used for measuring liquids in retail premises by Council Inspectors of Weights & Measures Department of Shire of Bulla and donated by Hume Council when amalagmation of Councils took place.Tapered metal container with pouring spout and handle used for measuring liquids.on side "1 GALLON" on spout "crown/15 91/VIC"shire of bulla, george evans collection -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyWatering Can

Possibly home made for a specific purpose requiring a long narrow spout. Used by a resident of the Kiewa ValleyOld pale green watering can with a very long spout narrowing to its end. Barrel has spout and handle attached. The opening at the top is an oblong. There is no lid.watering can, oil can -

![Functional object - spouted enamel feeding mug with handle, Kockums Jernverk enamel ware, [ca.1950]](/media/collectors/50187a8f023fd7201471f198/items/67c8ef0b232690f7307c6bc9/item-media/67c8f0d5b5418ee60347c3da/item-fit-380x285.jpg) Alfred Hospital Nurses League - Nursing History Collection

Alfred Hospital Nurses League - Nursing History CollectionFunctional object - spouted enamel feeding mug with handle, Kockums Jernverk enamel ware, [ca.1950]

Used by nursing staff to assist with feeding patientsUsed by nursing staff to assist with feeding patients white enamel spouted feeding mug with blue handlesticker label to upper surface near spout - GENUINE SWEDISH WHITE/ENAMELLED WARE/COMPANY LOGO/GUARANTEED PURE/AND OF HIGHEST QUALITYpatient care, alfred hospital nurses league, alfred hospital school of nursing, linay pavillion, nutrition -

Alfred Hospital Nurses League - Nursing History Collection

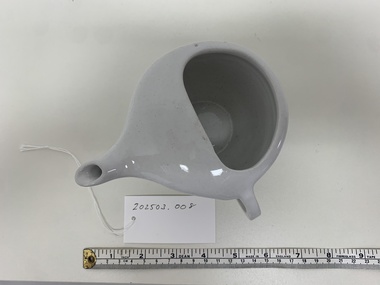

Alfred Hospital Nurses League - Nursing History CollectionFunctional object - Patient feeding cup, Fowler LTD

spouted ceramic feeding cup to assist patient nutritionused by nurses in caring for patients white china spouted feeding cup, Fowler LTD Australia stamp on baseFOWLER LTD/AUSTRALIAnursing, nutrition -

Gippsland Vehicle Collection

Gippsland Vehicle CollectionMaker's Name: Various oil companies (Golden Fleece, Shell, Castrol etc) Maker's Role: Oil & petroleum products et al, c.1950

Common in all service stations for engine oil top-up at pump service area by service station attendant.Before 'self serve' pump operations service station attendants 'serviced' the vehicle on the forecourt whilst filling with petrol, checking oil levels, water etc.Glass wide mouthed bottle with plastic conical spout and capBottle - "FILL TO LINE INDICATED BY ARROW' & "500ml B.T. N.S.W." Spout - Golden Fleece logo with "GOLDEN FLEECE Supreme Motor Oil"oil, oil bottle, golden fleece, motor oil, engine oil -

Puffing Billy Railway

Puffing Billy RailwayWatering Can with a large spout

Watering Can A watering can, with a large spout. Its former use is currently no known, but may have been used for oil, chemicals or even sand.Historic - Railway Permanent Way and Works - track equipment - Watering CanWatering Can with a large spout made of tin puffing billy, watering can -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Functional object - Soda Syphon, Early 20th century

This soda syphon used for making carbonated drinks is a French bottle made about the beginning of the 20th century. This bottle is of considerable antiquarian interest but unfortunately has no known local significance. It may, however, be the one given to the Historical Society by Mr and Mrs S. Lindsay of Koroit Street, Warrnambool. It will be useful for display. This is a French soda syphon made of clear glass in a double bulbous shape. It is covered with wire mesh and has a pewter spout. The pewter is somewhat corroded and there is one small bend in the wire mesh. There is a small glass tube inside the bottle and a there is a crack in the glass on the top sphere. On pewter spout: ‘Veritable Seltzogene D. Fevre Paris’. Label pasted on: ‘80’ soda syphon, veritable seltzogene de fevre,, paris, warrnambool -

Federation University Historical Collection

Federation University Historical CollectionPhotograph - Photograph - Black and White, A black and white photograph of Frank Wright

Frank Wright was a renown resident of Smeaton, where he was born. He lived at Laura Villa, and attended Smeaton State School. His father William was a gold miner and his mother's name was Sarah. Their family won many singing and instrumental awards. Frank was tutored by Percy Code and was awarded a gold medal for the highest marks in the ALCM examinations in the British Colonies at the age of seventeen years. He became the Australian Open Cornet Champion by the age of eighteen. A year later, Frank conducted the City of Ballarat Band, and later the Ballarat Soldiers’ Memorial Band. He formed the Frank Wright Frisco Band and Frank Wright and his Coliseum Orchestra. These bands won many South Street awards, and Frank as conductor won many awards in the Australian Band Championship contest. In 1933 Frank Wright sailed to England to conduct the famous St Hilda’s Band and was later appointed Musical Director of the London County Council, where he organized many amazing concerts in parks, in and around the London district. He was made Professor of Brass and Military Band Scoring and conducted at the Guildhall of Music and Drama. Frank was often invited to adjudicate Brass Band Championships around Europe, in Australia, including South Street and in New Zealand. The Frank Wright Medal at the Royal South Street competition is awarded to an individual recognized as making an outstanding contribution to brass music in Australia.A black and white photograph of a man leaning on a light pole while standing on a timber deck over water.There is a timber building behind him, on the building is a sign "Spout Bath". The man is Frank Wright.frank wright, spout, bath -

Alfred Hospital Nurses League - Nursing History Collection

Alfred Hospital Nurses League - Nursing History CollectionFunctional object - Patient feeding cup, Globe Pottery, Victorian Hospitals Association Feeding Cup, 1920's -!930's

Cup used to assist with patient nutritionUsed in patient careSpouted white ceramic feeding cup with handle on side. Crest of the Victorian Hospitals Association [words in a circular banner around a cross pattee] is stamped in blue above the spout.On base, stamped in blue, "STEELITE" VITRIFIED GLOBE POTTERY CO LTD ENGLAND SUPPLIED BY J. DYNON & SON MELBOURNEPrevious catalogue number written on small white sticker on base. Underneath the spout is a white sticker stamped "ALRED NURSES ARCHIVESnursing, nutrition -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Medical Equipment, porcelain invalid feeding cup, 19thC

These unusual china cups with elongated spouts were created in the days before drinking straws were common. Liquids and broth were fed through the spout to adults who were sick and could not take solid food, or to infants. The alternate name for these cups is “pap feeder.” Recipes for pap usually called for bread, flour and water. A more nourishing mixture “panada” was a pap base with added butter and milk, or cooked in broth as a milk substitute. Variations on the ingredients included Lisbon sugar, beer, wine, raw meat juices. These cups were apparently offered as accessory pieces to many regular china patterns.A white porcelain invalid or baby feeding cup decorated with a blue floral ( onion ) pattern. The cup has a spout , strainer, side handle and ‘spill-proof’ guard c19thCBase : m 8.pharmacy, medicine, melbourne, early settlers, market gardeners, moorabbin, bentleigh, cheltenham, nursing, invalid feeding, invalid cookery, porcelain -

Alfred Hospital Nurses League - Nursing History Collection

Alfred Hospital Nurses League - Nursing History CollectionEquipment - Copper Steam Kettle, extension and spout, not known

A steam kettle together with a steam tent was used to create a moist atmosphere. A steam tent was set up enclosing the whole bed by means of sheets/curtains and sometimes canvas, the kettle was heated over a gas or spirit stove, usually on the floor next to the bed, with the spout inserted inside the tent.Of significance to the AHNL as it is a tangible representation of nursing history. Steam inhalations were used to relieve patients with respiratory disorders and some drug therapy could be administered by this route. It was an effective method of treatment, observing the patient closely was difficult as they were completely hidden by the steam tent - many nurses got to share the steam therapy.Copper steam kettle with removable elongated straight extension spout and fan shaped nozzle on the end. There is a small opening for filling the kettle which holds 4 litres. Screw plug attached with chainnonesteam kettle, inhalation -

Friends of Westgarthtown

Friends of WestgarthtownSoda syphon

Glass bottle with protective wire winding in mesh pattern. Red line around top half of bottle. Metal attachment on top for gas cylinder and lever and spout.Sparkletes' embossed on gas cylinder holder. 'Sparkletes Ltd, Makers London' stamped on spout area. Printed around rim ' Made in England', 'C size; 'shake siphon well while piercing bulb'; 'never fill syphon above red line'. Printed on base of bottle 'Made in Czechoslovakia'.domestic items, food preparation, soda syphon, sparkletes, england, drink. -

Clunes Museum

Clunes MuseumEquipment - RETORT FLASK

FROM THE OLD CLUNES HOSPITALROUND GLASS CONTAINER WITH A SHORT SPOUT OUT ONE SIDE. JUST IN BACK OF THE SHORT SPOUT IS A LONG TUBE-LIKE SPOUT WITH SMALL OPENINGlocal history, medicine, medical equipment, medical -

Anglesea and District Historical Society

Anglesea and District Historical SocietyCan - Household Kerosine, Shell Company of Australia, Probably 1948 to 1955 (when logo changed)

Kerosine can with pourer painted red with yellow lettering and black band around bottom of can. Shell logo and yellow Pennant flag on pole. Includes pouring spout.Front: FILL THIS CONTAINER WITH PENNANT KEROSINE ONLY / PENNANT - HOUSEHOLD KEROSINE FOR LIGHTING, HEATING, COOKING , REFRIGERATORS AND ALL HOUSHOLD PURPOSES / 1 IMPERIAL QUART - THE SHELL COMPANY OF AUSTRALIA LIMITED / INCORPORATED IN GREAT BRITAIN. Back: PENNANT HOUSHOLD KEROSINE / QUALITY SHELL PRODUCT (in Shell logo). Red tin with yellow flag (black writing). Yellow writing and black band around bottom of tin. Includes cap with spout.household kerosine, pennant, the shell company of australia -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Jug

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/The form of the jug has been in use for many centuries.Stoneware jug. Two tone brown glaze with pierced lip behind spout. Spout chipped.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, jug, ceramic jug -

South West Healthcare

South West HealthcareInstrument - Inhaler, 1860-2000

Invented by Dr. Nelson in the mid 1860's, for the treatment of chest infections and inhalation issues.Ceramic inhaler with spout."Dr. NELSON'S / IMPROVED / INHALER"inhaler, inhalation, dr nelson, chest infection -

South West Healthcare

South West HealthcareDr. Nelson's Inhaler, Dr.Nelson, Medical Equipment, 20th Century

Ceramic inhaler with spout"DR.NELSON'S/ IMPROVED /INHALER" -

Ballarat Base Hospital Trained Nurses League

Ballarat Base Hospital Trained Nurses LeagueInhalation Jug

Inhalation JugCeramic jug with spoutinhalation, jug, ballarat -

Whitehorse Historical Society Inc.

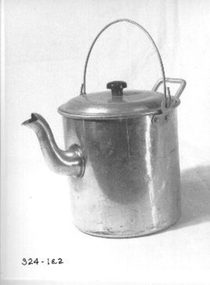

Whitehorse Historical Society Inc.Equipment - Camping Billy

Shiny aluminium body, lid, spout wire handle,firm handle opposite spout and red bakelite knob on lid. Rivets join handles to body. spout soldered to body.Black circle encircling a white G with a diagonal 'LODA'containers, domestic -

Federation University Historical Collection

Federation University Historical CollectionPhotograph, Clare Gervasoni, Spouting at the Ballarat School of Mines, 08/09/2016

Spouting at the Ballarat School of Mines. J & T Muir Founders Melbourneballarat school of mines, spouting, muir foundry, architecture, plumbing -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Domestic object - Kettle- copper, Copper kettle, Unknown

From Miriam Armstrong's great uncle born 1903 - 2003Copper kettle with lid and spout.kettle, copper -

Parks Victoria - Days Mill and Farm

Parks Victoria - Days Mill and FarmFunctional object - Funnels

Used for pouring liquids and other substances.Funnels x 7, handmade. 6 conical shaped, 2 of these have angled spouts, vertical spouts on other 4. 1 x squarish shaped funnel, spout, vertical. 6 funnels have a ring for hanging purposes. Some have mesh where the spout joins body of funnel.[square funnel]: shell motif/ "BIO.." -

Royal Australian and New Zealand College of Obstetricians & Gynaecologists (RANZCOG)

Royal Australian and New Zealand College of Obstetricians & Gynaecologists (RANZCOG)Ceramic feeding cup associated with midwife Mary Howlett, c.1866-1920

This type of cup was designed for use by an adult and was in common usage from the early 1900s to the 1930s. Feeding cups were used both in the home and in hospitals, and were also often made of white enamel. Mary Howlett (1840-1922) began practising as a country midwife in 1866 in the western district of Victoria. She qualified as a 'ladies monthly nurse' in 1887 and continued to practise as a nurse and midwife until 1920. She began her six months training at the Melbourne Lying-In Hospital. She was known by many as 'Auntie', and her career spanned more than 50 years. Mrs Howlett's midwifery box and contents were given to Dr Frank Forster, and he donated them the museum collection in 1993. Feeding cup made out of white china, now discoloured. The cup has a curved spout (similar to a teapot spout) with a handle. There are four small holes inserted inside the cup diagonally at the proximate end of the spout. midwifery -

Clunes Museum

Clunes MuseumInstrument - GLASS FLASK, UNKNOWN

SMALL GLASS FLASK WITH POURING SPOUTlocal history, medicine, medical appliance, clunes hospital -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Domestic object - Copper kettle, Unknown

Copper kettle with wooden handle and spout.copper, kettle -

Ballarat RSL Sub-Branch Inc.

Ballarat RSL Sub-Branch Inc.Teapot - Leather Cased

Red Maltese Cross above spoutcollectables, ballarat rsl, ballarat -

University of Melbourne, School of Chemistry

University of Melbourne, School of ChemistryGlass Bowl & Wooden Base

Glass bowl with spout on wooden support