Showing 90 items

matching door plate

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageLock

Lock for door with pull action door knob, locking pin and keyhole. Cover plate has ornate floral design. Made by Pye USAflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Boiler, ca 1880

This little steam boiler has been beautifully built. It could have been used to drive an engine in a small workshop, a boat or launch, or even farming equipment. It is an example of the steam technology and mechanisation of the 19th century. William Cook introduced steam heating in England in the 18th century. Steam combined with pressure was used for powering transport, such as steam engines for trains, and manufacturing, such as steam engines driving manufacturing machines. Steam boilers are still used today as an energy-efficient means of power.This steam boiler would have been suitable to drive a small engine, possibly that of a small boat. Coal was added to the firebox for fuel to heat water in the boiler. It is an example of the power used to drive machinery and equipment in the mid-to-late 19th century. Steam boilers like this one have played a part in the evolution of steam power. Steam engine boiler; vertical cylindrical coal-fired boiler with a black firebox at its base and a dome top. The cylinder's sides and top have brass fittings, inlet and outlet taps. A round opening near the base is covered by an adjustable metal plate that controls the boiler's temperature. The front door of the firebox has two hinges at the base and when the side clips are opened. A shiny brass collar tops the tall chimney. Oak wood planks around the sides of the boiler, and held in place by brass bands with nut and screw fixtures. The boiler stands on a metal and wood frame with a looped handle at the back. An inscription has been noted. Circa 1880. "1948 D/430" flagstaff hill, warrnambool, maritime museum, maritime village, great ocean road, boiler, steam engine, steam boiler, coal fired boiler, vertical boiler, boat boiler, power source, steam driven, engine boiler, steam machine, firebox, steam engine boiler -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Plate

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/Ceramics have evolved over thousands of years.White earthenware dinner plate. Crazing evident all over.Backstamped ‘Made in England S LTD’flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, ceramics, tableware -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Plate, Alfred Meakin

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/Ceramics have evolved over thousands of years.Earthenware dessert plate, cream colour. Made by Alfred Meakin, England. Backstamped ‘Alfred Meakin England’. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, alfred meakin, ceramics, earthenware, kitchenware -

Federation University Historical Collection

Federation University Historical CollectionInstrument - Scientific Instrument, Boxed Petrographic Polarizing Microscope

Used at BIAE in petrology laboratoryAn optical, petrographic, polarizing microscope with a single objective lens in a blonde timber case with key. Black enamel frame, chrome accessories.POS marking on steel plate Olympus Tokyo 202108 engraved on barrel On Box door "P6" engraved labelmicroscope, polarizing microscope, olympus optical co. ltd, ballarat institute of advanced education, petrology laboratory, scientific instrument -

Federation University Historical Collection

Federation University Historical CollectionInstrument - Scientific Instrument, Petrographic Microscope

This microscope used in SMB/BIAE/BCAE geology laboratoriesOptical Microscope, petrographic type, with 4-lens objective turret. Black enamel frame, chrome-plated accessories. Cream, plastic container with clear plastic speciman jars. Small, brown Reichert case containing objective and glass plate. Housed in a polished wood case. REICHERT, ser. No. 273065 Inside storage box "3" in red marker pen. On microscope frame a self-adhesive sticker "Ballarat CAE Geology". Also riveted to base frame a label "Supplied by H.B. Selby & Co Pty Ltd, Australia". Inside carry case door a card giving visual magnifications.microscope, reichert, selby, laboratory -

Federation University Historical Collection

Federation University Historical CollectionInstrument, Oertling Beam Balance

... 33439 on back of beam support. Small plate on top of door... plate on top of door: Townen and Mercer, Sydeny A two-pan beam ...This balance was used at the Ballarat School of Mines. A two-pan beam balance, mounted on a wood base board. Housed in a timber-framed glass-sided cabinet. Aluminium pans. No balance weights. 25.5 beam length.33439 on back of beam support. Small plate on top of door: Townen and Mercer, Sydenybalance, scientific instrument, oertling -

Federation University Historical Collection

Federation University Historical CollectionTool - Electrical Instrument, Electric Belt Sander, c1960s

Used in Building Studies at Ballarat School of Mines. The sander used to sand rough timber smooth, remove old finish from wood, put a bevel on a door, reduce the thickness of timber, dress up a poor saw cut. Also used for back cutting miter cuts for neater joints and for polishing and cutting.Stainless steel with rollers and sanding plate. Hand held. Continuous loop of sandpaper would be mounted.Maker's Plate: MILLER FALL TOOLS CATALOG 830 3 INCH BELT SANDER MODEM "C" USE 3" X 21" BELT 230/250 VOLTS 3 AMPS 25-60 CYCLES MADE IN USA PATENT 2,991,595 MILLER FALLS COMPANY, GREEFIELDS, MASS. TO CHANGE BELT PULL LEVER DIRECTION OF BELT ballarat school of mines, building studies, david flintoff, timber, smooth, miter cuts, polishing, buffing, thinning -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Functional object - Punch Clock, manual, circa 1880

The large, early, manual, ‘Punch-Clock’, (also known as a Time Clock), used by the Shire of Moorabbin employees to “clock-on and off” each working day circa late 1800s early 1900s.This 'Punch-Clock' was used by employees of the Shire of Moorabbin circa 1880 - 1900 and was donated to the City of Moorabbin Historical Society by the now defunct Moorabbin City Council in 1984.The large manual, ‘Punch-Clock’, (also known as a Time Clock), used by the Shire of Moorabbin employees to “clock-on and off” each working day circa late 1800s early 1900s. The clock face is exposed and the internal mechanism is encased in a wooden cupboard with two glass framed side panels. Right side panel is a door that accesses the clock mechanism.Around Centre of Clock face " DEY TIME REGISTERS LTD"/ "HOWARD BROS./ made in USA/ 75 Queen Victoria St./ LONDON E.C."/ On Brass plate at base are Patent registrations moorabbin, clocks, wages, punch clock -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Functional object - Kitchen Equipment, Coolgardie Safe, c1900

The invention of the Coolgardie Safe is credited to Arthur Patrick McCormick, a contractor in Coolgardie, and later the Mayor of Narrogin. Coolgardie is in the Eastern Goldfields region of Western Australia. Gold was first discovered there in 1892; the townsite became a municipality in 1894, and by 1898 its population of 15,000 made it the third largest town in Western Australia after Perth and Fremantle. In the last decade of the 19th century, Coolgardie was the capital of the West Australian goldfields. Being 180 kilometres from the nearest civilisation, food supplies were initially scarce and expensive. As fresh food was a valuable commodity there was incentive to preserve it, and keep it out of reach of scavengers such as birds, dingos, dogs, ants, and flies. It was in an effort to do this, in the extreme heat of the Australian Interior, that McCormick came up with his design for the Coolgardie Safe. McCormick noticed that a wet bag placed over a bottle cooled its contents. He further noted that if this bottle was placed in a breeze, the bag would dry out more quickly, but the bottle would get colder. What McCormick had discovered was the principle of evaporation: ‘to change any liquid into a gaseous state requires energy. This energy is taken in the form of heat from its surroundings.’ Employing this principle, McCormick made a box for his provisions which he covered with a wet hessian bag. He then placed a tray on top, into which he poured water twice daily. He hung strips of flannel from the tray so that water would drip down onto the hessian bag, keeping it damp. As the water evaporated, the heat dissipated, keeping the food stored inside cool and fresh. The success of McCormick’s invention would not have worked without a steady supply of water. Fresh water was scarce in the eastern goldfields at this time but the demand for water from a steadily growing population encouraged innovation. The solution was to condense salt water. Heating salt water in tanks produced steam that was condensed in tall cylinders, cooled and then collected in catchment trays. By 1898 there were six companies supplying condensed water to the goldfields, the largest company producing 100,000 gallons of water a day. In the early 20th century, Coolgardie Safes were also manufactured commercially. These safes incorporated shelving and a door, had metal or wooden frames and hessian bodies. The feet of the safe were usually placed in a tray of water to keep ants away. (MAV website) The early settlers of Moorabbin Shire depended on this type of Food Safe to protect their food from flies and vermin as they established market gardens in the fertile area around the notorious Elster Creek A metal framed, 4 sided structure standing on 4 legs with 2 hinged doors on one side, a metal tray at base of food safe and a metal cover over top. Ridges on which to rest trays carrying food are inside safe. The Safe is enclosed by fly-wire mesh.'...IN.....GEELONG' A manufacturer's oval metal plate is embossed on one side of Safe but it is illegible.elster creek, moorabbin, brighton, dendy's special survey 1841, market gardens, infant mortality, disease, cemeteries, fruit, vegetables, pioneers, coolgardie safe, mccormick arthur patrick, dendy henry, vaccination, jones martha, jones ethel may -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Lock, 1800s to early 1900s

This lock was recovered from an unknown shipwreck in the coastal waters of Victoria in the late 1960s to early 1970s. It is part of the John Chance Collection. The small size of the lock indicates that it was possibly used for cabinetry such as a cupboard, desk or wardrobe. It may have been part of the ship’s fittings or perhaps luggage or cargo. The blue-green patina on the metal is caused by a reaction from its exposure to external elements such as the sea water. The lock is likely to have been in the water for over 100 years, as the more widely known shipwrecks along Victoria’s Shipwreck Coast date from 1837 to 1940. Although the lock is not linked to a particular shipwreck, it is recognised as being historically significant as an example of hardware either as part of the ship’s fittings or imported for use in Colonial Victoria in the 19th to early 20th century. The lock is also significant as it was recovered by John Chance, a diver in Victoria’s coastal waters in the late 1960s to early 1970s. Items that come from several wrecks have since been donated to the Flagstaff Hill Maritime Village’s museum collection by his family, illustrating this item’s level of historical value. Lock, brass, with separated moving parts. Rectangular plate with keyhole, plus two cogs and a latch.flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, john chance, hardware, door fitting, ship’s fitting, furniture fitting, security, 19th century lock, cabinetry, brass lock -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - H.A. & S.R. WILKINSON COLLECTION: CONTRACT OF SALE

Conditions of sale by private contract dated 4th April, 1933 between E.M. Dudley (seller) and C.J. Tyack for land situate No.161 honeysuckle street, Bendigo being land described in certificates of registration as residence area no. 32525 and residence area no. 32526, together with 6-roomed weatherboard dwelling, garage and all sundry outbuildings and erections on said land. Also all electric light fittings, duck blinds in sleep-out, all wire doors and windows, window blinds and name plate. Price 545 pounds.organization, business, h.a. & s.r wilkinson real estate -

Port Melbourne Historical & Preservation Society

Port Melbourne Historical & Preservation SocietyPhotograph - Under Port Melbourne Railway, Hobsons Bay Main Sewer, "Melbourne water supply", 1890s

Three black and white images taken from: "Melbourne water supply - sewerage schemes" Special edition of the "Building, engineering and mining journal" The operations of the Melbourne and Metropolitan Board of Works. (.03) Plate XXXI. Under Port Melbourne Railway, Hobsons Bay Main Sewer, Section No 3. This view was taken in compressed air, and shows shield doors in background with men placing extra htdraulic power in position. This view also shows the method of constructing with concrete blocks and iron centreing on which to build the upper portion of the sewer.engineering - board of works, built environment - civic, mmbw, sewer, melbourne and metropolitan board of works -

National Vietnam Veterans Museum (NVVM)

National Vietnam Veterans Museum (NVVM)Award, Door Latch

A door latch that has a small bar with handle hold by an omega plate with texts: "Ashwells System".Above the latch is plate with text "Presented by CPO Jim Britz" and below latch is plate with text "lock from four deck officers' heads HMAS Sydney. Why were offciers able to lock their heads when the remainder of the crew could not".Presented by CPO Jim Britz. Lock from four deck officers' heads HMAS Sydney. Why were officers able to lock these heads when the remainder of the crew could not !!!door latch, hmas sydney -

St James Old Cathedral

St James Old CathedralCathedral Building, St James Old Cathedral, 09/11/1839

St James Church, "Church of the Pioneers", was the first Church, first Anglican Church, and is the oldest building in Melbourne. The foundation stone was laid in 1839 by the Superintendent of the District of Bourke, Charles La Trobe, later Governor of the Colony of Victoria. The Church was opened in 1842 and the first Bishop Charles Perry was installed in the Cathedral in 1848 when its status changed to that of Cathedral. Its status changed back to that of a Parish church after 1891 when St Paul's Cathedral in Swanston Street was opened. St James is known as the "Church of the Pioneers" as it served as the place of worship, marriage, baptism and burial of many of the first families in the District of Bourke and the Colony of Victoria. St James Old Cathedral is of the most important historic value to the community of Victoria and to the Australian nation as the first Anglican Church founded within 4 years of the settlement of Melbourne. It represents and conserves the very earliest history of white settlement in Victoria and preserves the church associated history of the Pioneer families of Victoria in its collection of original records and artefacts. Late Neo-Georgian style stone church building with bluestone footings. Octagonal upper one storey bell tower housing eight bells supported by two storey square towers. Body of church has sloping roof and 4 stained glass ornamental windows on each of west and east sides with decorative sanctuary window to the north. Decorative Portico with columns on the north outside elevation. National Trust Commemorative plate on outside wall to right of east entry door. -

Bendigo Historical Society Inc.

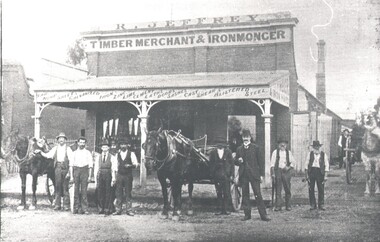

Bendigo Historical Society Inc.Photograph - HARRY BIGGS COLLECTION: R JEFFERY TIMBER MERCHANT & IRONMONGER

Photograph. Harry Biggs Collection. 2 black & white photos (1 smaller) of 8 men with horses & drays standing in front of the R Jeffery Store. At the back of this group can be seen 3 people under the verandah. At the side is another man & also a horse & dray. On the verandah structure are the words - Bar, Hoop, sheets galvanised iron, zinc, lime cement, laths, doors, sashes, cast shear Blistered Steel. At the side of the verandah are the words Timber & Iron Yard. Plate 126 Premises of Jeffery Bros, Victoria Street, Eaglehawk. (Robinson Photo). 1 photocopy of these photos.Robinson Photoplace, building, commercial, harry biggs collection, r jeffery timber merchant & ironmonger, eaglehawk -

Dutch Australian Heritage Centre Victoria

Dutch Australian Heritage Centre VictoriaDecorative Plate (Sierbord)

The Dutch are generally content with their Royal family and usually celebrate the birth of a new member of the ruling family. Beatrix was Queen Wilhelmina's first grandchild and destined to succeed the Queen's daughter and her mother Crown Princess Juliana. This is exactly what happened and Beatrix's own eldest child is the current (2018) King Willem Alexander. It was not unusual to present members of the populace with a commemorative item such as this plate.Round plate with orange crown in centre. The crown is surrounded with the inscription Beatrix Wihelmina Armgard 31 Jan.1938. Around that are orange apples and green leaves. The outside of the plate is outlined with an orange border.On the back are the words "Geschonken door de Gemeente Nijmegen ter Gelegenheid van Prinsesjes Geboorte". (Presented by the municipality of Nijmegen on the occasion of the princess' birth). -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumToy - stove, 1940's

Made by internee and used by Helga Weid (niece of Karl Kaztenbach) Blue painted steel model of a cooking oven used as a childs toy. Has two doors to two ovens either side of a smaller door on the fire box.3 holes on top of stove representing hot platestatura, toys, dolls, furniture, toy stove, weid -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Functional object - Door Pin Tumbler Lock, 1924

Lock was installed on door to Mitcham Post Office constructed 1924. Was removed 1953. Used on rental property until 1980's.1. Black metal door lock 2. Black tumbler lock with plate 3. 2 screw 4. 2 keys"H & TV" patent No 175445vaughan h & t, markhan p j, mitcham post office -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumPhotograph - Army Hut

Army Hut that was used at the Tatura Racecourse after the war. The gumtree plantation was plated by Tatura Primary School students.Long Grey corrugated iron hut with corrugated iron roof. Six wood framed windows painted white and one black framed possibly aluminium window in centre of the hut. Four wooden doors with stone steps. A row of gumtree behind the hut. Lawn and gravel road around the hut.racecourse, hut, army, war, tatura primary school, plantation -

Ballarat Tramway Museum

Ballarat Tramway MuseumPhotograph - Digital Image, Keith Kings, Geelong Pengelley interior, 1955

Digital image of a Photograph of the interior of one of Pengelley-built trramcars that operated in Geelong. Photo by Keith Kings. Shows the door arrangements and the location of a builders plate.Yields information about Geelong tramcars that were built by Pengelley of Adelaide.Digital image of a colour slide - Keith Kings K(f)(83)trams, tramways, geelong, pengelley -

Ballarat Tramway Museum

Ballarat Tramway MuseumFunctional Object - Square Key

Has a strong association with Dave Kellett, motorman and inspector in Ballarat; would have been issued to crews in order operate the tram car doors. Has been stamped for Dave Kellett's traffic number.Piece of chrome plated steel rod bent at 90 degrees and shaped at longer end to give a square shape for use in external doors on SECV Ballarat Trams - known as a square key. Was used to secure doors in both open and closed positions. Has been stamped 67 on one side at short end. See also Reg Items 6552 and 8317 for similar items."67"trams, tramways, tramcars, doors, locks, security -

Ballarat Tramway Museum

Ballarat Tramway MuseumFunctional Object - Square Key

Has a strong association with tram crews, possibly inspector (Dave Kellett?) in Ballarat, would have been issued to crews in order operate the tram car doors. Normally a L shaped key.T shaped steel piece, with a round top piece or handle with a rod that has been forged at the lower end to give a tapered square shape for use possibly in external doors on SECV Ballarat Trams - known as a square key. Was used to secure doors in both open and closed positions. Was probably chrome plated at the time of manufacture. .1 - square key fashioned from rod and welded at the top.trams, tramways, tramcars, doors, locks, security -

Ballarat Tramway Museum

Ballarat Tramway MuseumPhotograph - Colour Photograph/s, Warren Doubleday, mid 12/1997

Yields information about a piece of the original equipment from the ESCo Ballarat power station.Colour photograph of the ESCo Wendouree Parade power station - DC face plate starter for one of the rotary converters - DC hand operated drum and multiple lever panel" - see Jan. 1998 issue of Fares Please! for details of the donation and a copy of the photograph as used. Photo taken by Warren Doubleday. Printed on Kodak Paper. Photo taken mid Dec. 1997. Photos of cabinet with doors opened and signs added 2/4/2018. Images .1 - Brookhirst makers plate with Patent Nos. .2 - Machine with doors open .3 - wiring diagram .4 - Brookirst cabinet latch at the bottom of the machine. .5 - Safety sign re opening the doors. .6 - bottom section of cabinet with cable found in machine .7 - top half of machine .8 - similar to .6 .9 - close up of the cable. See January 1998 Fares Please!esco, power station, rotary converters -

Ballarat Tramway Museum

Ballarat Tramway MuseumPhotograph - Digital image Set of 15, Warren Doubleday and Paul Mong, 11/12 to 18/12/2004

Set of 15 Digital Images of the aftermath of the sub-station repairs, wiring it up and the installation of the isolating transformer taken between 11/12/2004 and 18/12/2004 .1 - Garry Wood with some concrete for the substation floor .2 - Alan Snowball and Paul Mong laying the floor. .3 - Part of the Switchboard modified to position the new Isolating Transformer .4 - ditto .5 - the Transformer arrives - 15/12/2004 .6 - being positioned in the depot .7 - the manufacturers plate - Illawarra Transformers Wollongong .8 - unpacked .9 - being positioned .10 - In position .11 - the door to no where - the platform across to the store and archives yet to be built .12 - some of the equipment installed but found not to be suitable for the purpose. Was ex an PTC sub .13 - wiring it up .14 - Paul working .15 - the new control panel. trams, tramways, btm, substation, testing, isolating transformer -

Ballarat Tramway Museum

Ballarat Tramway MuseumFunctional object - Tramcar door square key, State Electricity Commission of Victoria - Ballarat office, Mid 1930's?

Used by tram crews to secure doors in the open or closed position and to open the used ticket box. Part of the items issued to each traffic crew or maintenance staff to access or lock tramcars.Would have been issued at the time to a driver or conductor with the cap or traffic number of 18Piece of chrome plated steel rod bent at 90 degrees and shaped at longer end to give a square shape for use in external doors on SECV Ballarat Trams - known as a square key. Was used to secure doors in both open and closed positions. Has been stamped 18 on one side at short end.18ballarat, tramcars, equipment, crews, doors, tramways -

Ballarat Tramway Museum

Ballarat Tramway MuseumPhotograph - Interior photo of a Geelong Pengelley tram, Keith Kings, 1955

Digital image scan of a Keith Kings slide showing the interior of a Geelong Pengelley tram in particular the detail of the end seat arrangement, doors, pay as you enter sign and the location of the builders plate.Yields information about the interior of a Geelong Pengelley tram.Digital image - Keith Kings number K(f)(83),geelong, pengelley, trams, tramways, builders plate -

![Letter Plate, 'Reno', St John's Parade [Kew]](/media/collectors/550653872162f11fb04854aa/items/57a03863d0cdd1210435bac1/item-media/57a038b1d0cdd1210435f155/item-fit-380x285.jpg) Kew Historical Society Inc

Kew Historical Society IncFunctional object - Letter Plate, 'Reno', St John's Parade, c.1900

Comparatively few weatherboard houses in Kew survived from the early years of settlement into the second half of the 20th century. One such property was ‘Reno’, which once stood on the east side of St John’s Parade. Its earliest recorded owner was the architect Samuel Cocking who lived there from c.1865 until his death in 1888. The original landholding was bordered by Cotham Road, Glenferrie Road, Wellington Street, and Charles Street. The southern portion of this land included a fine orchard, with many imported trees. The old summer house, at first in the orchard, was later removed to the house garden. The MMBW Detail Plan No.1576 (1904) shows the remaining portion of the original land holding, including a semi-circular pathway at the front, and garden features such as an aviary, a fountain and grotto, and a fernery. None of these are apparent in photographs dating from the 1960s, where the garden, which once included rare plants provided by Baron Von Mueller, surrounds the cottage in a tangled frenzy. Despite a ‘local significance’ classification by the National Trust, the house was demolished in 1977.Brass letter plate, originally from the front door of Reno in St John's Parade, Kew. Donated by Miss McDowell in 1977, in the year the house was demolished.reno, st john's parade, kew -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncModel Truck, 20th century

"Tarrengower Times" model truck registration plate TLJ 10. Flat tray, spoked wheels with pneumatic tyres, leaf springs front and rear, leather upholstery. "Century" battery behind cabin with" Century" in black on gold. Painted maroon with gold trim, gold painted headlights and radiator frame.On driver's door in gold lettering "The / Tarrengower / Times /High St. / Maldon / Est. 1858" Logo on oval plate at top of radiator.transport commercial model -

National Wool Museum

National Wool MuseumVehicle - Ford Truck, Ford Motor Company, 1930

1930 AA Ford 1.5 tonne (30cwt) truck. Originally owned by Blakiston & Company, Geelong. Built in 1930, this truck carried wool and general goods in Geelong and the Western District until the early 1940s. It was restored in 1989-1990 by David Malkit Automotive, Belmont, Geelong East Technical School. Specifications: 4 cyclinder side valve engine 201 cu.in. capacity 24 hp (R.A.C.) rating 40 bhp @2200rpm Optional 4 speed non-synchronised gearbox Heavy duty rear axle with torque rod Transverse front springs Cantilever back springs Coach built cab and tray bodyDark green truck with painted lettering on door and tray. The cabin has a black bench seat, and body has a wooden tray.printed: NATIONAL WOOL MUSEUM / GEELONG / BLAKISTON & Co. / Pty. Ltd. / CARRIERS / GEELONG / No 1 Licence plate: WOOL - 30ford, truck, transport, 1930s, vehicles