Historical information

Gold bearing ore is pulverized by cast iron stampers (steam driven) and material then passes over a large copper plate covered in mercury causing the gold particles to combine with the mercury to form an amalgam which is scraped of and placed in a retort. The retort is heated causing the mercury to evaporate leaving the gold to be refined into ingots. The mercury is cooled as it leaves the retort and is reused. A second tray covered in what is called a blanket traps any fine gold that has passed the first plate. Finally the residue material goes over a vibrating table called a Wilfley Table which captures any iron pyrites which may contain about three percent gold. this is roasted and treated to recover any remaining gold at a special treatment plant.

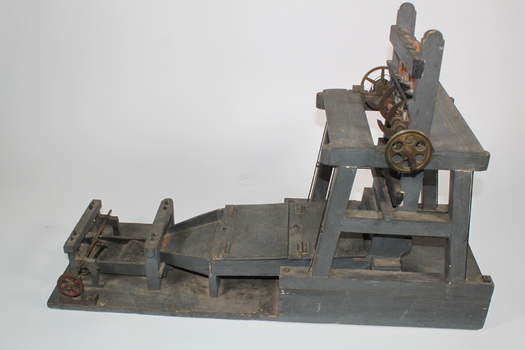

Physical description

Wooden model of a five heads gold stamper battery. The gold stamper battery is a device for crushing ore. The parts of the battery are cams; dies; guides; kingposts; mortar box; shoes; stamps (or stampers); tappets.