Showing 37 items matching "stylus"

-

Vision Australia

Vision AustraliaEquipment - Object, Plastic stylus

Designed to create an impression on paper, the stylus allows users to create Braille through the applied use of pressure that creates a depression on one size of the paper and a raised dot on the alternative side. Used in combination with a slate to guide placement, this was the primary source of Braille books in the late nineteenth and early twentieth century before Braille typewriters were commonly used. In this example the handle is made of plastic and it has a metal tip.1 plastic stylus with metal tipbraille equipment, royal victorian institute for the blind -

Vision Australia

Vision AustraliaEquipment - Object, Safety stylus

Designed to create an impression on paper, the stylus allows users to create Braille through the applied use of pressure that creates a depression on one size of the paper and a raised dot on the alternative side. Used in combination with a slate to guide placement, this was the primary source of Braille books in the late nineteenth and early twentieth century before Braille typewriters were commonly used. In this example the handle is made of Vulcanite (according to the RNIB Illustrated Catalogue of Apparatus and Games, 1968), and the metal tip can be shielded by rotating the rounded section near the tip, which loosens and drops down.1 stylus with metal tipbraille equipment, royal victorian institute for the blind -

Vision Australia

Vision AustraliaEquipment - Object, Wooden stylus

Designed to create an impression on paper, the stylus allows users to create Braille through the applied use of pressure that creates a depression on one size of the paper and a raised dot on the alternative side. Used in combination with a slate to guide placement, this was the primary source of Braille books in the late nineteenth and early twentieth century before Braille typewriters were commonly used. In this example the handle is made of boxwood (according to the RNIB Illustrated Catalogue of Apparatus and Games, 1968), and is the standard model.1 wooden stylus with metal tipbraille equipment, royal victorian institute for the blind -

Vision Australia

Vision AustraliaEquipment - Object, Braille hand frame and stylus

Braille hand frames and styluses were the primary way to produce Braille for over a century. The stylus was used to make a separate indentation for each dot, and the hand frame to keep dots within the same cell. Braille rows are produced from right to left. The process was very time consuming. Volunteer transcribers for the library could take an average of ½ hour to produce one page of Braille using this method. For example: “Oliver Twist” required approximately 600 sheets equating to 300 hours of work! This wooden slate, which was used to make the system portable, served as a firm base needed to sustain puncture pressure. The frame can also be slotted into both sides of the slate, thereby ensuring that the lines of Braille were straight across the page. The metal clasp at the top of the frame held the wooden which kept paper from slipping. In this example, the Rules of Membership for the Victorian Braille Writers were attached to the board.1 wooden back board with metal hand frame and stylus156 carved into wooden framebraille equipment, victorian association of braille writers -

Vision Australia

Vision AustraliaEquipment - Object, Braille hand frame and stylus with Braille maths slate and pegs

Braille hand frames and styluses were the primary way to produce Braille for over a century. The stylus was used to make a separate indentation for each dot, and the hand frame to keep dots within the same cell. Braille rows are produced from right to left. The process was very time consuming. Volunteer transcribers for the library could take an average of ½ hour to produce one page of Braille using this method. For example: “Oliver Twist” required approximately 600 sheets equating to 300 hours of work! Various metal hand frames accompanied by a metal stylus with wooden handle. Some include a wooden slate, which was used to make the system portable as a firm base was needed to sustain puncture pressure. The frame can also be slotted into both sides of the slate, thereby ensuring that the lines of Braille were straight across the page. Transcribing maths was an extremely complex task and a metal grid was utilised to reproduce graphs and diagrams.1 wooden hand frame with metal grid and metal and wooden stylus, 1 metal maths grid with metal pegs in metal container inside a brown suitcase and numerous sheets of Braille paperT.C. Coughlin 5 doz sausage rolls Wilmington Southend is written inside the lid of the suitcasebraille equipment, james murphy -

Vision Australia

Vision AustraliaPhotograph - Image, Transcribing Braille with frame and stylus

Two sighted women sit in an outside porch at the Braille Library in South Yarra, transcribing the books in front of them into Braille, using a stylus and frame. This image shows sighted volunteer Braille transcribers. At this time all Braille was manually transcribed using a hand frame and metal stylus. These volunteers worked at Australia's first Braille Library created by the Victorian Association of Braille Writers.Black and white image of two Braille writersbraille equipment, victorian association of braille writers -

Vision Australia

Vision AustraliaEquipment - Object, Small hand frame with stylus, 1905-1908

This wooden board has hinged flap to allow paper to be inserted, and two tacks under on the lower part secure the paper. The top flap is then closed and a metal clasp holds it firmly in place. A row of holes either side of the board, allow for a hand frame to be attached, to guide the writer in maintaining straightness when transcribing.Wooden rectangular Braille hand frame with holes evenly spaced and built in hinged paper clamp. Pivoted metal Braille guide with two rows of Braille, each 25 cells long. 'Armitage memorial' pressed into framebraille equipment, association for the blind -

Ambulance Victoria Museum

Ambulance Victoria MuseumComputer, Portable, Walkabout HH3, Circa 1990s (guess)

Probably used to record patient details and allow computerised upload of details in hospital. This item used by Rural Ambulance Victoria. Portable computer (lap top) in black carry case aperture so that the screen can be 'written on' using attached stylus.WALKABOUT HH3 CEFC -

Ambulance Victoria Museum

Ambulance Victoria MuseumComputer, Portable, Walkabout HH3, Circa 1990

Probably used to record patient details and allow computerised upload of details in hospital. This item used by Rural Ambulance Victoria.Portable computer (lap top) in black carry case aperture so that the screen can be 'written on' using attached stylus.WALKABOUT HH3 CEFC -

Ambulance Victoria Museum

Ambulance Victoria MuseumComputer, Portable, Walkabout HH3, Circa 1990 (guess)

Probably used to record patient details and allow computerised upload of details in hospital. This item used by Rural Ambulance Victoria.Portable computer (lap top) in black carry case aperture so that the screen can be 'written on' using attached stylus.WALKABOUT HH3 CEFC -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Audio - Record Player, C. 1960

Bought by donor in 1976 to play 78 rpm records. Second hand purchase probably first played C. 1960. 16 rpm records first produced in 1955.Light brown and red case with white band around middle. Has hinged lid and white carry handle on front. Lid hinges to rear with two clips to hold shut on sides. Inside has 18cm turntable, volume control knob and stylus arm with LP and 78 stylus on end. Has speed control marked N_16_33_45_78. 240 volt electric power lead coming through hole in base plate. Has small clip to hold down stylus arm when in transit. In working order.No markingsaudio-visual technology, audio appliances -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Functional object - Needles for gramophone

Small plastic container from the Bendigo & Northern District Base Hospital. Originally it contained tablets. Now used to store spare needles for a gramophone. There are forty-five needles. Errol Bovaird Collectionmusic, gramophone, stylus -

Coal Creek Community Park & Museum

Coal Creek Community Park & MuseumInstrument - Gramaphone

Rectangular oak based varnished Gramaphone - Windsor Desktop type. Large cone shaped, burgundy coloured speaker (phonogram). It has silver brackets and a metal stylus head and round metal turntable.The word Windsor is inscribed on the metal plate -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Book - Aileen and John Ellison Collection: Cooke's Universal Letter Writer

BHS CollectionGreen covered book with ornate edges. On the front in gold colour is a depiction of an inkwell with two stylus. On the spine also in gold lettering "Cooke's Universal Letter Writer". Revised and improved. Published by T, Nelson and Sons in 1868.On first page: H. B. Staley from his father as a token of love, October 9th 1869, Eaglehawk.english grammar, letter writing, cooke -

Greensborough Historical Society

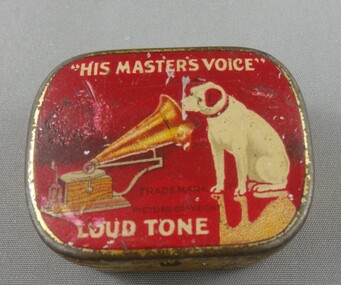

Greensborough Historical SocietyGramophone Needles, His master's voice, His Master's Voice Gramophone needles in tin, 1950c

Gramophone needles (stylus) used in gramophones which played 78 rpm shellac records. Tin has the His Masters Voice dog on lid.Metal box containing brass gramophone needles"His Master's Voice" Loud tone English gramophone needles, manufactured for the Gramophone Company Limited, Sydney N. S. W.his masters voice, styluses (audio), gramophone needles -

J. Ward Museum Complex

J. Ward Museum ComplexInstrument - Electrocardiograph Machine - Cardiotrace Heat Mark II, circa 1920

With the advent of electricity, so to came the invention of the Electrocardiograph Machine. This piece of medical equipment gave nursing staff and doctors a more precise indication of a patients heart beat and was used extensively across Victoria's medical institutions. The equipment is significant because it is a fully intact example of diagnostic equipment used in a mental health hospital in Victoria Australia.Cardiotrace Electrocardiograph Machine in blue plastic case with black handle. Contains: Electric cord Cords to link electrodes Graph paper to measure heart beats Instruments on panel marked 'stylus heat', 'off', 'run', 'position', 'test', 'record', '1', '2', '3', 'aVR', 'aVL', 'aVP', 'V', '1/2V', 'lmV', marker.Manufacturer: Medical Instrument Co. Pty. Ltd. Distributor: Watson Victor Limited Serial No: 3362 Cardiotrace Heat Mark III Electrocardiograph/Voltage 220-240 A/C /Frequency 50 cycles per second/Watts 45 serial 3362/Caution: Refer to Manual for full detail.electrocardiograph machine, medical instrument, medicine, health, mental health, ararat mental hospital, j ward -

Hymettus Cottage & Garden Ballarat

Hymettus Cottage & Garden BallaratFunctional object - Bellows camera & box, Kodak No2A folding autographic Brownie

The Kodak No2A folding autographic Brownie was introduced by the Eastman Kodak Co in 1915 and several variants were produced between 1915 and 1925. There is a door in the back,and a stylus for writing on the back of the film for labelling the negatives. A Christmas present from her parents to Mary Burke (Taffe) in 1928. Basic bellows or folding camera unusual for its time because the lens is behind the shutter. There is a screw thread in front of the shutter for additional 'portrait' lenses. Base of the box has 691162 inscribed in pencil (possibly a stock number) followed by £3/9/6 and Xmas Eve 1928 in blue ink indicating its price and date of presentation. This is followed in pencil by a later signature M.Taffe.camera, mary burke, donald, ballarat, -

Forests Commission Retired Personnel Association (FCRPA)

Forests Commission Retired Personnel Association (FCRPA)IBM Port-A-Punch

The Forests Commission began using computers in the 1960s for resource inventory under the Chief Forest Assessor Murray Paine IBM introduced the Port-A-Punch in 1958 as a fast, accurate means of manually punching holes in specially scored IBM punched cards. Designed to fit in the pocket, Port-A-Punch made it possible to create punched card documents anywhere. The product was intended for "on-the-spot" recording of data such a assessment plotsThe IBM Port-A-Punch prepared computer data and programming cards. Normally there is a a separate stylus pen, similar to a ball-point pen to punch the holes in the cards, but it is missing This instrument consists of a plastic frame that holds 13 long plastic rectangles along its length. A transparent plastic template which has an array of evenly spaced holes fits over the rectangles, and cards are placed over this. IBM Portapunchforest measurement -

Vision Australia

Vision AustraliaEquipment - Object, Hand frame with grid

Braille hand frames and styluses were the primary way to produce Braille for over a century. The stylus was used to make a separate indentation for each dot, and the hand frame to keep dots within the same cell. Braille rows are produced from right to left. The process was very time consuming. Volunteer transcribers for the library could take an average of ½ hour to produce one page of Braille using this method. For example: “Oliver Twist” required approximately 600 sheets equating to 300 hours of work! This wooden slate, which was used to make the system portable, served as a firm base needed to sustain puncture pressure. The frame can also be slotted into both sides of the slate, thereby ensuring that the lines of Braille were straight across the page. The metal clasp at the top of the frame held the wooden which kept paper from slipping.Brown plastic rectangular hand frame with holes evenly spaced on either long side. Hinged Braille metal guide with space for 2 rows of Braille, each 35 cells long. braille equipment, rnib -

Vision Australia

Vision AustraliaEquipment - Object, Howe Press, Small Braille label maker

Designed to create an impression on paper, the slate allows users to create Braille by guiding the stylus into the correct alignment to produce Braille, through the applied use of pressure that creates a depression on one size of the paper and a raised dot on the alternative side. In this example, the frame has two hinges which allow it to sit over the paper edge, and a single line of Braille could be written.2 metal Braille frames for single line usagebraille equipment, assistive devices -

Vision Australia

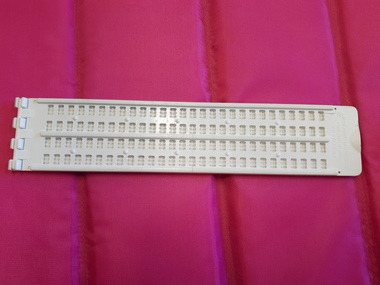

Vision AustraliaEquipment - Object, APH (American Printing House for the Blind), Plastic Braille slate

Designed to create an impression on paper, the slate allows users to create Braille by guiding the stylus into the correct alignment to produce Braille, through the applied use of pressure that creates a depression on one size of the paper and a raised dot on the alternative side. In this example, the frame has two side hinges which allow it to sit over the paper edge, and four lines of Braille could be written.1 plastic Braille frame with 4 lines of 28 cells with side hingebraille equipment, equipment -

Vision Australia

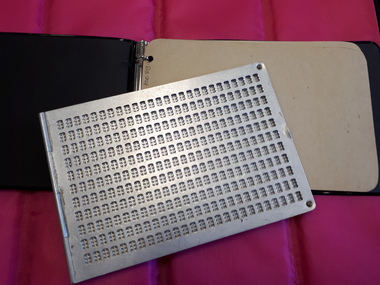

Vision AustraliaEquipment - Object, Tylor postcard Braille slate and notebook

Designed to create an impression on paper, the slate allows users to create Braille by guiding the stylus into the correct alignment to produce Braille, through the applied use of pressure that creates a depression on one size of the paper and a raised dot on the alternative side. In this example, a postcard sized frame fits over a notebook of the same size, and allows the user to fill the page without re-positioning the slate.1 metal Braille frame and 1 vinyl covered metal ring binder with braille pagesbraille equipment, equipment -

Vision Australia

Vision AustraliaEquipment - Object, Braille eraser

Designed to create an impression on paper, the stylus allows users to create Braille through the applied use of pressure that creates a depression on one size of the paper and a raised dot on the alternative side. However sometimes mistakes were made and rather than re-emboss the whole page, a Braille eraser was sometimes used by flattening out indentation on card, one dot at a time.1 wooden piece with blunted tipbraille equipment, association for the blind -

Vision Australia

Vision AustraliaEquipment - Object, Two line Braille frame

Designed to create an impression on paper, the slate allows users to create Braille by guiding the stylus into the correct alignment to produce Braille, through the applied use of pressure that creates a depression on one size of the paper and a raised dot on the alternative side. In this example, the frame has two side hinges which allow it to sit over the paper edge, and four lines of Braille could be written.1 metal Braille frame with two lines of Braille windows and 4 small prongs to keep frame positioned correctly.braille equipment, assistive devices -

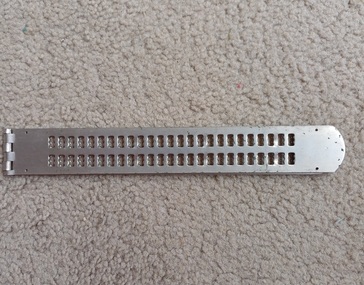

Vision Australia

Vision AustraliaEquipment - Object, Howe Press, Four line Braille frame

Designed to create an impression on paper, the slate allows users to create Braille by guiding the stylus into the correct alignment to produce Braille, through the applied use of pressure that creates a depression on one size of the paper and a raised dot on the alternative side. In this example, the frame has two side hinges which allow it to sit over the paper edge, and four lines of Braille could be written.1 metal Braille frame with four lines of Braille windowsPerkins Model 140 RVIB sticker has been attached to the back of the framebraille equipment, assistive devices -

Geoffrey Kaye Museum of Anaesthetic History

Geoffrey Kaye Museum of Anaesthetic HistoryEquipment - Sphygmograph, c. 1881 - 1901

They sphygmograph was devised as an improved device to measure blood pressure, and was a marked improvement on the first machine of its type. The sphygmomanometer was considered cumbersome and the Dudgeon sphygmograph was smaller, and once placed into its box, could be carried in a pocket. The Dudgeon sphygmograph was introduced in 1881. It was strapped tot he wrist with a metal strip that moved a stylus. This transmitted a record of the pulse onto smoked paper, creating a record of blood pressure.The sphygmograph is housed in a purple-lined, leather bound case with a metal hinge and clasp located halfway up the case. It is constructed from chrome and comprises several moving parts including wires, knobs and handles. A black fabric strap with a metal attachment is also present, used to attach to the patient's wrist.blood pressure, dudgeon, pocket-sized, portable -

Vision Australia

Vision AustraliaEquipment - Object, Braille hand frame

Braille hand frames and styluses were the primary way to produce Braille for over a century. The stylus was used to make a separate indentation for each dot, and the hand frame to keep dots within the same cell. Braille rows are produced from right to left. The process was very time consuming. Volunteer transcribers for the library could take an average of ½ hour to produce one page of Braille using this method. For example: “Oliver Twist” required approximately 600 sheets equating to 300 hours of work! This wooden slate, which was used to make the system portable, served as a firm base needed to sustain puncture pressure. The frame can also be slotted into both sides of the slate, thereby ensuring that the lines of Braille were straight across the page. The metal clasp at the top of the frame held the wooden which kept paper from slipping. Sometimes the board was labelled with organisational labels. In this example, the Rules of Membership for the Victorian Association of Braille Writers was attached, which included the costs of being a transcribing member and the length of the loan period. It is signed by Millicent Ritchie (Hon. Secretary) and Minnie H Crabb (Asst Sec and Librarian) at the base of the sheet.Brown rectangular wooden board with hinged paper clamp and metal hinged guideFree Lending Library for the Blind label is attached to boardbraille equipment, victorian association of braille writers -

Vision Australia

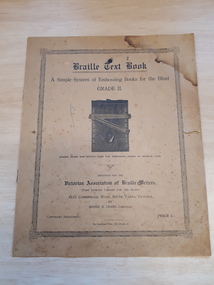

Vision AustraliaEquipment - Object, Braille wooden board and Braille text book

Braille hand frames and styluses were the primary way to produce Braille for over a century. The stylus was used to make a separate indentation for each dot, and the hand frame to keep dots within the same cell. Braille rows are produced from right to left. The process was very time consuming. Volunteer transcribers for the library could take an average of ½ hour to produce one page of Braille using this method. For example: “Oliver Twist” required approximately 600 sheets equating to 300 hours of work! This wooden slate, which was used to make the system portable, served as a firm base needed to sustain puncture pressure. The frame can also be slotted into both sides of the slate, thereby ensuring that the lines of Braille were straight across the page. The metal clasp at the top of the frame held the wooden which kept paper from slipping. This donation includes the signature of Miss Bertha Yoxon, who was a student that transcribed braille around the 1920's for the Victorian Association of Braille Writers, and the owner of this board and textbook. Some originals of her work and a translated letter from her friend James Grubb accompany the frame. 1 wooden board and Braille paper, with 1 Braille text bookbraille equipment, victorian association of braille writers -

Vision Australia

Vision AustraliaMachine - Object, Clarke & Smith talking book player, 1950's

The first tape based talking book machine from the late 1950s, produced by Clarke & Smith, that allowed the listener to hear up to 20 hours of recordings. Although bulky (each tape cartridge alone weighed over 2 kgs), the MK1 was the first magnetic, multi-track tape produced and considered quite novel for it's time. The cartridge designed to be played on the Clarke & Smith Model12 Talking Book gramophone was designed to house the pick up mechanism (the phono cartridge which contains the stylus) in the lid, so that visually impaired people could just close the lid to play the record. Initially these players designed to handle only 24 rpm, but soon added 33 rpm and 16 rpm options via the dial located on the left hand corner of the disk base. Directions for using as well as reminders to use on alternating current only are located inside the lid. On the side of the player are two plastic dials: one for turning on and volume, the other for tone.Metal record player housed in a brown wooden carry case, with a speaker grill in the front, two plastic dials on the side and an electric cord extending from the back of the case.Manufactured for Nuffield Talking Book Libraryaudio equipment, clarke and smith -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

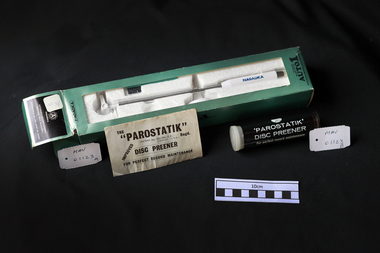

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Manufactured Objects, Vinyl record cleaner kit 'NAGAOKA', c1970

a) Nagaoka Record Anti-Static & Disc Guard Kit The Nagaoka STAT-10 is a record protecting agent that serves both to protect your records from static and to significantly reduce record and stylus wear. By using this product you will improve the sound that you hear from your records, but will also protect your records. The unique charge reducing formula significantly reduces the amount of static electricity present on the surface of the vinyl recording. It also reduces the irritating noise produced by the scratches present on the surface of the vinyl recording. This record protecting agent also contains a special lubricant / protecting fluid agent.This lubricant / protecting fluid reduces record wear so that your recordings are as good as new. b) 'PAROSTATIK' Disc preener -: Use while rotating record slowly on Turntable. Press gently during one or two revolutions. Dust collected on plush surface should be removed before re-use. Device has "built-in" anti-static requiring occasional moisture replacement. Remove cap from centre tube withdraw and moisten wick (when dry) with clean water and replace Always return "Parostatik" to case when not in use. Vinyl records became very popular mid 20thC and cleaners were used to preserve the audio quality of the record surface.A box containing Vinyl record cleaning equipment manufactured by a) Nagaoka Pty Ltd Japan and b) 'Parostatik' C.E Watts Pty Ltd England a ) Box : NAGAOKA / A / trademark / NAGAOKA / AUTOMATIC RECORD CLEANER / ORIGINAL BEST PRODUCTS / NAGAOKA & CO LTD. MADE IN JAPAN / AUTOMATIC / RECORD CLEANER / AUTO 1 / NAGAOKA ORIGINAL BEST PRODUCTS b) Packet ; THE / "PAROSTATIK" PATENT .... REGD./ IMPROVED / DISC PREENER / FOR PERFECT RECORD MAINTENANCE Cylinder; Watts / "PAROSTATIK" / DISC PREENER / For perfect record maintenancerecord players, music, vinyl records, moorabbin, bentleigh, cheltenham, japan, nagaoka pty ltd ,, watts c. e. pty ltd, parostatik disc preener, england