Showing 7 items matching "supply of electric energy"

-

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumDocument, Tatura Butter Factory Co

... supply of electric energy... of electric energy is made... of electric energy tatura dairy industry elecgtricity documents ...Description of supply and rules for providing electricty to Tatura Butter FactoryLaminated page of conditions under which a supply of electric energy is madetatura butter factory, supply of electric energy, tatura, dairy industry, elecgtricity, documents, history, local -

Kiewa Valley Historical Society

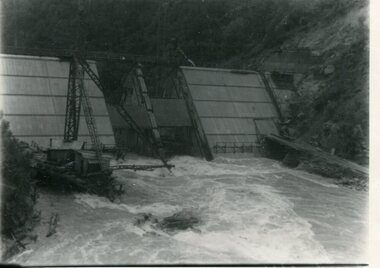

Kiewa Valley Historical SocietyPhotograph - Kiewa River in flood at Clover Dam

As part of the push to cut electricity costs and diversify supply, the Victorian Government (circa 1930) implemented the conversion strategy from mainly brown coal supply to hydro - electricity. The Kiewa Hydroelectric Scheme became the largest scheme of its kind in the State Of Victoria and the second largest scheme in Australia. Clover Dam and Power Station were built by the State Electricity Commission of Victoria as part of the Kiewa Hydro Electric Scheme from the late 1930's to the early 1940's. This dam was constructed to supply water to feed four turbines (62 mega watts) at the West Kiewa Power Station. This was at the forefront of sustainable "Green" energy. Costs associated with power supplies is still a major incentive of governments, however environmentally friendly alternatives such as wind and nuclear have also made inroads. The Kiewa valley and its surrounding alpine catchment were looked at(Victorian State Government), from the beginning of the twentieth century as a source of alternate power for an ever-increasing demand for electricity by growing population and heavy industrial areas within Melbourne City and State regions. Construction of dams, such as Clover Dam provided the large quantity holding areas of water required to turn the turbines at the various power stations to provide the electricity needed. The impact of these controls by moderating water run-off from the alpine regions is beneficial in reducing flooding from thawing of snow on the alps. This by-product allows agriculture and grazing to be less vulnerable to seasonal flooding thereby resulting in a more stable annual production level.Black and white photograph of Clover Dam with Kiewa River in flood. .5mm white boarder on 3 sides of photo.Handwritten on back of photograph in black pen - Kiewa in flood. Clover Dam.clover dam, secv -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPhotograph - Clover Dam

As part of the push to cut electricity costs and diversify supply, the Victorian Government (circa 1930) implemented the conversion strategy from mainly brown coal supply to hydro - electricity. The Kiewa Hydroelectric Scheme became the largest scheme of its kind in the State Of Victoria and the second largest scheme in Australia. Clover Dam and Power Station were built by the State Electricity Commission of Victoria as part of the Kiewa Hydro Electric Scheme from the late 1930's to the early 1940's. This dam was constructed to supply water to feed four turbines (62 mega watts) at the West Kiewa Power Station. This was at the forefront of sustainable "Green" energy. Costs associated with power supplies is still a major incentive of governments, however environmentally friendly alternatives such as wind and nuclear have also made inroads. The Kiewa valley and its surrounding alpine catchment were looked at(Victorian State Government), from the beginning of the twentieth century as a source of alternate power for an ever-increasing demand for electricity by growing population and heavy industrial areas within Melbourne City and State regions. Construction of dams, such as Clover Dam provided the large quantity holding areas of water required to turn the turbines at the various power stations to provide the electricity needed. The impact of these controls by moderating water run-off from the alpine regions is beneficial in reducing flooding from thawing of snow on the alps. This by-product allows agriculture and grazing to be less vulnerable to seasonal flooding thereby resulting in a more stable annual production level.Black and white photograph of Clover Dam buildings and Kiewa River. Has a .4cm white border around photograph Printed on bottom left corner of photograph in white - Clover Flatclover dam, secv -

Kiewa Valley Historical Society

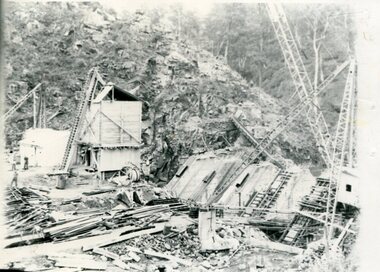

Kiewa Valley Historical SocietyPhotographs x 2 - Clover Dam, Circa 1940's

As part of the push to cut electricity costs and diversify supply, the Victorian Government (circa 1930) implemented the conversion strategy from mainly brown coal supply to hydro - electricity. The Kiewa Hydroelectric Scheme became the largest scheme of its kind in the State Of Victoria and the second largest scheme in Australia. Clover Dam and Power Station were built by the State Electricity Commission of Victoria as part of the Kiewa Hydro Electric Scheme from the late 1930's to the early 1940's. This dam was constructed to supply water to feed four turbines (62 mega watts) at the West Kiewa Power Station. This was at the forefront of sustainable "Green" energy. Costs associated with power supplies is still a major incentive of governments, however environmentally friendly alternatives such as wind and nuclear have also made inroads. The Kiewa valley and its surrounding alpine catchment were looked at(Victorian State Government), from the beginning of the twentieth century as a source of alternate power for an ever-increasing demand for electricity by growing population and heavy industrial areas within Melbourne City and State regions. Construction of dams, such as Clover Dam provided the large quantity holding areas of water required to turn the turbines at the various power stations to provide the electricity needed. The impact of these controls by moderating water run-off from the alpine regions is beneficial in reducing flooding from thawing of snow on the alps. This by-product allows agriculture and grazing to be less vulnerable to seasonal flooding thereby resulting in a more stable annual production level. Photographs also document early engineering and building techniques used in the construction of dams and power stations during the 1940’s and 1950’s. Note the lack of safety equipment and suitable work attire worn by construction workers on the sites 1. Black and white photograph of Clover Dam under construction. Has a .5cm white border around photo 2. Black and white photograph of Clover Dam under construction showing workmen at work. Has a .5cm white border around photo Written in pencil on back of both photographs - Clover Damclover dam, secv -

Kiewa Valley Historical Society

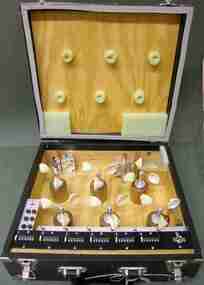

Kiewa Valley Historical SocietyTester Direct Current, mid 1900's

This tester was used between 1950 and 1980's. As part of the Occupation, Health and Safety requirements, equipment used to monitor the performance of electricity producing generators, regularly, hand held testers were used to check the insulation and the "earth" pin were up the the required operational levels. As the generators and their ancillary monitoring equipment was spread over a large area and cumbersome to service small hand held devices were required. These had to always be safe for the user to operate. A selected range of high quality meters were recalibrated every two years in the Meter and Calibration Laboratory at Yarraville(near Melbourne) This meter is very significant to The Kiewa Hydro Electricity Scheme because it was an integral part of maintaining the electricity producing water driven generators of the power stations. The reason why this meter was so essential is that provided the safety check on equipment used to monitor each Hydro Generator that they were complying within the grid network parameters. Grid parameters are set so that if there is an electrical fault on the system, that fault can be attended to with a very small change in the output stability of each generator. It is essential that the voltage of the network remain within the set limits. Generators are at Dartmouth, Mackay, Clover, West Kiewa, Yarrawonga, Cain Curran and three Power Stations in the Thornton area.This hand driven current generator produces 500 volts by winding the handle(on funnel curved side) to keep the voltage constant(one minute per test). The whole body is made from caste aluminium. One of the functions of this meter is to test the isolation resistance of any equipment being tested. This is to see if that equipment is safe to handle(no electrical shocks). The second function is to test the earth pin of any portable electrical equipment. The turn key on one side can direct which function is required(marked insulation or continuity). On the top side(enclosed in a glass fronted marked scale) is a continuity scale(top) and an insulation scale(bottom). This is covered , when not in use by "flip up" lid with manufacturer's details and name of the instrument. Opposite the winder are two screw tight knobs. One marked earth(left side) and one marked line(right side). On the top and next to the glass windowed scales in a post manufacture SEC Vic equipment equipment ID number. For carrying purposes there is chromed steel (fold together) handle.The bottom of the unit has two metal "feet" 150mm long by 114mm wideManufacturer's details on top side "MEG" underneath "INSULATION AND CONTINUITY TESTER" below this "constant 500 VOLT pressure" below this "REGISTERED MEG MEGGER TRADE MARK" below this "REG DESIGN NO. 690326" below this "UNITED KINGDOM PATENT Nos. 193746, 197178, 198182, 202062, 202398, 204649, 350715" below this "SUPPLIED BY THE GENERAL ELECTRIC Co. Ltd OF ENGLAND" below this "MAGNET HOUSE, KINGSWAY LONDON W.C.2" 'sec vic kiewa hydro scheme, alternate energy supplies, alpine feasibility studies temperature, rainfall -

Federation University Historical Collection

Federation University Historical CollectionScientific Instument, Anemometer, 6 Cup Model: Serial No. AM1-6-8875, c1975-1980

An anemometer is intended for determining velocity distribution over an area or in a boundary layer. This item was purchased by Mechanical Engineering upon the request of Dr Len Cubitt, to determine wind speed at various heights above the ground. Investigation related to wind energy harnessing projects, including that undertaken by MARS Industries in Ballarat. The 6-cup anemometer had a marked superiority in tests over the 3-cup anemometer and also had lower starting speeds.Anemometer in a case complete with mounting blocks, but without electric leads for connecting the black finished wood case which also incorporates pulse counters and connections for power supply and for other logging instruments. Serial Number AM1-6-8875 Name Plate on lid between clasps. 'RIMCO" RAUCHFUSS INST & STAFF Pty Ltd 12 Monomeath Drive, Mitcham, Vic. 3132" scientific instrument, anemometer, len cubitt, mechanical engineering, energy harnessing projects, starting speeds -

Box Hill Historical Society

Box Hill Historical SocietyPhotograph - Consolidated Electricity Services Centre

Unveiling of a plaque at the opening of the Consolidated Electricity Services Centre, by the Hon. D R White, Minister for Minerals and Energy on Saturday 24th November 1984. On the left is John Wilkins, Chief Electrical Engineer with the Box Hill Electric Supply.Black and white photographbox hill electric supply, electricity, opening ceremonies, wilkins> john, white> david