Showing 72 items

matching cast iron on wood

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageWeapon - Cannon, mid to late 19th century

The history of the Thunderchild gun is not known. It was presumably manufactured in Torquay in the second half of the 19th century. Such guns were often attached to a ship’s rail through the holes in the swivel base, as in the base of this gun. The guns fired grapeshot and were originally used on ships to repel boarders. They were also used to launch whaling harpoons and were sometimes employed for signalling. The relatively late date makes the latter application most likely. This Thunderchild gun is complete with ramrod and wad remover. It is in good working order and easily assembled. It is used locally for special ceremonies and for Whaleboat Races as a starting gun. (Guns and Cannon, South Wester Victoria, May 2008, ref W/F/03) The small bore cannon is part of a collection of nineteenth century Flagstaff Hill Guns and Cannon, which is classified as being a high level of significance, on State, National and World The nineteenth century artillery pieces are a very rare and representative collection of artillery of this era. The artillery pieces, individually and as a collection, are highly significant for historical, scientific and aesthetic reasons at the state, national and world levels. The artillery pieces are excellent examples of nineteenth century artillery designed for the shore defence of western Victoria in the mid to late 1800s. The collection demonstrates the system of nineteenth century Imperial Defence implemented by Britain and of the recycling of obsolete technology to the colonies by Britain. The collection represents the methods of artillery technology, its advancement and its modifications in order to remain active. It also illustrates the transference of defence technology from Britain to Australia and demonstrates the level of reliance Australia had on British defence equipment. The artillery pieces form prominent elements in their landscapes and, together with the batteries and sites in which they are located, create a strong visual link to the region’s defence history. Importantly the artillery pieces, individually and as a collection, represent a very rare and intact group of nineteenth century artillery. Very few examples of nineteenth century artillery have survived worldwide, the largest collections being sited in Canada. The collection is a rare collection of artillery which demonstrates the advancements made in artillery technology during the nineteenth century, and is one of the largest collections of nineteenth century artillery in Australia. Further, the collection is extremely intact, with most pieces retaining original carriages and many located within their original emplacement. This collection of artillery, with their carriages and in their locations, are of exceptional national significance as they represent the largest intact collection of artillery within a single defensive network, outside of major colonial ports. The collection of nineteenth century carriages and slides are in themselves an extremely rare and important collection, however their significance is enhanced by their placements within batteries and with guns. (Conservation Management Plan for Victorian Guns and Cannon, South Western Victoria, May 2008) Cannon; small 1pdr cast iron, smooth bore muzzle loading swivel gun, painted glass black. 19th century cannon has polished wood handle, two detachable metal stirrups and metal swivel base with cuff, attached to block of wood by four bolts. Accessories are a wood tamper and wood ramrod. Name on gun is Thunder-Child, Torquay, Vic. There are Maker’s Marks on the gun and base, and a number on the cannon.. Marks; Barrel "Thunder/ Child". Base cuff " THUNDER / -CHILD / TORQUAY / VIC ", Trunnion "2825/H"flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, cannon, torquay, thunder child cannon, thunderchild cannon, signal cannon, muzzle loading cannon, ordinance, munitions -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Pot Set

This set of pots represents the type of pot or saucepan used on an open range wood fired stove. The pots are heavy and thick, and have a solid lid suitable for slow cooking.This pot set is currently not associated with a historical event, person or place at this time and is being used to augment Flagstaff's village display.Pots; two cast iron pots with lids. Wooden handles on pots have ring on end for hanging. Pots have inscriptions. The large post has the capacity of 3 quart (3 quarts or 2.84 litres) and the small pot holds a capacity of 2qt (2 quart or 1.89 litres). Stamped on large pot "Made in Taiwan" "3qt" Stamped on small pot "Taiwan" and "Sauce Pan 2qt"flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, pot, saucepan, sauce pan, cooking pots, cook ware, food, slow cooking -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Fire fender, Late 19th to early 20th century

A fender is part of the hardware used in open fireplaces to prevent the fire from spilling out of the fireplace. Wood fires were the main source of domestic heating in the 19th century.This fender is significant for its association with domestic heating in the 19th and early 20th century.Fire fender, cast iron, painted black, sides bolted onto front as is base plateflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, shipwreck coast, great ocean road, fire fender, fire guard, domestic heating, fender -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Stove, 1960 - 1983

The Mont Eltham Pot Belly Stove History The Mont Eltham Pot Belly Stoves were first manufactured in the 1960s at the Burrowes family business The Lyn Iron Foundry in Coburg Victoria by Barry and his father Charles Thomas Burrowes. The manufacture of The Mont Eltham Pot Belly continued in Victoria as The Mont Eltham Stove Co. by Barry and Glenda Burrowes in Montmorency and later in Thomastown. The castings were produced by leading Melbourne foundries, Cox & Rosetti , and Anderson & Ritchie. They were also made in Ballarat by The Harding Bros Foundry, and in Shepparton by The Furphy Foundry. The Mount Eltham pot belly stoves were manufactured until the late 1980s. Stove; cast iron pot belly stove. Very large cylinder shape with square base, grate shelf around centre, on 4 legs. Inscription on door. "Swagman" model. Made by Mont Eltham Stoves, Victoria. "Mont Eltham Stoves Vic Swagman Aust"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, domestic heating, domestic heating, stove, pot belly stove, wood fired stove, old world stove, the mont eltham stove co., the lyn iron foundry, barry and glenda burrowes -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing Machine, late 19th or early 20th century

This Eclipse model, treadle operated sewing machine was made by the Oldham Sewing Machine Company in Greater Manchester U.K.. It was used by sailmakers for sewing sails with box shape top and slim neck. Sewing machine, foot treadle, for sewing sails with box shape top and slim neck. Brand is Eclipse. Cast iron base is bolted to square wooden table-top with drawer under table. Drawer has 3 partitions and wood fitting with 5 drilled holes for needle storage, lock has diamond shaped, decorative metal surrounds; half of inside drawer is painted black. Decorative metal stand, painted green, with 2 foot pedals; 1 foot pedal drives the wheel wheel. Padals both have "ECLIPSE" cast into the iron.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, textile machines, sailmaker's machine, maritime sewing machine -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Stove, 1850-1890

In the industrialized world, as stoves replaced open fires and braziers as a source of more efficient and reliable heating, models were developed that could also be used for cooking, and these came to be known as kitchen stoves. The first manufactured cast-iron stove was produced at Lynn, Mass., in 1642. This stove had no grates and was little more than a cast-iron box. About 1740 Benjamin Franklin invented the “Pennsylvania fireplace,” which incorporated the basic principles of the heating stove. The Franklin stove burned wood on a grate and had sliding doors that could be used to control the draft (flow of air) through it. Because the stove was relatively small, it could be installed in a large fireplace or used free-standing in the middle of a room by connecting it to a flue. The Franklin stove warmed farmhouses, city dwellings, and frontier cabins throughout North America. Its design influenced the development of the pot-bellied stove, which was a familiar feature in some homes well into the 20th century. The first round cast-iron stoves with grates for cooking food on them were manufactured by Isaac Orr at Philadelphia, Pa., in 1800. The base-burning stove for burning anthracite coal was invented in 1833 by Jordan A. Mott. The subject item is a mid to late 19th century settlers stove probably of Canadian manufacture imported into Australia around this time. The stove gives us a social snapshot into what life must have been like for our early colonialists using this device for heating and cooking in their meagre homes. Cast iron stove with four-legs, 2 plates on top and a hinged front door. The door has been cast with a maple leaf design and the sides have a pattern cast into them.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, stove, domestic heating, domestic cooking, heater, cooking unit, pot belly stove, wood fired stove, wood stove -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Brush

This stove brush is shaped to fit into grooves and crevices on a cast iron stove range and fenders. A brush like this would be used in the 19th and early 290th centuries to apply a blackening agent to the metal to clean and preserve it would be polished to make it look more attractive.This object is significant as an example of an item in common use in the 19th and early 20th centuries.Stove brush, wooden with wooden raised handle and black bristles. The bristles at the ends of the brush are longer than in the centre, and flare outwards. The brush' is rounded at one end and pointed at the other.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, cast iron stove, oven range, stove brush, blackening brush, cooking, kitchen equipment, wood fired stove -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Stove, Cox and Rizzetti Stove Works, ca. 1918-1930s

... Warrnambool great-ocean-road Cast iron stoves burn solid fuel ...Cast iron stoves burn solid fuel such as wood or coal, and are used for cooking and warmth. The stoves have a firebox with a grate where the fuel is burned. The hot air flows through flues and baffles that heat the stove top and the oven. Before cast iron stoves were invented, cooking and heating were carried out in outdoor open fires, and later, in fireplaces inside the home. In 1642 the first cast iron stove was manufactured in Lynn, Massachusetts, where molten cast iron was poured into a sand mould to make rectangular plates that were then joined together to make a box. Benjamin Franklin invented the more efficient Pennsylvania stove in 1744, and this efficient design is still used today. After the mid-19th century cast iron stoves were produced with burners in different positions, giving varied temperatures, so a wide variety of foods could be cooked at the same time at the most suitable heat, from slow cooking to baking scones. In contemporary times people the new wood-burning stoves had to meet the anti-pollution standards now in place to protect our environment. By the 1920s gas cookers were being introduced for domestic use, and by the 1930s electric home cookers were being offered to householders. PLANET STOVES In August 1925 the firm Cox and Rizzetti, Stove Works, and also Sydney Road, South Melbourne, advertised in the Brunswick and Coburg Leader of November 11, 1925 as "formerly with Harnwell and Sons" and as "specialists in solid cast iron Planet stoves ... which merit an inspection from builders and householders". The firm continued in business and was mentioned as sponsors in the King Island News in 1971. Harnwell and Sons was listed in the Victorian Government Gazette of 1894. It is curious that the firm was mentioned in an article in the Sunrasia Daily of June 14, 1934 titled 'Planet Stoves' as a manufacturer of Planet Stoves. This Planet No 3 stove is an uncommon example of cooking equipment used in kitchens in the early 20th century, as the firebox is above the oven rather than beside it. The cast iron combustion stove is significant as part of the evolution of domestic cooking. Previously cooking was mostly carried out in outdoors in open fires, and later in fireplaces indoors. Cast iron stoves are still used today and have additional features such as thermostats to monitor and maintain temperature, water heating pipes connected, and environmentally approved anti-pollution fittings. Stove; a compact, blackened cast iron combustion cooker, installed within a fireplace and enclosed by bricks on both sides. The upright rectangular stove has a flat top with three round, removable cook plates and a flue connected at the back. The front has three doors with round knob handles; a swing-down firebox door above a sliding ashtray, and two side-hinged oven doors above a sliding opening. Inside on the side walls are two pairs of runners. Behind the pair of doors is an oven with two pairs of rails and two removable metal shelves. The stove has cast inscriptions on the chimney flue and on the front of the right hand side stove door. The model of the stove is The Planet No 3, made in Melbourne.Chimney flue, "[within rectangle] THE / PLANET" Stove door, "(within oval) PLANET / No 3"flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, stove, cast iron stove, combustion stove, wood-burning stove, wood stove, wood oven, solid fuel stove, cooker, the planet, planet, planet no. 3, kitchen equipment, baking, domestic cooking, cooking equipment, food preparation, planet stove, planet cooker, cooking range, slow combustion stove, antique, range cooker, cox and rizzetti, harnwell and sons, melbourne manufacturer -

Blacksmith's Cottage and Forge

Blacksmith's Cottage and ForgeBoiler Pot, A.Kenrick, Early 20th century

Food preparationThis is a typical cast iron cooking pot used on a wood stove. Used for food preparation.cast iron, oval boiler with centre hook in the handle, 3 gallon capacity, no lidA. Kenrick and sons. West Bromerickdomestic, kitchen, pot, boiler, cast iron -

Blacksmith's Cottage and Forge

Blacksmith's Cottage and ForgeBoiler Pot, Clark and sons, Early 1900's

... . cooking kitchen pot cast iron food preparation Clark and co ...Domestic cooking item used on a wood stove.Black oval cast iron pot with handle on one side Makers name embossed on one side.Clark and co. on one side. 6.G/ On bottom black and co. Patened St davids star with O in centrecooking, kitchen, pot, cast iron, food preparation -

Blacksmith's Cottage and Forge

Blacksmith's Cottage and ForgeBoiler pot with lid, clark and co, early 1900's

Cooking pot used on wood stoveThis is a domestic cooking pot used for food preparation.oval shaped boiler with a handle and lid, cast ironClark and co. 2 1/2gallonsdomestic, kitchen, pot, boiler, cast iron -

Federation University Historical Collection

Federation University Historical CollectionBook, New York Post, The School of Mine Quarterly: A Journal of Applied Science, 1889-1809

... Malleable Cast iron Electrolytic treatment of Galena turpentine ...The School of Mines Quarterly was a jpournal of Applied Science from Columbia College, New York City.The Index to the School of Mines Quarterlu Volumes X1-XX (1900) and 32 green covered journals school of mines, new york, columbia college, schools of mines, columbia school of mines, witwatersrand goldfield, inter-continental railway, mine ropes, harbor improvememnts on the pacific coast, glycerine and artificial butter industry, transit factors for teh columbia college observatory, tables for the reducation of transit observations, ancienct methods for dividing and recoording time in japan, assay of tin, john strong newberry, standards of linnear measure, comparison of costs of electric lighting, huanchaca mine bolivia, el callao gold mine venezuela, john magnus adams, ores in saxony, hartz and rhenish prussia, hofmann apparatus, adjustment of trangulation, determination of carbonic acid in white lead, lower coals in western clearfield county pennsylvania, old telegraph mine ningham canon utah, mechanical preparation of ores, modern waterworks construction, curdling of milk, french regenerative gas furnace, irrication canals, peruvian salt mine, collection of metallurgic dust and fume, permeability of iron and steel, assay of silver, explosion in a zinc fume condenser, teaching archtectural history, liquid air, between the mine and the smelter, ballistic galvonometer, assay of telluride ores, analytical chemistry, theory and design of the masonry arch, silver pick mine wilson colorado, telegraphy and telephoney, mineralogy, morse code, michigan mining practices, titaniferous magnetites, paradox of the pantheon, rocks from wyoming, witwatersrand goldfields, gaseous sun, alternating current distribution, engineering tests on direct current electrical machinery, thomas egleston, ore dressing, frederick morgan watson, camp bird gold mine and mills, magnetic properties of iron and steel, morphology of organic compounds, antimony, structure of the starch molecule, cerrillos hills new mexico, geology, rossie lead veins, practical electrochemistry, lines of graphic statics, anistic acid by the ozidation of anniseed oil, bromate method for antimony, john krom rees, trust company of america building, helion lamp, frederick arthur goetze, mine surveying, pine wood oils, malleable cast iron, electrolytic treatment of galena, turpentine and pine oils, bluestone, ashokan dam bluestone, road resistances, oxy-gas blowtorch, mine dumps, segregation of steel ingots, masonry dam formulas, putnam county magnetic belts, gases, continuity of education, hydraulic diagrams, standardistion of potassium permanganate, sewerage discharge into sea water, modern waterworks, true column formula, slags from lead furnaces, missouri river, tempreture of gases, rocks, architectural history, modern dome, oil machine, undulations in railway tracks, irrigation engineering, cleps-tachymeters, electrical engineering, new york shales, fan pump, sucrose, isaac newton, french school of anstronomers, electrolytic polarization, benjamin bowden lawrence, diamond drilling, new york ciy water front, engineering profession ethics -

Flagstaff Hill Maritime Museum and Village

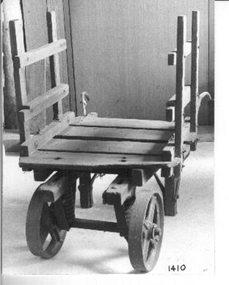

Flagstaff Hill Maritime Museum and VillageFunctional object - Luggage Trolley, Harry Crowther Slingsby, 1930 - 1950

In 1893 Harry Crowther Slingsby founded the company the family firm was at first wholesale bottlers and had established themselves in Bradford, England, later they had a branch in London. Harry Crowther Slingsby began to look into the invention of labor-saving devices for the company. He had recognised that working practices in the local factories relied heavily on manual hauling and gravity for the movement of raw materials and products from floor to floor. However, this did not solve the problem of moving items horizontally around large buildings. Slingsby then set about creating robust trucks and trolleys to move heavy loads with relative ease. Different designs were created for different purposes sack trolleys for moving large sacks of flour, sugar and dried fruit around grocery stores; high wheeled flat carts towed by one or two people; trucks fitted with wicker baskets carried fibers around textile mills and railway platform trolley to move luggage. The company is still in existence today manufacturing many different types of products.An item from the early to mid 20th century connected with railway memorabilia and a company that had humble beginnings to become today a leading UK manufacture. Railway platform luggage trolley large metal frame & wood top with 4 black metal cast iron wheels & metal structure at front with holes to put rope/harness through. Front 2 wheels swivel. Trolley painted red. Wheels are marked Bradford & Londonflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Bench Saw Vice, Henry Disston & Sons, 1910 -1925

The subject item is a saw blade sharpening clamp that attaches to a bench allowing the operator to sharpen the teeth on a saw with a file while keeping the saw blade in an upright position. Henry Disston (1819–1878) began his career as an American saw maker in Philadelphia. He emigrated from England in 1833 and started making saws and squares in 1840. In 1850, he founded the company that would become the largest saw maker in the world the ”Keystone Saw Works” on the Delaware River. Some five years later, Disston built a furnace possibly the first melting plant for steel in America and began producing the first crucible saw steel ever made in the United States. While his competitors were buying good steel from Britain, he was making his own, to his specification, for his own needs. Disston subsequently constructed a special rolling mill exclusively for saw blades. Over the following decade, the Disston company continued to grow, even while dedicating itself to the Union Army's war effort. In 1865, when his son Hamilton Disston rejoined the business after serving in the Civil War, Disston changed the company's name to Henry Disston & Son. Henry Disston and his sons set the standards for American saw makers, both in terms of producing high-quality saws and developing innovative manufacturing techniques. Disston also started making files in 1865. In September 1872, Henry Disston and two other men dug a part of the foundation for what was to become the largest saw manufacturing facility in the world: Disston Saw Works. This was in the Tacony section of Philadelphia. Having previously moved his expanding business from near Second and Market Streets to Front and Laurel Streets, Disston sought to establish his business away from this cramped area. It took over 25 years to move the entire facility to Tacony. This Philadelphia neighborhood seems to have been the only company town in the United States established within an existing city. At its peak of operations, Disston Saw Works employed 8,000 people and the factory covered 300 acres. The company, known as Henry Disston and Sons, Inc by the early 20th century, cast the first crucible steel in the nation from an electric furnace in 1906. The firm's Armour plate building near Princeton Avenue and Milnor Street contributed tremendously to the World War II effort. But the company's innovation and industriousness would not last forever. In 1955, with mounting cash-flow problems and waning interest on the family's part to run the firm, Henry Disston and Sons were sold to the H.K. Porter Company of Pittsburgh. Porter's Disston Division was sold in 1978 and became the Henry Disston Division of Sandvik Saw of Sweden. This division was then sold in 1984 to R.A.F. Industries of Philadelphia and became known as Disston Precision Incorporated, a maker of specialized flat steel products. In 2013, R.A.F. Industries sold Disston Precision Inc. in a private sale. Although the company has ceased making Disston handsaws, the Disston brand name still exists in this firm. A significant American company that pioneered the making of high-quality steel and saws along with other tools and accessories. The subject item is significant as it was made at a time when the company was in its hay day. Adjustable Ball & Socket Saw Sharpening vice, cast iron, with clamp to attach to a workbench. Made by Henry Disston & Co. No 1 painted greyflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, saw clamp, henry disston & sons, saw sharpening, tool accessories, wood saws -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, steel 'C' or 'G' clamp, c1900

A clamp is a fastening device to hold or secure objects tightly together to prevent movement or separation through the application of inward pressure. The tool is for temporary use for positioning components during construction and wood working. There are many types of clamps available for many different purposes. Some are temporary, as used to position components while fixing them together, others are intended to be permanent. A C-clamp or G-clamp is a type of clamp device typically used to hold a wood or metal work piece, and often used in carpentry and welding. C-clamps or G-clamps are typically made of steel or cast iron, though smaller clamps may be made of pot metal. At the top of the "C" is usually a small flat edge. At the bottom is a threaded hole through which a large threaded screw protrudes. One end of this screw contains a flat edge of similar size to the one at the top of the frame, and the other end usually a small metal bar, perpendicular to the screw itself, which is used to gain leverage when tightening the clamp. When the clamp is completely closed, the flat end of the screw is in contact with the flat end on the frame. When the clamp is actually used, it is very rare that this occurs. Generally some other object or objects will be contained between the top and bottom flat edges. A steel ‘C’ or ‘G’ Clamp used to hold a wood or metal work piece, used in carpentry and welding.L.W.BANKtools, woodwork, metalwork, welding, carpentry, pioneers, market gardeners, early settlers, bank w.l., moorabbin, cheltenham, bentleigh, ormond -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, steel 'G' Clamp, early 20thC

A C-clamp or G- clamp is a type of clamp device typically used to hold a wood or metal work-piece, and often used in, but are not limited to, carpentry and welding. These clamps are called "C" clamps because of their C shaped frame, but are otherwise often called G-clamps or G-cramps because including the screw part they are shaped like an uppercase letter G. The fixed end is not adjustable so size is not variable. G-clamps are typically made of steel or cast iron, though smaller clamps may be made of pot metal. At the top of the "G" is usually a small flat edge. At the bottom is a threaded hole through which a large threaded screw protrudes. One end of this screw contains a flat edge of similar size to the one at the top of the frame, and the other end usually a small metal bar, perpendicular to the screw itself, which is used to gain leverage when tightening the clamp. When the clamp is completely closed, the flat end of the screw is in contact with the flat end on the frame When used some other object or objects will be contained between the top and bottom flat edges. A steel 'G' Clamp tools, g clamp, screws, steel, clamps, metalwork, woodwork, carpentry, early settlers, pioneers, market gardeners, moorabin, bentleigh, cheltenham -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Domestic object - Kitchen Equipment, sad iron with Mrs Potts handle, c1900

Sad-irons or "solid" irons were made by blacksmiths and used to smooth out material by pressing the hot iron over it. A piece of sheet -iron was placed over the kitchen fire and the irons placed on it could be heated whilst remaining clean of ash.. The women used 2 irons - one heating while the other was used. Thick cloth or gloves protected their hands from the hot irons. The handle was removed from the cool iron and re- attached to remove the hot iron from the fire. The cool iron was replaced on the fire or stove to heat again. Mrs Florence Potts invented in 1871 a detachable handle made from walnut wood with a metal latch to release the handle. These wooden handles prevented burned hands and were sold to grateful women all over the world. These irons were cleaned with steel wool to prevent them marking the material. If the iron was too hot the material would scorch. Most homes set aside one day for ironing and some large households had an ironing room with a special stove designed to heat irons. However, most women had to work with a heavy, hot iron close to the fireplace even in summer.Mrs Florence Potts invented this type of detachable walnut wood handle with a meta release latch for sad irons in 1871 and it sold widely throughout the world to grateful women including those in Moorabbin Shire. The family of Ms May Curtis were early settlers in Moorabbin ShireA) A sad iron, made of cast iron , has a special handle invented in 1871 by Mrs Florence Potts of Iowa, USA. B) The detachable handle made of walnut wood to prevent burned hands, was attached to the iron by a metal latch.A) UNITED/ N0 / 50 / AUSTRALIApotts florence, iowa usa, melbourne, moorabbin, sad irons, kitchen equipmentn fireplaces, walnut wood, sewing, laundry, table ware, linen, pioneers, early settlers, washing days, craftwork -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Domestic Object - CAST IRON TRIVET

Hand made flat iron trivet using 2 wood screws as legs.domestic equipment, laundering, flat iron base -

Stratford and District Historical Society

Stratford and District Historical SocietyPoison Cart

Cart was operated by the Briagolong Rabbit Suppression League. It was purchased by the donor at the clearing sale for Jim Kelly in the late 1980s/early 1990s. Jim was the son of the main organiser of the Briagolong Rabbit Suppression League. Copies of the Minutes and accounts have been obtained, and are catalogued separately. Wood on cart was in much degraded condition, whole cart repaired by George Parker of the Stratford and District Historical Society, 2010.Rabbit poison cart by T.H. Hicks of Sydney. Consists of wooden frame and floor 80cm high, wheels with cast iron hubs. Chain-driven from one wheel, operator's seat at rear, with a lever mechanism to control the trench forming attachment. Horse shafts 2.6 metres long. Serial number is cast in one side of the bait bin, and not on the other."Ideal" / T.H. Hicks / Patentee / Nth Botany No 5102 / N.S.W.rabbits, vermin destruction -

Royal Australasian College of Surgeons Museum and Archives

Royal Australasian College of Surgeons Museum and ArchivesTool - LIster's Carbolic Spray, circa 1930's

The College’s spray was one of the first pieces of surgical memorabilia to come into the possession of the College. It had been used in the Listerian wards of the Glasgow Royal Infirmary, and was presented , along with some other artefacts, by James Hogarth Pringle in 1930. Joseph Lister (1827-1912) is known as a father of modern surgery. His methods of preventing infection were controversial in their time, but are today recognized as a major advance in the practice of surgery. Lister’s life and achievements are too well known to be recounted here. The definitive biography was written by his nephew, Sir Rickman Godlee (PRCSE 1911-13), and published in 1917. Douglas Guthrie gives an glimpse of Lister at work: “...He never wore a white gown and frequently did not even remove his coat, but simply rolled back his sleeves and turned up his coat collar to protect his starched collar from the cloud of carbolic spray in which he operated...” From advances in bacteriology, and discoveries by Robert Koch and others, it became increasingly evident that airborne bacteria were not a significant contributor to sepsis in surgical wounds. They also demonstrated that the body had its own defences against invading organisms, which were seriously compromised by the effects of the carbolic spray. Gradually the use of the spray was curtailed, Lister himself finally abandoning it in 1887. Lister performed the first antiseptic operation, the dressing and splintage of a compound fracture of the lower leg, in 1865. At this time he used carbolic solution by application, and dressings soaked in the solution. The spray was developed later, after many different methods, including carbolic and linseed oil putty, had been tried in order to reduce the harmful side-effects of undiluted carbolic acid. The steam spray was developed in 1869, and announced to the medical world in 1871. Lister’s purpose in adopting the spray was to kill airborne bacteria in the vicinity of the operation before they could reach the patient. It came to be used all over the world for many years. However, it had serious disadvantages, which even Lister acknowledged. The principal problem was the inhalation of carbolic vapour by everyone in the vicinity, including the patient and the operator. In addition, if the patient had been anæsthetized using chloroform, the gas lights decomposed the vapour into chlorine gas, making any procedure an ordeal of endurance.The spray consists of a steam boiler heated by a wick, a nozzle for the steam to escape, and a glass jar for the carbolic solution. Fuel for the wick is carried in a tank at the base. Valves regulate the pressure of the steam, and the nozzle is adjustable. The boiler is made of cast iron, the fittings are brass, and the handles are of wood. Empty, the apparatus weighs 8 lbs (3.2 kg). lister, carbolic spray, antiseptic -

Anglesea and District Historical Society

Anglesea and District Historical SocietyButter Worker, E. Cherry & Sons, Pre 1912

Wooden with cast iron gearing components and round butter worker is hand operated. The rotary butter worker has a round tray carved from wood. Protruding upwards from the centre of the tray is a column with arched top. The column has a small square outlet on one side near the base that provides for excess buttermilk to be drained away. Around the circumference of the butter worker protruding outwards from the sides is a thick cast-iron track. The wooden paddle has a unique curved shape that has a wave appearance. It has a slight arch which forces the butter to remain in the tray and to direct any excess buttermilk to the centre. Through the wooden paddle is an iron rod connected to a crank handle. By turning the handle the rod rotates a gear system that leads the table to rotate on the metal track.Side: CHERRY'S PATENT NO. 1 GISBORNE VICTORIA 4407 Etched into upper arm of wooden frame.cherry's patent, bubb family, evans family -

Stawell Historical Society Inc

Stawell Historical Society IncPhotograph, Wooden Home at no.1 Seaby Street -- Coloured photo

Home in Seaby Street no.1 next to railway line. Built by Luke Kinsella about c 1870. Photo taken March 1992 about time of sale. A series of nine coloured photos in Album 8. p 37-42 of the Seaby house and interior. Photos in album 8 show 3 different views of the side of the building. One of the wood paneling in the entrance hall. Also 3 photos of the mantlepieces and cast iron grates in the fireplace. Luke Kinsella, brother to Thomas Kinsella's (part owner of Magdala cum Moonlight mine). Thomas was the eldest of the boys then Luke and John Kinsella the youngest. Home in Seaby Street no.1 next to railway line. Built by Luke Kinsella about c 1870. Colour photograph. Series of 9 photos in Album 8. p37-42.stawell dwellings -

Yarrawonga and Mulwala Pioneer Museum

Yarrawonga and Mulwala Pioneer MuseumWooden Butter Worker, circa 1910

... and cast iron components... and cast iron components Wooden Butter Worker Cherry & Sons ...Large Wooden Butter Worker circa 1910 rotary, wood body and cast iron components -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Domestic object - Copper

Cast iron copper with pull out door for fuel at base. Round copper insert with galvanised flue pipe. Round wooden top reinforced with two pieces of wood and a wooden handle.domestic items, laundering -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Functional object - Barrow

Hand Barrow. Appears to be handmade and it was used to transport products around the pottery.The wheels are made of cast iron; it has a steel frame with springs and the sides are made of wood.ceramics, terracotta -

Kew Historical Society Inc

Kew Historical Society IncPhotograph - 'Glencara', 59 Sackville Street, 1988

The first documentary evidence of this house comes from Rate Books which record that in 1893 a Mrs Treadway was the owner of this building with an N.A.V. of £80. At that date the occupier of the house was Charles B. Kelly, a clerk, while by 1910 Kelly had become the owner of the property described in that year as a six-roomed stone, brick and wood house with stables and outbuildings.(Kew Conservation Study, 1988)Colour photographic positive of one of 'Glencara'. It is a single storeyed house clad in render and dominated by a verandah that wraps around the front and sides, following the line of the projecting polygonal bay window. The verandah has elegance, being supported on coupled candy-twist columns and decorated with cast iron, and it returns around to the side entrance. The slate roof is intact. (Kew Conservation Study, 1988)glencara -- sackville street -- kew (vic.) -

Kew Historical Society Inc

Kew Historical Society IncPhotograph - 'Glencara', 59 Sackville Street, 1988

The first documentary evidence of this house comes from Rate Books which record that in 1893 a Mrs Treadway was the owner of this building with an N.A.V. of £80. At that date the occupier of the house was Charles B. Kelly, a clerk, while by 1910 Kelly had become the owner of the property described in that year as a six-roomed stone, brick and wood house with stables and outbuildings.(Kew Conservation Study, 1988)Colour photographic positive of one of 'Glencara'. It is a single storeyed house clad in render and dominated by a verandah that wraps around the front and sides, following the line of the projecting polygonal bay window. The verandah has elegance, being supported on coupled candy-twist columns and decorated with cast iron, and it returns around to the side entrance. The slate roof is intact. (Kew Conservation Study, 1988)glencara -- sackville street -- kew (vic.) -

Kew Historical Society Inc

Kew Historical Society IncPhotograph - 'Glencara', 59 Sackville Street, 1988

The first documentary evidence of this house comes from Rate Books which record that in 1893 a Mrs Treadway was the owner of this building with an N.A.V. of £80. At that date the occupier of the house was Charles B. Kelly, a clerk, while by 1910 Kelly had become the owner of the property described in that year as a six-roomed stone, brick and wood house with stables and outbuildings.(Kew Conservation Study, 1988)Colour photographic positive of one of 'Glencara'. It is a single storeyed house clad in render and dominated by a verandah that wraps around the front and sides, following the line of the projecting polygonal bay window. The verandah has elegance, being supported on coupled candy-twist columns and decorated with cast iron, and it returns around to the side entrance. The slate roof is intact. (Kew Conservation Study, 1988)glencara -- sackville street -- kew (vic.) -

Stawell Historical Society Inc

Stawell Historical Society IncPhotograph - Valentine Series No. 1082 Lake Victoria Park, Stawell, Victoria Park Stawell with two Rotundas one cast iron and one wood (Now Cato Park)

... Victoria Park Stawell with two Rotundas one cast iron and... Rotundas one cast iron and one wood (Now Cato Park) Photograph ...Valentine Series Postcard. Victoria Park later Cato Park at Head of the St George Mine Dam originally established with donations from Mr E Simmons and voluntary efforts. Shows two rotundas.B/W Photo. Valentine Series No. 1082 Lake Victoria Park, Stawell. Taken between the two rotundas showing lake, pier and older willows. Both now renamed Cato lake and Cato park.Valentines Real Photo Series Logo. Published by the Valentine Publishing Co. Pty. Ltd. Queen St. Melb.stawell -

Mont De Lancey

Mont De LanceyKnife Cleaner

Round wooden barrel with metal and wood handle for turning barrel, which also had brass fittings All placed on a cast iron base."Snye & Co Manufacturing London" written on a brass plaque, on front of the barrel.knife cleaners