Showing 45 items

matching belt driven

-

National Wool Museum

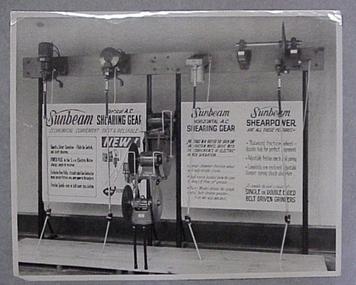

National Wool MuseumPhotograph, Commercial display - full range Sunbeam shearing gear

... and double ended electirc and belt driven grinders circa 1956... electirc and belt driven grinders circa 1956 Ingerson-Arnold ...Photograph of Sunbeam shearing machinery at a commercial display.Photograph of Sunbeam shearing machinery at a commercial display.Commercial display - full range Sunbeam shearing gear electric vertical & horizontal heavy duty models farm models for small flock owners Shearpower overhead shearing gear single and double ended electirc and belt driven grinders circa 1956 Ingerson-Arnold Studios Limited 84-88 Franklin St., Adleaide telephones LA 2848 LA 5867 To reorder quote No ....... AB 4569shearing machinery, ingerson-arnold studios ltd -

Harcourt Valley Heritage & Tourist Centre

Harcourt Valley Heritage & Tourist CentreCider Press, 1880s

... to press apples. It was then belt-driven by an electric motor... by Harcourt Coolstores to press apples. It was then belt-driven ...A 'BUCKEYE" grape and cider press, manufactured by P.P. Mast & Co. of Springfield, Ohio, USA and distributed by P. Rohs, Sandhurst (Bendigo). The PP Mast Company was established in 1854. Their Buckeye drills, seeders and other implements played an important role in the development of American farm machinery, being sold in every American state, Europe and Australia. This press was used by the Gaasch family of Harcourt over several generations from 1898 to crush grapes for wine and vinegar making, subsequently to crush apples and then press the pulp to make apple vinegar and cider. The crushing was accompanied by lusty singing of songs and hymns such as 'Ein Feste Burg ist unter Gott'. The press was designed to be hand-operated but was later used by Harcourt Coolstores to press apples. It was then belt-driven by an electric motor. The press was restored (timber cleaned and varnished, metal shoes on base of wooden uprights, which had rotted ) by Mr. Howard Carr, 2001-An early application of mechanics to the crushing of grapes. Hand-driven, geared drive metal crushing parts, with metal flywheel, wooden feed hopper in vertical arrangement, wooden frame, tray and vat, with metal pressing screw installed in heavy metal yoke at front. Metal crushing section carries cast-in maker's name and patent details'BUCKEYE" manufactured by P.P. Mast & Co. of Springfield, Ohio, USA distributed by P. Rohs, Sandhurst (Bendigo). -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - NEW MOON MINE - COPIES OF NEGATIVES OF THE NEW MOON MINE

... and tables. They are driven by long belts being driven by a long.... They are driven by long belts being driven by a long overhead shaft. Two ...Four copies of negatives, three showing mining machinery and the fourth, a table. (a) shows machinery driven by a large flywheel. A man is operating the machine. (b) shows the crushing machine and tables. They are driven by long belts being driven by a long overhead shaft. Two men are at the machine. A tub is in the foreground. (c - shows a view of the fitting shop at crushing machine. Picture is not very clear. There are four men in the picture. (d) shows a reverse image table of gross total of tons, gold, dividends and calls to June 30th, 1906. photo, new moon mine, copies of negatives of the new moon mine, mine machinery, crushing works, a richardson -

National Wool Museum

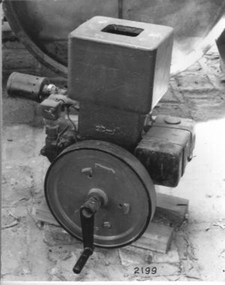

National Wool MuseumTool - Grinder, 1960-69

... to have been produced in the 1960s. It is belt driven... driven, with the other end of the belt being attached ...Cooper S.E. Ball Bearing Grinder made and guaranteed by Sunbeam Corporation Limited. Grinders like this example have been made the same since the early 1900s, with this grinder thought to have been produced in the 1960s. It is belt driven, with the other end of the belt being attached to an engine; the same engine that would have powered the overhead shearing equipment in shearing sheds. It was common for shearing teams to bring their own equipment, especially pre-1960 as most shearing sheds were not connected to power, and shearers preferred to work with their own equipment. The engines that powered the shears and grinder were typically fuelled with kerosene or petrol. The large circular disks are attached to the bolt that protrudes from the grinder and fastened tightly with a nut. An example of seeing a similar grinder in action can be found on the following link - https://www.youtube.com/watch?v=O7eimI_Gm9o. Inventor Frederick Wolseley made the world's first commercially successful power-shearing system in Australia in 1888. US company Cooper, which had been founded in 1843 as a maker of sheep dip, began selling Wolseley equipment in the USA in 1895. The Chicago Flexible Shaft Company successfully entered the power-shearing market a few years later and entered a joint venture with Cooper. It set up a branch in Sydney and sold shearing sets, and engines to power them, into the Australian market. In 1921 the US parent company, realising it needed to make products whose sales were not as seasonal as those of shearing equipment, made its first household appliances and branded them Sunbeam. In 1933, changes in exchange rates and taxes led the company to manufacture engines and shearing equipment in Australia via subsidiary Cooper Engineering, which changed its name to Sunbeam in 1946. Although most Australians know of this company as a major manufacturer of household appliances, its rural division flourished and retained the Sunbeam name for shearing equipment even after it was taken over by New Zealand company Tru-Test in 2001. The grinder is formed from a central arch shaped block of green painted metal. Much of this paint has been lost to age, leaving the grinder in a ‘farm used’ condition with much surface oxidation present. On the front of the arch is a specification plate, reading “Cooper S.E. ball bearing grinder. Made and guaranteed by Sunbeam”. At the foot of the arch, three bolt holes are found for securing the grinder to the base of a solid wooden surface. Two of the bolt holes are found on the front of the grinder, with another found on the rear. From the central arch, a bolt protrudes to the right of the grinder. This large bolt is for securing a grinding plate to the grinder. Above the central arch is a pendulum which holds the comb / cutter that is being sharpened. From the pendulum, a large arm extends down (not pictured) to meet and strike the plate spinning at a rapid speed. On the left-hand side of the central arch of the grinder, a wheel is found which a belt is attached to for power. This belt is then attached to a separate engine, spinning the wheel and hence powering the grinder. The wheel is partially covered with a section of protective bent tube, designed to provide protection from the rapidly spinning wheel. Below this wheel is the belt shifter. It is designed to move the protective bent tube from one side of the grinder to the other, to accommodate the grinder in the setup of different shearing sheds. The two separate grinding plates are identical. They have a slight slope for sharpening the comb and cutters in the correct method, with a slight bias towards the base, or “tooth”, of the equipment. The disks have a large central bolt for attaching to the grinder. They have tags on the horizontal axis of the grinding plates, for securing the plates in transportation, and to help with initial alignment when setting up the grinder. The reverse of these grinding plates has the same green painted metal finish found on the grinder. This paint is also in a ‘farm used’ condition, with surface oxidation present. The grinder would be provided from the factory with a comb holder, shifter for securing the grinding plates, emery cloth and emery glue. The emery cloth is what does the actual grinding and is applied to the grinding disks, replacing once well worn. These items can be seen in the final images in the multimedia section, showcasing advertising for this grinder. Plate. Inscribed. “Cooper / S.E. BALL BEARING GRINDER / MADE AND GUARANTEED BY / Sunbeam / CORPORATION LIMITED / SYDNEY MELBOURNE / ADELAIDE BRISBANE ”sheep shearing, shearing equipment, sunbeam, grinder -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAudio - Phonograph, Thomas A. Edison, Edison Laboratory, c.1909

... on the side of the machine to start the belt-driven, spring-loaded... the crank handle on the side of the machine to start the belt-driven ...The Edison Fireside Phonograph Combination Type A model phonograph was an open horn model. This machine was produced around 1909, just after the introduction of 4-minute record cylinders in 1908.; the selection lever on the front was either 4 or 2-minute choice. This Fireside model has a fluted octagonal horn that attaches to the reproducer on the machine and is suspended by on ring by a horn crane attachment. The phonograph machine is powered purely by mechanical means, winding the crank handle on the side of the machine to start the belt-driven, spring-loaded motor inside. The sound comes from a pre-recorded, vertical cut record cylinder, which slides over the Mandle, a smooth rotating drum. The reproducer, an all-in-one needle, amplifier and speaker, is lowered onto the cylinder, the needle picks up the sound and plays it on the speaker and the attached horn amplifies the sound. The phonograph machine was invented by Thomas Alva Edison in the late 19th century. Edison adopted the idea from the technology of the telegraph machine. He patented the phonograph in early 1878. It was able to record sound and play it back. This amazing invention opened up a whole new world of entertainment, where wax cylinders of pre-recorded sound could be purchased with a wide variety of music and played over and over. The first wax cylinders were white and used a combination of bees' wax and animal fax or tallow. By 1892 Edison was using 'brown wax' cylinders that ranged from cream through to dark brown. The Edison Phonograph Company was formed in 1887 to produce these machines. He sold the company in 1855 to the North American Phonograph Company but bought that company in 1890. He then started the Edison Spring Motor factory in 1895, and the National Phonograph Company in 1896. In 1910 the company became Thomas A. Edison Inc. In 1898 Edison produced the Edison Standard Phonograph, the first phonograph to carry his own trade mark. He began mass producing duplicate copies of his wax cylinders in 1901 using moulds instead of engraving the cylinders. The wax was black and harder than the brown wax. The ends of the cylinders were bevelled so that the title's label could be added. The last phonograph machine to use an external open horn was produced in 1912 due to the much more robust round records being invented. In 1913 Edison started producing the Edison Disc Phonograph. The company stopped trading in 1929.This Edison Fireside Phonograph model is significant for being one of the last models to have an external horn. It is also significant for its connection with the invention of the phonograph, which made music and sound available for domestic enjoyment. It was used for entertainment and education, even teaching languages. It signalled a new era of music that could be reproduced and played anywhere. It is also significant for its short time span of popularity, just a few decades, due to the growing use of records, which gave a much higher quality sound and were more robust.Phonograph; Edison Fireside Phonograph, Combination Type, Model A. It is in a wooden case with a domed lid, metal catches on each side and a folding wooden handle. It has a metal drum and a reproducer mechanism. The metal and wood crank handle starts the machine’s motor. A sliding lever at the front selects the speed for four- or two-minute cylinders. The inscribed plate has the maker, serial number, patents and other information. The reproducer also has an inscription. It has a curved metal open horn attachment. Made in Orange, New Jersey in c.1909. NOTE: the fluted octagonal horn is catalogued separately.Case front, in script, Edison’s early ‘banner’ decal “Edison” On the front of the machine “Thomas A Edison TRADE MARK” On the maker’s plate; "Edison Fireside Phonograph Combination Type" Serial number “14718” Around sound outlet; “C 4076” “REPRODUCER LICENCED FOR USE ONLY ON EDISON PHOTOGRAPHS SOLD BYT.A. EDISON INC.” At the front edge “4 MINUTES 2flagstaff hill, maritime museum, maritime village, warrnambool, great ocean road, shipwreck coast, gramophone, phonograph, music player, entertainment, audio equipment, edison, thomas a edison, horn, phonograph horn, amplifier, audio, sound recording, sound playback, phonograph machine, phonograph cylinder, external horn, edison phonograph company, wax cylinders, sound reproduction, edison spring motor factory, national phonograph company, thomas a. edison inc, crank-operated motor, open horn phonograph, 4 speed, 2 speed -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDrill Press, early to mid-20th century

This post drill press has been made by Melbourne business, Dawn Manufacturing Company. It can be operated manually or by a pulley driven flywheel, with the aid of an engine connected to a power supply. In the late 1800s early 1900s a drill press like this would have been driven by steam from a boiler, the main power source for manufacturer’s power at that time. Dawn’s Golden Anniversary 1917-1967 Catalogue describes this model 611 drill as … “Ruggedly constructed with accurately reamed bearings. The coupling between the main spindle and feed screw engages the full circumference of the spindle, and embraces a ball-bearing thrust race. The pillar, as in all “Dawn Drilling Machines” is a solid bright steel bar, in place of the usual light tubing. Adjustable automatic feed.” And “F. & l. Pulleys extra, if required”. DAWN MANUFACTURING CO. The Dawn Manufacturing Co. was founded in Coburg, Melbourne, in 1917 by the four Blake brothers, who were all engineers. After World War I Dawn was supplying drills Australia wide and the company was growing at a healthy rate. During the depression they remained busy, with employees working 60-80 hour weeks. Dawn was contracted to supply vices and clamps to the Australian Defence Department and munitions factory during the World War II. - 1959 the company was taken over by G.N. Raymond Group. - 1967 the Dawn Manufacturing Co. had distributors in Australia and overseas, including USA, Canada, New Zealand, Asia and the Middle East. - 1973 the Siddons Ramset Limited acquired Dawn. - December 1991, Dawn became a unit of the United States owned Stanley Works Pty. Ltd. - November 1998 Dawn became 100 per cent Australian owned. The drill is a typical tool of a blacksmith, cart wright, wheelwright and garage business. It is an example of the tools of the blacksmiths’ trade in Victoria in the early to mid-20th century.Post type drill press machine with gear driven flywheel. Drill press is attached to a post and is fitted with a pulley belt and will run at a speed of maxim 200 r.p.m. The machine can also be manually operated. It has an aperture in the centre, a chuck, for the drill bit and has two metal handles at the centre, on the right hand side. Gear ratio 2:1 main drive, 6" diam, 3:1 reduction gear. Made by Dawn of Melbourne, Australia. Model No. 611, Code No. 9157"DAWN MFG COY”, “MELB. AUSTRALIA", " 611"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, blacksmiths, blacksmith’s drill, blacksmith tools, dawn drill model no. 611, dawn drill code no. 9157, dawn manufacturing coy melbourne, dawn manufacturing coy coburg, dawn post drill, drilling machine, drill with gear driven flywheel, forging tool, metal working tool, post drill, steam powered drill, trade tool, warrnambool district 1900s -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Tilting Saw Bench, W F & John Barnes, 1874 to 1880

he subject item is a pedal-powered rip saw with a tilting table made in the USA by W.F. & John Barnes Co. of Rockford, Illinois, between 1874 and 1890. The saw's blade moves rapidly in a circular motion and is driven by a pedal that spins a heavy flywheel with a leather belt attached to a gear drive that in turn drives the circular saw blade. The operator holds a wood workpiece on the table and moves it forward so the blade cuts it to the desired width and length. Company History: WF & John Barnes Co. was established in 1869, by making a formal partnership between William F. Barnes and John Barnes in 1872, and then incorporating in 1884. This company was an early manufacturer of pedal-powered equipment. By 1881 they were also making powered machinery such as lathes and pedestal drills. Many companies were making lightweight foot-powered equipment, but Barnes and the Seneca Falls Co. were the only ones to also make professional-grade workshop machines. From the beginning of their existence, they focused on pedal-powered machinery and specialised in making scroll saws. By 1937 the company focus had completely shifted to automotive assembly machinery, and custom-built machinery, machine tools, electrical, hydraulic, and mechanical controls and systems, including nuclear hardware. their production of foot-powered machinery had ceased. In the intervening years, they have got out of manufacturing completely. After a series of ownership changes, their equipment parts and stock were purchased in 1998 by LeBlond Ltd. of Amelia, Ohio. An item that although incomplete gives a snapshot into the manufacture and use of early woodworking machinery before the introduction of electricity or electric motors to power machines.A Treadle powered tilting table saw benchWF & J Barnes, Rockford Ill USA flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Bendigo Historical Society Inc.

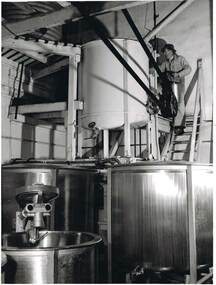

Bendigo Historical Society Inc.Photograph - COHN BROTHERS COLLECTION: STORAGE/MIXING TANKS

... has an agitator which is driven by a large belt and pulley... them. The higher vat has an agitator which is driven by a large ...Photograph. Cohn Bros. Collection. Black & white photo of three steel vats and one other vat above them. The higher vat has an agitator which is driven by a large belt and pulley. A man holding a bucket is standing on a stairway beside it. ML45/6 (written on the back).organization, business, cohn bros, cohn bros. collection, brewers, cordial & aerated water manufacturers -

Yarrawonga and Mulwala Pioneer Museum

Yarrawonga and Mulwala Pioneer MuseumGrain Grister, 1925

... are adjustable .Machine driven by flat leather belt on a pulley from... Rollers are adjustable .Machine driven by flat leather belt ...grinding grainWooden delivery /storage box on top of metal Grister with three cogs and flywheel [approx. 30 cm diameter] and metal grinding cylinders [rollers] with horizontal grooved lines all around .This is bolted to a wooden stand [painted green] which has a wooden box to receive the crushed grain Rollers are adjustable .Machine driven by flat leather belt on a pulley from a small stationary engine Metal plaque attached to top of delivery box. J Buncle Parkside Ironworks North Melbournegrain, grister, farming, machinery -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Equipment - Stationary Motor

Used by Ted Beddiscomb of Gormandale near Traralgon, brother in law of donor. Ted was a dairy farmer and used the motor for about 10 years to pump water. It is possible it was on his farm for some years prior to this. Tom did some reconditioning and preservation on the unit.3 HP 4 cycle motor primarily used to belt drive other equipment such as pumps and machinery on a farm etc. Petrol driven, magneto ignition and water cooled.Bronze plate 'The Rosebery Engine C25387 RPM 1000 HP3 manufacturer Westinghouse Rosebery Ltd Sydney. 3C-103 on water jacket; 3D-1 on engine housing; 3C-15 on flywheel.rural industry, farm machinery, machinery, engines - internal combustion -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncOil Engine

Bartram type AK, 5 HP horizontal cylinder water cooled magneto ignition oil Engine mounted on a metal and timber chassis with 4 wheels. It has its own cam driven water pump which pumps cooling water over metal gauze for evaporative cooling. Painted green. It has two flywheels, one at each end of the crankshaft, with a flat belt pulley attached to one flywheel. Cooling tank of galvanised steel with Bartram stencilled on one side. In working order.Cast nameplate on front of crankcase with a Bartram logo cast on also "Bertram / Type / AK" -

Whitehorse Historical Society Inc.

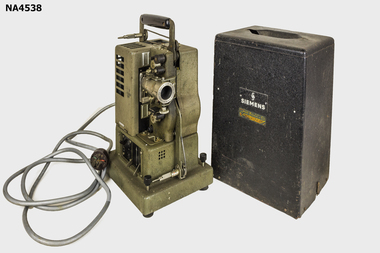

Whitehorse Historical Society Inc.Equipment - Projector, 1930

... siemens name on it and is focusable. Reels are driven by spring... siemens name on it and is focusable. Reels are driven by spring ...Black case containing Siemens movie projector. The carry case has an opening in top for handle to come through and two locking tabs on bottom of two sides and Siemens metal label on side. Camera is dark grey with two folding reel holders, one of which doubles as a carry handle through case top. Camera has electric cord and power switch on bottom right with two other switches. Two sides fold down, probably for cooling. Lens has siemens name on it and is focusable. Reels are driven by spring belts. Number H77702 on small tag on side above switches.SIEMENS ASH BESTER & CO. H77702photography, projectors -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumLathe (Model)

"This is a rough model of the woodturning lathe Kurt Beilharz built from scrap as a 17 year old in Camp 3, Tatura. The drive wheel was a hollow redgum block from the firewood supply. The shaft was a 1/2" water pipe, the bearings of the spindle were 3/4" water pipe with tooth paste tubes melted into and honed out for the spindle. They had holes for oiling. The drive belt came from my Mother's sewing machine. I used screws in the model, but in reality bolts were used, which were bought as well as the framing timber"Wooden model of a lathe made and used at Camp 3. Triangular upright frame with a hollow drive wheel, driven by a piece of wire with a handle on one end. Drive belt is a piece of fine cord.lathe, model, beilharz, k, camp 3, tatura, ww2 camp 3, handcrafts, models -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Boiler, T & F Johnson, boilermakers, late 19th century

A steam boiler like this late 18th century boiler, is often called a colonial boiler. Steam boilers were used in factories throughout Australia, mounted over similar designs of brick furnaces. This heat from the fire travels through the tubes in this fire tube boiler and the water heats as it circulates around them. Another kind of boiler is a water tube boiler, in which the water is inside the tubes and the heat of the combustion surrounds the tubes. The boiler in our collection burned wood as fuel but others of this design could also burn coal, coke, gas and liquid fuels. The boiler was made by T & F Johnson, boilermakers. In 1922 their factory was located at Coventry Street, South Melbourne. They were still advertising their 'Colonial, multi, vertical boilers, all sizes' at the same address in 1934. The connected pressure gauge, made in London by Dewrance, measures 0 to 400 pounds per square inch. John Dewrance is renowned as a pioneer of the steam locomotive in the early 19th century. He founded John Dewrance & Co. in South London in 1844. His son Sir John Dewrance took over in 1879. In 1939 the company became a subsidiary of Babcock & Wilcox, and was eventually owned by Emerson. How the boiler works: - A boiler is about two-thirds filled with water and heat is applied, in this case in the form of burning wood. The heat is transferred through the metal of the boiler to the water. When the water boils the steam rises to the top, and as it escapes from the boiler the steam pressure builds up in the steam space to later be released to do work; drive machinery such as ship and train engines, turbines, presses, wheels, and driving belts to operate looms and saws. The heat associated with the boiler can be used for preserving food, sterilising, factory manufacturing processes, and steaming wood for shipbuilding. Every boiler has several components fitted for safe operation: - - Safety valves - Gauge glass - Pressure gauge - Main steam stop valve - Water check valve - Blowdown valve - Manhole doorThe boiler is a significant item that gives us a snapshot of early Melbourne's industrial history. It is an example of the technological advancement during the Industrial Revolution where steam-driven machinery and motors could perform tasks more efficiently than manual labour. The makers were one of many boilermaker businesses in Melbourne during the early late-19th andearly 20th centuries. The maritime trade and skills of boilermaking are still learned and applied today. The Dewrance steam pressure gauge connected to the boiler was made by the London firms foundered by John Dewrance. He was renowned for developing the steam locomotive in the early 19th century.Boiler; a horizontal cylindrical underfired steam boiler. It is a multi-tubular design and is timber plank-clad, with brass fittings and pressure gauges. The boiler has an iron door at one end with a metal chimney above it. It is installed over a brick-enclosed solid fuel furnace. Two large, wood-mounted pressure gauges are connected to the boiler and have inscriptions. An inscription is on a red, cast iron plaque above the boiler door. The boiler's maker is T & F Johnson, South Melbourne. One of the pressure gauges was made by Dewrance, London..Maker's plate: "T & F JOHNSON / BOILERMAKERS / SOUTH MELBOURNE" Pressure gauge: "POUNDS PRESSURE / PER [square] INCH / DEWRANCE LONDON"flagstaff hill, warrnambool, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, boiler, multi tube boiler, steam boiler, steam technology, underfired boiler, horizontal boiler, timber clad boiler, steam power, industrialisation, boilermakers, south melbourne, dewrance, john dewrance, pressure gauge, dewrance pressure gauge, t & f johnson, london, steam engine, steam locomotive, pounds per square inch, 19th century, steam machine, johnson tyne foundry, colonial boiler, fire tube boiler -

Stawell Historical Society Inc

Stawell Historical Society IncPhotograph, Bush Sawmill beside the Wimmera River in Dunolly 1993

Dunolly 1993. Bush Sawmill beside the Wimmera River. Wooden buildings in Background. Chimney of what appears to be a steam driven engine with flywheel and belt driving a saw bench. Several men in photo. Original photographic taken by Charles Nettleton.Black & white photograph of timber and logs beside a water body with buildings and a tall chimney in the background. Around seven people in the background.Bush Saw Mill Wimmera River near Stawell 1877 Negative Reversed copy also 2641water industry