Showing 4 items matching "sulphur in pyrites"

-

Federation University Historical Collection

Federation University Historical CollectionBook - Diary, John Kennedy, John Kennedy's Ballarat School of Mines Lecture Notes, 1889

... sulphur in pyrites... pyrites sulphur in pyrites sugar slags wolfram preparation of pure ...John Kennedy was born on 04 April 1862, the son of ship carpenter Robert Kennedy and his wife Florinda (Aitken), and the brother of Malcolm and Colin Kennedy. In 1860 the family migrated to Melbourne where Kennedy senior set up as a shipwright. In 1879 Malcolm and John, who trained as a naval architect, joined their father as Robert Kennedy & Sons, shipbuilders and shipsmiths. On 27 December 1883 at North Melbourne, Malcolm married Ann White with Presbyterian forms. Next year Robert Kennedy & Sons removed to Hobart where with John W. Syme and W. J. Duffy, partners until 1889, they took over the Derwent Ironworks & Engineering Co., a foundry formerly owned by the (Alexander) Clark family. The Kennedys also acquired the patent slipyard, formerly Ross's, at Battery Point. After the shipbuilding industry in Hobart began to flag John also turned to mining: he attended the Ballarat School of Mines, and reopened the Hobart smelters which had been an adjunct of the Derwent Ironworks in the 1870s. He made several voyages overseas on smelting business and as mining promoter, and was a member of the London Stock Exchange. In 1913-14 he was manager of Tongkah Compound (1910); Robert Kennedy & Sons was reputed to have contributed to the success of the Hobart-run Tongkah Harbour, Thailand, tin mines by developing a suitable dredge. The brothers also held shares in the Irrawaddy Burma Co. John was a member of the Australasian Institute of Mining Engineers and from 1932 an honorary life member of the American Institute of Mining & Metallurgical Engineers. John died in Hobart on 10 January 1937. (Ann G. Smith, 'Kennedy, John (1862–1937)', Australian Dictionary of Biography, National Centre of Biography, Australian National University, http://adb.anu.edu.au/biography/kennedy-john-7092/text11963, published first in hardcopy 1983, accessed online 24 April 2020.) A book covered in black leather with 'John Kennedy' embossed on the front in gold. The book contains notes from the time he studies at the Ballarat School of Mines. The beginning of the book has an alphabetical section where John Kennedy has created an index.Inside front cover 'John Kennedy Nena Wharf Hobart Tasmania.' john kennedy, australasian institute of mining engineers, ausimm, american institute of mining metallurgical engineers, ballarat school of mines, lecture notes, lecture notebook, antinomy, brick clay, carbon, coal, copper, chemistry, clay, chrome, electricity, fire clay, gas, gold, gold bullion, glass, gold test for, iron metallurgy, light, lead, metallurgy, mica, mineralogy, pyrites, sulphur in pyrites, sugar, slags, wolfram, preparation of pure gold, scorification, gold bullion assay, petrography, melting poinys of bodies, metric system, geology, mount morgan, queensland, rock salt, assay of tailings, classification of rocks, muffle furnace, ballarat school of mines wind furnace, assay of antinomy, recovery of silver from solutionsheat pyrometer, spectroscope, organic acids, metallurgy of iron, assat of copper, cornstock lode nevada, mount morgan queensland, scarification, elmwood, metallurgy of lead, specific gravity, copper assay, seperation of gold from other metals, test for gold, wet assay, mercury -

Federation University Historical Collection

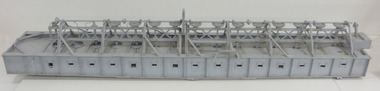

Federation University Historical CollectionUnknown - Model, Edwards' Ore Reduction Furnace Model, pre 1924

This model of a mechanical ore roasting and chloridising furnace was invented and patented by Thomas Edwards of the Edwards Pyrites Smelting and Ore Reduction Company. This new type of furnace produced a high standard of sulphur free ore known as ‘sweet roasted’. Edwards used this model for demonstrations in the USA. Of note is the central large vertical cogwheel (externally driven) which drives small vertical cogwheels via angled cogging drives. These in turn drive a horizontal wheel. Each side of the vertical wheel is set on an opposite side to the horizontal wheel of its neighbours, resulting in opposite direction rotation of neighbouring horizontal wheels. Each horizontal wheel turns a rabble (set of vertical iron paddles) within the furnace. These rabbles, each turning in opposite direction to its neighbours, move the roasting ore in a zig-zag path through the furnace. The elongated furnace with its line of rabbles produced a much ‘sweeter’ roasted ore than could be obtained from a typical tank-shaped furnace. In 1924, when the model was donated to the Ballarat School of Mines, Ballarat’s Courier newspaper reported, ‘Apart from its historical and education value, the gift should serve to stimulate the inventive faculties of the students who have to win fame for the school and for themselves in the metallurgical world.’ The furnace model was donated to Ballarat School of Mines and used as an educational prop from 1924. The model relates to the mining industry which is a significant part of Ballarat's history and heritage. Ballarat School of Mines is the oldest Technical School in Australia and is celebrating 150 years in 2020.Metal model of Edwards' Ore Reduction Furnace. The model includes cogwheels, rabbles and other details. Scale is thought to be around 1:20M259ballarat school of mines, edwards, pyrites, ore reducation, edward retallack, mining, model -

Federation University Historical Collection

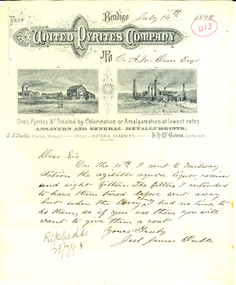

Federation University Historical CollectionLetter - Correspondence, Letter on Bendigo United Pyrites Company Letterhead, 1898, 1898

"The United Pyrites Company's Works are situated about three quarters of a mile from Spargo Brothers, and are on the northern side of the Marong road, in Pinch-gut Gully. Two processes are followed at these works, viz., the amalgamating process and the treatment by means of chlorine gas. The latter is called the Newbery-Vautin system, and the mode pursued is that laid down by Mr. Cosmo Newbery and Mr Vautin, whose names have been given to the process. Mr. Edwards manages these works. Three reverbatory furnaces are used to roast the pyrites, which is weighed in the truck before being put into the furnaces. At this weighbridge a sample of each lot is kept, and if the yield is not equal to expectation, the works are carefully gone over to see where the fault occurs. Care is taken at the furnace to regulate the heat, otherwise the pyrites might slag instead of roasting evenly right through. An immense revolving furnace (made of boiler iron) was used at these works. It was found to be suitable for treating blanket sand, but was not a success for roasting coarse pyrites. The process of amalgamating by means of Chilian mills is the same in these works as at the Western Works, but the United Works are on a larger scale, and eleven mills are utilised. It is the chlorine gas process which is most interesting here. The gas is made from sulphuric acid, black oxide of manganese, and common salt, and the gas is introduced into huge vats, where it works its way through a filter of pieces of quartz and then through the bed of roasted pyrites lying above. The action of the gas transforms the gold into chloride of gold. This is easily dissolved in water, and in that form is drawn off into huge delf jars, where the use of sulphate of iron precipitates the gold to the bottom. A small battery—eight head of stamps in two boxes—is in use here to crush small consignments of stone sent for trial. Test crushings come from all the Australasian colonies, and even from India. The jars used are manufactured at Epsom, and some of the salt used is also of home manufacture, from the Salt Lakes on the Northern plains. Mr. Edwards took us over a new building in course of erection, and in which the chlorine gas is to be generated in the midst of the pyrites— a still further advancement in the new process. There is some very good machinery in this new building, and the tailings from the ordinary pyrites works will also be treated by this chlorine gas system, which has been found to work well at Mount Morgan, in Queensland. The purest of gold is obtained by this process, the gold passing in solution into a charcoal filter, from which it emerges in the shape of metallic gold. We saw some nice cakes of retorted gold at the works. One of 26oz. was from some New Zealand pyrites (2½ tons), and assayed over 23 carats. There were also cakes of Avoca gold, of silver, and of the tremulous amalgam." (The Argus, 4 February 1887)Two handwritten letters to the Ballarat School of Mines on Bendigo United Pyrites Company Letterhead.bendigo united pyrites company, pyrites, ballarat school of mines, j.j. deeble, joel deeble, joel james deeble, a.m. dean, fred j. martell, martell, s.h. cowan, letterhead -

Bendigo Historical Society Inc.

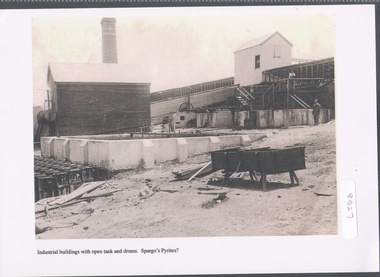

Bendigo Historical Society Inc.Photograph - Spargo's Pyrites, Specimen Hill

Historic photo of mining at Specimen Hill. After crushing ore, the sand pyrites remaining could be treated to extract even finer gold. The sand was placed in large brick ovens to be roasted, which freed the sand of arsenic, sulphur etc, with the fumes containing these elements released into the atmosphere via a large chimney. Spargo's Pyrite Company operated from about 1870. It closed when there became a shortage of workers during WW1 and appears to have not restarted after the war. Black and white image, possibly copy. Weatherboard building on left hand side, elevated weatherboard building centre with chute descending to lower building. Possibly Spargo's Pyrites works, date unknownspargo's, pyrites