Showing 83 items matching "water boilers"

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Water Boiler, Jackson Boilers Ltd, 1920s

... Water Boiler...Patent Water Boilers... and sheet metal works made this tube water boiler. It was a fitting...Water boiler, free standing Jackson's Tube boiler. A tall... and sheet metal works made this tube water boiler. It was a fitting ...Jackson Boilers Ltd., brass founders, electro platers and sheet metal works made this tube water boiler. It was a fitting in the vessel Reginald M, a small cargo ship built at Port Adelaide in 1922 and named after her builder and first owner, John Murch. The Reginald M was launched at Largs Bay, South Australia, in 1922 to carry cargo around South Australia that included guano, barley, wool, horses, cattle, timber, explosives, potatoes, shell grit, and gypsum. It passed through numerous owners over the years and primarily maintained its purpose as a cargo vessel. In 1975, the decommissioned Reginald M was purchased by Flagstaff Hill Maritime Museum as an attraction. Although restoration efforts were undertaken and maintained for the craft above the water line, deterioration occurred below the surface and resulted in the ship being unsafe for visitors to board. It was broken up and removed from Flagstaff Hill in 2018, but items such as the historical boiler remain in Flagstaff Hill’s Collection. JACKSON BOILERS LTD.: - In 1911, Henry Jackson was the Managing Director at Jackson Boilers Ltd. He had gained around 30 years’ experience as a tin plate worker, plumber and gas fitter at Ilkey in 1881, then at Leeds by 1901. By 1921, he had changed employment from Jackson Boilers to Managing Director of Patent Water Boilers. During World War I, Jackson Boilers Ltd of Leeds performed war work like many other manufacturers at that time. The firm made cases for the explosive picric acid and electroplated fuse hole plugs. In 1918, the firm employed 15 males and 19 females. Jacksons Boilers became very successful throughout the first half of the twentieth century with showrooms and sales offices in Scotland, the Midlands and Southern England. It also had an office in Dublin, Ireland. In the post-war 1920s, the firm’s production included instantaneous water boilers and coffee machines for cafes, restaurants and canteens. Jackson Boilers also began to supply shipping lines with catering water boilers for their ships. The firm applied for a USA patent for the tube boiler in 1930, for the design which appears to have been invented in 1926. A 1971 advertisement adds the credentials, Members of the Catering Equipment Manufacturers’ Association. The tube water boiler was designed specifically for use in a ship's restaurant or dining area and patented by Jackson Boilers Ltd. of Leeds. The boiler is significant as a patented design, illustrating the evolution of maritime, commercial and domestic water boilers that have led to many innervations and improvements in today's boilers that are used in heating and in producing hot water for domestic and catering use. It is also significant as it is one of the earlier boilers the Jackson company made in the early 1920s before they applied for a US patent on their revised design in 1926.Water boiler, free standing Jackson's Tube boiler. A tall metal cylindrical stand with a metal sphere on top and several pipe fittings on the sides. A brass tap with a lever handle is connected to the front. A plaque with maker's details is attached under the tap. Details are also impressed into the cylinder above the tap.Jackson Boilers Leeds Ltd. "JACKSON'S PATENT" . Other details indecipherable. flagstaff hill maritime museum and village, flagstaff hill maritime museum, flagstaff hill, maritime museum, maritime village, warrnambool, great ocean road, leeds, jackson boilers ltd, jackson boilers, henry jackson, brass founders, electro platers, sheet metal works, patent water boilers, leeds manufacturer, tube water boiler, domestic boiler, tube domestic boiler, tube boiler, water heaters, water boilers, self-feeding water boilers, sheet metal work instantaneous water heaters, engineering, allied trades, metal workers, metal trade, food machinery, hospitality equipment, ship equipment, ship water boiler, ship heater, catering boilers, café boiler, restaurant boiler, canteen boiler, catering equipment manufacturers’ association, cema, kitchen equipment, kitchen appliance, war work, world war i, wwi, picric acid, picric acid cases, fuse hole plugs, electro plated fuse hole plugs, reginald m, cargo ship, port adelaide, 1922, john murch -

Federation University Historical Collection

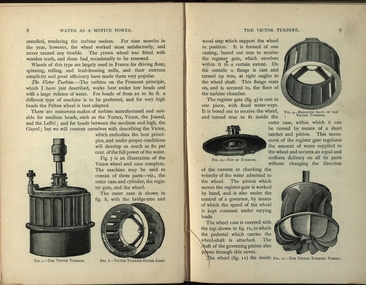

Federation University Historical CollectionBook, Machinery for Metalliferous Mines, 1894, 1894

... ventilation oil engine california america water steam boilers steam ...The 1st edition of this famous work, giving an excellent account of the machinery used in late 19th century metal mining in the UK and overseas is very rare. It covers a wide range of equipment - pumps, steam engines, drills, winding engines, stamps & concentration mills, aerial ropeways, tramways and early uses of electricity etc. Brown hard cloth covered book. xvi 564 pages with additional advertisements, with over 300 illustrations and drawings, some fold out. Chapters include Water as a motive power, Wind engines and ventilating machinery, Steam boilers/engines and oil engines, hoisting machinery, draining of Mines, pumping engines, rock drilling machinery, boring machinery, concentration machinery, sizing and classifications trommels, joggers and jigging, fine concentration, milling of gold ores, milling of silver ores, amalgamation plates and machinery, dry and roasting machinery, chlorination and cyandide processes for the extraction of gold, electricity as a motive power for mining, electric lighting and blasting, aerial wire ropeways, transport by rail and road. There a a number of lovely line illustrations in the book including: Poncelot's undershot waterwheel; Fromont furnace;Victor turbine; Pelton waterwheel; Root's positive blower;Cross section and front elevation of Lancashire boiler; Robey's Compound Mill Engine; Portable Winding Plant; Iron Pit Head Gear ; Loading Arrangement in an Incline Shaft; kibble; Worthington Pump; California Pump; Scram's Air Compressor; Rock drill Bits; Special Sharpening tools; Boring tools;Rotating Picking table; Ore Feeder; roller crusher; stamp battery; round buddle; slime table; vanner; amalgamating plant; belt elevator;roasting furnace;splicing wire rope; capel; tipping waggon;mining, cornish pump, linkenbach table, water wheel, ventilation, oil engine, california, america, water, steam boilers, steam engines, oil engines, pumpimg, rock drilling, boring, jiggers, milling, silver, gold, drying and roasting, chlorination, cyaniding, lead, zinc, copper, electricity, electric lighting, wire ropes, transport, wind engine, poppet head -

Federation University Historical Collection

Federation University Historical CollectionBook, D.C. Davies et al, Metalliferous Minerals and Mining, 1892, 1892

... boring dynamite electricity blasting horse whims water wheels ...Brown hard covered, illustrated book of 518 pages. It includes a bookplate of the Ballarat Ironworkers' and Polytechnical Association Library Rules. The book was bequethed to the Ironworkers' Association by the late James Oddie.mining, minerals, quartz, nova scotia, california, germany, ural mountains, gold deposits, virginia, new england, new brunswick, brazil, australia, new south wales, mount morgan, new zealand, africa, statistics, india, phillipines, aruba island, silver, russia, nevada, ruby hill, nevada, utah, emma mine, nevada, colarado, red mountain district, colorado, yankee girl mine, arizona, mexico, peru, bolivia, chili\copper, south africa, italy, austria, norway, swedan, france, cornwall, dolcoath mine, sandstone, parys mines of anglesea, carnarvonshire, cardiganshire, wicklow, ireland, mississippi valley, wisconsin, lake superior, wyoming, cuba, jamaica, venezuela, south australia, york peninsula, flinders ranges, japan, tin, banca, malaysia, bohemia, saxony, sweden, spain, cligga point, rin lodes of cornwall, andalusia, belgium, shropshire, isle of man, durham, westmoreland, limestone, flintshire, dengigshire, canada, lead, zinc, siberia, hungary, silesia, sardinia, algeria, ireland, new jersey, iron, lancashire, missouri, michigan, superstitions, equipment, cages, stopes, winzes, timbering, ventilation, fans, drilling, boring, dynamite, electricity, blasting, horse whims, water wheels, boilers, petterson's elephant ore stamp, stamper battery, jogs, linkenbach table, panning, cradle, quartz mining, hydraulic mining, alluvia; mining, altai mountains, north wales, neugluck mine, freiberg, christbescherung mine, drei prinzen lode, miask, woodville, virginia, gongo soco, brazil, sierra nevada, california, st john del rey mine, brazil, leydenberg gold field, south africa, banket reefs, transvaal, kongsberg, norway, santa rosa mine, peru, huelva, spain, dolcoath mine, cornwall, parys mine, anglesea, waterbury copper mine, lake superior, copiapo, chilli, altenberg, saxony, whea; uny, cornwall, wast wheel mine. redruth, cornwall, cligga point, cornwall, old hewas mine, cornwall, hartz, germany, snailbeach mine, shropshire, llangynog, north wales, van mine, mongomeryshire -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - BILL ASHMAN COLLECTION: PRINTED MATERIAL ON WATER TREATMENT

... For Water Treatment in Boilers, Testing Water by the Volumetric... of water, The Need For Water Treatment in Boilers, Testing Water ...Three small publications on treatment of water, The Need For Water Treatment in Boilers, Testing Water by the Volumetric Method, Threshold Treatment With Calgon.books, technical, chemistry -

Melbourne Tram Museum

Melbourne Tram MuseumPhotograph, The Herald, "Happy at their work", 17/1/1948

... around the hot water boiler at Hanna St depot, all smiling... around the hot water boiler at Hanna St depot, all smiling ...Photograph shows five tramway crews with their pannikins around the hot water boiler at Hanna St depot, all smiling and except for one, wearing their caps. From The Herard, 17 Jan. 1948 - Trove link. Story includes conductress Beryl Hall leaning out from a tramcar doorway. The Trove link has a story about the end of a 13 day strike by Melbourne tram workers - see reference for Trove link and background to the photo.Yields information about a 13 day strike and crews returning to work.Black and white photograph with an undated press cutting on the rear. "Vict Tramways" on rear in pencil.tramcars, tramways, hanna st depot, south melbourne depot, crews -

Puffing Billy Railway

Puffing Billy RailwaySteam Driven Weir Pump, 1900s

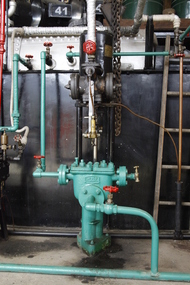

... used for various duties from pumping oil fuel and feed water... pumping oil fuel and feed water for boilers, to draining bilges ...Weir Pumps - these types of vertical pumps were used extensively with both land and marine steam pumps. The pumps were also used for various duties from pumping oil fuel and feed water for boilers, to draining bilges on steam ship[s They are a single cylinder, double acting vertical pumps used by G. & J. Weir Ltd. , of Cathcart, Glasgow Historic - Weir Vertical PumpSteam Driven Weir Pump Green and Black with metal parts.No. B49717puffing billy, weir, steam pump -

Puffing Billy Railway

Puffing Billy RailwayWeir Pump ( no. 2 ), Vertical ( no. 2 )

... oil fuel and feed water for boilers, to draining bilges... from pumping oil fuel and feed water for boilers, to draining ...Weir Vertical Pump Weir Pumps - these types of vertical pumps were used extensively with both land and marine steam pumps. The pumps were also used for various duties from pumping oil fuel and feed water for boilers, to draining bilges on steam ship[s single cylinder, double acting vertical pumps used by G. & J. Weir Ltd. , of Cathcart, Glasgow .Weir Vertical Pump ( no. 2 ) - Steel vertical pumpWeirpuffing billy, fluid pump, weir, vetical pump -

Bendigo Historical Society Inc.

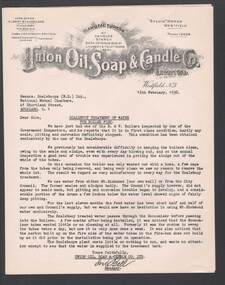

Bendigo Historical Society Inc.Document - BILL ASHMAN COLLECTION: CORRESPONDENCE

... of water for boiler feed. Mentioned is how clean the boiler were... of water for boiler feed. Mentioned is how clean the boiler were ...Four copies of a typed letter from ? Bell, Manager of the Union Oil, Soap & Candle Co. Ltd. To Scalebuoys (N. Z.) Ltd., dated 16 February, 1938. Letter refers to Scalebuoy treatment of water for boiler feed. Mentioned is how clean the boiler were of scale and sludge. Letter typed on paper with printed letterhead.sciences, instruments - general, scalebuoy, bill ashman collection - correspondence, union oil soap & candle co limited, scalebuoys (n.z.) ltd, ? bell -

Bendigo Historical Society Inc.

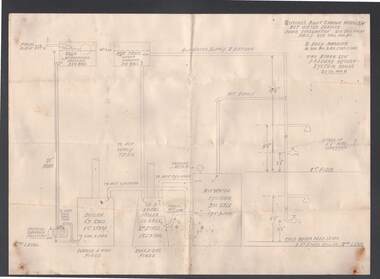

Bendigo Historical Society Inc.Document - BILL ASHMAN COLLECTION: CORRESPONDENCE

... are situated, capacity of hot water cylinder and boilers. Also... water system for Gifford's Mount Gambia Hotel, SA. Plan includes ...Detailed pencil drawn plan of the hot water system for Gifford's Mount Gambia Hotel, SA. Plan includes where Scalebuoys are situated, capacity of hot water cylinder and boilers. Also measurements of the height of taps and shower.sciences, bill ashman collection - correspondence, gifford's mount gambia hotel sa -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - BILL ASHMAN COLLECTION: CORRESPONDENCE

... with the Scalebuoy treatment of the water for Boiler Feed that they want... of the water for Boiler Feed that they want to install another one ...Two typed copies of a letter from ? Bell, Manager of the Union Oil, Soap & Candle Co. Limited to Scalebuoys (N.Z.) Ltd., dated 7 March, 1938. He mentions that they are so satisfied with the Scalebuoy treatment of the water for Boiler Feed that they want to install another one for a small boiler. He asks to let him know what is required. Letter has printed letterhead.sciences, instruments - general, scalebuoy, bill ashman collection - correspondence, union oil soap & candle co limited, scalebuoys (n.z.) ltd, national mutual chambers auckland, bell -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - MINING REPORTS - GOLDEN AGE MINE MANAGER'S REPORT

... of no water for boilers. Also a M. D. Report mentioning crushings... air to mines north, mine idle on account of no water ...Handwritten notes by Albert Richardson, with typed copy, from the Golden Age Mine Manager, S. Richards, Reports Aug 6th 1907, Sep 3 1907 and Jan 8 1907. Reports mention testing Air Compressor, supplying air to mines north, mine idle on account of no water for boilers. Also a M. D. Report mentioning crushings, gold yield, depth of shaft, Calls and Dividends.document, gold, mining reports, mining reports, golden age mine manager's report, s richards, m d report, j r extended -

Puffing Billy Railway

Puffing Billy RailwayVertical Pump, Weir, 1948

... used for various duties from pumping oil fuel and feed water... pumping oil fuel and feed water for boilers, to draining bilges ...Weir Pumps - these types of vertical pumps were used extensively with both land and marine steam pumps. The pumps were also used for various duties from pumping oil fuel and feed water for boilers, to draining bilges on steam ship[s They are a single cylinder, double acting vertical pumps used by G. & J. Weir Ltd. , of Cathcart, Glasgow The large pump serial number 231703 was built in 1948 and worked at the old Victoria Brewery in East Melbourne before coming to the Museum in 1985. Historic - Weir Vertical Pump used at the old Victoria Brewery in East Melbourne The large pump serial number 231703 was built in 1948 and worked at the old Victoria Brewery in East Melbourne before coming to the Museum in 1985.Weir Vertical Pump - Large Steel PumpWeir puffing billy, weir vertical pump, victoria brewery -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Tool - BILL ASHMAN COLLECTION: SCALEBUOY SAMPLE CASE

... and boilers by supposedly "softening" the water. ... and boilers by supposedly "softening" the water. scalebuoy W. Abbott ...Leather display case holding scalebuoys belonged to Bill Ashman, who was a salesperson for the Abbott company. A Scalebuoy is a handheld water treatment device, invented by Hartley Abbott and patented under the name of the Bendigo Electronic Company, designed to prevent scale buildup in water vessels and boilers by supposedly "softening" the water. Brown leather case with 2 keys containing 4 scalebuoys of various types and sizes held in a blue velvet holder & a pocket in lid holding 9 publications by W.N.Abbott on the uses of Scalebuoys along with 2 letters attesting to the success of Scalebuoys.scalebuoy, w. abbott -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - BILL ASHMAN COLLECTION: CORRESPONDENCE

... for an illustrated descriptive brochure on the treatment of boiler feed water... for an illustrated descriptive brochure on the treatment of boiler feed water ...Handwritten letter from Mr. Barrett asking for an illustrated descriptive brochure on the treatment of boiler feed water as advertised in 'The Power & Works Engineer'. Letter dated 16/7/38.sciences, instruments - general, scalebuoy, 'the power & works engineer' -

Puffing Billy Railway

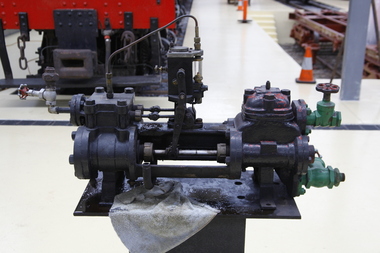

Puffing Billy RailwaySteam Pump, Worthington - Simpson steam driven pump, circa 1917

... by side. Worthington pumps of this size would feed a small boiler... a small boiler with water whilst larger similar pumps up to six ...Worthington Steam Pump This type of horizontal duplex steam pump was most commonly made by Worthington-Simpson Ltd., England. It was really two double-acting pumps placed side by side. Worthington pumps of this size would feed a small boiler with water whilst larger similar pumps up to six feet long would be used to pump bulk liquids. This type of horizontal duplex steam pump was most commonly made by Worthington-Simpson Ltd., England. It was really two double-acting pumps placed side by side. Worthington pumps of this size would feed a small boiler with water whilst larger similar pumps up to six feet long would be used to pump bulk liquids.Historic - horizontal duplex steam pump made by Worthington - SimpsonSteam Pump made of Steel, bronzeWorthington-Simson ltd Newark-on-trent England No 5073449 Size 4 1/2 x 2 3/4 x 4puffing billy, worthington steam pump, worthington - simpson -

Bendigo Historical Society Inc.

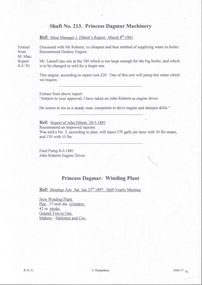

Bendigo Historical Society Inc.Document - MINING REPORTS - EXTRACTS FROM PRINCESS DAGMAR MINE MANAGER'S REPORT

... reported on include supply of water to boiler, new engine- driver... supply of water to boiler, new engine- driver, stolen gold ...Two copies of handwritten extracts from the Mine Managers of the Princess Dagmar Mine, Garden Gully line. Mine managers were J. Ebboth, Charles Gambetta, A. Williams and S. Richards. Subjects reported on include supply of water to boiler, new engine- driver, stolen gold, engine house destroyed by fire, painting and cementing the chimney stack, sale of galvd iron and oil barrels, contractors erecting machinery, crushings, repair to shaft, new ropes, broken indicator on winding engine and work stopping and recommencing seven months later. Reports range in date from 1881 to 1914.document, gold, mining reports, extracts from princess dagmar mine manager's report, john ebbott, mr roberts, mr lansell, john roberts, bendigo advertiser sat jan 23rd 1897, harkness and coy, almond williams, mr r eddy, f warren, s richards -

Bendigo Historical Society Inc.

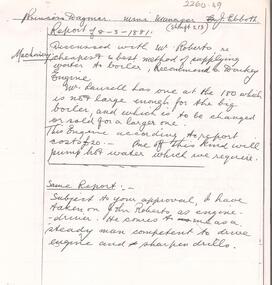

Bendigo Historical Society Inc.Document - ALBERT RICHARDSON COLLECTION: PRINCESS DAGMAR MINE, GARDEN GULLY LINE

... water to boiler, recommend a donkey engine. Mr. Lansell has one... method of supplying water to boiler, recommend a donkey engine ...4 page handwritten document, (copy) detailing some of the Mine Manager's reports for Princess Dagmar mine 1881 - 1914. Example: Reportof 8.3.1881, shaft 213, Mine Manager J. Ebboth. 'Discussed with Mr. Roberts re cheapest and bst method of supplying water to boiler, recommend a donkey engine. Mr. Lansell has one at the 180 which is not large enough for the big boiler and which is to be changed or sold for a larger one. This engine according to report costs 20 pounds. One of this kind will pump hot water which we require. Subject to your approval I have taken on John Roberts as engine driver. He comes to me as a steady man competent to drive engine and sharpen drills.'bendigo, mining, princess dagmar -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - BILL ASHMAN COLLECTION: CORRESPONDENCE

... the benefits of using scalebuoys in the water to the boilers and hot... in the water to the boilers and hot water systems. It had removed scale ...Three copies of a Letter, dated November 5, 1936, from Sister M. Monica to Sister Mary Gonzaga, relating to her the benefits of using scalebuoys in the water to the boilers and hot water systems. It had removed scale from the pipes. The only problem they had was the scale that had fallen off blocking the traps and that soon stopped. Scalebuoys were going to be installed in the cold water system as soon as there was more money to do it.Letterhead -St Josephs Hospital Phoenix Arizonasciences, instruments - general, scalebuoy, bill ashman collection - correspondence, st joseph's hospital arizona, sister mary gonzaga, mater misericordiae hospital auckland, mr herzog, st mary's hospital san francisco, mr abbott, sister mary monica -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - BILL ASHMAN COLLECTION: ALFLOC SYSTEM

... Eleven page article titled Water Softening in the Boiler... page article titled Water Softening in the Boiler ...Eleven page article titled Water Softening in the Boiler by the 'Alfloc' System. This is an internal method of conditioning boiler feed water and the use of coagulants designed to prevent scale formation in the boiler and accessory plant, to reduce corrosion to a minimum, and further to provide for those conditions in the boiler water which from present experience are believed to prevent the occurrence of caustic ombrittlement. Different chemicals were used to suit different types of water in different areas. Items discussed are: Summary, Introduction, External treatment, Internal Treatment, General Principles of the 'Alfloc' Internal Treatment, Precipitation of the Scale-forming Salts, Temporary Hardness, Permanent Hardness, Conditioning of the Precipitate - Floc Formation, Efficient Control of the Concentration of both Dissolved and Suspended Solids by Blowdown, Prevention of Corrosion, Testing and Control, The 'Alfloc' Reagents for Internal Treatment, 'Alfloc' Liquors, 'Alfloc' Briquettes, Alfloc' Powders, Methods of Application, Liquors - Stationary boilers and Locomotive boilers, Briquettes - Stationary boilers and Locomotive boilers, Powders, Blowdown, Sludge, Caustic Embrittlement, Control of 'Alfloc' System, Cost and Economies of 'Alfloc' Internal Treatment and 'Alfloc' Water Treatment Service. Listed on page 11 are ICIANZ Sales Offices the Australian States. Between pages 7 and 8 is a page of diagrams. They are: Showing method of feeding liquors to the feed tank of boilers for 'Alfloc' internal treatment, typical arrangement of pressure vessel and typical arrangement of 'Alfloc' by-pass feeder.sciences, instruments - general, scalebuoy, bill ashman collection, alfloc system, imperial chemical industries limited alkali division, alfloc liquors, alfloc briquettes, alfloc powders, imperial chemical industries of australia and new zealand limited, elder smith & co limited, chemical & textile agencies pty ltd -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Boiler, T & F Johnson, boilermakers, late 19th century

... boiler and the water heats as it circulates around them. Another... boiler and the water heats as it circulates around them. Another ...A steam boiler like this late 18th century boiler, is often called a colonial boiler. Steam boilers were used in factories throughout Australia, mounted over similar designs of brick furnaces. This heat from the fire travels through the tubes in this fire tube boiler and the water heats as it circulates around them. Another kind of boiler is a water tube boiler, in which the water is inside the tubes and the heat of the combustion surrounds the tubes. The boiler in our collection burned wood as fuel but others of this design could also burn coal, coke, gas and liquid fuels. The boiler was made by T & F Johnson, boilermakers. In 1922 their factory was located at Coventry Street, South Melbourne. They were still advertising their 'Colonial, multi, vertical boilers, all sizes' at the same address in 1934. The connected pressure gauge, made in London by Dewrance, measures 0 to 400 pounds per square inch. John Dewrance is renowned as a pioneer of the steam locomotive in the early 19th century. He founded John Dewrance & Co. in South London in 1844. His son Sir John Dewrance took over in 1879. In 1939 the company became a subsidiary of Babcock & Wilcox, and was eventually owned by Emerson. How the boiler works: - A boiler is about two-thirds filled with water and heat is applied, in this case in the form of burning wood. The heat is transferred through the metal of the boiler to the water. When the water boils the steam rises to the top, and as it escapes from the boiler the steam pressure builds up in the steam space to later be released to do work; drive machinery such as ship and train engines, turbines, presses, wheels, and driving belts to operate looms and saws. The heat associated with the boiler can be used for preserving food, sterilising, factory manufacturing processes, and steaming wood for shipbuilding. Every boiler has several components fitted for safe operation: - - Safety valves - Gauge glass - Pressure gauge - Main steam stop valve - Water check valve - Blowdown valve - Manhole doorThe boiler is a significant item that gives us a snapshot of early Melbourne's industrial history. It is an example of the technological advancement during the Industrial Revolution where steam-driven machinery and motors could perform tasks more efficiently than manual labour. The makers were one of many boilermaker businesses in Melbourne during the early late-19th andearly 20th centuries. The maritime trade and skills of boilermaking are still learned and applied today. The Dewrance steam pressure gauge connected to the boiler was made by the London firms foundered by John Dewrance. He was renowned for developing the steam locomotive in the early 19th century.Boiler; a horizontal cylindrical underfired steam boiler. It is a multi-tubular design and is timber plank-clad, with brass fittings and pressure gauges. The boiler has an iron door at one end with a metal chimney above it. It is installed over a brick-enclosed solid fuel furnace. Two large, wood-mounted pressure gauges are connected to the boiler and have inscriptions. An inscription is on a red, cast iron plaque above the boiler door. The boiler's maker is T & F Johnson, South Melbourne. One of the pressure gauges was made by Dewrance, London..Maker's plate: "T & F JOHNSON / BOILERMAKERS / SOUTH MELBOURNE" Pressure gauge: "POUNDS PRESSURE / PER [square] INCH / DEWRANCE LONDON"flagstaff hill, warrnambool, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, boiler, multi tube boiler, steam boiler, steam technology, underfired boiler, horizontal boiler, timber clad boiler, steam power, industrialisation, boilermakers, south melbourne, dewrance, john dewrance, pressure gauge, dewrance pressure gauge, t & f johnson, london, steam engine, steam locomotive, pounds per square inch, 19th century, steam machine, johnson tyne foundry, colonial boiler, fire tube boiler -

Tarnagulla History Archive

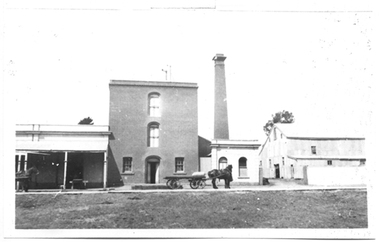

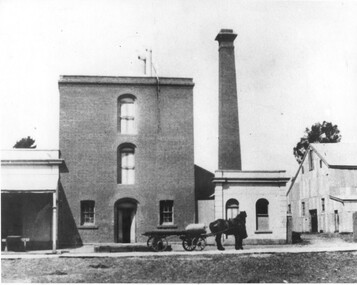

Tarnagulla History ArchivePhotograph - Photograph: Workers at Tarnagulla Flour Mill, c. 1873-1920, probably around 1900

... to Company's Dam to obtain water for the Mill's boilers. Steam was got... to Company's Dam to obtain water for the Mill's boilers. Steam was got ...Williams Family Collection. A meeting was called at the Golden Age Hotel on 11th June 1868 when it was resolved to build a flour mill. Tenders were called by H.C. Bristol, in the Tarnagulla Courier of January 10, 1874, for the erection of the mill. Building of the Mill commenced in 1874. Pipes were laid to Company's Dam to obtain water for the Mill's boilers. Steam was got up for the first time on 30th March, 1882. A boiler burst about April 29th. Two men (J.H. Smith and W. Hargreaves) died as a result and two others were seriously injured. The mill commenced operations on 13th June 1882 with Mr. W. Fitzgerald as manager. Thomas Comrie was the proprietor and was responsible for the Mill being built. The Mill operated with grinding stones until 1899 when new rollers and a considerable amount of new equipment was installed, including a new, more powerful engine to drive the Mill. In January 1901, 6,000 bags of wheat were received weekly and it was a common sight to see the streets lined with wagons. In 1913, 15,000 bags of wheat were bought at three shillings and four pence per bushell. In January 1914, wheat came in at the rate of 1500 bags a day with 20,000 bags in storage. Thomas Comrie died on 4th August 1910. The Mill was carried on by his executors, then closed for a short period prior to being sold in September 1918 to a Mr. O. Albert of Talbot. Albert operated the Mill for a few years but during the 1920s it was closed down and then pulled down. It was later re-erected at Mildura where it operated for many years.Monochrome photograph depicting workers at Tarnagulla Flour Mill, some loading or unloading a horse-drawn cart. An original photograph, mounted on card. Handwritten on back: 'L.Williams Tarnagulla' and 'Leo Fitzgerald' and full recipe for a red currant dessert.tarnagulla -

Tarnagulla History Archive

Tarnagulla History ArchivePhotograph of Flour Mill, Tarnagulla, Flour Mill, Tarnagulla, circa 1920

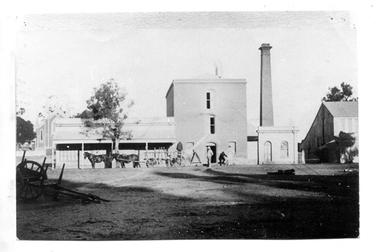

... commenced in 1874. Pipes were laid to Company's Dam to obtain water... to Company's Dam to obtain water for the Mill's boilers. Steam was got ...Murray Comrie Collection. Information written by Murray Comrie: A meeting was called at the Golden Age Hotel on 11th June 1868 when it was resolved to build a flour mill. Tenders were called by H.C. Bristol, in the Tarnagulla Courier of January 10, 1874, for the erection of the mill. Building of the Mill commenced in 1874. Pipes were laid to Company's Dam to obtain water for the Mill's boilers. Steam was got up for the first time on 30th March, 1882. A boiler burst about April 29th. Two men (J.H. Smith and W. Hargreaves) died as a result and two others were seriously injured. The mill commenced operations on 13th June 1882 with Mr. W. Fitzgerald as manager. Thomas Comrie was the proprietor and was responsible for the Mill being built. The Mill operated with grinding stones until 1899 when new rollers and a considerable amount of new equipment was installed, including a new, more powerful engine to drive the Mill. In January 1901, 6,000 bags of wheat were received weekly and it was a common sight to see the streets lined with wagons. In 1913, 15,000 bags of wheat were bought at three shillings and four pence per bushell. In January 1914, wheat came in at the rate of 1500 bags a day with 20,000 bags in storage. Thomas Comrie died on 4th August 1910. The Mill was carried on by his executors, then closed for a short period prior to being sold in September 1918 to a Mr. O. Albert of Talbot. Albert operated the Mill for a few years but during the 1920s it was closed down and then pulled down. It was later re-erected at Mildura where it operated for many years. This is a poor copy of an older original. Copy probably made by Murray Comrie in the late 1960s. Monochrome photograph of the Flour Mill in Tarnagulla, around 1920.tarnagulla, commerce, agriculture, food production, mill, milling, horses, transport, buildings, commercial road, main street -

Tarnagulla History Archive

Tarnagulla History ArchivePhotograph of Flour Mill, Tarnagulla, Flour Mill, Tarnagulla, circa 1920 (original image)

... commenced in 1874. Pipes were laid to Company's Dam to obtain water... to Company's Dam to obtain water for the Mill's boilers. Steam was got ...Murray Comrie Collection. Information written by Murray Comrie: A meeting was called at the Golden Age Hotel on 11th June 1868 when it was resolved to build a flour mill. Tenders were called by H.C. Bristol, in the Tarnagulla Courier of January 10, 1874, for the erection of the mill. Building of the Mill commenced in 1874. Pipes were laid to Company's Dam to obtain water for the Mill's boilers. Steam was got up for the first time on 30th March, 1882. A boiler burst about April 29th. Two men (J.H. Smith and W. Hargreaves) died as a result and two others were seriously injured. The mill commenced operations on 13th June 1882 with Mr. W. Fitzgerald as manager. Thomas Comrie was the proprietor and was responsible for the Mill being built. The Mill operated with grinding stones until 1899 when new rollers and a considerable amount of new equipment was installed, including a new, more powerful engine to drive the Mill. In January 1901, 6,000 bags of wheat were received weekly and it was a common sight to see the streets lined with wagons. In 1913, 15,000 bags of wheat were bought at three shillings and four pence per bushell. In January 1914, wheat came in at the rate of 1500 bags a day with 20,000 bags in storage. Thomas Comrie died on 4th August 1910. The Mill was carried on by his executors, then closed for a short period prior to being sold in September 1918 to a Mr. O. Albert of Talbot. Albert operated the Mill for a few years but during the 1920s it was closed down and then pulled down. It was later re-erected at Mildura where it operated for many years. This is a poor copy of an older original. Copy probably made by Murray Comrie in the late 1960s. Monochrome photograph of the Flour Mill in Tarnagulla, around 1920. Cropped version of 2019.0047.tarnagulla, commerce, agriculture, food production, mill, milling, horses, transport, buildings, commercial road, main street -

Tarnagulla History Archive

Tarnagulla History ArchivePhotograph of Flour Mill complex, Tarnagulla, Flour Mill complex, Tarnagulla, circa 1882-1920

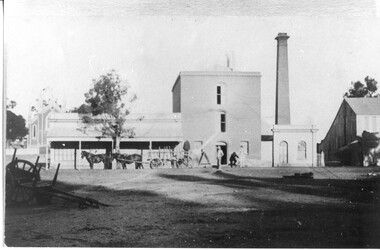

... commenced in 1874. Pipes were laid to Company's Dam to obtain water... to Company's Dam to obtain water for the Mill's boilers. Steam was got ...Murray Comrie Collection. Information written by Murray Comrie: A meeting was called at the Golden Age Hotel on 11th June 1868 when it was resolved to build a flour mill. Thomas Comrie was the proprietor and was responsible for the Mill being built. Tenders were called by H.C. Bristol, in the Tarnagulla Courier of January 10, 1874, for the erection of the mill. Building of the Mill commenced in 1874. Pipes were laid to Company's Dam to obtain water for the Mill's boilers. Steam was got up for the first time on 30th March, 1882. A boiler burst about April 29th. Two men (J.H. Smith and W. Hargreaves) died as a result and two others were seriously injured. The mill commenced operations on 13th June 1882 with Mr. W. Fitzgerald as manager. The Mill operated with grinding stones until 1899 when new rollers and a considerable amount of new equipment was installed, including a new, more powerful engine to drive the Mill. In January 1901, 6,000 bags of wheat were received weekly and it was a common sight to see the streets lined with wagons. In 1913, 15,000 bags of wheat were bought at three shillings and four pence per bushell. In January 1914, wheat came in at the rate of 1500 bags a day with 20,000 bags in storage. Thomas Comrie died on 4th August 1910. The Mill was carried on by his executors, then closed for a short period prior to being sold in September 1918 to a Mr. O. Albert of Talbot. Albert operated the Mill for a few years but during the 1920s it was closed down and then pulled down. It was later re-erected at Mildura where it operated for many years. The far left section of the complex was originally John Pierce's Southern Cross General Store, a wholesale grocer and spirit merchant. It was put up for sale after Pierce's death in 1871, and later incorporated into the Mill complex. This is a poor copy of an older original. Copy probably made by Murray Comrie in the 1960s. Monochrome photograph of men, horses and a wagon outside the Flour Mill complex formerly situated on the south east corner of King Street and Commercial Road in Tarnagulla. At far left the Methodist church is partially visible in the background. At far right is part of the Mill's storage shed. Same image as THA-2019.0211Written on reverse: 'M. Comrie'tarnagulla, commerce, agriculture, food production, mill, milling, horses, transport, buildings, commercial road, main street -

Tarnagulla History Archive

Tarnagulla History ArchivePhotograph of Flour Mill complex, Tarnagulla, Flour Mill complex, Tarnagulla, circa 1882-1920

... commenced in 1874. Pipes were laid to Company's Dam to obtain water... to Company's Dam to obtain water for the Mill's boilers. Steam was got ...Murray Comrie Collection. Information written by Murray Comrie: A meeting was called at the Golden Age Hotel on 11th June 1868 when it was resolved to build a flour mill. Thomas Comrie was the proprietor and was responsible for the Mill being built. Tenders were called by H.C. Bristol, in the Tarnagulla Courier of January 10, 1874, for the erection of the mill. Building of the Mill commenced in 1874. Pipes were laid to Company's Dam to obtain water for the Mill's boilers. Steam was got up for the first time on 30th March, 1882. A boiler burst about April 29th. Two men (J.H. Smith and W. Hargreaves) died as a result and two others were seriously injured. The mill commenced operations on 13th June 1882 with Mr. W. Fitzgerald as manager. The Mill operated with grinding stones until 1899 when new rollers and a considerable amount of new equipment was installed, including a new, more powerful engine to drive the Mill. In January 1901, 6,000 bags of wheat were received weekly and it was a common sight to see the streets lined with wagons. In 1913, 15,000 bags of wheat were bought at three shillings and four pence per bushell. In January 1914, wheat came in at the rate of 1500 bags a day with 20,000 bags in storage. Thomas Comrie died on 4th August 1910. The Mill was carried on by his executors, then closed for a short period prior to being sold in September 1918 to a Mr. O. Albert of Talbot. Albert operated the Mill for a few years but during the 1920s it was closed down and then pulled down. It was later re-erected at Mildura where it operated for many years. The far left section of the complex was originally John Pierce's Southern Cross General Store, a wholesale grocer and spirit merchant. It was put up for sale after Pierce's death in 1871, and later incorporated into the Mill complex. This is a reasonable copy of an older original. Copy probably made by Murray Comrie in the 1960s. Monochrome photograph of men, horses and a wagon outside the Flour Mill complex formerly situated on the south east corner of King Street and Commercial Road in Tarnagulla. At far left the Methodist church is partially visible in the background. At far right is part of the Mill's storage shed. Same image as THA-2019.0048Written on reverse: 'M. Comrie'tarnagulla, commerce, agriculture, food production, mill, milling, horses, transport, buildings, commercial road, main street -

Eltham District Historical Society Inc

Eltham District Historical Society IncDocument - Property Binder, 1184 Main Road, Eltham

... energy or water rated. Appliances in the timber kitchen include... energy or water rated. Appliances in the timber kitchen include ...Newspaper article: A sustainable award, Diamond Valley Leader, 1 November2006, Architect and building Llewellyn Pritchard won resource Efficiency Housing Award, finalist in HIA Greensmart Building of the Year Award. House – Environmental Leader (Published: Nillumbik Now and Then / Marguerite Marshall 2008; photographs Alan King with Marguerite Marshall.; p186) In 2006 environmental awareness was mushrooming in the community, which is reflected in the award-winning house at Main Road near Wattletree Road, Eltham. At first sight, the building appears a mix of a classic Eltham mud-brick house and an avant-garde building style. The crown of solar panels stretching along the width of the curved roof, indicates that this is no ordinary house. In fact it signals a new building trend of minimal impact on the environment. Yet it utilises the environment with high technical expertise to achieve comfort and cut running and maintenance costs. In recognition of this, its designer/builder, Conscious Homes, won the 2006 National HIA Greensmart Resource Efficiency Award. For Conscious Homes director, Llewellyn Pritchard, this house reflects a philosophy, strengthened by his connection with Aboriginal culture, through his foster siblings. Pritchard believes the sustainable way indigenous Australians lived and their spiritual connection with land, demonstrates how humanity is part of the ecology. His interest in environmental design stemmed from growing up in bushy Eltham Shire, with its mud-brick tradition. This was followed by studying Architecture at RMIT in the early 1980s, and learning about passive solar design. Pritchard says this house demonstrates that environmental sustainability is not about sacrifice, but about exceptional levels of occupant comfort, savings in running costs and modern fittings and appliances.1 The solar panels on the north roofs are intentionally obvious to make a statement about what the building is doing. But inside the systems are hidden and interactive with conventional services, such as the underground water tank. The house is water and energy self-sufficient and at 12 squares is much smaller than conventional houses, to minimise resources. Yet it accommodates his family of four with three bedrooms, a living/dining and kitchen area and a bathroom/laundry. Importantly the building is designed to last hundreds of years, by being able to be modified as the need arises, such as for commercial use. In this way the structure minimises its environmental impact. The solid double mud-brick walls (which are insulated) include steel beams and supporting frame, allowing the future removal or alteration of any section. The materials are local, recycled and of low toxicity where possible.2 Inside and out, the mud-brick is rendered and sealed with a combination of cement and sand and a mud-based coating in a soft golden hue increases its life. Inside, the golden-brown timber is plantation Mountain Ash and the concrete floors throughout – of local stone aggregate with a clear seal – have a natural looking random stone appearance. The house sustains a stable temperature of around 20 degrees, assisted by the concrete slab floor. The many large double-glazed windows and highlights (windows set high on walls) provide cross-flow ventilation. The north-facing living area maximises heating from the lower winter sun and is cooler in summer, because the sun is higher. Heating comes from a solar hydronic slab system. All appliances and fittings are high efficiency energy or water rated. Appliances in the timber kitchen include a gas stove and a dishwasher, using the building’s own power and water. French doors open from the living area to a deck, concealing the treatment system for all waste water. This is pumped through sub-soil drippers to the indigenous garden beds and no-dig vegetable patch. Below the carport is the 80,000-litre rainwater tank and at the back, the boiler room houses the solar boiler, water tank access, domestic water supply pump, filter gear and hydronic slab heating controls. The solar system is backed up with gas, which is needed to heat water only in winter. Gas used is less than one quarter of that for an average home with ducted heating. Excess power is fed back to the grid and the building uses about one quarter of the mains electricity of an average home. Other local builders have followed Pritchard’s lead in resource efficiency for minimal environmental impact.main road, eltham, businesses, llewellyn pritchard, hia greensmart building of the year award., efficiency housing award, conscious homes australia pty ltd -

Ringwood and District Historical Society

Ringwood and District Historical SocietyPhotograph, Boiler explosion at Ringwood station 20th June 1894 for engine 297R. "Heard in Box Hill"

... at 2001b. When the boiler was pumped full of water the pressure... at 2001b. When the boiler was pumped full of water the pressure ...Black and white photographs - 2 copiesTyped below photograph, "Boiler explosion at Ringwood station 20/6/1894. Heard in Box Hill". Article from newspapers:- Weekly Times (Melbourne, Vic. : 1869 - 1954), Saturday 27 January 1894, page 21 Official enquiry. The Board of Enquiry appointed by the Railway Commissioners to enquire into the causes of the boiler explosion which shattered the locomotive at Ringwood on Saturday night, assembled at the Railway department on Wednesday to commence its deliberations, The board consisted of Mr R. Fulton, engineer, C. W. McLean; engineer to the Marine Board, and Mr Mephan Ferguson, iron-founder. There is some difficulty at the outset about the constitution of the board; It was suggested that the Apt of Parliament contemplated that boards of experts, after the manner of the present one, needed, to have their appointments confirmed by the Governor-in-Council. The point, however, was not considered sufficiently important to prevent the board from proceeding with evidence. Robert Greyford, stationmaster at Ringwood, was the first witness. He said he saw the explosion on Saturday night at about twenty minutes to 8. There was a rush to the engine to see what had happened, and the driver and fireman were both found on the platform of the engine. The driver seemed badly hurt, but the fireman, to all appearances, was not so badly injured. They were both attended to and sent up to Melbourne by the last suburban train. Witness had a look at the engine and found the dome and all the plates round the boiler blown clean, away. The springs were also blown clean away. The Chairman (Mr Fulton) : Did you measure the distance ? Witness: Yes; one of the plates was 209 yards away. A piece from the top of the boiler 15 pounds in weight he found driven into the hard beaten track 410 yards away. Several pieces of boiler plate were found scattered at various distances. The buildings roundabout were injured. The Chairman; Did you notice anything peculiar about either of the driver or the fireman ? — No ; nothing wrong, with either of them. If the engine was blowing off at all, it must have been very light. In your opinion, were they perfectly sober ? — Perfectly. In approaching the station, is there a down or an up grade? — A very slight down grade. How is the road from Healesville ? — Up and down all the way. It is down, grade for about 200 yards coming into Ringwood station. They shut off ; steam about a quarter of a mile away, and come in at a good pace. They generally put on 15 pounds of steam while they are in the station. Mr Ferguson : Had the driver the usual load on ? — Yes ; about the usual load. Witness added that he had known the driver personally for about 10 years, and he had always been a careful, steady, sober man. He did not know the fireman so well. John Palmer, porter at Ringwood station, also saw the explosion. He was attending to the train on its arrival. He was knocked down by the force of the explosion. When he got up he saw the engine driver being carried into the office covered in blood. He noticed nothing peculiar about the driver and fireman, nor about the engine. Mr McLean : How far were you from the engine when you were knocked down ? — From ten to fifteen yards. William Paul, the guard of the train to which the injured locomotive Was attached, said he was looking at the engine at the very moment the explosion occurred. It seemed to come from exactly under the dome. The force of it took him off his feet. He was about 15 yards from the tender. When he rose he tried to reach the engine, but could not do so on account of the steam and coal dust. He called out to know whether any of the passengers were injured, and got no response, so that he concluded they were all right. All the lamps but about half dozen were extinguished by the force of the explosion, although the glass was not broken. He could testify most distinctly that the driver and fireman were both sober. The driver was a man who never drank. The steam started to blow off about a minute and a half before the explosion took place. The last place at which the engine took water was Healesville. The Chairman : Do yon know anything of the quality of the water there ? Is it creek water ? — Yes ; it comes from the Graceburn River. You never heard of its quality ?— No. How long have you known this engine on the road— About 13 months. Hew long have you known the driver on this line ? — About six weeks. I have known the fireman several years. The driver was a strict teetotaller, and I never saw the fireman take anything to drink in his life. Mr T. H, Woodroffe, chief mechanical engineer of the Victorian Railways, produced a report he had written to the secretary, about this explosion. The document gave facts concerning the engine and the explosion. It stated that the rapture seemed to have occurred at the rim of the plates adjoining the fire box. The engine was built at the Phoenix Foundry, Ballarat, in 1883. It was repaired at various times, the last time being in July of last year when it was sent to the Port Melbourne shops, and was then tested to a cold water pressure of 195 and found all right. It was the custom to overhaul all locomotives about every five years. The Chairman : There were no very heavy repairs in July, 1893; were there? — Not to the boilers. The shop manager's report says that the plug and safety tap holes were repaired, five new copper studs put in firebox, ash-pan door repaired, tender cleaned and overhauled, and studs re-rivetted, and boiler tested to pressure of 195, cold water. Mr Woodroffe read the report of the repairs effected to the boiler in December, 1888. That would be the time the plate was put in the boiler. On that occasion three new plates were put in the bottom and the boiler tested up to 195. The Chairman: Do you keep a record of the water used ?— Yes, the water in this case, I think, came from the Maroondah scheme. Mr Woodroffe said boilers were examined front time to time in the running sheds. In his opinion every possible care had been taken to keep the engine in proper care. There might, however, be lessons learnt from this. The Chairman: No doubt. From his examination of the plates [the] witness did not think the state of them could have been detected from the outside. There were no signs of leakage or sweating or anything of that sort. The next witness- was Walter Stinton, workshop manager at Newport and he said that the injured engine had been repeatedly repaired under his charge. He gave a technical account of the repairs effected on various occasions. The testing of locomotives was under his special notice. They had a high pressure pipe running; round the works, and a pump set at 2001b. When the boiler was pumped full of water the pressure when applied up to 1951b. The board appointed by the department to inquire into the Ringwood locomotive boiler explosion sat again at Spencer street on 25th inst. Mr R. Fulton presided and the other members of the board were. Mr Mephan Ferguson and Mr C. W. McLean. Charles Grubb, foreman of the boiler-makers at the Newport workshops, said he had inspected the pieces of plate that had been blown out of the engine, and after examining them, pointed out to the Chief Mechanical Engineer the portion where the plate had started to burst. It was under the lap, on the right hand side of the boiler. The grooving might be accounted for by bad water. During the past twenty years he had examined all the boilers that came into the Williamstown workshops, and while some were hardly marked at all, others were very badly eaten away. The practice was to cut out the defective portions. In this case the boiler was repaired in a similar manner. The Chairman : Can you suggest any other way of repairing so as to prevent accident ? — No, unless by taking out a plate on one side from the joint, and carrying it further up so as to avoid the joints meeting, or by taking out the plate altogether. What would.be the cost .of putting in a new " plate I—Perhaps about double the price; but I wouldn't recommend that course. It would be putting a new plate against plates that have been in use ten years or so and that would not be advisable. I think the present system better. I consider the present system of repairing the best. This is the first we have had so bad like that, to my knowledge. You attributed this to bad water. Is there no other probable cause ? — Well; unless the iron be bad. This was Lowmoor iron. I think this accident was caused by the eating away of plates. This one was the worst I have seen, for the short time it had been running. We use three classes of iron — Lowmoor, Monkbridge and Bowling. By Mr Woodroffe (Chief Mechanical Engineer) ; There are engines still running that were repaired at the same time as this one, in 1888, and. in the same way. These are engines 339 and 333. They have been recently examined and are in splendid order. What in your experience, is the age of a boiler on the Victorian railways? — From 17 to 20 years our earlier boilers stood. The later boilers don't stand so well. How is that? — There is difference in construction, and the material is lighter. The old boilers had thicker plates. Have you been asked in any way to curtail boiler affairs? — No, sir; nor in any way. You have never hesitated to carry out any necessary repairs? — Never. Our orders have been to exercise every care in examining, repairing and renewing boilers. Witness said that his practice was when an engine came into the workshop to find out how long she had been running. If over five years, he informed the workshop manager, and they thought it necessary the tubes were taken nut. If everything was in good order witness reported to the manager. The cost of taking out the tubes and putting them in again was about L20. Mr Woodroffe : Have you ever hesitated to repair a boiler on the score of expense ? — No, never. Mr McLean : Hew do yon ascertain whether a boiler requires repairs?— I keep a record of every boiler examined. From every boiler that comes in I have the dome covers taken off, and when it is practical I get inside. l can almost tell from the top of a boiler what the bottom is like. If there is any doubt about it I have the tubes taken out. If I have suspicion of defective plate I cause to have bored a triangle in the plate at the point where there is the most wear. There is a travelling inspector who visits all the running sheds of the colony except Port Melbourne and tests the boilers. He reports to us and we note what he points out. Alfred Thompson, locomotive inspector of the eastern section, said he knew this engine, 297R. He read a list of her repairs. He heard of the accident on Saturday night and went up to Ringwood. The Chairman : Did you ever notice anything peculiar about the engine? — No, I considered her A1 and would not have hesitated to have put on 140lb pressure owing to the repairs she had undergone. Witness considered that the explosion was caused by the expansion and contraction of the plates ; and, no doubt, the plate had been eaten away through bad water. The other side of the boiler showed: signs of corrosion: By Mr Woodroffe ; Is every care taken with the boilers ? — Yes, every possible care is taken for the safety of boilers, Weekly Times (Melbourne, Vic. : 1869 - 1954), Saturday 27 January 1894, page 7 EXPLOSION OF A LOCOMOTIVE BOILER, NARROW ESACPE FROM FATALITIES. THE DAMAGED ENGINE. [See drawing of loco – saved in “Railways” folder] The explosion of a locomotive boiler at Ringwood on Saturday evening, formed the subject of much discussion in railway circles on Monday. The Minister arrived at the office at an unusually early hour and immediately entered into a consultation with the acting chairman, Mr Kibble, and Mr Commissioner Murray. As the result of the interview it was resolved to ask three gentlemen of acknowledged engineering experience to sib as a board with the . object of inquiring into the cause of the accident and furnishing a report. Mr Richardson and the Commissioners are tally seized of the importance of having a searching investigation into the accident, and, with Mr Murray, the former went to Ringwood to inspect the scene of the disaster. They will he accompanied by Mr Woodroffe. During the morning no official report had come to hand from the driver or fireman of the engine in reference to the accident, but that is thought to be due to the circumstance that they have not sufficiently recovered to be able to give a circumstantial account of what occurred. The engine was one of the old R's, and, Mr Kibble pronounced them to be about the best class of engines used. So far nothing can be said as to the probable cause of the accident, as the broken plating of the engine has not been submitted to the inspection of experts. Weekly Times (Melbourne, Vic. : 1869 - 1954), Saturday 27 January 1894, page 7 STATEMENT BY THE FIREMAN. This morning Thomas Miles, fireman on the engine the boiler of which exploded on Saturday night, is suffering from an injury to the spine, as well as a very severe shaking to the system. He states that he was fireman on the engine attached to the train which left Healesville on Saturday evening, at ten minutes to 8. Everything went all right until Ringwood was reached, when, .just as the train was about to continue its journey, a load explosion took place and Miles remembers nothing more until he was picked np on the platform ; and found himself suffering from a pain in the back, and an injury to his arm. He cannot think of any reason which could have caused the explosion, as there was plenty of water in the boiler, and everything seemed working all right. Mr R. Fulton, consulting engineer, of Queen street; Mr McLean, a member of the Marine Board ; and Mr Mephan Ferguson, engineer, have consented to act as a board to inquire into the cause of the engine boiler explosion at Ringwood on Saturday evening. The board has been appointed under section 117 of Act 1135, which provides that the Governor-in-Council may direct the taking of a such a step. Mr1 Fulton will act as chairman of the board, which met for the first time at the railway offices, Spencer street, this forenoon. Before separating the members of the Board paid a visit to the Prince's Bridge locomotive sheds in company with Mr Woodroffe, the chief mechanical engineer, for the purpose of inspecting the shattered boiler. It has been stated that the explosion is known to have been caused by a flaw in a plate which was put on the boiler about four years ago, but enquiries have tailed to elicit anything in support of that view. The engineers connected with the department are not inclined to say anything on the subject. Weekly Times (Melbourne, Vic. : 1869 - 1954), Saturday 14 April 1894, page 20 The Ringwood Boiler Explosion, The Minister of Railways has received the supplementary report of the board appointed by him to investigate the circumstances connected with the explosion of a locomotive boiler at Ringwood. In their first report the board did not attach blame to anyone. Mr Richardson felt satisfied that the responsibility of having the engines properly inspected and overhauled periodically could be fixed if the inquiry were extended. He therefore referred the matter again to the Board, who took further evidence. In the report now furnished, the Board hold Loco. Inspector Thompson blameable, but point out as a mitigating circumstance that he had not received "written instructions" respecting inspections and overhauls. Weekly Times (Melbourne, Vic. : 1869 - 1954), Saturday 7 July 1894, page 32 The Ringwood Boiler Explosion. The Minister of Railways takes exception to the tone of a paragraph appearing in a morning contemporary respecting the Ringwood boiler explosion. It makes it appear that Mr Richardson has referred the report of the board which considered the facts connected with the explosion to the Crown solicitor simply because he differed from the finding of the board. The Minister explains that when he received the report he found that the responsibility for having boilers properly inspected and overhauled had not been clearly fixed. He personally obtained farther evidence on that point, and arrived at a conclusion, from which the commissioners differed. As he did not like to take upon himself the responsibility of deciding upon the effect of the evidence, he submitted the matter to the Crown Solicitor, but that officer did not furnish him with the information sought. He has, therefore, referred the question to the Attorney-General, together with the draft of a regulation respecting boiler inspections and overhauls in the future. Mr Richardson says that his whole aim is to have the responsibility positively fixed. Weekly Times (Melbourne, Vic. : 1869 - 1954), Saturday 28 April 1894, page 23 The Minister of Railways has completed his consideration of the supplementary report received by him from the Ringwood Boiler Explosion Board. The report, it will be remembered, held Loco-Inspector Thompson blameable for the non-inspection of the boiler, but considered there was extenuating circumstances. There was a certain amount of doubt as to the absolute instructions given for overhauling engines periodically. Mr. Richardson is sending the report on to the Commissioners with instructions that the responsibility respecting inspection of boilers shall be made clear for the future. -

The Beechworth Burke Museum

The Beechworth Burke MuseumGeological specimen - Brown coal

This particular specimen was recovered from the Lal Lal Coal and Iron Mine in Victoria, 19km from Ballarat. Brown Coal was discovered here in 1857, just alongside the Geelong to Ballarat Railway line. This discovery of lignite (brown coal) was the first in Victoria, which would bring important benefits to the region and state, both of which had previously been reliant on coal imports. In the 1860s, iron ore was found just 5km from Lal Lal, and the area was converted into an Iron Ore Mine. The Lal Lal Iron Mining Company took over operations in 1874, who then peaked iron production in 1884. This mine continued operations until June 1884, when the blast furnace was extinguished and never recommenced. The blast furnace at Lal Lal is considered one of the most important and highly significant sites ion early industrial history in Australia, as it is the only remaining best furnace from the nineteenth century in the Southern Hemisphere. The furnace ruins are 17 metres high, and are clearly visible today on Iron Mine Road, Lal Lal, near the Bungal Dam. This specimen of Lignite (brown coal) is significant, as it was mined from the area where brown coal was first discovered in Victoria, leading to an important and controversial future of the mining and use of brown coal in this State. The Victorian Heritage Database has listed the Lal Lal Coal Mine with local significance, with their Statement of Significance stating: "The Lal Lal coal mine is historically significant as the site of the first discovery of lignite (brown coal) in Victoria, and one that promised important benefits to regional and state industries that were reliant on coal imports at the time. The significance of the stie is reduced by the poor state of preservation of the coal mining and processing fabric". This specimen is part of a larger collection of geological and mineral specimens collected from around Australia (and some parts of the world) and donated to the Burke Museum between 1868-1880. A large percentage of these specimens were collected in Victoria as part of the Geological Survey of Victoria that begun in 1852 (in response to the Gold Rush) to study and map the geology of Victoria. Collecting geological specimens was an important part of mapping and understanding the scientific makeup of the earth. Many of these specimens were sent to research and collecting organisations across Australia, including the Burke Museum, to educate and encourage further study.A hand-sized light-weight, soft and combustable sedimentary rock specimen, that is dark brown in colour. The specimen has jagged edges, as though parts of the rock have crumbled away. Brown coal, or Lignite, is formed naturally from compressed peat, and is typically found in natural basins. The stages to the formation of coal ('coalification') begin with plant material and wood, which will decay if it is not subjected to deep burial or heating, and turn into Peat. Peat, when sufficiently compressed naturally, will turn into Brown Coal (Lignite), and finally into Black Coal (sub-bituminous, bituminous and anthracite). Each successive stage has a higher energy content and lower water content. It is brownish-black in colour. Brown Coal has a high moisture content, between 50 and 75 percent, and a low carbon content. Some Brown Coals may be stratified, with layers of plant matter, which means little coalification has occurred beyond the peat natural processing stage. When Brown Coal is submerged in dilute nitric acid or boiling potassium hydroxide solution, it reacts to produce a reddish solution, of which higher-ranked coals do not. When brown coal is pulverised and burned in boilers, the steam is used to drive turbines, which generates electricity. It is the lowest rank of coal, as when burned, it creates a relatively low heat content, which in turn does not create a great output of steam. burke museum, beechworth, indigo shire, beechworth museum, geological, geological specimen, mineralogy, brown coal, brown coal specimen, lignite, lal lal, lal lal coal mine, lal lal iron mine, ballarat, blast furnace -

Greensborough Historical Society

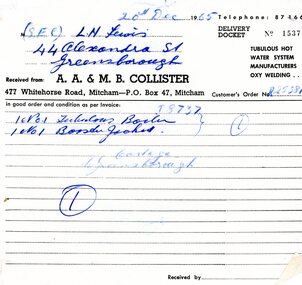

Greensborough Historical SocietyAdministrative record - Delivery docket, A. A. & M. B. Collister, 20/12/1965

Item is an electric hot water service, purchased from the manufacturer. The purchaser, L. N. Lewis, worked for the Greensborough SEC.Delivery docket, black print on white paper, handwritten details of purchaser and purchased itemsNo. 1 Tubulous boiler; No. 1 Booster jacket; (SEC) L.H. Lewis, 44 Alexandra St Greensborough T8737hot water service, lewis family -

Seaworks Maritime Museum

Seaworks Maritime MuseumShipbuilders model, Tri Ellis

Model ship was presented to the Melbourne Maritime Museum by the British Phosphate Commissioners. Built as Tri-Ellis (1958-74), Tryphena (1974-78), Man Tat (1978-80), 1980 broken up. DWT 13,756 SPEED 14 KNOTS.AT 112RPM. BOILERS LARKSON TRIMBLETUBE. FUEL CONSUMPTION 7 TPD. GENERATORS W.H.ALLEN - 4CYL.2SA290/470. 480B.H.P.320L.W.-220V 333RPM DAILY CONS - 1.5 TONS. EMERGENCY GEN R & H. 40 K.N. -220V. REFRIGERATING MACH: J & G HALL LTD. SUPERSTRUCTURE: FORECASTLE 62'..2 DECKS RIVETED AND WELDED. CARGO BATTONS NOT FITTED. 9 BULKHEADS. RISE OF FLOOR 6".WATER BALLAST 3,296 TONS INCLUDING TUNNEL TANKS 1,341 TONS. 'TWEEN- DECKS FORWARD 274 TONS. REFRIGERATED CARGO INSTALLATION - 6 HOLDS - 55.2',52',54',59.5',43' ,53'. GRAIN CAPACITY :621,640 CU. FT. BALE CAPACITY : 573,810 CU. FT. INSULATED CAPACITY : 5,050 CU.FT. 6 STEEL HATCHWAYS (27',30',30'* 30') (30'* 27.75') (27', 24' * 28' ). 12 WINCHES...DERRICKS 1 (25), 2 (10), 10 (5). MACHINERY: OIL 2SA 7CY.C20 * 1400MM EXHAUST 470MM. 6500 BHP. FUEL BUNKERS: 2135 TONS HIGH VISCOCITY FUEL. The main engine was an opposed piston type Harland & Wolff 6-620/ 1870 6 for the number of cylinders.. 620 for the cylinder bore and 1870 for the combined strokes of the main exhaust pistons in each cylinder. This engine was based no a Burmeister and Wain design but H & W gave these engines their own type designation. Sailed on board its maiden voyage to Australia via Casablanca Morocco where she collected her first load of phosphate. We sailed to Geelong via the Suez canal and the Port of Aden (Yemen) and Freemantle. The first load of phosphate was unloaded at Corio Bay (geelong) Formerly part of the collection of Melbourne shipping company, Howard Smith Ltd. Ship builder's model of the cargo ship Tri-Ellis IMO 5368196 - Body of moulded polyurethane painted in red, black and grey, the deck painted in red, with detailed fittings, machinery, rigging and superstructure, raised on a wooden base. Original ship built Clyde 1958, 11,761 gross tonnes, 531.5' x 68' x 31' (162.0 x 20.73 x 9.45m)plaque at foot of model "MV TRI ELLIS/ LENGTH B.P. 486'-3"- BREADTH MLD 68'0" - DEPTH MLD 40'6"/ TONNAGE GROSS 11,760/ Built by HARLAND & WOLFF LTD/ For BRITISH PHOSPHATE COMMISSIONERS" On model "TRI-ELLIS" painted black