Showing 24 items matching "stoneware jugs"

-

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Pottery, brown pottery x 5, Mid 19th and early 20th centuries

... stoneware jugs... These stoneware jugs and bowl had been perennially popular... These stoneware jugs and bowl had been perennially popular in homes ...These stoneware jugs and bowl had been perennially popular in homes for many years and are still in homes today.These jugs are kept as mementos of household items popular in the past. One jug (VC001906.3) appears to have come from Scotland in the mid 19th century and may have belonged to a member of a McGregor family.These are four brown earthenware jugs and one small brown bowl. .1 This jug has filter holes near the top of the rim and a mottled pattern on the lower part of the body of the jug with an ornamental pattern separating this mottled section from the smooth upper half. .2 This jug has a light brown lower section (both body and handle) and a darker reddish-brown upper section .3 This jug is dark brown with lighter shadings at the top section. The lip is chipped. .4 This jug has a mottled brown lower section and a smooth brown upper section. .5 the small bowl has a stipled lower section and plain upper.‘3 PT’ ‘1PT” household items, history of warrnambool, stoneware jugs, pottery jugs -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Jug, 1920-1940

... stoneware jug...Brown Stoneware jug with short neck... maritime village great ocean road jug stoneware jug Salt Glaze ...Stoneware is a rather broad term for pottery or other ceramics that is fired at a relatively high temperature. A modern technical definition is a vitreous or semi-vitreous ceramic made primarily from stoneware clay or non-refractory fire clay. Whether vitrified or not, it is non-porous, it may or may not be glazed. Historically, across the world, it has been developed after earthenware and before porcelain and has often been used for high-quality as well as utilitarian wares. As a rough guide, modern earthenwares are normally fired in a kiln at temperatures in the range of about 1,000°C (1,830 °F) to 1,200 °C (2,190 °F); stoneware's at between about 1,100 °C (2,010 °F) to 1,300 °C (2,370 °F); and porcelains at between about 1,200 °C (2,190 °F) to 1,400 °C (2,550 °F). Historically, reaching high temperatures was a long-lasting challenge, and temperatures somewhat below these were used for a long time. Earthenware can be fired effectively as low as 600°C, achievable in primitive pit firing, but 800 °C was more typical. Stoneware also needs certain types of clays, more specific than those able to make earthenware, but can be made from a much wider range than porcelain. A domestic item used to store food products as glazing makes the container non-porous, often used for pickling. Or larger containers for kitchen flour. Items age is difficult to determine given the same techniques for making stoneware are in use today. Stoneware containers were made by many potteries in Australia and England. They were in common domestic use before plastics were invented around 1940 to store goods so this subject item is probably from around 1900 to the 1940s. Item's significance is difficult to determine given it is not associated with a place, person, historic event, or manufacturer. Its significance lies with its use as a domestic object giving today a view into our social past.Brown Stoneware jug with short neckThe number "1" under neck flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, jug, stoneware jug, salt glaze -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Jug, 1900 - 1940

... stoneware jug... Stoneware jug badly cracked and repaired with handle... flagstaff hill maritime village great ocean road jug stoneware jug ...Stoneware is a rather broad term for pottery or other ceramics that is fired at a relatively high temperature. A modern technical definition is a vitreous or semi-vitreous ceramic made primarily from stoneware clay or non-refractory fire clay. Whether vitrified or not, it is non-porous, it may or may not be glazed. Historically, across the world, it has been developed after earthenware and before porcelain and has often been used for high-quality as well as utilitarian wares. As a rough guide, modern earthen wares are normally fired in a kiln at temperatures in the range of about 1,000°C (1,830 °F) to 1,200 °C (2,190 °F); stoneware's at between about 1,100 °C (2,010 °F) to 1,300 °C (2,370 °F); and porcelains at between about 1,200 °C (2,190 °F) to 1,400 °C (2,550 °F). Historically, reaching high temperatures was a long-lasting challenge, and temperatures somewhat below these were used for a long time. Earthenware can be fired effectively as low as 600°C, achievable in primitive pit firing, but 800 °C was more typical. Stoneware also needs certain types of clays, more specific than those able to make earthenware, but can be made from a much wider range than porcelain. A domestic item used to store food products as glazing makes the container non-porous, often used for pickling. Or larger containers for kitchen flour. Items age is difficult to determine given the same techniques for making stoneware are in use today. Stoneware containers were made by many potteries in Australia and England. They were in common domestic use before plastics were invented around 1940 to store goods so this subject item is probably from around 1900 to the 1940s.Item's significance and origin of manufacture is difficult to determine given it is not associated with a place, person, historic event, or manufacturer. Its significance lies with its use as a domestic object giving today a view into our social past. Stoneware jug badly cracked and repaired with handle and short neckNoneflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, jug, stoneware jug, earthenware jug, kitchen storage -

Clunes Museum

Clunes MuseumContainer - STONEWARE JAR, A.C.THOMSON & CO

... .1 & .2 TWO STONEWARE JUGS WITH DECORATIVE EMBLEM ON JUGS... WHISKY .1 & .2 TWO STONEWARE JUGS WITH DECORATIVE EMBLEM ON JUGS ....1 & .2 TWO STONEWARE JUGS WITH DECORATIVE EMBLEM ON JUGSJEROBOAM THE ROYAL BLEND WHISKYlocal history, ceramic, stoneware, william harris -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Jug

... Stoneware jug. Two tone brown glaze with pierced lip behind.... Stoneware jug. Two tone brown glaze with pierced lip behind spout ...The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/The form of the jug has been in use for many centuries.Stoneware jug. Two tone brown glaze with pierced lip behind spout. Spout chipped.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, jug, ceramic jug -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Jug, Hoffman Pottery Pty, Ltd, Circa 1929

... stoneware jug...Stoneware Demijohn jug with cream and brown glaze. ... stoneware jug hoffman potteries Printed around base of jug ...The Hoffman company was established in 1870 to mass-produce bricks using the Hoffman patent kiln and the Bradley and Craven brick press. Once established the company entered a period of expansion aided by Melbourne's building boom from 1870 to 1890. During this time approximately ten brick machines were in operation producing some 18,000 bricks per hour. An extensive pottery works were established initially supplying mainly tiles and drainpipes and later domestic pottery such as the company's Melrose ware. The company even had its locomotive shunt the works siding which connected with the Victorian Railways at South Brunswick. By 1890 Hoffman was the largest brick and pottery works in Victoria, however, the 1890s depression halted company expansion. The company joined the Brick Co-operative when it was formed in 1896. The cooperative regulated prices and output from member brickworks. As the depression ended business picked up and the works were expanded to increase the production of stoneware pottery, especially domestic wares. The brickworks, however, never recovered the momentum of the early period. During the 1920s and 1930s, the works gradually ran down, and following the Second World War, production reached an all-time low. The No.1 works were stripped and sold. (For further information regards Hoffman Kilns see note section of this document.) An item made in Melbourne by at the time the largest pottery works in Australia making industrial and domestic wares for the home and building industries. Stoneware Demijohn jug with cream and brown glaze. Printed around base of jug, MELBOURNE, 1929"flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, jug, melbourne, 1929, stoneware jug, hoffman potteries -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Ink Jug, Second half of 19th Century or first half of the 20th Century

This metal ink jug or can, was used to dispense portions of ink to individual inkwells contained on the top of each pupil's desk. The jug is not unlike a small indoor watering can. The ink would be supplied to schools in large glass or stoneware bottles, and these would have been too unwieldy and difficult to use to pour ink into the small inkwells. Therefore it was decanted into the metal ink jugs and then poured into the inkwells. After a child was deemed old enough to progress from just using slate and board, he/she would have been supplied with a pen shaft made of wood and with a very basic metal nib. The ink jug would be used to fill up the individual inkwells. This operation would have been conducted by the teacher him/herself, or by an older pupil under the close eye of the teacher.Ink jug, metal, black, with long spout & metal handleNone.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, ink, jug -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Ink Jug, Second half of 19th Century or first half of the 20th Century

This metal ink jug or can, was used to dispense portions of ink to individual inkwells contained on the top of each pupil's desk. The jug is not unlike a small indoor watering can. The ink would be supplied to schools in large glass or stoneware bottles, and these would have been too unwieldy and difficult to use to pour ink into the small inkwells. Therefore it was decanted into the metal ink jugs and then poured into the inkwells.After a child was deemed old enough to progress from just using slate and board, he/she would have been supplied with a pen shaft made of wood and with a very basic metal nib. The ink jug would be used to fill up the individual inkwells. This operation would have been conducted by the teacher him/herself, or by an older pupil under the close eye of the teacher.Ink jug metal black with long spout & metal handle.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, ink, jug -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Ink Bottle, Royal Doulton, Late 19th to early-20th century

The Royal Doulton company began as a partnership between John Doulton, Martha Jones, and John Watt was an English ceramic and home accessories manufacturer founded in 1815. Operating originally in Vauxhall, London, later moving to Lambeth, in 1882 it opened a factory in Burslem, Stoke-on-Trent, in the centre of English pottery. The business was specialised in making salt-glazed stoneware articles, including utilitarian or decorative bottles, jugs and jars, much of it intended for inns and pubs. The backbone of the business was a wide range of utilitarian wares, mostly stonewares, including storage jars, tankards and the like, and later extending to pipes for drains, lavatories and other bathroom ceramics. From 1853 to 1902 its wares were marked Doulton & Co., then from 1902, when a royal warrant was given, Royal Doulton. The company always made some more decorative items, initially still mostly stoneware, and from the 1860s the firm made considerable efforts to get a reputation for design, in which it was largely successful, as one of the first British makers of art pottery. Initially, this was done through artistic stoneware's made in Lambeth, but in 1882 the firm bought a Burslem factory, which was mainly intended for making bone China table wares and decorative items. An early utilitarian stoneware item made by a well-known company that specialised in making salt-glazed items that later earned a reputation for making stoneware art objects. This ink well is historically significant as it represents the method of hand written communication that was still common up until the mid-20th century, before fountain pens and ballpoint pens took over in popularity and convenience.Ceramic, salt-glazed, mid-brown ink bottle. It has a small round mouth, rounded lip that extends past neck, wide shoulders, straight sides, flat base. Handmade. The surface is matt. there are flecks of dark brown in the clay. The bottle has marks on the side.Noneflagstaff hill, warrnambool, shipwreck coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, shipwreck artefact, writing equipment, writing accessory, office equipment, stationery, domestic, stoneware, clay, ceramic, pottery, inkwell, penny ink well, nib pen, dip pen, ink, hand writing, record keeping, household, business, vintage, blotting paper, ink bottle, dwarf ink, salt glazed -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Ceramic Bottle (Chinese Style), Minton Potteries, Late 19th century

The subject item is believed to be a "Chinese style stoneware liquor bottle used to store "Tiger Whiskey" (rice wine). These Chinese liquor jugs are made of glazed pottery known as brown stoneware and have been made throughout the centuries by many makers until well after American Prohibition. Later varieties from the mid 20th century are commonly found in the USA with the raised lettering "Federal Law Forbids Sale Or Re-use of this bottle" a sure sign of post-1934 manufacture. This example is interesting as it has a British Minton mark of two triangles on the base indicating a date of 1879 and was likely exported to Australia by Minton. These ceramic bottles virtually always have irregularities and flaws which indicate a product has been hastily manufactured, in any event, this is a fine example of a relatively common item that may have been copied by Minton and sold as a decorative domestic item for display or mass produced for storing liquor. Giles Family: The pair of ceramic bottles were given to Vera Giles by Jim Thompson and are just many 19th century items of furniture, linen and crockery donated to Flagstaff Hill Maritime Village by, Vera and Aurelin Giles. The items are associated with Warrnambool and the Giles Family history. Items donated by the family have come to be known as the “Giles Collection”. Many items in the Lighthouse Keeper’s Cottage were donated by Vera and Aurelin Giles and mostly came from the home of Vera’s parents-in-law, Henry Giles and his wife Mary Jane (nee Freckleton) who married in 1880 and whose photos are on display in the parlour. Henry was born at Tower Hill in 1858, and was a labourer on the construction of the Warrnambool Breakwater before leaving in 1895 for around seven years to build bridges in NSW. Mary Jane was born in 1860 at Cooramook and she attended Mailor’s Flat State School and where she eventually was to become a student teacher. After which she became a governess at “Injemiara” where her grandfather, Francis Freckleton, had once owned land. Henry and Mary’s family consisted of six, some of the children were born at Mailor’s Flat and later some children at Wangoom. They lived with their parents at Wangoom and Purnim west, and this is where Henry died in 1933 and Mary Jane in 1940. A significant item of lead-glazed ceramic with the possibility it was made by the Minton potteries in England who were renowned for making quality pottery. The item style is in all probability a copy of a Chinese liquor bottle that was in common use throughout the British colonies and America up until the mid 20th Century. The Giles family collection has social significance at a local level, because it illustrates the level of material support the Warrnambool community gave to Flagstaff Hill when the Museum was established.Chinese liquor bottle one of a pair, lead glazed ceramic, dark brown and blue/black. Part of the Giles Collection.Mark of a double triangle, apex touching, on base, (Minton mark for 1879).flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, vase, pottery, ceramic ornament, domestic ware, late 19th - early 20th centuy ornament, giles collection, henry giles, tower hill, cooramook, warrnambool breakwater, mailor’s flat, wangoom, 19th century household goods -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Ink Bottle, Royal Doulton, 1853-1878

The ink bottle was made by the Royal Doulton company which began as a partnership between John Doulton, Martha Jones, and John Wattis an English ceramic and home accessories manufacturer founded in 1815. Operating initially in Vauxhall, London, it later moved to Lambeth, In1882 it opened a factory in Burslem, Stoke on Trent, in the centre of English pottery. The business specialised in making salt-glazed stoneware articles, including utilitarian or decorative bottles, jugs and jars, much of it intended for inns and pubs. The backbone of the business was a wide range of utilitarian wares, mostly stoneware's, including storage jars, tankards and the like, and later extending to pipes for drains, lavatories and other bathroom ceramics. From 1853 to 1902 its wares were marked Doulton & Co., then from 1902, when a royal warrant was given, wares were marked Royal Doulton. The company always made some more decorative items, initially still mostly stoneware, and from the 1860s the firm made considerable efforts to get a reputation for design, in which it was largely successful, as one of the first British makers of art pottery. Initially, this was done through artistic stoneware made in Lambeth, but in 1882 the firm bought a Burslem factory, which was mainly intended for making bone china table wares and decorative items. History of the Loch Ard: The Loch Ard got its name from ”Loch Ard” a loch that lies to the west of Aberfoyle, and the east of Loch Lomond. It means "high lake" in Scottish Gaelic. The vessel belonged to the famous Loch Line which sailed many vessels from England to Australia. The Loch Ard was built in Glasgow by Barclay, Curdle and Co. in 1873, the vessel was a three-masted square-rigged iron sailing ship that measured 79.87 meters in length, 11.58 m in width, and 7 m in depth with a gross tonnage of 1693 tons with a mainmast that measured a massive 45.7 m in height. Loch Ard made three trips to Australia and one trip to Calcutta before its fateful voyage. Loch Ard left England on March 2, 1878, under the command of 29-year-old Captain Gibbs, who was newly married. The ship was bound for Melbourne with a crew of 37, plus 17 passengers. The general cargo reflected the affluence of Melbourne at the time. Onboard were straw hats, umbrellas, perfumes, clay pipes, pianos, clocks, confectionery, linen and candles, as well as a heavier load of railway irons, cement, lead and copper. There were other items included that were intended for display in the Melbourne International Exhibition of 1880. The voyage to Port Phillip was long but uneventful. Then at 3 am on June 1, 1878, Captain Gibbs was expecting to see land. But the Loch Ard was running into a fog which greatly reduced visibility. Captain Gibbs was becoming anxious as there was no sign of land or the Cape Otway lighthouse. At 4 am the fog lifted and a lookout aloft announced that he could see breakers. The sheer cliffs of Victoria's west coast came into view, and Captain Gibbs realised that the ship was much closer to them than expected. He ordered as much sail to be set as time would permit and then attempted to steer the vessel out to sea. On coming head-on into the wind, the ship lost momentum, the sails fell limp and Loch Ard's bow swung back towards land. Gibbs then ordered the anchors to be released in an attempt to hold their position. The anchors sank some 50 fathoms - but did not hold. By this time the ship was among the breakers and the tall cliffs of Mutton Bird Island rose behind. Just half a mile from the coast, the ship's bow was suddenly pulled around by the anchor. The captain tried to tack out to sea, but the ship struck a reef at the base of Mutton Bird Island, near Port Campbell. Waves subsequently broke over the ship and the top deck became loosened from the hull. The masts and rigging came crashing down knocking passengers and crew overboard. When a lifeboat was finally launched, it crashed into the side of Loch Ard and capsized. Tom Pearce, who had launched the boat, managed to cling to its overturned hull and shelter beneath it. He drifted out to sea and then on the flood tide came into what is now known as Lochard Gorge. He swam to shore, bruised and dazed, and found a cave in which to shelter. Some of the crew stayed below deck to shelter from the falling rigging but drowned when the ship slipped off the reef into deeper water. Eva Carmichael a passenger had raced onto the deck to find out what was happening only to be confronted by towering cliffs looming above the stricken ship. In all the chaos, Captain Gibbs grabbed Eva and said, "If you are saved Eva, let my dear wife know that I died like a sailor". That was the last Eva Carmichael saw of the captain. She was swept off the ship by a huge wave. Eva saw Tom Pearce on a small rocky beach and yelled to attract his attention. He dived in and swam to the exhausted woman and dragged her to shore. He took her to the cave and broke the open case of brandy which had washed up on the beach. He opened a bottle to revive the unconscious woman. A few hours later Tom scaled a cliff in search of help. He followed hoof prints and came by chance upon two men from nearby Glenample Station three and a half miles away. In a complete state of exhaustion, he told the men of the tragedy. Tom then returned to the gorge while the two men rode back to the station to get help. By the time they reached Loch Ard Gorge, it was cold and dark. The two shipwreck survivors were taken to Glenample Station to recover. Eva stayed at the station for six weeks before returning to Ireland by steamship. In Melbourne, Tom Pearce received a hero's welcome. He was presented with the first gold medal of the Royal Humane Society of Victoria and a £1000 cheque from the Victorian Government. Concerts were performed to honour the young man's bravery and to raise money for those who lost family in the disaster. Of the 54 crew members and passengers on board, only two survived: the apprentice, Tom Pearce and the young woman passenger, Eva Carmichael, who lost her family in the tragedy. Ten days after the Lochard tragedy, salvage rights to the wreck were sold at auction for £2,120. Cargo valued at £3,000 was salvaged and placed on the beach, but most washed back into the sea when another storm developed. The wreck of Lochard still lies at the base of Mutton Bird Island. Much of the cargo has now been salvaged and some items were washed up into Lochard Gorge. Cargo and artefacts have also been illegally salvaged over many years before protective legislation was introduced in March 1982. One of the most unlikely pieces of cargo to have survived the shipwreck was a Minton majolica peacock- one of only nine in the world. The peacock was destined for the Melbourne 1880 International Exhibition. It had been well packed, which gave it adequate protection during the violent storm. Today the Minton peacock can be seen at the Flagstaff Hill Maritime Museum in Warrnambool. From Australia's most dramatic shipwreck, it has now become Australia's most valuable shipwreck artifact and is one of very few 'objects' on the Victorian State Heritage Register.An early utilitarian stoneware item made by a well-known company that specialised in making salt-glazed items that later earned a reputation for making stoneware art objects. Of additional significance is that it was recovered from the wreck of the Loch Ard. A shipwreck that is of additional significance as it is registered on the Victorian Heritage Register ( S 417). Flagstaff Hill has a varied collection of artefacts from Loch Ard and its collection is significant for being one of the largest accumulations of artefacts from this notable Victorian shipwreck of which the subject items are a small part. The collections objects give us a snapshot of how we can interpret the story of this tragic event. The collection is also archaeologically significant as it represents aspects of Victoria's shipping history that allows us to interpret Victoria's social and historical themes of the time. Through is associated with the worst and best-known shipwreck in Victoria's history. Salt glazed stoneware ink bottle, large capacity, tapered lip and body, two-tone brown with some encrustation on surface, still sealed with cork. Inscription in clay. Recovered from the wreck of the LOCH ARD.Stamped into clay "DOULTON LAMBETH"flagstaff hill, warrnambool, flagstaff hill maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, loch line, loch ard, captain gibbs, eva carmichael, tom pearce, glenample station, mutton bird island, loch ard gorge, ink bottle, bulk ink bottle, writing accessory, stationery, stoneware, doulton lambeth, royal doulton, writing equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Terracotta Cooler Top, Ovens Pottery, c. 1890-1892

The Ovens pottery operated from 1881 to1892 they had taken over H L & E pottery at Beechworth in 1888 but mounting debts forced the Ovens company to close in 1892. During their short ten years of operation they produced stoneware garden urns, vases, cheese dishes, ginger beer bottles, butter coolers, water filters, wine and spirit barrels, bread plates, jugs, teapots, storage jars, pots, tiles, flower pots, spittoons, basins, bowls, demijohns, lidded crocks, pipes and bricks.A significant item made by an early Australian pottery in Beechworth Victoria, this company made many utilitarian items for the Victorian domestic market. It gives us today a snapshot into early Australian companies that were unable to sustain manufacturing their products into the 20th century, due in part to the rising imports of cheaper items from overseas.Red terracotta butter cooler comprising, round base with ridged lip, and bell shaped, domed lid with spherical handle on topMarked "Ovens Pottery, Co Ltd, Patd 1890, Beechworth" flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, cooler, terracotta cooler, utensil, kitchen ware, terracotta, food container, food preservation, butter cooler, ovens pottery -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Stoneware Bottle, Doulton Lambeth, Circa 1870 - 1890

The Royal Doulton company began as a partnership between John Doulton, Martha Jones, and John Wattis an English ceramic and home accessories manufacturer founded in 1815. Operating originally in Vauxhall, London, later moving to Lambeth, in 1882 it opened a factory in Burslem, Stoke-on-Trent, in the centre of English pottery. The business was specialised in making salt-glazed stoneware articles, including utilitarian or decorative bottles, jugs and jars, much of it intended for inns and pubs. The backbone of the business was a wide range of utilitarian wares, mostly stone wares, including storage jars, tankards and the like, and later extending to pipes for drains, lavatories and other bathroom ceramics. From 1853 to 1902 its wares were marked Doulton & Co., then from 1902, when a royal warrant was given, Royal Doulton. The company always made some more decorative items, initially still mostly stoneware, and from the 1860s the firm made considerable efforts to get a reputation for design, in which it was largely successful, as one of the first British makers of art pottery. Initially, this was done through artistic stoneware's made in Lambeth, but in 1882 the firm bought a Burslem factory, which was mainly intended for making bone china table wares and decorative items. An early utilitarian stoneware item made by a well-known company that specialised in making salt-glazed items that later earned a reputation for making stoneware art objects.Ink bottle, brown salt glazed stoneware with narrow mouth tamped Doulton Lambeth cork missing. Stamp impressed into clay on edge "(2)32 / Doulton / Lambeth" flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, stoneware, stoneware jar, doulton lambeth, kitchen ware, salt glazed -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Stoneware Demijohn, Bendigo Pottery , 1904-1930s

This Sharpe Bros. one gallon stoneware Demijohn is in excellent condition and includes its original stopper. It was made between 1904 and 1930, the date from the patent of the handle until the time that the factory no long produced returnable items. The bottle was once part of Dr W.R. Angus' household and is part of the W.R. Angus Collection and could have been purchased from Warrnambool's Sharpe Bros. factory. SHARPE BROS. 1903-1972- The first Sharpe Bros. cordial factory was opened in Dunedin, New Zealand, in 1903 by English prohibition brothers John and Percy Sharpe. Sharpe Bros. made ‘health’ beverages that were non-alcoholic drinks such as ginger beer, ginger ale, lime juice, soda and cordials. The containers of these drinks were not sold with the drinks but were marked as returnable items, to be cleaned and re-used, until this practice ceased in the 1930s. Sharpe Bros. made a niche in the soft drink market by delivering drinks by horse and cart to its customers’ homes. John Sharpe patented the unique wire spiral handle in 1904. By 1905 the New Zealand company also had factories in Australia. By 1910 the company had over 20 factories including Wanganui, New Zealand; Adelaide, Albury, Ballarat, Bathurst, Forbes, Geelong, Goulburn, Lithgow, Melbourne, Newcastle, Orange, Sydney, Tamworth, Warrnambool and Wollongong. The Warrnambool factory was established in 1919 and existed until 1951. The company won awards at Australian exhibitions for its carbonated drinks, including First Prize for its ginger beer made in the Brisbane factory. The company was taken over in 1962 by Tarax Drinks Holdings Ltd, which was in turn taken over by Cadbury Schweppes in 1972. W.R. Angus Collection- The W R Angus Collection spans from 1885 to the mid-1900s and includes historical medical and surgical equipment and instruments from the doctors Edward and Thomas Ryan of Nhill, Victoria. Dr Angus married Gladys in 1927 at Ballarat, the nearest big city to Nhill where he began as a Medical Assistant. He was also Acting House surgeon at the Nhill hospital where their two daughters were born. He and his family moved to Warrnambool in 1939, where Dr Angus operated his own medical practice. He later added the part-time Port Medical Officer responsibility and was the last person appointed to that position. Dr Angus and his wife were very involved in the local community, including the early planning stages of the new Flagstaff Hill, where they contributed to the layout of the gardens. Dr Angus passed away in March 1970.This stoneware Demijohn is connected to the history of Warrnambool, as it was owned by the daughter of Dr W. R. Angus and his wife Gladys. It is part of the W.R. Angus Collection, which is notable for still being located at the site connected to Doctor Angus, Warrnambool’s last Port Medical Officer. It is also connected through its manufacturer Sharpe Bros. which had a branch in Warrnambool from 1919 to 1951, overlapping the time when the Angus family resided there from 1939 to the 1970s. The bottle is also significant as an example of the early-20th-century beverages found in local households and could have been purchased from the local Sharpe Bros. factory.This stoneware Demijohn is glazed, with a brown neck with internal thread and shoulders and a cylindrical cream base. The one gallon bottle has a flat, black stopper with a cork stem and a rubber, threaded tip. The ‘U’ shaped wire carry handle has a spiral of wire around the handpiece. An overhanging lip is on top of the bottle’s short neck above its rounded shoulder. The clay has been joined at the base of the neck, shoulder and body. The underneath is unglazed. The brown glazing on the shoulder has a run mark. Inscriptions are on the stopper and bottle. This container is part of the W.R. Angus Collection.Stamped in black on the shoulder: “KEEP THE / STOPPER TIGHT” Stamped in black on the body: “THIS JAR IS THE ABSOLUTE PROPERTY OF AND MUST BE RETURNED TO SHARPE BROS. AUSTRALIA / & NEW ZEALAND. ORIGINAL & LARGEST HYGIENIC BREWERY. CAUTION Persons Damaging, Willfully Retaining, Trading with or Misappropriating the Use of this Jar WILL BE PROSECUTED “ Stamped in script writing: “Sharpe Bros. TRADE - - - ED “ Embossed on the stopper: “AUSTRALIA AND NEW ZEALAND, SHARPE BROS.”flagstaff hill, warrnambool, maritime village, maritime museum, shipwreck coast, great ocean road, dr w r angus, dr roy angus, dr ryan, sharpe bros., bendigo pottery, bottle, stoneware bottle, demihohn, one gallone bottle, soft drink, non-alcoholic drink, drink container, jar, jug, warrnambool soft drink, hygienic brewery, cordial factory, new zealand, australia, john sharpe, percy sharpe, non-alcoholic, spiral wire handle, ginger beer, w.r. angus collection, demijohn -

Clunes Museum

Clunes MuseumContainer - JUG, SHARPE BROS

... TO CONTAIN GINGER BEER STONEWARE JUG GINGER BEER "HEALTH BEVERAGES ...JUG USED TO CONTAIN GINGER BEERSTONEWARE JUB WITH WIRE HANDLE, BROWN CERAMIC GLAZE AT THE NECK OF THE JUG AND CLAY COLOURED GLAZE AROUND TO JUG BELOW THE BROWN"HEALTH BEVERAGES - WHEN EMPTY RETURN TO SHARPE BROS AUSTRALIA AND NEW ZEALAND" IN BLACK LETTERING ON THE BODY OF THE JUGstoneware, jug, ginger beer -

Clunes Museum

Clunes MuseumDomestic object - STONE JAR

... jug stoneware Nil CREAM COLOURED STONE JUG WITH HANDLE ...CREAM COLOURED STONE JUG WITH HANDLENilpottery jug, stoneware -

Clunes Museum

Clunes MuseumDomestic object - STONE JAR

... Jug Stoneware CREAM COLOURED STONE JAR OR DEMIJOHN Domestic ...CREAM COLOURED STONE JAR OR DEMIJOHNpottery jug, stoneware -

Nillumbik Shire Council

Nillumbik Shire CouncilPottery: Gilbert BUCHANAN, Stoneware Jug

... Stoneware Jug...Nillumbik Shire Council melbourne Stoneware Jug Pottery ... -

Ballarat Heritage Services

Ballarat Heritage ServicesCeramic, Old Ballarat Pottery, Old Ballarat Pottery Jug

... is impressed 'Stoneware Old Ballarat Pottery Australia' with a kangaroo ...Old Ballarat Pottery was set up by John Gilbert as part of the Old Ballarat Village, opposite Sovereign Hill. Gilbert had lectured at Ballarat College of Advanced Education before establishing the Edinburgh Pottery at Sovereign Hill in 1972 to enable visitors to see traditional trades at work. The Old Ballarat Pottery was a much larger concern, producing wares for sale through department stores and on party plan via Faberware as well as through the village. Early works looked as though they might have been made in the 1850s, with unturned bases, crude marks and dark treacle-like glazes. Peter Pilven, one of Gilbert's students, worked there after graduating from the Ballarat College of Advanced Education, teaching throwing to students like the potter John Ferguson, who was there from 1978-79. Potters were initially employed by Gilbert's company Pontresina Pty Ltd, registered in 1973. (The Old Ballarat Pottery was registered as a company from 1984-1994.) Early works are marked with an impressed long-tailed 'B', or an 'OB' on either side of a mine tower. A printed stamp also features a mine tower surrounded by the text 'Old Ballarat Pottery Made in Australia'. Later work is impressed 'Stoneware Old Ballarat Pottery Australia' with a kangaroo.Hand thrown blue glazed jug.Stamped 'Stoneware Old Ballarat Pottery?old ballarat pottery, australian studio pottery, jug, pontresina, ceramics -

Federation University Art Collection

Federation University Art CollectionCeramic - jug, Salt Glazed Jug by Sandra Johnstone, c1985

Sandra JOHNSTONE (1936-1991) Worked California, USA Sandra Johnstone is a graduate from the University of California, Berkeley, California. She is known for her large wheel thrown stoneware pots with deep incision on interior and exterior surfaces. Iin 1985 Sandra Johnstone was a visiting artist to Gippsland Centre for Art and Design. (now Federation University Australia) Salt glazed jugJohnstone incised on basesandra johnstone, ceramics, jan feder memorial ceramics collection, gippsland campus, visiting artist -

Federation University Art Collection

Federation University Art CollectionCeramic, Tea Set by Ursula Nowicki, c1986

Ursula NOWICKIA woodfired stoneware Teapot, sugar bowl and milk jug.UN on baseursula nowicki, ceramics, jan feder memorial ceramics collection, jan feder, gippsland campus, woodfire 86 -

Mont De Lancey

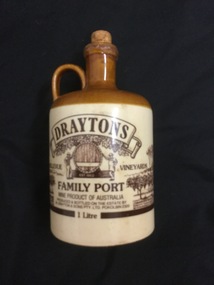

Mont De LanceyDomestic object - Ceramic flagon, Drayton & Sons Pty. Ltd, Unknown

Flagons are vessels with a handle and spout used to hold alcoholic beverages, usually wine. In colonial times it would have been set on a table to share with friends or family.A brown and beige ceramic Port wine flagon or jug, with a handle and cork stopper.'Draytons Bellevue Vineyards Family Port. Wine product of Australia. Produced and bottled on the estate by Drayton & Sons Pty. Ltd. Pokolbin 2320. 1 Litre'jugs, pouring vessels, flagons, containers, stoneware -

Ballarat Heritage Services

Ballarat Heritage ServicesPhotograph - Domestic Ware, Jug by Grashir Pottery, c1992

Grashir Pottery was based in Kyabram, Victoria, and between 1984-1999 was registered by ASIC under the trading name Grashir Handcrafts. The pottery was set up by Graham and Shirley Howard after Graham had worked for John Stroomer for many years. The pottery made functional stoneware marked with an impressed 'Grashir Pottery' or 'Grashir Kyabram' with a map of Australia. Small hand thrown jug by Grashir Potteryaustralian studio pottery, ceramics, jug, grashir pottery -

Alfred Hospital Nurses League - Nursing History Collection

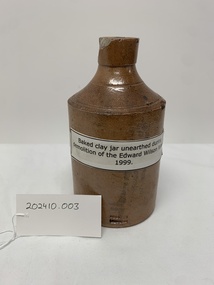

Alfred Hospital Nurses League - Nursing History CollectionCeramic - Stoneware bottle, Doulton Lambeth, Baked clay jar unearthed during demolition of the Edward Wilson Wing 1999, ca.1870 - 1890

The business was specialised in making salt-glazed stoneware articles, including utilitarian or decorative bottles, jugs and jars, much of it intended for inns and pubs. The backbone of the business was a wide range of utilitarian wares, mostly stone wares, including storage jars, tankards and the like, and later extending to pipes for drains, lavatories and other bathroom ceramics. From 1853 to 1902 its wares were marked Doulton & Co., then from 1902, when a royal warrant was given, Royal Doulton. The company always made some more decorative items, initially still mostly stoneware, and from the 1860s the firm made considerable efforts to get a reputation for design, in which it was largely successful, as one of the first British makers of art pottery. Initially, this was done through artistic stoneware's made in Lambeth, but in 1882 the firm bought a Burslem factory, which was mainly intended for making bone china table wares and decorative items. An early utilitarian stoneware item made by a well-known company that specialised in making salt-glazed items that later earned a reputation for making stoneware art objects. brown glazed earthenware bottle, circular grooves at throat of bottle x 3, cylindrical shape, narrow neck, makers stamp on side, large chip at opening, multiple small chips on sides. no stopper. paper label taped to front -Baked clay jar unearthed during demolition of the Edward Wilson Wing 1999 Doulton Lambeth stamp base of front - makers mark. label -paper label taped to front -Baked clay jar unearthed during demolition of the Edward Wilson Wing 1999ahnl, edward wilson wing alfred hospital, baked clay jar