Showing 25 items matching "worsted fabric"

-

National Wool Museum

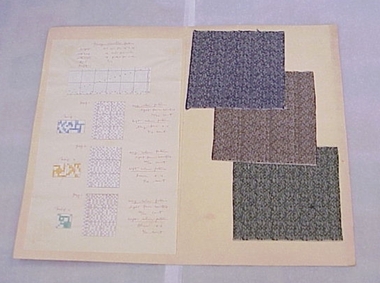

National Wool MuseumFolder, sample

... detailing 3 "Fancy Worsted Fabric" patterns with 1 blue, 1 brown...K.W. KAM (ink) RANGE No VI (ink) Fancy Worsted Fabric (ink)... sheet detailing 3 "Fancy Worsted Fabric" patterns with 1 blue, 1 ...Weaving sample folder: "RANGE No VI" contains sheet detailing 3 "Fancy Worsted Fabric" patterns with 1 blue, 1 brown and 1 black speckled cloth sample.K.W. KAM (ink) RANGE No VI (ink) Fancy Worsted Fabric (ink)weaving textile industry textile design, weaving, textile industry, textile design -

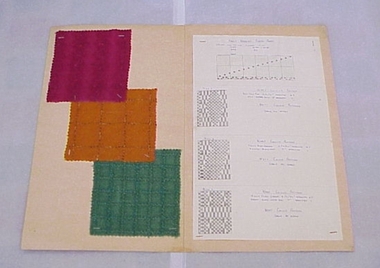

National Wool Museum

National Wool MuseumFolder, sample

... detailing 3 "FANCY WORSTED SCREEN FABRIC" patterns with 1 pink, 1...WAYNE BUGG RANGE No 6 (ink) FANCY WORSTED SCREEN FABRIC... sheet detailing 3 "FANCY WORSTED SCREEN FABRIC" patterns with 1 ...Weaving sample folder: "RANGE No 6" contains sheet detailing 3 "FANCY WORSTED SCREEN FABRIC" patterns with 1 pink, 1 orange and 1 green cloth samplesWAYNE BUGG RANGE No 6 (ink) FANCY WORSTED SCREEN FABRICweaving textile industry textile design, weaving, textile industry, textile design -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Hand operated embossing document press, 1910

... worsted fabric... in 1922 for machinery to make worsted fabric drained profits... in 1922 for machinery to make worsted fabric drained profits ...The woollen mill was a vital part of Warrnambool for all but 22 years of the town’s history since it's the establishment in 1847 when the first land sales were held and white settlement began. In 1869 the Warrnambool Meat Preserving Company began operations on the mill site, in 1875, shareholders of the then defunct Warrnambool Meat Preserving Company happily sold the land and buildings on the Merri river to Warrnambool Woollen Mill Company Ltd for £5,000. The site was sold again in 1876 to grazer Robert Hood of Sherwood, who was chairman of directors of the failed company, which couldn’t raise sufficient capital to keep the works operating. The entrepreneurial Hood then used the existing plant to turn his own wool into tweed cloth. But just as the mill was starting to show a profit, a fire destroyed the building and plant on the night of 25 March 1882. So again, the mill was operational for six short years. Insurers only paid a fraction over 10% of the damage, Hood couldn't raise sufficient capital to rebuild on his own, and so the site lay unused until 1910. In 1908 Marcus Saltau and Peter John McGennan convinced the Warrnambool Chamber of Commerce to invest in a secondary industry with local capital. A public meeting in September 1908 agreed to raise £40,000, electing Saltau chairman of directors, a post he held for 34 years. A year later, using mostly local money, the Warrnambool Woollen Mill Company dispatched its first manager, John E. Bennett, to buy a plant and recruit 20 experienced staff from the Yorkshire woollen industry in December 1909. Another year more, the new mill was officially opened on 14 November 1910 by Marcus Saltau as company chairman and town mayor. Eighteen months on, in May 1912, the mill paid its first half-yearly dividend of 2 ½%. It was now working two shifts, with a year's orders to fill. In 1914 the mill ordered its own generator, providing the town with electricity and effectively doubling its plant size by October 1915, six months after Gallipoli. Thereafter, government orders for cloth and military supplies assured the mill’s success right through the First World War and on until 1923. A plant upgrade in 1922 for machinery to make worsted fabric drained profits, which, with a fall in demand, led to a loss in 1925. Profits were restored by the 1930s, despite the Depression, mostly due to tight management and robust marketing. Production boomed again during the Second World War, but soon foreign competition bit into profits, forcing the company to consolidate operations. The ‘50s and ‘60s were golden years for the mill. Security and growth gave the company confidence to trial Australia’s first electric blanket in 1958 and to install Swiss Sulzer looms in 1965. Over time, the building facades took on the modern look that the mill presented until it closed. The Dunlop company bought the mill in 1968, fending off a challenge from Onkaparinga in South Australia, and continued to expand by adding Wendouree Woollen Mill in the same year and Dream-spun Textiles a decade later, in 1979. Soon after that purchase, however, the mill began its slippery slide into decline. Dunlop sold to its former rival bidder Onkaparinga Woollen Co. Ltd in 1982, which in turn was taken over by Macquarie Worsted's only a year later, in 1983. Operations remained stable for a decade until 1994 when the Macquarie Group signaled that its newly rationalised operations left no room for the Warrnambool investment. The final operator of the mill was The Smith Family charity group, which ran the site by agreement with the Warrnambool City Council and a state government grant in that same year, 1994. The mill became more of a fabric recycler than a manufacturer. The site was sold to private operators in February 2003 and rezoned four months later to allow for the mixed housing development. The embossing press is significant for its association with the Warrnambool Woollen Mills 1910-1968, a major employer in the Warrnambool district. The press is also significant as an example of commercial office equipment used in the 19th and 20th century.Press, metal, for Company seal of Warrnambool Woollen Mill, stamping their brand as Western District Worsted Mills Pty Ltd. Metal is black with red and gold floral markings. Inscription of stamp reads "WESTERN DISTRICT WORSTED MILLS PROPRIETRY LIMITED" flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, warrnambool woollen mills, western district worsted mills proprietry limited, worsted fabric, printing press, logo printing press, stamp printing press, shipwreck-coast, flagstaff-hill-maritime-village -

National Wool Museum

National Wool MuseumBook, I.C.S. Reference Library no. 92

... of woolen and worsted fabrics, twill weaves and derivatives, satin..., analysis of woolen and worsted fabrics, twill weaves ..."I.C.S. Reference Library no. 92: glossary of weaves, elementary textile designing, analysis of cotton fabrics, analysis of woolen and worsted fabrics, twill weaves and derivatives, satin and other weaves, combination weaves, construction of spot weaves, weaves for backed cotton fabrics, woolen and worsted ply weaves, leno weaves, pile weaves, color in textile designing, designing in general" International Correspondence Schools Ltd, 1921. There is a fine ex libris plate (designed by W.L. Trigg) on the inside of the front cover depicting the Anzac statue from the RSS Mill. This book is from the library of V.J. Schofield, son of Albert Schofield, the first managing director of the RSS Mill.EX LIBRIS / V.J. SCHOFIELD / W.L. TRIGGweaving textile design cotton textile mills, international correspondence schools ltd returned soldiers and sailors mill, cloth - woollen, cloth - worsted, twill, trigg, w. l., weaving, textile design, cotton, textile mills -

National Wool Museum

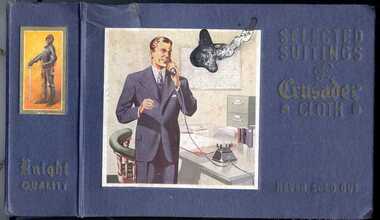

National Wool MuseumSample Book, "Selected Suitings of Crusader Cloth" sample book

... the 1960's when the oversupply of worsted fabrics from Europe... the 1960's when the oversupply of worsted fabrics from Europe ...This book dates from the 1940s and was part of the Running Stitch collection of quilts, probably because it was common for women to acquire these books from travelling salesmen. This sample book is an example of the type made by textile mills and given to tailors to sell fabric for made to measure suits. With little money to spare during the austere years of the war, women often acquired these books from tailors when the fabrics were no longer available. They made use of the fabric sample pieces to make quilts. The Australian Woollen Mills was an example of a woollen mill which went into worsted production making good quality English-type suiting. They were very successful until the 1960's when the oversupply of worsted fabrics from Europe and Asia led to the decline of the industry in this country. This book was displayed in the Running Stitch exhibition "Wool Quilts Old and New" of 1985 where it was catalogue entry number 40.Australian Woollen Mills Crusader fabric sample book, c.1940sKnight / QUALITY SELECTED / SUITINGS / of / Crusader / CLOTH / NEVER SOLD OUT Crusader / CLOTH / Makes the best suits "Crusader" / WORSTEDaustralian woollen mills pty ltd running stitch group, cloth - worsted, running stitch collection -

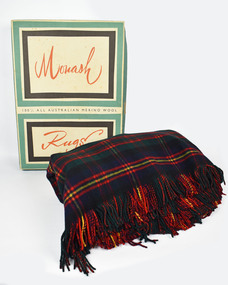

National Wool Museum

National Wool MuseumTextile - Rug, Returned Soldiers and Sailors Mill, 1963

... and lighter worsted fabrics for more casual clothing. Modern day... and lighter worsted fabrics for more casual clothing. Modern day ...The Returned Soldiers and Sailors Mills was located near the Barwon river on Pakington Street, Geelong, where its building still stands. The mill was established in October 1922 with capital acquired from War Gratuity Bonds. The mill produced fine grade woollen products with its speciality being ‘Retsol’ travelling rugs. The mill first began to run into financial troubles with the ‘Credit Squeeze’ or the ‘Holt Jolt’ of the early 1960s. This saw import restrictions lifted which triggered the start of a minor recession and a rise in unemployment. Included in these troubles was the RS&S Mill which saw the number of employees gradually decrease and business declining with cheaper imports beginning to grab an expanding part of the market share. The mill was eventually purchased by Godfrey Hirst in 1973 who tried to continue operations without success and in June 1975 textile production at the site ceased. Outside of financial considerations contributing to the closure of Woollen Mills in this period was the declining need for heavier fabrics as in-home heating and insulation improved. This need had been replaced for a demand for ever softer, finer and lighter worsted fabrics for more casual clothing. Modern day textile production requires fewer steps in the processing of materials for this use. This meant large factory complexes such as early woollen mills like the RS&S mills were no longer required. Compared to modern textile production which can spin a fine yarn out of synthetic fibre or imported cotton easily, spinning fine yarn from medium quality wool at a textile factory was cumbersome and no longer financially viable to suit new consumer demands. This rug provides context to this statement. It was gifted to Shirley and Gordon Green as a wedding present in November 1963 by one of Gordon's colleagues in the wool industry. Living in areas such as Neutral Bay, the Hornsby area and later in life retiring to the Central Coast, the blanket was too heavy for use in these weather conditions and hence it stayed in its original box for nearly 60 years. Top and bottom of rug has frilled edges. Pattern is titled the 'Clan Cameron' and is repeated in a 7x7 grid. Front of rug has a red background with 4 vertical and horizontal lines. All is surrounded by a yellow boarder. Label is stitched into the bottom right corner. Reverse of rug also has a repeating 7x7 grid. Blue background with thick green horizontal stripe. Yellow and red boarder to the grid with 4 red vertical and horizontal lines making up the interior. Rug measure 1550 x 2040mm, approximately the same size as a queen size mattress.Wording, Bottom right corner. THE GEELONG R.S&S. WOOLEN MILLS/ PURE/ WOOL/ AUSTRALIA/ The John Monash Rug (cursive)/ The Clan Cameron (cursive)rs&s mills, textile manufacture, rug, clan cameron, sydney greasy wool exchange -

Parks Victoria - Cape Nelson Lightstation

Parks Victoria - Cape Nelson LightstationFunctional object - Flag set, navigational

... pennants) are made of bunting, a coarse fabric of worsted (open... fabric of worsted (open yarn wool) in various colour combinations ...The flags were used for communicating messages to passing ships. Knowledge of visual signaling was mandatory for all lightkeepers and all stations maintained a set of these flags. Although used for centuries, visual flag signaling formally developed in the nineteenth century and was published internationally as a system in 1857. By the early twentieth century it had developed into an effective means of conveying all kinds of short range visual messages.The Cape Nelson Lightstation is architecturally and scientifically (technologically) important as the most intact complex of lightstation buildings in Victoria. The octagonal signal station is a unique feature which is all the more important for its complete set of signal flags’. Cape Nelson Lightstation’s complete set of 41 alphabetic and numeric visual signaling flags (including substitute and answering pennants) are made of bunting, a coarse fabric of worsted (open yarn wool) in various colour combinations, and some of the fabric is hand sewn and bears inscriptions. Attachments include handmade wooden toggles, brass clips and hemp rope. -

Parks Victoria - Gabo Island Lightstation

Parks Victoria - Gabo Island LightstationFlags & Pennants, navigational, signal

... or pointed ends. They are made of bunting, a coarse fabric of worsted.... They are made of bunting, a coarse fabric of worsted (open yarn wool ...The 41 alphabetic and numeric visual signalling flags (including substitute and answering pennants) have either square or pointed ends. They are made of bunting, a coarse fabric of worsted (open yarn wool) in various colour combinations. Some of the flags are marked with inscriptions, for example “B”. Attachments to the flags include hemp rope and metal clips. Each flag has its own galvanised canister and lid, each of which is painted grey and marked with a letter, number or word. The flags were used for communicating messages to passing ships. Knowledge of visual signalling was mandatory for all lightkeepers and all lightstations maintained a set of flags. Although used for centuries, visual flag signalling formally developed in the nineteenth century and was published internationally as a system in 1857. By the early twentieth century it had developed into an effective means of conveying all kinds of short range visual messages. The signal flags and canisters at Gabo Island form a complete set and are not historically linked to the lightstation and their provenance is unknown. It is known however that they originate from a lightstation in Victoria and for some years were on loan from AMSA to the Queenscliff Maritime Museum, where they were held in storage and not displayed. Three of the six lightstations that Parks Victoria manages have sets of signal flags in their collections. Forty navigational signal alphabet flags & numeral pennants. Flags are made of wool. -

Parks Victoria - Gabo Island Lightstation

Parks Victoria - Gabo Island LightstationFlag canisters

... or pointed ends. They are made of bunting, a coarse fabric of worsted.... They are made of bunting, a coarse fabric of worsted (open yarn wool ...The 41 alphabetic and numeric visual signalling flags (including substitute and answering pennants) have either square or pointed ends. They are made of bunting, a coarse fabric of worsted (open yarn wool) in various colour combinations. Some of the flags are marked with inscriptions, for example “B”. Attachments to the flags include hemp rope and metal clips. Each flag has its own galvanised canister and lid, each of which is painted grey and marked with a letter, number or word. The flags were used for communicating messages to passing ships. Knowledge of visual signalling was mandatory for all lightkeepers and all lightstations maintained a set of flags. Although used for centuries, visual flag signalling formally developed in the nineteenth century and was published internationally as a system in 1857. By the early twentieth century it had developed into an effective means of conveying all kinds of short range visual messages. The signal flags and canisters at Gabo Island form a complete set and are not historically linked to the lightstation and their provenance is unknown. It is known however that they originate from a lightstation in Victoria and for some years were on loan from AMSA to the Queenscliff Maritime Museum, where they were held in storage and not displayed. In three of the six lightstations that Parks Victoria manages have sets of signal flags in their collections. Forty-one galvanised canisters with separate lids. The canisters are painted a grey/white colour and have either numbers, letters or words painted on the lid and on the cannister in black paint. There are variations in the style of canister and in the style of the inscriptions. -

National Wool Museum

National Wool MuseumClothing - 1984 Los Angeles Olympics Men's Opening Ceremony Shirt, c. 1984

... weave fabric from Macquarie Worsted. This fabric had a small... weave fabric from Macquarie Worsted. This fabric had a small ...On the 1984 Los Angeles Olympic Uniforms donator Doug wrote- During the 1980s the Australian wool industry was at its most prosperous times with record numbers of sheep producing wool receiving ever increasing values due to the success of the Reserve Price Scheme, and the overall guidance of the Australian Wool Corporation (AWC). As a humble technician, my role was a low profile newly created position of “Controller, Technical Marketing” where wool was to be marketed on its technical properties, as distinct from the “Product Marketing Group” which exploited trhe traditional high profile approach of marketing wool;s superior fashion attributes. The Woolmark was the tool central to this approach. When the forthcoming Los Angeles Olympic Games was announced, the Product Marketing Group seized upon the chance to show the world that we could make top fashion garments and display them on our elite athletes on the world stage. A concept was launched using a contemporary top designer, Adel Weiss, with the most exclusive fabrics and knits available, and all with a lot of hype. This launch failed dismally for the following reasons- - The designer did a wonderful job presenting an excellent fashion range on perfect skinny models. The AOC however wanted a uniform which had an obvious Australian appearance when fitted to elite, and frequently muscular, athletes. - The fabrics chosen did not reflect the performance required by travelling athletes, there was no recognition of the need for ‘easy care.’ - There was no recognition given to the problem of measuring, manufacturing and distribution of a range of articles when the selected athlete could be domiciled anywhere in Australia. - There was no appreciation of such historical facts as Fletcher Jones, who had been unofficial suppliers dating back to the 1954 Olympics in Melbourne, and the Fletcher Jones board member, who was also an AWC board member, and was not in favour of the change. The project passed from Product Marketing to Public Relations, a big spending off-shoot of the AWC Chairman David Asimus, and due to the day to day operations of the project was passed to me and PR took care of the financial matters. The first task was to meet with the AOC and find out exactly their requirements. This lead to the production of a design and manufacturing brief, cointaining exact time lines for each event required to ensure an appropriate uniform on every athlete chosen to represent his/her country on the date given for the Opening Ceremony in Los Angeles. Working backwards the timeline becomes- 1. Noted the exact date of the Opening Ceremony. 2. Estimated the date for distributing completed garments to each athlete. 3. Estimated the time span available for measuring each athlete and commence making each component of the ensemble to the individual measurements of each athlete. 4. Decided the date for making the final choice of uniform design concept. 5. Decided the date for distribution of the design brief to selected designers. These five steps were spread out over a two year period. The Commonwealth Games occur midway between each Olympic Games, work on the Olympic uniform commences the week after the Commonwealth Games closing ceremony and MUST be ready by the prescribed day two years hence. The project also had to remain cognisant of trade politics existing within the span of the task, as well as the temperament of designers in general. It is no overstatement to say that in the past every designer in Australia believed they could, and should, be chosen to design the Australian Uniform. The final choice of designer almost always faced criticism from the fashion press and any designer who had been overlooked. However, with the contenders receiving an exacting brief the numbers of serious contenders greatly reduced. The Los Angeles Olympic Uniforms. A further reason for the AWC bid failure to design the LA uniform was that the AOC had already chosen Prue Acton to design it. This was based on her proven performance during previous games as she had a talent for creating good taste Australiana. Her design concepts also considered the effect when they were viewed on a single athlete as well as the impact when viewed on a 400 strong team coming on to the arena. A blazer trouser/skirt uniform in bright gold was chosen for the formal uniform. It was my task to select a pure wool faille fabric from Foster Valley weaving mill and have sufficient woven and ready within the prescribed timeline. The trouser/skirt fabric selected was a 60/40 wool polyester plain weave fabric from Macquarie Worsted. This fabric had a small effect thread of linen that was most attractive when dyed to match some eucalyptus bark Prue had brought back from central Australia. For the Opening Ceremony uniform, Prue designed a series of native fauna, a kookaburra for the men’s shirt and a pleated skirt with a rural scene of kangaroos, hills and plants. This presented an insurmountable printing challenge to the local printing industry as it had an unacceptably large repeat size and the number required (50) was also commercially unacceptable. The solution was a DIY mock up at RMIT and the employment of four student designers. The fabric selected for this garment was a light weight 19 micron, pure wool with a very high twist yarn in alternating S and Z twist, warp and weft. This fabric proved to be the solution to a very difficult problem, finding a wool product which is universally acceptable when worn next to the sin by young athletes competing in the heat of a Los Angeles summer. Modifications to this fabric were developed to exploit its success when facing the same problem in future games. Garment Making- The most exacting garment in the ensemble is the tailored blazer, plus the related trouser/skirt. Unfortunately tailoring athletes that come in various shapes and sizes such as; - Weight lifters develop an enormous chest, arms and neck size. A shirt made to a neck size of 52 would produce a shirt with cuffs extending well beyond the wearer’s hands. - Basketball players are up to 7 feet tall and garments relying ona chest measurement grading would produce a shirt with cuffs extending only to elbow length. - Swimmers develop enormous shoulders and slim hips, cyclists by contrast develop thighs I liken to tree trunks and a uniform featuring tight trousers must be avoided at all cost. Suffice to say many ensembles require specialist ‘one off’ treatment for many athletes. Meanwhile there is a comfortable in between group who can accept regular sizes so you can cater for these by having back up stock with plenty of built in contingencies. Athletes may be domiciled anywhere in Australia, this creates a fundamental problem of taking their measurements. The Fletcher Jones organisation was key to answering this problem due to their presence in every capital city, as well as many provincial towns around Australia. Each athlete on being selected for the Olympic Team was simultaneously requested to visit their nearest Fletcher Jones shop. The standardised measurement data collected was shared with the other manufacturers, e.g. Pelaco Shirts, Holeproof Socks and Knitwear, Maddison Belts, and even Hush Puppy Shoes. As the time for the Games approached the AOC made arrangements for combining meeting of all. Selected available athletes at the Australian Institute of Sport, Canberra, where, among other things, they were fitted and supplied with their uniform. The method evolved as follows.Men’s cream coloured button up, collared shirt. Images of a kookaburra have been printed onto the shirt, a single kookaburra on the left breast and a pair of kookaburras on the reverse of the shirt. The kookaburras are printed in a brown tone to complement the cream colour of the fabric.On tag - FMaustralian wool corporation, 1984 los angeles olympics, olympic uniforms, men's uniforms, sport, athletes -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Clothing - Lady's nightdress crepe de chine, floral c1950, c1950

Gladys Reed was a member of the Ormond Choral Society c 1950. who performed plays and musicals in the City of Moorabbin and she made this nightdress c1950 Crepe de Chine, also spelled Crêpe De Chine, (French: “crepe of China”), light and fine plain woven dress fabric in silk, wool, or synthetic fibre fabric with a distinctively crisp, crimped appearance produced either with all-silk warp and weft or else with a silk warp and hard-spun worsted weft. This material was easy to sew, wash and dry and required no ironing . . This crepe de chine nightdress is an example of the popular style worn by women in the post World War 11 Estates in the City of Moorabbin c1950 A lady's floral crepe de chine, full length, nightdress with shoulder straps and waist ties clothing, nightdress, crepe de chine, theatrical props, craftwork, sequins, beading, early settlers, moorabbin shire, mechanics institute cheltenham, ormond choral society, postworld war 11 settlers, housing estates moorabbin 1950, bentleigh, ormond, moorabbin, cheltenham, drama societies, musical society cheltenham, clark judy, reed gladys, reed george -

National Wool Museum

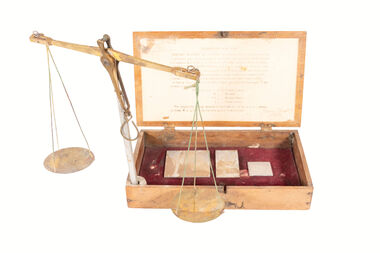

National Wool MuseumInstrument - Scales, 1880-1898

At the time of sale, the last of the Hirst family to work in the mill located in Geelong gave Donald (donor Bruce's father) Doherty a set of scales that had been used by several generations of Hirsts and adapted by them over time for specific use in their mill. These Scales were saved from waste and being thrown away at the time of sale to remain in use in the industry in the hands of someone who knew how to use them. The scales were used in calculating the weight of cloth and simultaneously calculating the amount of yarn required to weave it following the instructions printed within the box. The box bears the signatures of two Hirst family members, one being Lewis Hirst dated at 1898. The original brass pole has been replaced with a replica metal somewhere throughout the years after the brass pole broke through use. Hirst was brought by McKendrick in the 1960s and these scales sat for 12 months as part of the 12 month "cooling off" period. The scales were then handed to Donald rather than being disposed of.Scales used for weighing and calculating weight and thread count of textile samples. Originated from Godfrey Hirst Mills in Geelong. Writing describes how to utilise scales. Scales are made from brass, pole for holding scales once brass now replaced with metal pole. Scales held inside wooden box with black text in ink depicting use of scales on paper located inside and outside of box.Outside of box. Wording: APPARTUS for TESTING the WEIGHT per YARD of CLOTHS & COUNT of YARN from a small SAMPLE. -------------------------------------------------------------------------------------------------------------------------------------------------- Indispensable to Manufactures, Merchants & handling Woollen, Worsted, Cotton, Linen, Jute, Hemp, Flannel, Felt, Army, Navy, Police, Railway, Sail & other Cloths -------------------------------------------------------------------------------------------------------------------------------------------------- USED IN GOVERNMENT DEPARTMENTS -------------------------------------------------------------------------------------------------------------------------------------------------- The apparatus consists of Scales, Weights, 1, 2 & 4 sq. inch Cutting Templates & Book of Tables --------------------------------------------------------------------------------------------------------------------------------------------------By weighing a small Sample the accurate Weight in Ounces of a yard of Cloth any width from 18 to 64 inches, the Weight per Square Metre in Grams, the Counts* of Warp and Weft, and the approximate length of full & short ends of pieces of fabrics, [without unrolling and measuring for stocktaking & other purposes] can be ascertained without any Calculation --------------------------------------------------------------------------------------------------------------------------------------------------Price in United Kingdom, 25s., Carriage Paid. Price to Canada & U.S.A. $6.75 do. H. Lord. 10, And Place, Bradford, England. --------------------------------------------------------------------------------------------------------------------------------------------------*When ordering, state on what system you base your YARN COUNTS. Inside of box. Wording: DIRECTIONS FOR USE --------------------------------------------------------------------------------------------------------------------------------------------------TESTING WEIGHT OF CLOTHS. Place sample to be tested on a piece of cardboard, put a Cutting Template on it, cut card and cloth round template with scissors and weigh it according to instructions given in Book of Tables. TESTING FOR YARN COUNTS. Cut out 1 square inch of cloth, draw out wrap or weft threads, according to which is being tested, and the number of inches so drawn, that balance respective weight is the approximate Count. The same rule holds good when number of inches are drawn from a bobbin. In testing from the cloth, allowance has to be made for loss or gain in the process of manufacture. Weight marked C is for Cotton Counts " " W " " Worsted " " " WS " " Woollen Skeins " " L " " Linen Counts. The weights for testing samples of cloth are 20, 10, 10, 5, 3, 2, 1, grains in brass & '5, '3, '2, '1 [tenths of a grain] in aluminium. Inside of box. Signtures, handwritten: Bottom right: Lewis Hirst !898 Top Left (Smudge ?) W Hirst !935godfrey hirst, hirst family, textile design, textile creation -

National Wool Museum

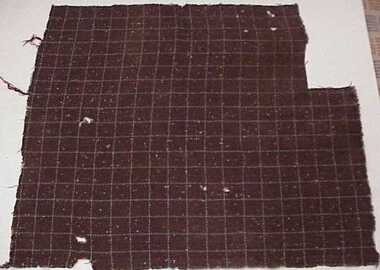

National Wool MuseumSample, Textile

Fred Murgatroyd's twed fabric to be used in conjunction with Nino at Foster Valley for Loom in G2textile industry textile mills, foster valley mill pty ltd valley worsted mill, tweed, murgatroyd, mr fred, textile industry, textile mills -

National Wool Museum

National Wool MuseumBook, Hand books of the textile industry, vol 2: manufacture of narrow woven fabrics

"Hand books of the textile industry, vol 2: manufacture of narrow woven fabrics" - E A PosseltK M Chisholm/ Denholm/ Bowenfelstextile calculations textile industry weaving textile industry - education, weaving, weaving looms, yarn - woollen, yarn - worsted, ribbon, textile calculations, textile industry, textile industry - education -

National Wool Museum

National Wool MuseumTag, All Together Australian

Swing tag, guarantee that product is made in Australia from fabric knitted or woven by an Australian mill.Swing tag, guarantee that product is made in Australia from fabric knitted or woven by an Australian mill.woollen mills, valley worsted mill -

National Wool Museum

National Wool MuseumBook, Cloth Sample, Cumberland "Light kid mohair"

A cloth sample book, containing samples of Cumberland "light kid mohair" suiting fabric.textile design, cumberland, cloth - worsted, mohair -

National Wool Museum

National Wool MuseumBook, Cloth Sample, Cumberland "extra light super 100's"

A cloth sample book, containing samples of Cumberland "extra light super 100's" suiting fabric.textile design, cumberland, cloth - worsted -

National Wool Museum

National Wool MuseumBook, Wool Fabric Resource Guide

"Wool Fabric Resource Guide" - Australian Wool Corporation, c.1985.textile production machine knitting woollen mills, australian wool corporation, cloth - woollen, cloth - worsted, textile production, machine knitting, woollen mills -

National Wool Museum

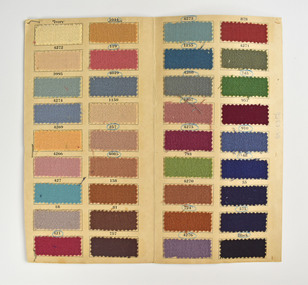

National Wool MuseumBook, cloth sample

Cloth sample book of Botany Certified Fabrics contains 36 different coloured cloth samples, part of Collins Bros collection.weaving mills, botany worsted mills -

National Wool Museum

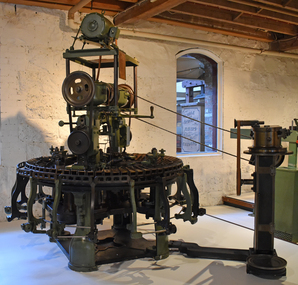

National Wool MuseumMachine - Noble Comb, Prince Smith & Sons, Burlington Shed, Keighley, 1915

Combing removes the short or broken fibres and draws out the long fibres into even strands suitable for spinning. The process is necessary to produce long and soft strands needed for worsted yarn. These machines remove the short fibres and blend the remaining long fibres together to form the top. The short fibres that are removed, known as the noil, are used in the woollen system. The long fibres are drawn together, ready for spinning. To retain as many of the valuable long fibres as possible, a skilled operator always needed to be on duty in the factory to precisely set the machine. A Nobel Comb separates short (Noils) fibres while also blending long (Tops) fibres together. The long fibres are used for worsted materials while the short fibres are used for woollen fabrics. Woollen materials are soft, bulky and fuzzy, such as a picnic blanket; whereas worsted materials are fine, smooth and crisp, such as a suit jacket. The Valley Worsted Mills in Geelong, now the Little Creatures Brewery, ran 12 noble combs up until 1981. Gold plaque on display with machine until 2018 read: G.H. Mitchell & Son, Adelaide have celebrated 125 Years of involvement with the Australian Wool Processing Industry by contributing the funds necessary to restore The Carding Machine, Noble Comb & The Gill Box.Noble Comb with plates - 'Prince Smith & Sons, Burlington Shed, Keishley' (One plate located on each gear box). 'Prince Smith & Sons, Burlington Shed, Keishley' (One plate located on each gear box).wool manufacturing, noble comb, textile industry, geelong, little creatures brewery, valley worsted mills, fibres, wool, factory -

National Wool Museum

National Wool MuseumBook, Cloth Sample, Cumberland "extra light" new trends

A cloth sample book, containing samples of Cumberland "extra light" suiting fabric.textile design, cumberland, cloth - worsted -

National Wool Museum

National Wool MuseumClothing - Shirt, 1925-1938

Male wool shirt made in Bradford, U.K. The shirt is cut from first fabric woven from 100% traceable Australian wool. Bradford Mills differ to Australian mills in that the entire process of producing worsted material does not take place at the one firm/factory. Rather it is split between many firm/factories specialising in their task in the production of worsted material. For example, the wool goes from merchants to combers to produce tops, the tops to spinners to produce yarn and then the yarn is sold to manufactures who weave it into cloth. After the weaving is done the cloth has to be sent to the dryers and finishers, who scour, dye and finish the cloth. Finally, the finished cloth is purchase by a fresh set of merchants, who will later sell the cloth elsewhere in England or abroad. At each these steps a new firm is handling the wool/cloth making it hard to track lineage of wool through this process and hence hard to guarantee 100% Australian wool. This shirt was purchased and worn by the donor’s husband, George H. Gerber, an Australian Wool Buyer. The shirt was purchased on one of George’s trips to Bradford in the U.K. on company business. Gerber was a second-generation Wool Traders in his family. His father, also named George H. Gerber, worked for Kreglinger & Furneau. He worked for them in Boston, U.S.A. before he died from the Spanish Flu in 1918. The company then promised a job to his oldest son (donor’s husband) once he finished school. Thus, George came to be trained as a Fine Wool Classer by Kreglinger & Furneaux (Aust.) Pty Ltd where he was employed as a Wool Buyer all his working life. He retired in 1969 as the head of their Australian office when the company was taken over Also of note, the shirt was sold with 2 add-on collars. Having additional collars was advantageous as changing only the collar increased the number of days the shirt could be worn without washing. Cream coloured shirt with black and red single thread verticle stripes.“Grandpa” collar (with 1 of its 2 supplied add-on collars included). French cuffs. Sold with 2 add-on collars, hence both ends of the collar have buttonholes to take a stud, and a partially-opened button-hole is at the centre of the neck on the outside of the collar for a second stud.Letering label on shirt: GENT’S OUTFITTER Herbert Winfield 23 CHEAPSIDE, BRADFORDbradford, u.k, kreglinger & furneaux (aust.) pty ltd, 100% australian wool -

National Wool Museum

National Wool MuseumStencil - HUDDERSFIELD

This stencil was used as a location stamp for the transportation of wool bales. HUDDERSFIELD Valley Worsted Mills is located in Geelong. Stencils marked HUDDERSFIELD would have been transported to the Worsted Mills to be made into yarn and fabric.Wool bale stencil - HUDDERSFIELDHUDDERSFIELDwool - transportation, wool sales -

National Wool Museum

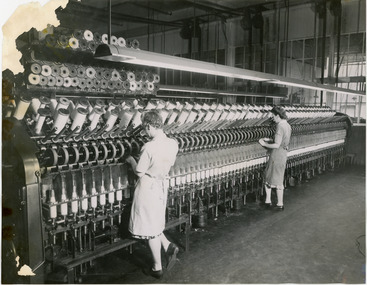

National Wool MuseumPhotograph - Worsted Spinning, 1960s

One of fifty one photographs originally in a photo album found in the National Wool Museum’s office. The album was water damaged and the images were removed for conservation. The images follow the process of wool. Beginning in a sheep paddock and finishing as a folded fabric. It includes all the steps in between in this process, including shearing, transporting, selling, washing and the many different steps in the process of turning a single thread of wool into fabric.Black and white image showing two women working at a worsted spinning machine.AUSTRALIAN NATIONAL PUBLICITY / ASSOCIATION / FLINDERS STREET RAILWAY BUILDING, / MELBOURNE AUSTRALIA / W19 / W19. , Worsted Spinning.wool industry, working life, women, boonoke station, farming, sheep farming, agriculture, sheep stations, transport, wool processing, shearing, textile industry, wool -

National Wool Museum

National Wool MuseumTextile - Fabric Sample, Valley Worsted Mills

... , with metal eyelet at the top Textile Fabric Sample Valley Worsted ...Sample of woollen fabric, with tag, produced at the Valley Worsted Mills, Geelong.9080.1 - piece of grey woollen fabric 9080.2 - paper label with printed and handwritten text, with metal eyelet at the topfront of label: [printed] VALLEY / GUARANTEED / PURE / AUSTRALIAN / WOOL back of label: [printed] VALLEY WORSTED MILLS LTD. / GEELONG / Piece No. / Quality / Yards / Strings back of label: [handwritten] 3.7 mts / 2 1/2 YRDSvalley worsted mills, geelong, wool, textiles, woollen fabric sample, fabric tag, production tag, wool mill, textile industry