Showing 100 items

matching crank handle

-

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

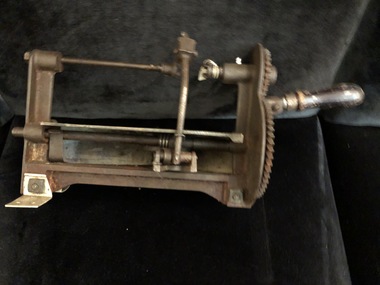

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Kitchen Equipment, Mechanical Cake mixer c 1890, c1880

... screw . A crank handle with a wooden black knob attached.... and is clamped into place by a metal screw . A crank handle with a wooden ...A mixer is a kitchen utensil which uses a gear-driven mechanism to rotate a set of beaters in a bowl containing the food to be prepared. It automates the repetitive tasks of stirring, whisking or beating. Mixers for the kitchen first came into use midway through the nineteenth century; the earliest were mechanical devices. The mixer with rotating parts was patented in 1856 by Ralph Collier a tinsmith in Baltimore, Maryland .This was followed by E.P. Griffith's whisk patented in England in 1857. A circular tin used for mixing batters. The 2 beaters are of wire, with metal gears, suspended from a metal strip that fits over the tin bowl. and is clamped into place by a metal screw . A crank handle with a wooden black knob attached by a screw is turned by hand to mix the batter in the base. This tin could be secured to a table by a clamp and screw. cooking, kitchen equipment, dairy, cakes, housework, early settlers, pioneers, baking, nutrition, blacksmiths, market gardeners, cake mixers, moorabbin, cheltenham, bentleigh, brighton -

Orbost & District Historical Society

Orbost & District Historical Societyscythe blade, late 19th - early 20th century

... with a crank handle on one side. This was hand powered and used... with a crank handle on one side. This was hand powered and used ...Scythes were used to manually mow wheat or grass. Scythes were used with a long sweeping movement which made them much less tiring for labourers to use than reaping hooks or sickles though they still involved great physical labour and considerable skill to perfect. Both hands were in use and the operator did not have to bend his back to reach down to the crop. On farms scythes were sharpened on a sandstone wheel mounted on an axle with a crank handle on one side. This was hand powered and used with water. Scythes were not used as often on farms after the mechanisation of harvesting. They were still used for cutting awkward shaped small plots and for opening a path for the tractors. This item is an example of a tool used by the early settlers of the Orbost district. An iron scythe blade, curved and tapered. There is no handle and the blade is rusted and pitted."ROSE"scythe tool agriculture rural -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing Machine & case

... Sewing machine, Singer, hand operated by crank handle..., Singer, hand operated by crank handle, rounded wood case ...Sewing machine, Singer, hand operated by crank handle, rounded wood case with lock on one side. Machine has hinges at back and recessed accessory compartment containing pins and needles. Machine has shuttle bobbin. Singer Trade Marks gold transfers on lid and machine, with Singer badge on front of machine. Serial Number "F1841984" on front right. Serial Number "F1841984" on front rightflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sewing machine, singer, singer sewing machine, dressmaker, taylor, domestic machines -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing Machine, 1911-1920s

... is hand-operated and the crank handle is wooden. The machine... and the crank handle is wooden. The machine is on a wooden base and has ...This machine was made in Baden, Germany, for the Ward Brothers of Melbourne, who imported machines from various manufacturers and had them branded with their Ward Brothers decals. This machine is most likely dated after 1911, when the Ward Brothers became two separate businesses, as there are only remnants of two portrait decals on the machine bed. There is a fitted embedded ruler in the wood of the base. Many sewing machine manufacturers in Germany produced their machines specifically for export. A company could mass-produce its machines and give the same product several different brand names, according to their overseas buyers. There was a huge market for domestic machines as it enabled tailored clothing to be made in households at a fraction of the retail prices. Ward Brothers began in Australia in the late 1890s and early sewing machines sold by them had the three brothers on their decals. In 1911 the brothers divided into two separate firms, one operating on his own, the other two remaining together, and all still operating in Melbourne and at first still using the name Ward Brothers.This sewing machine is one of two hand-operated Ward Brothers machines in our collection that were made in Baden, Germany, and the only one that has the two Ward Brothers on its decal and that has side to side slide plates. This machine represents the early domestic market for sewing machines, making it possible for the everyday homemaker to produce fashionable garments and linen ware that was affordable. The owner of this machine could work at more than one location as it was portable and did not require a large space to set up. The machine is associated with the well-known Ward Brothers of Melbourne, who sold imported sewing machines that were branded with their own name.Sewing machine with case. The black-painted metal machine is hand-operated and the crank handle is wooden. The machine is on a wooden base and has a box included that contains many machine accessories. Made in Baden, Gemnamy, for Ward Brothers of Melbourne. There is an attached metal plate on the front with rows of groups of numbers on it. The wooden bed has an embedded ruler. The machine had decals with geometric designs and the maker's name.Printed in script: "Specially made in Baden / by Ward Broth Melbourne"flagstaff hill, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, sewing machine, hand operated, domestic sewing, homemade clothing, fashion, ward brothers, made in germany, baden, front and rear slide plates, post wwi, post 1911 -

Parks Victoria - Cape Nelson Lightstation

Parks Victoria - Cape Nelson LightstationFunctional object - Telephones

... and a crank handle at the side. Three phones have brass bells, two...‐mounted Bakelite telephones with crank handles can be found at all ...Each of the five telephones is attached to a timber, wall‐mounted box. They are original to the precinct buildings and date from the early twentieth century. Located in the lighthouse lantern room, the former head keeper’s quarters, the former assistants’ quarters, and the buildings known today as the generator shed and the café, they formed an intercom system that facilitated communication between the lightstation buildings.Wall‐mounted Bakelite telephones with crank handles can be found at all six light stations, however Gabo Island has the only other example of a timber‐mounted phone. Its design is slightly different for incorporating an inclined surface for jotting down notes. As fixtures, the telephones are considered to be part of the building fabric and included in the Victorian Heritage Register listing for the Cape Nelson Lightstation (H1773; 18 February 1999). They are historically significant for their historical and technical values as part of the early communications system used at the lightstation.Five similar intercom system telephones. All are wall mounted timber boxes with Bakelite black hand sets and black cords. The five phones each have two bells at the top of the box and a crank handle at the side. Three phones have brass bells, two have black metal bells. All phones have instructions on the front either in a frame or glued to the timber."C of A" and "PMG" Written instructions on how to use the phones are printed on paper fixed to the front of the telephones. "TO CALL ....../ TO ANSWER...../ WHEN FINISHED....." -

Mont De Lancey

Mont De LanceyPotato Peeler, Circa 1920

... Lathe potato peeler, hand-cranked with a wooden handle....-and-dandenong-ranges Potato peelers Lathe potato peeler, hand-cranked ...Lathe potato peeler, hand-cranked with a wooden handle.potato peelers -

Federation University Historical Collection

Federation University Historical CollectionObject, Mystery Item

... with a crank handle. The diameter of the two brass domes is 6 cm..., facing each other. The right hand shaft is fitted with a crank ...It is thought that this item may have been made for use at the Ballarat School of Mines. The use is unknown. At one time it was thought to have something to do with lens-making, but this is no longer thought to be the case. A photograph of this item has the catalogue number 01002.A mechanism made of cast brass mounted onto a second hand timber base board. Two horizontal coaxial shafts, each ending with a hemispherical cup, facing each other. The right hand shaft is fitted with a crank handle. The diameter of the two brass domes is 6 cm. The space between the two brass domes from spindle to spindle is 7 cm. Only one dome turns, the one attached to the handle. Brass plate on second handtimber base board "J. Sturrock, Dundee. Patentee. Wholesale Agents Jeffries & Co. Woolwich and London." ballarat school of mines, scientific equipment, scientific objects, j. sturrock -

Melbourne Tram Museum

Melbourne Tram MuseumPhotograph - Set of 2 Black & White Photograph/s, Sutcliffe Pty Ltd, late 1920's

... lights and other details including the crank handle - shows... and other details including the crank handle - shows the destination ...Photographs, Black and White, of the MMTB bus 45? - large Garford Chassis - .1 - Front on view showing the radiator, head lights and other details including the crank handle - shows the destination of Brighton Rd. Registration Number 68945. .2 - Side on view of the bus showing the lettering, logo, doorways and destination "via High St". Photos Print and photograph by Sutcliffe of Cromwell buildings 366a Bourke St. Melbourne.In ink on the rear: .1 - "M&MTB Garford Bus No. 45 - late 1920's". .2 - "MMTB Large Garford Bus (Probably No. 45), Late 1920's and in pencil "Large Garford" KSK print numbers SA955 and SA956.trams, tramways, mmtb, buses, brighton rd, garford, tram 7 -

Mont De Lancey

Mont De LanceyCoconut Grater, Circa 1910

... Cast iron coconut grater, hand-cranked with a wooden handle....-cranked with a wooden handle. Coconut Grater ...Cast iron coconut grater, hand-cranked with a wooden handle.fruit graters -

Melbourne Tram Museum

Melbourne Tram MuseumPhotograph - Set of 2 Black & White Photograph/s, Sutcliffe Pty Ltd, late 1920's

... the crank handle - shows the destination of Elsternwick via High St... lights and other details including the crank handle - shows ...Set of two Photographs, Black and White, of the MMTB bus 7 - Tilling Stevens, petrol electric bus. .1 - Front on view showing the radiator, head lights and other details including the crank handle - shows the destination of Elsternwick via High St. Registration Number 68907. .2 - Side on view of the bus showing the lettering, logo, doorways and destination. Photos Print and photograph by Sutcliffe of Cromwell buildings 366a Bourke St. Melbourne.In ink on the rear: .1 - "M&MTB Tilling Stevens, Petrol Electric Bus No. 7, late 1920's. .2 - as above plus "33 seats" KSK print numbers SA951 and SA952.trams, tramways, mmtb, buses, elsternwick, tilling stevens, tram 7 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDrill

... Hand drill metal 3 wooden handles crank missing 310mmL x... metal 3 wooden handles crank missing 310mmL x 145mmW. One handle ...Hand drill metal 3 wooden handles crank missing 310mmL x 145mmW. One handle greenflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBrace

... Brace metal with barber chuck, metal crank, wooden head... Brace metal with barber chuck, metal crank, wooden head ...Brace metal with barber chuck, metal crank, wooden head and handle.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, brace -

Southern Sherbrooke Historical Society Inc.

Southern Sherbrooke Historical Society Inc.Meat mincer with attachments

... Metallic mincer with clamp and wooden handle on crank... and wooden handle on crank. Includes four attachments. Meat mincer ...Manufactured by John Harper & Co.Metallic mincer with clamp and wooden handle on crank. Includes four attachments.Labelled 'No.1 Beatrice'. Attachment labelled 'Beatrice No.4 Very Fine'. -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyMilk and Cream Fat Tester Centrifuge

... (by cranking the handle) causing the cream to separate from the non-fat... of milk were put in the glass vial and then spun (by cranking ...In 1890 D. Babcock invented a test for measuring the amount of butter fat in milk, either on the farm or in the dairy or creamery. Samples of milk were put in the glass vial and then spun (by cranking the handle) causing the cream to separate from the non-fat milk thus determining the percentage of cream in the milk. The product was then priced accordingly.Dairy farming in the Kiewa Valley was the main industry with farmers keen to test the quality of their milk before selling it. This centrifuge enabled them to test the amount of milk and cream being produced by their herd. This '1903 Butter Fat Tester' made 100 turns per minute. Early hand crank centrifuge for measuring the butterfat content of milk in the farm dairy or creamery. It has 4 brass / copper removable canisters with glass vials and tubes that fit inside. The glass vials bulge at the bottom and are marked with measurements 1, 2 etc.Numbers on the glass vialsmilk and cream tester, dairy farming, centrifuge -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyElectric Megger (Insulation Tester) and its case

... fixing knobs in black. On one side is a crank handle with a knob... fixing knobs in black. On one side is a crank handle with a knob ...Megger as the device was called, is in fact its brand name. It is a device that supplies a DC (direct current as per car batteries) voltage to enable testing of electrical apparatus. This particular device produces 250volts DC when the handle is turned vigorously. If an electrical device, such as a kettle or toaster, blew a fuse or tripped a circuit breaker, when switched on, then it must be checked electrically before any more use. Following the repair of the faulty item a megger would be used to check if either of the AC 240volt plugs leads were touching the metal case (earth). The output leads of the megger would be connected with one to the earth (metal case) and the other to each of the power connections in turn. A good megger reading of 50,000 ohms (resistance) would enable the device to be returned to service. A reading of zero ohms resistance would mean that it would again blow a fuse, and was therefore unsafe to use. In the electrical industry e.g. the former State Electricity Commission, a megger would be used to test lots of similar item in sequence. Because of the vigorous job of winding the handle, two persons were often used to save time. One would crank madly whilst the other shifted the leads. This particular megger is of a small voltage, but other meggers are bigger and have a few ranges of DC voltages able to be selected. The optimal megger for large Generating machines was motor driven megger. This was applied to the device being tested for a duration of approximately 30 minutes with reading of the resistance taken at regular intervals.All equipment belonging to the State Electricity Commission of Victoria was labelled with a metal plaque attached to it. The SECV constructed the Kiewa Hydro Electric Scheme in the Upper Kiewa Valley and on the Bogong High Plains. The scheme began in 1938 and finished in 1961 when this megger was used and also possibly later as the SECV remained to maintain and operate the Scheme. This megger is of significance in relation to the advancement of technology.A rectangular box in dark brown bakerlite casing. It has an agent's plaque fixed to the left of the face and on the right is the marker's recessed stamp. In the middle in a transparent window so the level of ohms can be read. The front also has two recessed fixing knobs in black. On one side is a crank handle with a knob that lifts up and is turned vigorously to create the voltage. The back has four recessed screws and four small leather pads. There is a hole on each side to insert wires. There are two copper insulated wires. The SECV Plaque states: State/Electricity Commission/of/Victoria/ Electrical Engineer's Section/ No.1747 The Agent's Plaque states: H. Rowe & Co. Pty Ltd/Melbourne & Sydney/Sole Agents/in Australia for/Evershed & Vignoles Ltd Maker's states: 500 volts/Megger/Regd Trade Mark/Made in England/Patent No/400728electrical meters, electrical equipment, fuses, safety, state electricity commission of victoria, mt beauty, bogong village -

Melbourne Tram Museum

Melbourne Tram MuseumPhotograph - Set of four Black & White Photograph/s, Sutcliffe Pty Ltd, late 1920's

... the crank handle. .3 - Interior view looking along the bus from... the crank handle. .3 - Interior view looking along the bus from ...Set of four Photographs, Black and White, of the MMTB Tourist Bus late 1920's. .1 - Side on view of the MMTB Tourist bus showing the lettering and logo. .2 - Front on view showing the radiator, head lights and other details including the crank handle. .3 - Interior view looking along the bus from the front. Shows the curtains and the extensively upholstered seats. .4 - ditto showing the woven cane seats. Photos Print and photograph by Sutcliffe of Cromwell buildings 366a Bourke St. Melbourne.In ink on the rear: All "M&MTB Tourist bus late 1920's" and the photographers stamp, with .3 and .4 adding "Interior" KSK print number SA957 to 960trams, tramways, mmtb, tourist bus, buses, interiors -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMagneto Electric Machine

... Box wooden containing a magneto electric machine cranked... cranked by metal handle which assists nervous and other diseases ...Box wooden containing a magneto electric machine cranked by metal handle which assists nervous and other diseases including rheumatism.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, magneto electric machine -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing Machine, early 20th century

... . Has folding crank handle, body painted black with floral... logo. Has folding crank handle, body painted black with floral ...Sewing machine, portable, hand operated, with Premier logo. Has folding crank handle, body painted black with floral design, wooden base and separate wooden cover with lock. Base has compartment with accessories, covered by curved ended, sliding wooden panel. Decorative linework on side, carvings on each corner. Wooden handle on cover is carved in rings, folds down. Below handle is decorative inlaid pattern. Serial number on plate at back of machine. Accessories include 13 attachments, key (broken), screwdriver, sewing machine needle, razor blades (2) and buttons. Attached to inside of case is a square of paper with a number on it. Instruction book for Singer Sewing Machines is included. Also with machine are white tailor's chalk and a cut out, fabric pocket with tissue paper pattern pinned to it.Serial number "579200" is stamped into plate at back of machine. Brand on transfer on front of machine is "Premier". Paper inside case has hand written number "334A". Instruction book "Instructions for using Singer Sewing Machines No. 66 - Oscillating hook for family use" flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sewing machine, permier sewing machine, hand operated sewing machine, dressmaker, fasion, singer no. 66 manual, textile, flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sewing machine, permier sewing machine, hand operated sewing machine, dressmaker, fasion, singer no. 66 manual, textile -

Anglesea and District Historical Society

Anglesea and District Historical SocietyButter Worker, E. Cherry & Sons, Pre 1912

... to a crank handle. By turning the handle the rod rotates a gear... connected to a crank handle. By turning the handle the rod rotates ...Wooden with cast iron gearing components and round butter worker is hand operated. The rotary butter worker has a round tray carved from wood. Protruding upwards from the centre of the tray is a column with arched top. The column has a small square outlet on one side near the base that provides for excess buttermilk to be drained away. Around the circumference of the butter worker protruding outwards from the sides is a thick cast-iron track. The wooden paddle has a unique curved shape that has a wave appearance. It has a slight arch which forces the butter to remain in the tray and to direct any excess buttermilk to the centre. Through the wooden paddle is an iron rod connected to a crank handle. By turning the handle the rod rotates a gear system that leads the table to rotate on the metal track.Side: CHERRY'S PATENT NO. 1 GISBORNE VICTORIA 4407 Etched into upper arm of wooden frame.cherry's patent, bubb family, evans family -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageGramophone

... it and is covered by brown cloth. There is a handle for cranking. ... with speaker behind it and is covered by brown cloth. There is a handle ...Gramophone, Edison, in wooden cabinet with hinged lid. Front has open fretwork panel with speaker behind it and is covered by brown cloth. There is a handle for cranking. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, gramophone, music, entertainment, furniture, edison -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Kitchen Equipment, meat mincer, c1900

... meat - that is operated by a steel crank with a wooden handle.... conneticut butchers Front ; 2 'Universal' Crank arm : L.F&C. NEW ...This meat mincer was a common kitchen utensil used by housewives for the preparation of meat when cooking food for their familiesA 'Universal' steel, meat mincer with clamp to attach to table or bench, funnel top, and an adjustable screw - to cut meat - that is operated by a steel crank with a wooden handle.Front ; 2 'Universal' Crank arm : L.F&C. NEW BRITAIN, CONN, USAearly settlers, pioneers, market gardeners, moorabbin, bentleigh, housewives, home cooking, meat preparation, thatcher frank, l f & c pty ltd conneticut, butchers -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Butter Churn, Cherry and Sons, Circa 1890-1920

... to an exterior metal hand crank with turned wood handle, through a hole... to an exterior metal hand crank with turned wood handle, through a hole ...The subject item is a good example of a large, hand-operated Bentwood box butter churn used to make up to 14 pounds of butter. It was made in Gisborne, Victoria, by the famous manufacturer, E. Cherry, and is known as an Improved Patent No.2 model probably dating from the late 1800s. The Cherry works specialised in making all types of butter churns and equipment for both domestic use on farms and small butter factories during the late nineteenth and early to mid. twentieth centuries. Milk was "separated" to retrieve the cream which was then beaten to make butter. E Cherry began making various models of Cherry butter churns in 1858, Edward Cherry migrated from Herefordshire England to Australia in 1855 with his wife Ann Appleby, nee Davis, and established a joinery workshop at Gisborne, Victoria. He began by making butter churns in his spare time and his product soon became popular allowing him to establish a viable business. A factory was established in 1875 and he started to make churns of all sizes including up to industrial scale. He exported his products to many countries around the world, Edward Cherry died in 1909 and the business was then run by his son George until he died in 1917. E Cherry's other son Thomas (1861-1945) was also involved in the firm maintaining an interest for several years. He had been born in Gisborne and became a senior house medical surgeon at the Melbourne Hospital in 1890. He continued his studies at Kings College London, eventually becoming a renowned bacteriologist and agricultural scientist. A significant giving an snapshot into how early rural and industrial manufacturing became established in Australia.Rectangular butter churn, a footed wooden box containing an X-shaped wooden interior rack, which is joined to an exterior metal hand crank with turned wood handle, through a hole in the box. Beneath the hand crank is a hole from the interior lined with metal. The lid has a carry handle affixed to the lid on two cross pieces attached to the lid by brass screws.Lettering in black on a transfer "CHERRY & SONS PTY LTD. GISBORNE VICTORIA". Model 00warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, flagstaff-hill-maritime-village, butter churn, gisborne, edward cherry, george cherry, thomas cherry, ann appleby, dairy equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Butter Churn, Cherry and Sons, 1890-1920

... to an exterior metal hand crank with turned wood handle, through a hole... crank with turned wood handle, through a hole in the box ...The subject item is a good example of a large, hand-operated Bentwood box butter churn used to make up to 14 pounds of butter. It was made in Gisborne, Victoria, by the famous manufacturer, E. Cherry, and is known as an Improved Patent No.2 model probably dating from the late 1800s. The Cherry works specialised in making all types of butter churns and equipment for both domestic use on farms and small butter factories during the late nineteenth and early to mid. twentieth centuries. Milk was "separated" to retrieve the cream which was then beaten to make butter. E Cherry began making various models of Cherry butter churns in 1858, Edward Cherry migrated from Herefordshire England to Australia in 1855 with his wife Ann Appleby, nee Davis, and established a joinery workshop at Gisborne, Victoria. He began by making butter churns in his spare time and his product soon became popular allowing him to establish a viable business. A factory was established in 1875 and he started to make churns of all sizes including up to industrial scale. He exported his products to many countries around the world, Edward Cherry died in 1909 and the business was then run by his son George until he died in 1917. E Cherry's other son Thomas (1861-1945) was also involved in the firm maintaining an interest for several years. He had been born in Gisborne and became a senior house medical surgeon at the Melbourne Hospital in 1890. He continued his studies at Kings College London, eventually becoming a renowned bacteriologist and agricultural scientist. A significant giving an snapshot into how early industrial manufacturing became established in Australia.Rectangular manual butter churn, footed wooden box containing an X-shaped wooden interior rack, which is joined to an exterior metal hand crank with turned wood handle, through a hole in the box. Beneath the hand crank is a hole from the interior lined with metal. The lid has a carry handle affixed to the lid on two cross pieces attached to the lid by brass screws.Label in block transfer Manufactured by Cherry & Sons Pty Ltd Gisborne, Victoria Size "00"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, butter churn, cherry and sons, wooden butter churn -

Whitehorse Historical Society Inc.

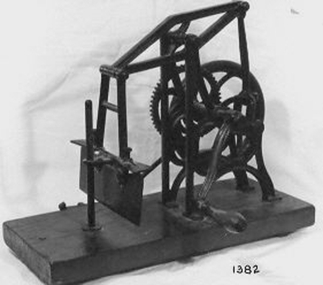

Whitehorse Historical Society Inc.Machine - Household Chopping Machine, Mechanical Chopper, c1886

... boats. When the crank handle of the chopper is turned... the crank handle of the chopper is turned, this sets in motion ...Used in kitchen to cut carrots, cheese slices, onions. boiled eggs, etc.Painted black guillotine on a wooden stand. An iron pole keeps the guillotine in vertical position at one end of the block. Driven by two wheels when a handle is turned. A tilting beam moves the guillotine up and down to cut vegetables, etc. Blade 18cm long by 6.5cm wide. Metal plate missing under blade. A rotatable drum to contain the food to be chopped, which is rotated by a cog at the base (also missing) turns the container. The upright holding chopper blade e is a modification made because of the missing container.|The following description is from Ken Turner Booklet referred to under 'Reference'. ----|The Starrett food chopper would certainly have to be considered one of the more interesting inventions, which incidentally is now considered the ultimate in kitchen collectables. Laroy Starrett in later years' told of how the design of his food chopper was inspired by the action of the walking beam engine used on the Mississippi steam boats. When the crank handle of the chopper is turned, this sets in motion a mechanism which is just fascinating to watch. The crank activates a flywheel which in turn, by a series of cogs and levers, simultaneously rotates a food holding container and raises and lowers within the rotating container, a guillotine like 'chopping blade - the action does not only look like that of a beam steam engine, it even in a way sounds like one, although somewhat noisier. Starrett produced seven different models of these choppers, ranging in size appropriate for domestic use to heavy duty models for butchers, restaurants and for hotel use. The small model was capable of chopping 3lbs in three minutes, and the largest had a capacity for chopping something like 100 lbs in an hour. The mechanical chopper, which became affectionately known as the 'hasher', was the first of some one hundred of Starrett's inventions, and these include a washing machine patented in 1865 which had a similar action to his food chopper, a food press patented in 1873, and a device for lacing shoes he patented in 1886.domestic items, food preparation -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Treadle Lathe, 1920-1923

... works in Sheffield for handling cranks up to 14 foot long... installed in Ambrose Shardlow’s works in Sheffield for handling ...The lathe-making business incorporated in 1902 as Drummond Bros Ltd originated in the fertile mind of Mr Arthur Drummond, said to have been living at that time at Pinks Hill, on the southern edge of Broad Street Common, west of Guildford. Mr Drummond, whose accomplishments included several pictures hung in the Royal Academy, was unable to find a lathe suitable for use in model engineering. In 1896 he designed for himself a ‘small centre lathe … which had a compound slide rest with feed-screws and adjustable slides’. He also designed and built ‘lathes of 4.5 inch and 5 inch centre height, which had beds of a special form whereby the use of a gap piece was eliminated but the advantages of a gap-bed lathe were retained’. Assisted by his brother, Mr Frank Drummond, who had served an apprenticeship to an engineering firm at Tunbridge Wells, the first lathes were made in a workshop adjoining Arthur Drummond’s house. The demand that speedily built up led to the decision to form a company and manufacture the lathes for sale commercially. Land was acquired nearby, at Rydes Hill, and the first factory built. The enterprise was a success, and the company quickly established ‘a high reputation in this country and abroad for multi-tool and copying lathes, and gear-cutting machines’. Other lathes were added to the range, including the first of the ’round bed’ machines for which the firm became widely known. A Drummond 3.5 inch lathe was among the equipment of Captain Scott’s 1912 expedition to the South Pole, and large numbers of 3.5 inch and 4 inch designs were exported to Australia, Canada and India. By the outbreak of war in 1914, 5 inch, 6 inch and 7 inch screw cutting lathes, arranged for power drive, were on sale. Large orders were received from the government for 3.5 inch lathes, for use in destroyers and submarines, and 5 inch lathes for the mechanised section of the Army Service Corps. The latter were used in mobile workshops. The factory worked night and day to supply the forces’ needs, until production was disrupted by a fire which destroyed a large part of the works in May 1915. As soon as rebuilding was complete work restarted. At the end of the war the entire production was being taken by the Government departments, a special feature being a precision screw lathe, bought by the Ministry of Munitions in 1918. Between the wars Drummond Bros Ltd introduced new machines for the motor vehicle, and later the aircraft industry, and the works were extended on many occasions to fulfill the increasing orders. The Maxicut multi-tool lathe (1925), designed for high-production turning operations, was one of the first machines of this type to be built in England. It was followed (1928) by an hydraulic version for turning gear blanks, and similar work. Further developments provided machines which, during the Second World War, turned all the crankshafts and propeller shafts for Bristol engines. Others, ordered by the Ministry of Supply were employed in turning shells, and many other specific needs of vehicle and aircraft manufacture were catered for by new types of Drummond lathes. Production of the small centre lathes ceased during the war when the company needed to concentrate on building multi-tool lathes and gear shapers. After the war a completely new Maxicut range was introduced, replacing the older versions, and fully automatic. The types were continually developed, and new versions manufactured until the end of the company’s life in 1980. The disappearance from the scene of Mr Arthur Drummond in 1946, and the end of the company’s autonomous existence in 1953 when the company was acquired by William Asquith Ltd, which was in turn bought by Staveley in 1966, meant that the factory at Rydes Hill became one – albeit very effective – part of a large national engineering company. Achievements at the Guildford works during its last years included the development of automated Maxicut gear-shapers in what was ‘probably the most fully automated gear shop in the country’, while a machine from Guildford was sent to the Osaka Fair in 1962. In 1963 an agreement was signed with Hindustan Machine Tools for the manufacture of Maxicut gear-shapers in state owned factories in Bangalore and Chandigarh. During 1963 the two largest multi-tool lathes ever made in the UK were installed in Ambrose Shardlow’s works in Sheffield for handling cranks up to 14 foot long. In 1976 Drummond lathes were included in Staveley’s £14,000,000 installation in Moscow of an automated production line for Zil motor cars. Up to the end invention continued at Guildford: a new Drummond Multi-turn memory-controlled machine was shown at the International Machine Tool Exhibition in 1977. This could not save the works from the pressures of the late 1970s, and Staveley Industries closed its Guildford site in 1980.An early example of a lathe that was designed primarily for the hobbyist model maker. It is in good condition and sought today by collectors as many of it's attributes were innovative at the time and lead to further development and incorporation of some of its features into more industrial models of production machinery. Lathe, round bed, treadle powered lathe, Drummond Type A, Serial number and maker's inscription. 1920-1923, Made by Drummond Brothers in Guildford, Surrey, England. Lathe is complete with Chuck, Tool post and Tail Stock in situ (30 extra parts)"MADE BY DRUMMOND BROTHERS LIMITED - PATENT TEES - RYDE'S HILL n GUILDFORD SURREY", "Serial Number 01470," "L44" or "L45 " flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, lathe 1920-1923, round bed lathe, treadle lathe, drummond type a, guildford surrey, drummond brothers guildford surrey england, tread'e -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Mortice Machine, Mathieson and Son, 1910-1940

In 1792 John Manners had set up a workshop making woodworking planes at 14 Saracens Lane Glasgow. He also had employed an apprentice Alexander Mathieson (1773-1851). But in the following year at Saracen's Lane, the 1841 census describes Alexander Mathieson as a master plane-maker now at 38 Saracen Lane with his son Thomas Adam working with him as a journeyman plane-maker. Presumably, Alexander must have taken over the premises and business of John Manners. Now that the business had Thomas Adam Mathieson working with his father it gradually grew and became more diversified, and it is recorded at the time by the Post-Office Glasgow Annual Directory that by 1847-1848 Alexander Mathieson was a “plane, brace, bit, auger & edge tool maker” In 1849 the firm of James & William Stewart at 65 Nicolson Street, Edinburgh was taken over and Thomas was put in charge of the business, trading under the name Thomas A. Mathieson & Co. as plane and edge-tool makers. Thomas's company went on to acquire the Edinburgh edge-tool makers “Charles & Hugh McPherson” and took over their premises in Gilmore Street. In the Edinburgh directory of 1856/7, the business is recorded as being Alexander Mathieson & Son, plane and edge-tool makers at 48 Nicolson Street and Paul's Work, Gilmore Street Edinburgh. In the 1851 census, Alexander is recorded as working as a tool and plane-maker employing eight men. Later that year Alexander died and his son Thomas took over the business. Under the heading of an edge-tool maker in the 1852/3 Post-Office Glasgow Annual Directory the firm is now listed as Alexander Mathieson & Son, with further entries as "turning-lathe and vice manufacturers". By the early 1850s, the business had moved to 24 Saracen Lane. The directory for 1857/8 records that the firm had moved again only a few years later to East Campbell Street, off the Gallowgate area, and that through further diversification was also manufacturing coopers' and tinmen's tools. The ten-yearly censuses report the firm's growth in 1861 stating that Thomas was a tool manufacturer employing 95 men and 30 boys; in 1871 he had 200 men working for him and in 1881 300 men. By 1899 the firm had been incorporated as Alexander Mathieson & Sons Ltd, even though only Alexander's son Thomas appears ever to have joined the firm so the company was still in his fathers' name. In September 1868 Thomas Mathieson put a notice in the newspapers of the Sheffield & Rotherham Independent and the Sheffield Daily Telegraph stating that his firm had used the trade-mark of a crescent and star "for some time" and that "using or imitating the Mark would be proceeded against for infringement". The firm had acquired its interest in the crescent-and-star mark from the heirs of Charles Pickslay, the Sheffield cutler who had registered it with the Cutlers' Company in 1833 and had died in 1852. The year 1868 seems also to be the one in which the name Saracen Tool Works was first adopted; not only does it figure at the foot of the notice in the Sheffield press, it also makes its first appearance in the firm's entry in the Post-Office Glasgow Annual Directory in the 1868/9 edition. As Thomas Mathieson's business grew, so too did his involvement in local public life and philanthropy. One of the representatives of the third ward on the town council of Glasgow, he became a river bailie in 1868, a magistrate in 1870, and a preceptor of Hutcheson's Hospital in 1878. He had a passion for books and was an "ardent Ruskinian". He served on the committee handling the bequest for the setting up of the Mitchell Library in Glasgow. When he died at Coulter Maynes near Biggar in 1899, he left an estate worth £142,764. Company's later years: Both Thomas's sons, James Harper and Thomas Ogilvie were involved in the continuing life of the firm. James followed in his father's footsteps in becoming a local public figure. He was appointed Deputy Lieutenant of the County of the City of Glasgow and was made a deacon of the Incorporation of the Hammermen of Glasgow in 1919. His brother Thomas Ogilvie was recorded as a tool manufacturer and employer in the 1911 census. Thomas Ogilvie's son Thomas Alastair Sutherland Ogilvie Mathieson was born in 1908 took a rather different approach to engineering, however, by becoming a racing driver. In 1947 he wed the French film actress Mila Parély. The firm had won many awards at world fairs for their goods. At the Great Exhibition, London, 1851. Prize medal for joiners' tools in the class of Cutlery & Edge Tools, Great London Exposition, 1862. Prize medal honoris causa. International Exhibition, Melbourne, 1880. Gold medal International Exhibition of Industry, Science and Art, Edinburgh, 1886 Prize medal. See note section for Thomas McPherson Australian Retailer information: The firm of Alexander Mathieson & Sons was one of the leading makers of hand tools and later woodworking machines in Scotland. Its success went hand in hand with the growth of the shipbuilding industries on the Firth of Clyde in the nineteenth century and the emergence of Glasgow regarded as the "second city of the Empire". It also reflected the firm's skill in responding to an unprecedented demand for quality tools by shipyards, cooperages, and other industries, both locally and throughout the world. McPherson's started as an Australian retailer of hardware products in Melbourne going on to become a company that supplied machinery and other items for the establishment of major infrastructure projects in Australia during the early days of the colony that assisted in linking the various states and territories which became a precursor of Federation. From a humble beginning McPherson's became one of Australia's leading retail, and later manufacturing businesses that is still in existence today.Mortice machine metal with long metal lever handle with counter weight & 3 adjustment wheels & metal crank with wood end. Has 4 feet that can be bolted to floor & vertical moving piece that a cutting bit would fit into.Imprinted Alex Mathieson & Son Trademark Saracen Tool works Glasgow' also a brass plate "Thomas McPherson & Son Machinery Importer Melbourne"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageSeparator

Hand-cranked separating maching, made in Sweden for Melbourne Crown Separator Co. Pty Ltd. Machine is used for separating cream from milk, with the machine speed being 70 revs per minute.Separator machine. Hand-crank operated milk separator, small, painted red, Crown Separator Co Pty Ltd. Base and spinning mechanism only (mechanism spins very rettly). Stamped on handle "70 per minute", Stamped on body "S7071", Manufacturer plate "SYLVIA NO. 19/ MADE IN SWEDEN / CROWN SEPARATOR CO PTY LTD / 547 FLINDERS ST, MELBOURNE" Stamped on handle "70 per minute", Stamped on body "S7071", Manufacturer plate "SYLVIA NO. 19/ MADE IN SWEDEN / CROWN SEPARATOR CO PTY LTD / 547 FLINDERS ST, MELBOURNE" flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, milk separator, cream separator, dairy machinery, farming machinery, crown separator co pty ltd -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyGrinder/Mincer - Meat

Old farm kitchen tool used for mincing meat manually.Used at Tawonga, in the Kiewa Valley, by resident Des WartonCast iron with dull smooth surface consisting of a tap to screw it onto a table, a barrel enclosing the auger that turns when the handle is wound around and forces the meat to spill out of a circular grinder. The hand crank is curved with a wooden knob . The outlet is oval shaped.Embossed on barrel: "Universal" Embossed on outlet "2" Embossed on handle "L.F. & c - New Britain Conn U.S.A."household tool, kitchen, meat mincer, grinder, universal no. 2 -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionEquipment - Equipment - Divers air pump, 1900-1930

Port of Portland CollectionFront: C. E. Heinke/ Submarine Engineer 103 GI Portland St London (brass plate on side of pump)port of portland archives -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Kitchen Equipment, mechanical hand whisk c1940, c1940

An eggbeater is a hand-held device with a crank on the side geared to one or more beaters. The user grips the handle with one hand and operates the crank with the other, creating the rotary action. A hand-turned rotary egg beater was patented by J.F. and E.P. Monroe in 1859 in the US. This egg beater patent was one of the earliest bought up by the Dover Stamping Company, whose Dover egg beaters became a classic American brand. The Monroe design was also manufactured in England. In 1870, Turner Williams of Providence, R.I., invented another Dover egg beater model. The Hobart Manufacturing Company was an early manufacturer of large commercial mixers. A mechanical egg beater with a wooden handle and steel gears and crank c1940cooking, kitchen equipment, dairy, cakes, housework, early settlers, pioneers, baking, nutrition, blacksmiths, market gardeners, cake mixers, moorabbin, cheltenham, bentleigh, brighton, monroe e.p., monroe j.f., egg beaters, williams turner, dover stamping compant ltd., hobart manufacturing company ltd.