Showing 186 items

matching electrical power

-

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyMould Candle Making, Circa mid 1900's

... it was not until the 1950's that adequate domestic electrical power could... it was not until the 1950's that adequate domestic electrical power could ...Candle stick manufacturing moulds were extensively used throughout the Kiewa Valley and its regions to provide rural homes and businesses with illumination during times of limited light e.g. night time. These candles were used before the Kiewa Valley was placed of the electrical grid. The candles were made from parrafin wax. Before the 1920"s electricity was in limited supply due to the inability of the private electricity suppliers to service isolated rural regions. It was not until the Victorian State Government passed legislation (1920) to improve electricity supplies by forming the State Electricity Commission of Victoria (S.E.C.V.) Isolated rural communities could not meet the higher costs to have electricity supplies connected and therefore it was not until the 1950's that adequate domestic electrical power could be supplied.The isolation that the Kiewa Valley provided was of a greater hindrance to any utility (power,roads & telephone) where the cost per instillation was beyond the rural population's ability to pay either directly or indirectly. One of the benefits that the "closed" community of Mount Beauty had, when it was administered by the SECV was that some utility costs were a lot lower than that of the other settlements in the Kiewa Valley. This disparity led to a conference in 1928 of the rural and regional councils to demand from the Government an equality of electricity tariffs. This equality did not take place until 1965. The demand and usage of cheaper and affordable lighting that wax candles provided was for some rural families a way of life until the mid 1900's.This candle making mould is made from mild rolled sheet steel(tin). The top basin is rectangular in shape with beveled edges(facing in on all sides. There are six holes in the top basin for vertical hollow tubes to feed off. The six tapered cyclindrical tubes running from the top basin to the bottom raised platform base. All connections are welded together. The bottom of each cylinder has an opening for the candle wick. The wick is positioned in place before the molten wax is poured into the cylinders. A positioning ring has been welded to one bottom ring for stability.parrafin wax, candles, domestic household ighting -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyMantle for Gas Lantern

... started in 1891. These mantles were used before electrical power... were used before electrical power street lighting was installed ...Originally these mantles where produced to be used in gas street lights in Europe and North America cities.There use started in 1891. These mantles were used before electrical power street lighting was installed. They have been used ever since until safety concerns regarding radiation from their thorium infused particles made alternate mobile lamps more attractive. The age of open flame recreational lighting is fast coming to a close. The greater use of battery and generator powered lighting(ease of operation) has brought the costing of these alternative lighting to an acceptable level. The age of miniaturisation and volatility of the open flame has seen a greater swing to smaller and more stable lighting. These incandescent gas mantles were initially used in the Coleman White Gas LanternsThe Kiewa Valley, with its closeness to the Victorian Alps, allows greater opportunity for the "happy" campers to enjoy the outdoors. The lighting provided by the incandescent gas lamps allow the adventurer at heart to enjoy an alternative lifestyle and still having the comforts of "home" at their finger tips. The numerous camping facilities in the Kiewa Valley and the upper alpine region is testament that those living in the cities need a break from the day to day grind and go to a quieter and more spiritual environment. Artificial lighting, as provided by mobile apparatus, is highly valued by the urban gypsy. The outdoor recreational industry has significantly provided for, if only at holiday time, an industry that has a relatively high employment rate and beneficial to local communities.The gas mantle is in a fabric, pear shaped, of rayon fabric impregnated with cerium. It's appearance is similar to a very small fishing net. The fabric is very ply-able until it is heated by an open flame then it becomes more rigid and lets out an incandescent white light. Its colour is white to off white. It has a draw string fastened a t the bottom (to wrap around the flame source)lighting, gas, heating, camping, outdoor equipment lamp -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyTypewriter Mechanical Portable, 1950s

... and academics. This typewriter needed no electrical or battery power... and academics. This typewriter needed no electrical or battery power ...The Olivetti company was founded in Italy in 1908.This particular typewriter is a Olivetti Lettera 22, oblique front stroke and portable manufactured after 1950. The 1950s and 1960s was a time when British manufactured goods were still purchased by many Australian consumers. The later 1960s onwards, there was a shift, mainly in the cities, to European made goods. The invasion of Japanese manufactured goods was relatively slower, especially in rural areas. The demand for long lasted and dependable merchandise was in the rural area still the most important criteria. The ease of setting up this typewriter and its compact mobility was its major benefit to trades people and travelling professionals, e.g. rural doctors, other medical professionals, accountants, lawyers and educators. This item facilitated the growing numbers of professional nomads requiring a relatively light office stationery package e.g. travelling novelist, writer, businessman and academics. This typewriter needed no electrical or battery power to operate it. Outback Australia, where at this point in time, was still relatively isolated from a good available electrical power reticulation and battery power, and therefore could not be totally measured as a highly efficient office environment.Although this typewriter was purchased from a business in Penrith, Sydney, N.S.W., it is significant that it travelled easily to the Kiewa Valley, demonstrating the mobility of certain sections of the community. This typewriter was designed by an Italian industrial designer, Marcello Nizzoli, in line with the art deco style of the 1930s and the colour and flexibility of the vibrant 1950s. The underlying theme of manufacturing in the 1950s was to produce equipment that was more efficient than what was inherited from the earlier period of 20th century. Improvements were made to this Olivetti typewriter by Giuseppe Beccio by reducing the number of parts made from 3,000 to 2,000. This reduction of parts and therefore cost of production was the major principle of the Japanese manufacturing juggernauts of the post World War II era. Efficiency and low costs material was becoming prime factors in the success of rural industries from the 1960s. Competition from overseas producers was starting to affect rural industries and the removal of the large range of tariff protection, especially rural products, required not only a shift of farm management but a more efficient cost savings modus operandi. This Olivetti Lettera 22, oblique front stroke portable (weighs 4kg) mechanical typewriter has a coral coloured plastic casing. The keys are made of black hardened plastic with white lettering, numbers and symbols (imperial fractions, and pound). It has a QWERTY keyboard as opposed to the Italian QZERTY. It has a lever to move the ribbon between black, neutral (for mimeograph stencils)and red colours (a red key is provided for highlighting specific words,letters or symbols) . This machine is fitted with only a black ribbon. It has a black rubber paper rollers and chromed metal parts on the carriage way. It has four rubber feet underneath the main body. On the left side of the roller there is a lever to adjust the roller from fixed (when mobile) through 1,2 and 3 line space gradients. This model has a key for zero but not one for the number one (uppercase letter l is used) see KVHS 0459 for the carrying bag.On the cover over the ribbon wheels letter strikers has a plate marked "Lettera 22" and the back plate behind the paper roller and in front of the paper supports has a silver metal label marked "olivetti made in great britain".commercial, mobile office equipment, mechanical typewriter -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyMeter AVO, circa 1930 to 1951

... , with a needle pointer, the amount of electrical power being tested... electrical power indicators i.e., amps, volts and ohms into one ...When this AVOMETER was being utilised in the early 1950's it was at the "leading" edge of electrical measuring instrumentation.The first meter was produced by Automatic Coil Winder and Electrical Equipment Co. in 1923. This model was produced in the time from 1933 to 1951 when it was superseded by the most popular model, Model 8 (1951 to 2008).This AVO meter brought the measuring of three electrical power indicators i.e., amps, volts and ohms into one measuring unit. By using a "one fits all" unit, the carrying of separate measuring devices was reduced considerably. The need for a mountainous and a large area of operational requirements, such as the SEC Vic Kiewa Hydro Electricity Scheme, to minimise the weight of equipment carried by electricians and technicians was of the utmost relevance. The significance of this meter to the Kiewa Valley region relates to the impact of modern technology (at that time) upon a mainly rural environment. This equipment shows how the boost of "modern" equipment into the area because of the "Hydro Scheme" was facilitated a lot faster than would have taken under "normal" evolutionary time. The speed of information on all "new technology" had a relatively slow assimilation rate to those living in rural communities. This AVOMETER is a Model 7 MKII, production pre 1951. This meter measures electrical Amps, Volts and Ohms and has two internal batteries for its power. The main casing is made from aluminium with a bake-lite front. The front has a "window" detailing, with a needle pointer, the amount of electrical power being tested. There are two big dial switches, detailing Direct Current(DC) and Alternating Current(AC) when reading measurements of Ampere, Voltage and Ohms for power. This meter took the place of three or four meters used earlier. Modern meters (2000 onwards) have become digilised and are considerably lighter in weight and smaller. There are two electrical connection leads (one black and one red) each has a removable clasp and is 125cm long.Molded on the front centre panel " UNIVERSAL AVOMETER". Below this and above the left hand dial "D.C. SWITCH" .Above the right hand switch the right "A.C. SWITCH". On the left of each switch is an arrow pointing to it.The left switch is marked with a "+" and the right one with a "-". There is a "divisional 2" mark. Between and below the dials is "CUT OUT" plunger.electrical meters, electrical equipment, sec vic., state electricity commission of victoria, mt beauty, bogong village -

Geoffrey Kaye Museum of Anaesthetic History

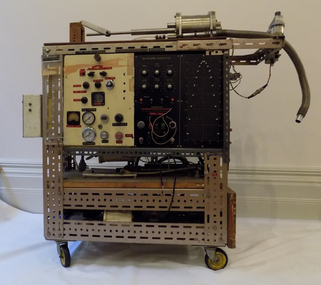

Geoffrey Kaye Museum of Anaesthetic HistoryMachine - Waveform Ventilator, 1970

... of the objects has 3 electrical power outlets.... electrical power outlets. Machine Waveform Ventilator ...Professor Arthur Barrington (Barry) Baker was the first Australian anaesthetist to gain a DPhil in anaesthesia. He completed his DPhil at Oxford University at the Nuffield Department of Anesthesia in 1971, titled, Physiological Responses to Artificial Ventilation. The Waveform Ventilator is the machine developed to illustrate his DPhil. The waveform ventilator was used in several scientific studies on 'the effects of varying inspiratory flow waveforms and time in intermittent positive pressure ventilation (IPPV)', published in the 'British Journal of Anaesthesia'. Professor Arthur Barrington Baker had an extensive career in research and clinical practice including holding the position as the Nuffield Professor of Anaesthetics at Sydney university (1992 - 2005) and also as the Dean of the Australian and New Zealand College of Anaesthetists (ANZCA) (1987-1990).The variable waveform ventilator is of national significance, due to its association with Professor Arthur Barrington Baker (Prof. Baker) the first Australian academic anaesthetist, and the representation of historical social themes and research and design, in anaesthesia. Historic significance – It is a rare type of ventilator in good condition and well provenanced. It is a tangible record of the beginning of the long established and distinguished career of Prof. Baker, the first anaesthetist in Australia to gain a DPhil. Prof Baker has a strong involvement in the Australian and New Zealand College of Anaesthetists (ANZCA) organisation. The object is a product of Prof Baker’s Doctorate of Philosophy (DPhil) on respiratory physiology and is associated with the prestigious Oxford University and the well-known Nuffield Department of Anaesthetics. It also represents the social theme of migration to England from Australia in the 1960s and 1970s to access and experience academic and artistic opportunities limited in Australia at the time. Scientific Value – The object is of scientific value as it offers major potential for education and interpretation in anaesthesia. Although ventilators are common equipment, this specific design and construct prototype is one of a kind, designed and used specifically for research purposes. A rectangular shaped object on a trolley with four wheels. The top half of the object consists of two panels, one of cream coloured painted wood, the other black plastic, both containing several dials of different shapes and sizes. The wood surface also contains several gauges and a safety pressure clear plastic box. The plastic surface also contains a pin board. The bottom half of the object consists of two shelves. The whole object's perimeter is lined with perforated metals. The top wooden surface has several metal pieces of equipment and a long tube. The rear of the object contains numerous types of tubing and wire, a gas cylinder and two leather straps with buckles. The bottom half of one side of the objects has 3 electrical power outlets.Waveform Generator, Drs Colliss N Cowie, Dr Baker Dr Murray Willson, Dr Babbington, Safety Pressure, Error POS F/B, Position, Feedback, Set Balance, Reset, Full Stroke, Velocity, Converter Current, line Pressure, Low Pressure, Bias Pressure, Start, Stop, Stop, Reset Press, Max Press, W/G Output, A/CRO B/2.baker, arthur barrington, baker, barry, professor, academic anaesthetist, oxford university, nuffield department of anaesthesia -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyRelay Protection Instrument, Circa 1950's

... Scheme's electrical power producing generators. These generators... electrical power producing generators. These generators are powered ...This protection relay apparatus (a large electrical fuse), which permits the easy monitoring and disconnection of faulty electrical apparatus connected to the large SEC Victoria Hydro Scheme's electrical power producing generators. These generators are powered by the hydro force of "stored" water at a higher altitude. The establishment of both the NSW and Victorian Hydro Schemes was achieved from the early 1900's to the 1960's. At this point in time the need for additional power sources to quench both an industrial and domestic demand for electricity was purely an economic and not and environmental (carbon reduction) factor. This hydro scheme was instigated by "the Government of the day" as a bold move and was the major force of the World War II refugee and "technical" workforce inclusion of skilled and unskilled migration into the Australian environment. Although this mass "invasion" of workers with families was thought of in some circles as intrusive, the expansion of population post war years and its integration into the Australian rural sector, produced the multi- lingual multi-cultural diversity of later years.This protection relay is very significant to the Kiewa Valley as its use was introduced during the Kiewa Hydro Scheme. Although only a small apparatus it was part of the explosion of human resources into the valley. This influx of population transformed the region from that of a basically quiet rural region to one which evolved into both an industrial and a larger residential community. This evolution in the valley created a change, not only in the "physical" landscape but also the socio-economic expansion which permitted other "tourist" based industries into the valley.This protection relay unit has a black painted metal shell with four copper enclosed "prongs" fastened to the rear of the housing(from a bake-lite plate) . Between these "prongs" are four "empty" points allowing additional "screw on" bases. The front glass enclosed meter and recorder allows for the identification and automatic disconnection of any faulty equipment connected to the main power generator. This equipment acts similarly to a modern day circuit breaker found on the electrical circuit boards of residential homes.On the top section of the front panel "ASEA" to the left "Made in Sweden" and to the right "Frabrique en Suede" below this "RIS" below this a graph and next to it two columns of numbers and a pointer for each setkiewa hydro electricity scheme, victorian state electricity commission, relays, generators -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyTypewriter Case Olivetti, Circa 1950

... no electrical or battery power to operate it therefore the inside... no electrical or battery power to operate it therefore the inside ...This typewriter case allowed the Olivetti typewriter to be securely and free from contaminants to be totally mobile. The Olivetti typewriter company was founded in Italy in 1908 and became a leader in portable dependable typewriters.This particular typewriter contained is a Olivetti Lettera 22, oblique front stroke and portable manufactured after 1950. During the 1950s and 1960s was a time when British and European manufactured goods were still purchased by many Australian consumers. After the 1970s however, there was a shift, mainly in the cities, to Japanese made goods. The invasion of Japanese manufactured goods was relatively slower, especially in rural areas. The demand for long lasting and dependable merchandise was in the rural area still the most important criteria. The ease of setting up this typewriter and its compact mobility was its major benefit to trades people and travelling professionals, e.g. rural doctors, other medical professionals, accountants, lawyers and educators. This item(carrying case) facilitated the growing numbers of professional nomads requiring a relatively light office stationery package e.g. travelling novelist, writer, businessman and academics. This typewriter needed no electrical or battery power to operate it therefore the inside compartment did not require additional storage pockets . Outback Australia, where at this point in time, good available electrical power reticulation and battery power, was a scarce and therefore could not be totally measured as a highly efficient office environment. The protective carrying bag provided the only mobile way to operate in some business and home locations.Although this typewriter cover and its typewriter was purchased from a business in Penrith, Sydney, N.S.W., it is significant that it travelled easily to the Kiewa Valley, demonstrating the mobility of certain sections of the community. This typewriter cover protected the expensive typewriter it contained which was designed by an Italian industrial designer, Marcello Nizzoli, in line with the art deco style of the 1930s and the colour and flexibility of the vibrant 1950s. The underlying theme of manufacturing in the 1950s was to produce equipment that was more efficient than what was inherited from the earlier period of 20th century. Improvements were made to this Olivetti typewriter by Giuseppe Beccio by reducing the number of parts made from 3,000 to 2,000. Protection of such a typewriter was of an utmost necessity. The need for mobile expensive typewriters waned as less expensive typewriters became available. This was the major principle of the Japanese manufacturing juggernauts of the post World War II. Efficiency and low cost material was becoming prime factors in the success of rural industries from the 1960s. Competition from overseas producers was starting to affect rural industries and the removal of the large range of tariff protection, especially rural products, required not only a shift of farm management but a more efficient cost savings modus operandi.This is a semi hard cover (cloth over cardboard on inside, plastic over cardboard on outside), camel coloured outside and tartan cloth covered pattern inside the typewriter case. the case can be opened up by "unzipping" the top from the bottom halves of the case. For carrying purposes the case has two plastic covering metal handles with brass fittings. There are two stitched on brown reinforcement straps encompassing both sides of the case. The two reinforcing straps are brown in colour and a securing strap with a press button at one end to allow an extra securing tongue to keep the cover secure. The top inside of the case has a three quarters long paper compartment (flap style). See KVHS 0455 for Olivetti Lettera typewriter.commercial, protective carry bags/cases for mobile office equipment, mechanical typewriter -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Domestic object - Belt, Carter Saddler Warrnambool, 19th century to mid 20th century

... electrical, which allowed the power to be disippated to a number..., with one central motor sometimes steam but later electrical, which ...This belt is typical of those used in the lineshaft system of operation, with one central motor sometimes steam but later electrical, which allowed the power to be disippated to a number of points. This belt links into Warrnambool’s past with the name of S Carter. Samuel Carter emigrated from Yorkshire in 1865 and opened his saddlery in 1866 in partnership with a Mr Roach until he moved his business to Fairy Street around1885. Samuel Carter died in 1892 and his son continued the business until around 1940.Brown hard leather with 9 metal staples in each end Two oval stamps with S. Carter Warrnambool around outer edge and Saddler stamped in centre. All uppercase. Larger stamp is incomplete. warrnambool, samuel carter, saddlery lineshaft belt lava street fairy street -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyTimer Favag, Circa 1950

... connected to the large SEC Victoria Hydro Scheme's electrical power... connected to the large SEC Victoria Hydro Scheme's electrical power ...This Favag Timer apparatus was a part of the first electronic control system -(1960's), in Victoria), which worked using telephone stepping selectors to convey a change in voltage providing a regulated pulse from the control centre(Mount Beauty) to the remote Power Stations opening and closing (stop/start) of various devices at the Power Station and a return signal confirmed the action taken. Testing of this unit was carried out using a "dummy" device at the remote Power Station so as not to disrupt the power plant's operation. This timer was one of many electrical apparatus connected to the large SEC Victoria Hydro Scheme's electrical power producing generators. These generators are powered by the hydro force of "stored" water at a higher altitude. The establishment of both the NSW and Victorian Hydro Schemes was achieved from the early 1900's to the 1960's. At this point in time the need for additional power sources to quench both an industrial and domestic demand for electricity was purely an economic and not and environmental (carbon reduction) factor. This hydro scheme was instigated by "the Government of the day" as a bold move and was the major force of the World War II refugee and "technical" workforce,inclusion of skilled and unskilled, migration into the Australian environment. Although this mass "invasion" of workers with families was thought of in some circles as intrusive, the expansion of population post war years and its integration into the Australian rural sector, produced the multi- lingual multi-cultural diversity of later years.This Favag Timer was one of the crucial pieces of equipment that made it possible for the Mount Beauty Terminal Station to control the operations of these Power Stations; McKay, Clover, West Kiewa Power Stations and the Dederang Terminal Station.This aluminium and anodised "FAVAG" (pulse) timer is fastened to a base structure which comes with its own metal cover that is fastened by two metal hooks. From the top of these hooks runs a thick leather "carry" strap.The instrument, itself, a small "micro motor" at one end tape feeding spool on the other. Aluminium metal structures offer a preventative barrier against any electronic spikes from static electricity sources. There are two toggle switches to the bottom right hand side and twelve coloured "pin" connection points.There is a sliding access sleeve which exposes a circuit board.with various leads fastened on each side. In front of one of this slide are two "screw in" fuses, spare fuses are in a small envelope taped above. Circuit diagrams are etched white on black background on the top face of the main structure. At the base of the back section is a two pronged input terminal. There is a fine black rubber layer (cushioning) for the mian top cover.On the cover fastened with two rivets "FAVAG" underneath in small print "Fabrique d'appareils electriques S.A." underneathe "NEUCHATEL-SUISSE". on one end is a "STATE ELECTRICITY COMMISSION OF VICTORIA" metal label screwed on.The back label has manufacturers' type and model number.sec vic kiewa hydro scheme, alternate energy supplies, alpine population growth -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyCalendar Desk Perpetual, circa mid 1950s

... or its region. The time this item was first used, electrical... was first used, electrical or battery powered desk and office ...This item appears to be a calendar which was in use for a multiple clientele office e.g. post office, commercial office or bank, school or educational administration area, small government office or hospital administration in the Kiewa Valley or its region. The time this item was first used, electrical or battery powered desk and office calendars did not exist for semi isolated rural regions. These type of perpetual calendars not only looked impressive but were not affected by power shortages. This was a time when not all of Victoria was adequately supplied by power. This item is quite relevant to the Kiewa Valley as it demonstrates that the time before the Hydro electricity generators where built (Mount Beauty to Falls Creek), power supplies were not keeping up to the ever increasing demand from city and rural customers. This item was in a period before mass produced automated date and time pieces were available and hand operated date and time pieces were both in a social and commercial sphere a necessity.Wooden box (varnished) with three openings (on the front) detailing ,the day(Monday to Sunday), the date (1st to 31st) and the month (January to December). On the right side of the calendar box are two winding screws (RHS 6 steel) for each opening. These permit the scrolling of the information i.e. day, number and month. This ability results in a desk calendar which is perpetual. On the back there is a steel (screwed on) hanger with a slot for wall screw.perpetual calendar, office calendars, desk calendars, desk furniture -

Ballarat Tramway Museum

Ballarat Tramway MuseumSlide - 35mm slide/s, David Verrier, 6/10/1964 12:00:00 AM

... in the view. Note the traction power electrical box on the corner... and the fountain in the view. Note the traction power electrical box ...Yields information about the appearance of the City Centre tramway area, and the tram services that ran from there.Agfa colour slide, white blue plastic mount. Photograph by David Verrier of looking west at the intersection of Sturt and Lydiard St with trams 28 (south side)( Gardens), and on the north side tram 34 (Mt Pleasant) and behind it No. 40 (Lydiard St North). Has the Town Hall, tram stop shelter and the fountain in the view. Note the traction power electrical box on the corner with an elderly lady about to cross the road. Photo taken 6/10/1964.On back of slide in pencil "Tues 6/10/64 Ballarat, Sturt and Lydiard St, RT 34 Mt Pleasant, 40 Lydiard Nth LT 28 Gardens"tramways, trams, sturt st, tramway centre, lydiard st, town hall, tram 34, tram 40, tram 28 -

Bendigo Military Museum

Bendigo Military MuseumMemorabilia - TRENCH ART, LAMP, Post WW2

... to the tip of the bomb. An electrical cord with power plug... to the tip of the bomb. An electrical cord with power plug ...Possibly made by the donor.This object is an example of trench art. .1 The lamp base consists of a chrome plated deactivated mortar bomb attached to a turned brown wooden base. A globe and switch socket are attached to the tip of the bomb. An electrical cord with power plug is threaded through the base of the bomb. .2 The lampshade is made of stiffened brown paper laced to a wire frame with dark brown cord. Handpainted coloured flowers decorate the outer surface of the shade. The shade is attached to the globe via a wire clamp.On the base of the mortar bomb: ' ?LB, IM, MF, 1940'ornaments, lighting - electrical, trench art, souvenir -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Dentist Drill, Late 19th century

... to most communities the electrically powered dental engines began... accessible to most communities the electrically powered dental ...The design of this and other similar treadle powered dental engine (or dentist drill) was in common use by dentists from the 1870’s into the 1920's. When electricity became accessible to most communities the electrically powered dental engines began to take over from the treadle power. Over the ages teeth were extracted using picks and scissors and other gouging instruments. Bow drills, hand drills and even a "bur thimble" drill were later used to prepare cavities for filling. Some drills were made bendable by attaching flexible shanks between the metal bur and the handle, giving access to the teeth at the back of the mouth. Other mechanical devices were introduced along the way, such as clockwork drills, but they were hard to handle and inefficient. Over the centuries “dentistry has been performed by priests, monks and other healers. This was followed by barbers; the barber’s chair may well have been the precursor to the dental chair. “(SA Medical Heritage Society Inc.) In 1871 James Morrison patented the first commercially manufactured 'foot treadle dental engine', the first practica dental engine although others had been introduced as early as 1790 (by John Greenwood). Handmade steel burs or drills were introduced for dental handpieces, taking advantage of the significant increase in the speed of the drill. In 1891 the first machine-made steel burs were in use. The treadle drill reduced the time to prepare a cavity from hours to less than ten minutes. In 1876 the Samuel S. White Catalogue of Dentist Instruments listed a 12 ½ inch wheel diameter dental engine, with 14 bright steel parts, for sale at US $55 In today’s market, this is the equivalent to US $1200 approx. The specifications of that dental engine are very similar to the this one in our Flagstaff Hill Maritime Village’s collection. It is interesting to note that workings of a similar treadle dentist drill were used and modified to power a treadle spinning wheel of one of the volunteer spinners at Flagstaff Hill Maritime Village. The foot treadle dental engine was a milestone in dental history. “Historic importance of treadle powered machines; they made use of human power in an optimal way” (Lowtech Magazine “Short history of early pedal powered machines”) The invention of a machine to speed up the process of excavation of a tooth lead to the invention of new burs and drills for the handpieces, improving speed and the surgical process of dentistry. They were the fore-runner of today’s electrically powered dental engines. This treadle-powered dentist drill, or dentist engine, is made of iron and steel and provides power for a mechanical dental hand-piece that would be fitted with a dental tool. The drill has a three footed cast iron base, one foot being longer than the other two. A vertical C shaped frame is joined into the centre of the base, holding an axle that has a driving-wheel (or flywheel) and connecting to a crank. A slender, shoulder height post, made from telescoping pipes, joins into the top of this frame and is height adjusted by a hand tightened screw with a round knob. On the post just above the frame is a short metal, horizontal bar (to hold the hand-piece when it is not in use). A narrow tubular arm is attached to the top of the stand at a right angle and can move up and down. At the end of the arm is a firmly fixed, flexible rubber hose protected for a short distance by a sheath of thin metal. At the end of the hose there is a fitting where the drill’s hand-piece would be attached; a small, silver coloured alligator clip is also at the end. A treadle, or foot pedal, is hinged to the heel to the long foot of the base, and joined at the toe to the crank that turns the driving-wheel. There is a spring under the toe of the treadle. The metal driving-wheel has a wide rim. Touching the inside of the rim are four tubular rings that bulge towards the outside of the driving-wheel, away from the pole, and all meet at the hub of the axle. The axle is bulbous between the inside of the driving-wheel and the frame then passes through the frame and is attached on the other side. The driving-wheel has a groove around which a belt would sit. The belt would also fit around a pulley on the arm, at the top of the post. The pulley is joined to a rod inside the arm and this spins the drill's hand-piece and dental tool holder. The two shorter feet of the base are made from a long metal bar that has been curved outwards, and its centre is bolted to the base of the pole. Under the ends of the curved legs of the base are wedge shaped feet. The driving-wheel is decorated in light coloured paint on both sides, each side having three sets of floral decals evenly spaced around them, and each about a sixth of the wheel's circumference. Similar decoration is along the sides of the frame. The foot pedal has decorative cutout patterns in the centre of the foot and at the toe. On the long foot of the stand is some lettering with a fine, light coloured border around it. The lettering is hard to read, being a dark colour and flaking off. There are also remnants of fine, light coloured flourishes. The foot pedal has lettering of the maker’s trade mark cast into the metal at the ball of the foot. Lettering on the base is peeling and difficult to read. The foot pedal has a trade mark cast into it that looks like a combination of ‘C’ , ‘S’ , ‘A’, ‘R’. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, dentist, teeth, dental drill, dental engine, treadle drill, foot powered drill, treadle engine, orthodontics, dental surgery, james morrison -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Dentist Drill, Late 19th century

... to most communities the electrically powered dental engines began... accessible to most communities the electrically powered dental ...The design of this and other similar treadle powered dental engine (or dentist drill) was in common use by dentists from the 1870’s into the 1920's. When electricity became accessible to most communities the electrically powered dental engines began to take over from the treadle power. Over the ages teeth were extracted using picks and scissors and other gouging instruments. Bow drills, hand drills and even a "bur thimble" drill were later used to prepare cavities for filling. Some drills were made bendable by attaching flexible shanks between the metal bur and the handle, giving access to the teeth at the back of the mouth. Other mechanical devices were introduced along the way, such as clockwork drills, but they were hard to handle and inefficient. Over the centuries “dentistry has been performed by priests, monks and other healers. This was followed by barbers; the barber’s chair may well have been the precursor to the dental chair. “(SA Medical Heritage Society Inc.) In 1871 James Morrison patented the first commercially manufactured 'foot treadle dental engine', the first practica dental engine although others had been introduced as early as 1790 (by John Greenwood). Handmade steel burs or drills were introduced for dental handpieces, taking advantage of the significant increase in the speed of the drill. In 1891 the first machine-made steel burs were in use. The treadle drill reduced the time to prepare a cavity from hours to less than ten minutes. In 1876 the Samuel S. White Catalogue of Dentist Instruments listed a 12 ½ inch wheel diameter dental engine, with 14 bright steel parts, for sale at US $55 In today’s market, this is the equivalent to US $1200 approx. The specifications of that dental engine are very similar to the this one in our Flagstaff Hill Maritime Village’s collection. It is interesting to note that workings of a similar treadle dentist drill were used and modified to power a treadle spinning wheel of one of the volunteer spinners at Flagstaff Hill Maritime Village. The foot treadle dental engine was a milestone in dental history. “Historic importance of treadle powered machines; they made use of human power in an optimal way” (Lowtech Magazine “Short history of early pedal powered machines”) The invention of a machine to speed up the process of excavation of a tooth lead to the invention of new burs and drills for the handpieces, improving speed and the surgical process of dentistry. They were the fore-runner of today’s electrically powered dental engines. This treadle-powered dentist drill, or dentist engine, is made of iron and steel and provides power for a mechanical dental handpiece that would be fitted with a dental tool. On the foot is painted lettering naming it "The Brentfield" and there is a fine line of light coloured paint creating a border around the name. The paint under the lettering is peeling off. The drill has a Y-shaped, three footed cast iron base, one foot being longer than the other two. A vertical frame is joined into the centre of the base, holding an axle that has a driving-wheel (or flywheel) and connecting to a crank. A slender, shoulder height post, made from adjustable telescoping pipes, joins into the top of this frame. On the post just above the frame is a short metal, horizontal bar (to hold the hand-piece when it is not in use). A narrow tubular arm is attached to the top of the stand at a right angle and can move up, down and around. There is a pulley each side of the joint of the arm and a short way along the arm is fitted a short metal pipe. A little further along the arm a frayed-ended cord hangs down from a hole. At the end of the arm is another pulley and a joint from which hangs a long, thin metal pipe with two pulleys and a fitting on the end. A treadle, or foot pedal, is joined to the long foot of the base, and joined at the toe to the crank that turns the driving-wheel. The metal driving-wheel has a wide rim. Touching the inside of the rim are four tubular rings that bulge towards the outside of the driving-wheel, away from the pole, and all meet at the hub of the axle. The axle fits between the inside of the driving-wheel and the frame then passes through the frame and is attached on the other side. The driving-wheel has a groove around which a belt would sit. The belt would also fit around a pulley on the arm, at the top of the post. The pulley is joined to a rod inside the arm and this spins the drill's hand-piece and dental tool holder. The foot pedal has a cross-hatch pattern on the heel and the ball of the foot has tread lines across it. The end of the toe and the instep areas have cut-out pattern in them. "The ____/ Brentfield / __ DE IN L___" (Made in London) painted on the long foot of the base. Marked on the drill connection is “Richter De Trey, Germany”flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, dentist, teeth, dental drill, dental engine, treadle drill, foot powered drill, treadle engine, orthodontics, dental surgery, james morrison, the brentfield, richter de trey, german dental fitting, london dental drill -

Federation University Historical Collection

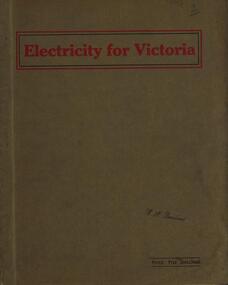

Federation University Historical CollectionBook, Electricity for Victoria, 1927, 1927

... Plant at the Yallourn Power Station Electrical Equipment... at the Yallourn Power Station Electrical Equipment at the Yallourn Power ...Brown soft covered book. Contents include: Winning Brown Coal at Yallourn Dredge Operation for Overburden Removal Boiler Plant at the Yallourn Power Station Electrical Equipment at the Yallourn Power Station Steam Plant at the Yallourn Power Station Yallourn-Melbourne High Tension Line Yarraville Terminal Station Transmission distribution High Transmission Towers for River Crossing Sugarloaf-Rubicon Hydroelectric Development Briquette factory Subsidiary Activities at Yallourn Future Developments thompson's engineering & pipe co. ltd, briquettes, electricity, power generation, yallourn, yallourn briguetting works, transmission lines, high tension switchgear, insulators, australian porcelain company, substation, brown coal, high tension line, sugarloaf-rubicon, plans, suspension tower, transposition tower, yarraville terminal station, condenser, newport power station, gippsland, hydroelectric -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyTransformer Lamp System, late 1950's

... . The SEC Victoria Hydro Scheme's electrical generators are powered... Hydro Scheme's electrical generators are powered by the hydro ...This transformer lamp system, which has a dial to transform 240 volts to a minimum of 32 volts was used by electrical technicians to inspect internal parts of the large generators (even in small confined spaces). The reason for the reduction of the 240 volts to the 32 volts was for the safety of the inspector. The SEC Victoria Hydro Scheme's electrical generators are powered by the hydro force of "stored" water at a higher altitude. The establishment of both the NSW and Victorian Hydro schemes was achieved from the mid 1900's to the 1960's. At this the point in time the need for additional power sources to quench both an industrial and domestic demand for electricity was purely an economic and not and environmental (carbon reduction) factor. This hydro scheme was instigated by "the Government of the day" as a bold move and was the major force of the World War II refugee and "technical" workforce inclusion of skilled and unskilled migration into the Australian environment. Although this mass "invasion" of workers with families was thought of in some circles as intrusive, the expansion of population post war years and its integration into the Australian rural sector, produced the multi- lingual multi-cultural diversity of later years.This transformer lamp is very significant to the Kiewa Valley as it was introduced as a very small part of the explosion of human resources into the valley. This influx of population transformed the region from that of a basically quiet rural region to one which evolved into both industrial and larger residential community. This evolution in the valley created a change, not only in the "physical" landscape but also the socio-economic expansion which permitted other "tourist" based industries into the valley. This is also a specific electronic item which was manufactured in Melbourne and not sourced from Europe or Asia. This demonstrates the fast evolution of Australian technology to a high standard compatible to that of the rest of the world.This heavy hand held electrical transformer (transforms 240 volts to 32 Volts) an has one leather handle on the top with three small (gauze filtered) air holes. It also has two 2 pin directional cable distribution (clipsal) in/out points 10amps / 240 volts. There is one glassed in volts/ac meter and one variable switch (180 to 150 voltage in settings of 10 volt increments.There are two vents (one on each of the smaller sides). There is also one three pin electrical lead coming out from the top.On one side is a manufacturer's plaque with "ELECTRONIC A & R EQUIPMENT MELBOURNE" and underneath "TYPE 1719, PRI V. 180 250" underneath "V.A. 1250" underneath "CYC 50" underneath "SEC V. 115" underneath "SEC A. 10 . 8". The label on topside "CAUTION SET SWITCH TO 250 v BEFORE CONNECTING TO MAINS THEN, WITH EQUIPMENT OPERATING, SET METER TO RED LINE.kiewa hydro electricity scheme, victorian state electricity commission, transformers -

Wodonga & District Historical Society Inc

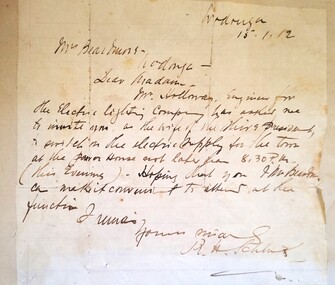

Wodonga & District Historical Society IncLetter - Electricity comes to Wodonga - 1912 letter to Mrs Beardmore

... Beardmore, was invited to switch on the electrical current... Beardmore, was invited to switch on the electrical current ...Mrs Jessie Beardmore, wife of the Shire President, Mr Henry Beardmore, was invited to switch on the electrical current at the power house in Wodonga on 15th January 1912. This was not the official opening of the newly installed system which took place a few weeks later. Disagreement existed amongst Shire Councillors about the official opening, several of them including Mr Beardmore believing the opening should only take place when the scheme was completed. However Dr Schlink, Mr D. M. Stavely, Cr Twomey and Mr C. Holloway, Engineer for the Electric Lighting Company, arranged a small ceremony to turn lights on for the first section of the scheme. This included street lighting along Sydney Street between South Street and the Shire Hall as well as a few business houses and private establishments, with the balcony of the Terminus Hotel illuminated by over 100 lights. Other areas and buildings were connected over the following weeks. Mr Beardmore was not present at the beginning of proceedings but joined the crowd in the street. During a small number of speeches, credit for his work to instigate and further the introduction of electricity to Wodonga was given to Councillor Twomey, referred to as “the father of the scheme”. This item is significant because it records the first connection of electricity to Wodonga in 1912.A hand written letter addressed to Mrs Beardmore of Wodonga. A portrait of Mrs Beardmore is also included. A transcript of the letter is included below. Wodonga 15 -1-12 Mrs Beardmore Wodonga Dear Madam, Mr Holloway, Engineer for the Electric Lighting Company, has invited me to invite you as the wife of the Shire President to switch on the electric supply for the town at the power house not later than 8.30PM (this evening). Hoping that you and Mr Beardmore can make it convenient to attend. I remain yours sincerely, R. H. Schlinkbeardmore family, electricity in wodonga -

The Beechworth Burke Museum

The Beechworth Burke MuseumPhotograph, 1960s

... Australians. Facilities such as electrical outlets to power caravans... Australians. Facilities such as electrical outlets to power caravans ...This photograph was taken in the 1960s at Lake Sambell Caravan Park and visible in the photograph are individual caravan sites with electricity outlets, a large single-story building with a caravan park banner, dirt roads, a freestanding message board, and a parked car. Lake Sambell Caravan Park opened in 1959 owing to the work of R.E. Carter, Beechworth Shire engineer from 1954-63. Carter advocated for improvements to the lake and surrounding area in order to encourage tourism in Beechworth. The opening of the caravan park was part of many improvements to Lake Sambell made in this period by Carter including: the swimming pool in 1961, water skiing and boating facilities, and increased lake surface in 1964. These improvements were financed mainly by grants from the Tourist Development Authority. The popularity of caravanning in Australia exploded during this post-war period of the late 1950s and 1960s. This popularity was driven by multiple factors, including: the stopping of fuel rations, the accessibility of car ownership through the manufacturing of affordable cars, technological developments in caravan design, and the increase in prosperity and leisure time for many Australians. Facilities such as electrical outlets to power caravans are present in this photograph of Lake Sambell Caravan Park. Lake Sambell is an artificial lake that was developed on the previous site of the Rocky Mountain Mining Company workings and was officially opened by Minister for Lands, Mr Baily, on October 5, 1928. The disused and unattractive remains of the mine were converted into a recreational area intended for swimming, boating, and fishing. The lake is named after Mr L.H. Sambell, shire engineer and secretary of the Forward Beechworth Committee, who advocated for the enhancement of Beechworth into a tourist destination and was central to the planning and establishment of the lake. This photograph is of historical and social significance in providing insight into caravanning during the 1960s in Australia. Caravanning was extremely popular during the 1960s in Australia due to multiple social and economic factors including the stopping of fuel rations, the accessibility of car ownership through the manufacturing of affordable cars, technological developments in caravan design, and the increase in prosperity and leisure time for many Australians.Black and white rectangle photograph printed on photographic paper and unmounted.Reverse: 3536/ [logo back printing: KODAK/ VELOX/ PAPER] / C798 lake sambell caravan park, lake sambell, caravanning 1960s, caravan park, rocky mountain mining company, kodak velox paper, r.e. carter, l.h. sambell, caravan electricity outlets, tourist development authority, post-war prosperity, forward beechworth committee, lake sambell boating, lake sambell swimming pool, lake sambell fishing, artificial lake, travel 1960s, recreation 1960s -

The Beechworth Burke Museum

The Beechworth Burke MuseumPhotograph, 1960s

... Australians. Facilities such as electrical outlets to power caravans... Australians. Facilities such as electrical outlets to power caravans ...This photograph was taken in the 1960s at Lake Sambell Caravan Park, visible in the photograph are individual caravan sites with electricity outlets, a large single-story building, a parked car, and two caravans partially obstructed by trees. Lake Sambell Caravan Park opened in 1959 owing to the work of R.E. Carter, Beechworth Shire engineer from 1954-63. Carter advocated for improvements to the lake and surrounding area in order to encourage tourism in Beechworth. The opening of the caravan park was part of many improvements to Lake Sambell made in this period by Carter including: the swimming pool in 1961, water skiing and boating facilities, and increased lake surface in 1964. These improvements were financed mainly by grants from the Tourist Development Authority. The popularity of caravanning in Australia exploded during this post-war period of the late 1950s and 1960s. This popularity was driven by multiple factors, including: the stopping of fuel rations, the accessibility of car ownership through the manufacturing of affordable cars, technological developments in caravan design, and the increase in prosperity and leisure time for many Australians. Facilities such as electrical outlets to power caravans are present in this photograph of Lake Sambell Caravan Park. Lake Sambell is an artificial lake that was developed on the previous site of the Rocky Mountain Mining Company workings and was officially opened by Minister for Lands, Mr Baily, on October 5, 1928. The disused and unattractive remains of the mine were converted into a recreational area intended for swimming, boating, and fishing. The lake is named after Mr L.H. Sambell, shire engineer and secretary of the Forward Beechworth Committee, who advocated for the enhancement of Beechworth into a tourist destination and was central to the planning and establishment of the lake. This photograph is of historic and social significance in documenting the enhancement of the Lake Sambell area overseen by R.E. Carter and providing insight into caravanning during the 1960s in Australia. Caravanning was extremely popular in Australia during the late 1950s and 60s due to multiple social and economic factors including the stopping of fuel rations, the accessibility of car ownership through the manufacturing of affordable cars, technological developments in caravan design, and the increase in prosperity and leisure time for many Australians. Black and white rectangle photograph printed on photographic paper and unmounted.Reverse: 3538/ [logo back printing KODAK/ VELOX/ PAPER] / C798lake sambell caravan park, lake sambell, lake sambell 1960s, lake sambell fishing, lake sambell boating, lake sambell swimming pool, r.e. carter, l.h. sambell, tourist development authority, caravanning 1960s, caravan electricity outlets, caravan park, forward beechworth committee, rocky mountain mining company, lake caravan park, caravan mid 20th century, beechworth tourism, travel in the 1960s, holiday 1960s -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Can Opener, Bottle Opener & Corkscrew

... for electrically powered can openers to become practical. In the 1950s... for electrically powered can openers to become practical. In the 1950s ...It took 15 years to invent the can. It took 100 more to invent a standard way to open it. In the 19th century, decades after the invention of canning, there were virtually no can openers. Canned food, such as sardines, came with its own "key" to peel back the tin lid. Birth of the can One of the oddest things about the can opener is that the can predates it by almost 150 years. Though common today, cans were once military-grade technology. In 1795, Napoleon, to whom the phrase "an army marches on its stomach" is attributed, offered 12,000 francs to anyone who could find a way to preserve food. Without any knowledge of bacteria or their role in food spoilage, scientists didn't even know where to begin. It took 15 years before a chef named Nicholas Appert claimed the prize after successfully jarring food. Soon after that, his countryman Philippe de Girard came up with a variant on Appert's method—metal tins—and sold the idea to the British. Spoiled food, and the sickness it caused, was a widespread problem. The public would have benefited from canned food, but for decades cans were almost exclusively for the army and the navy. The canning process, with its hours of boiling and steaming, its scrupulous cleanliness, its heated metal, and its need for a great deal of disposable material, made canned food far too expensive for anyone but the military. No can openers were needed or even possible. The metal of early cans was too thick to make openers practical. Soldiers and sailors had plenty of sharp objects on hand and made ample use of them when they wanted to eat. During the 19th century, the process of canning was refined and mechanised, and the metal wall of the average can slimmed down enough that a civilian could get it open—if that civilian had the right tool. No one had that tool yet, so early cans had to open themselves. In other words, they came with built-in openers. The result was a confusing but pleasing free-for-all, in terms of product engineering. Each type of food came with its own kind of can, and each kind of can came with its own kind of opener. Tinned fish and meat were often sold in rectangular cans. These cans were fitted with a "key" that would roll down the top of the can. Coffee, beans, and other types of meat were packaged in cylinders with metal strips that could be peeled back with their own kinds of built-in keys. Cans of milk, which didn't need to be completely opened, came with puncture devices. As tinned food became more common, its containers became more regular. A nice cylindrical can became the norm, and, as these cans filled kitchens, more engineers put their minds to finding a convenient way to open all of them. The first standalone can opener worked on a simple principle: point, stab, and pull. From the mid-19th century to the end of World War I, the typical can opener looked roughly like a wrench, if the lower 'jaw' of the wrench were replaced with a blade. People used the blade to puncture the top of the can near its edge, push the upper jaw against the side of the can, and drag the blade through the metal along the rim. Because meat was the first and most popular canned substance, these can openers were often shaped to look like cows and given the nickname 'bully beef can openers'. The bully beef can opener, popular in the mid-19th century, resulted in many lost fingers. Later, a corkscrew was added that was seated in the handle, and could be pulled out for use. Bully beef can openers were so common, effective, and sturdy that they are still frequently available on collectors' sites. Some are advertised as “still working,” and every last one of them is, without a doubt, soaked in the blood of our ancestors. Dragging a sharp blade along the edge of a can is certain to cause injury sooner or later. So once people got a reliable can shape and a reliable way to get the can open, the search was on for a reliable way to get a can open without the possibility of losing a finger. The answer came in 1925, from the Star Can Opener Company of San Francisco. This is probably the first can opener that resembles the one people have in their kitchens today. Instead of using a blade to pry open a metal can, buyers could clamp the edge of the can between two wheels and twist the handle of one of the wheels to move the blade around the lip. The Star can openers weren't perfect. Compared to the bully beef model, they were flimsy and breakable, but they probably prevented a few injuries. Six short years after the Star model came to market, the first electric can opener was invented. It was patented in 1931 by the Bunker Clancey Company of Kansas City, who had already been sued by the Star Can Opener Company for trying sell a double-wheeled can opener like the Star model (the case was dismissed). The electric can opener must have seemed like the wave of the future and a sure-fire seller, but it proved to be too far ahead of its time. In 1931 not that many households had electricity, and those that did weren't interested in buying can openers. The Bunker Clancey Company was subsequently bought by the Rival Company, which still makes small appliances like can openers today. It took another 25 years for electrically powered can openers to become practical. In the 1950s, Walter Hess Bodle and his daughter, Elizabeth Bodle, developed an electric can opener in the family garage. Walter came up with the opener's blades and motor, and Elizabeth sculpted the outside. Their can opener was a free-standing unit that could sit on the kitchen counter. The Udico brand of the Union Die Casting Company put it on the market in time for Christmas in 1956 and had great success with it. Over the next few years it came out in different styles and colours, and, like the bully beef can opener, has become a collector's item. Also like the bully beef model, Udico can openers often still work. They don't make 'em like they used to. Although there have been some design changes and refinements over the last sixty years, there have yet to be any more leaps forward in can opener technology. If you're resentfully opening a can, you are almost certainly doing it using the Star design, manually forcing the can between two wheels, or the Bodle design, clamping the can into a free-standing electrical opener. Whether or not you enjoy your holiday meals, at least you can be happy that you are not getting poisoned by your own food or cutting open your hand with the blade you use to get at it. That's something, right?The can opener, Bottle opener and the corkscrew are still very important and essential items in most kitchens.Metal can opener, chromed, with bottle opener, and a corkscrew seated in the handle.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, canning, can opener, corkscrew, bottle opener, kitchen equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Can Opener

... . It took another 25 years for electrically powered can openers.... It took another 25 years for electrically powered can openers ...It took 15 years to invent the can. It took 100 more to invent a standard way to open it. In the 19th century, decades after the invention of canning, there were virtually no can openers. Canned food, such as sardines, came with its own "key" to peel back the tin lid. Birth of the can One of the oddest things about the can opener is that the can predates it by almost 150 years. Though common today, cans were once military-grade technology. In 1795, Napoleon, to whom the phrase "an army marches on its stomach" is attributed, offered 12,000 francs to anyone who could find a way to preserve food. Without any knowledge of bacteria or their role in food spoilage, scientists didn't even know where to begin. It took 15 years before a chef named Nicholas Appert claimed the prize after successfully jarring food. Soon after that, his countryman Philippe de Girard came up with a variant on Appert's method—metal tins—and sold the idea to the British. Spoiled food, and the sickness it caused, was a widespread problem. The public would have benefited from canned food, but for decades cans were almost exclusively for the army and the navy. The canning process, with its hours of boiling and steaming, its scrupulous cleanliness, its heated metal, and its need for a great deal of disposable material, made canned food far too expensive for anyone but the military. No can openers were needed or even possible. The metal of early cans was too thick to make openers practical. Soldiers and sailors had plenty of sharp objects on hand and made ample use of them when they wanted to eat. During the 19th century, the process of canning was refined and mechanised, and the metal wall of the average can slimmed down enough that a civilian could get it open—if that civilian had the right tool. No one had that tool yet, so early cans had to open themselves. In other words, they came with built-in openers. The result was a confusing but pleasing free-for-all, in terms of product engineering. Each type of food came with its own kind of can, and each kind of can came with its own kind of opener. Tinned fish and meat were often sold in rectangular cans. These cans were fitted with a "key" that would roll down the top of the can. Coffee, beans, and other types of meat were packaged in cylinders with metal strips that could be peeled back with their own kinds of built-in keys. Cans of milk, which didn't need to be completely opened, came with puncture devices. As tinned food became more common, its containers became more regular. A nice cylindrical can became the norm, and, as these cans filled kitchens, more engineers put their minds to finding a convenient way to open all of them. The first standalone can opener worked on a simple principle: point, stab, and pull. From the mid-19th century to the end of World War I, the typical can opener looked roughly like a wrench, if the lower 'jaw' of the wrench were replaced with a blade. People used the blade to puncture the top of the can near its edge, push the upper jaw against the side of the can, and drag the blade through the metal along the rim. Because meat was the first and most popular canned substance, these can openers were often shaped to look like cows and given the nickname 'bully beef can openers'. The bully beef can opener, popular in the mid-19th century, resulted in many lost fingers. Bully beef can openers were so common, effective, and sturdy that they are still frequently available on collectors' sites. Some are advertised as “still working,” and every last one of them is, without a doubt, soaked in the blood of our ancestors. Dragging a sharp blade along the edge of a can is certain to cause injury sooner or later. So once people got a reliable can shape and a reliable way to get the can open, the search was on for a reliable way to get a can open without the possibility of losing a finger. The answer came in 1925, from the Star Can Opener Company of San Francisco. This is probably the first can opener that resembles the one people have in their kitchens today. Instead of using a blade to pry open a metal can, buyers could clamp the edge of the can between two wheels and twist the handle of one of the wheels to move the blade around the lip. The Star can openers weren't perfect. Compared to the bully beef model, they were flimsy and breakable, but they probably prevented a few injuries. Six short years after the Star model came to market, the first electric can opener was invented. It was patented in 1931 by the Bunker Clancey Company of Kansas City, who had already been sued by the Star Can Opener Company for trying sell a double-wheeled can opener like the Star model (the case was dismissed). The electric can opener must have seemed like the wave of the future and a sure-fire seller, but it proved to be too far ahead of its time. In 1931 not that many households had electricity, and those that did weren't interested in buying can openers. The Bunker Clancey Company was subsequently bought by the Rival Company, which still makes small appliances like can openers today. It took another 25 years for electrically powered can openers to become practical. In the 1950s, Walter Hess Bodle and his daughter, Elizabeth Bodle, developed an electric can opener in the family garage. Walter came up with the opener's blades and motor, and Elizabeth sculpted the outside. Their can opener was a free-standing unit that could sit on the kitchen counter. The Udico brand of the Union Die Casting Company put it on the market in time for Christmas in 1956 and had great success with it. Over the next few years it came out in different styles and colours, and, like the bully beef can opener, has become a collector's item. Also like the bully beef model, Udico can openers often still work. They don't make 'em like they used to. Although there have been some design changes and refinements over the last sixty years, there have yet to be any more leaps forward in can opener technology. If you're resentfully opening a can, you are almost certainly doing it using the Star design, manually forcing the can between two wheels, or the Bodle design, clamping the can into a free-standing electrical opener. Whether or not you enjoy your holiday meals, at least you can be happy that you are not getting poisoned by your own food or cutting open your hand with the blade you use to get at it. That's something, right?The can opener is still a very important and essential item in most kitchens.Can opener, right handed, metal, upper blade section serrated, inscription 'Peerless Pat.Feb 11-90'.Peerless Pat.Feb 11-90flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, cannning, can opener, kitchen equipment -

Phillip Island and District Historical Society Inc.

Phillip Island and District Historical Society Inc.Photograph, Power station, Cowes 1930s, 1995

The Cowes Power station was in Cowes west, corner of Chapel Street and Osborne Avenue. James Norman Day was in charge c. 1935.HistoricalPhotocopy of letter from Mr & Mrs Ronald Day, Mermaid Beach, Queensland, sent to the Electrical Engineer, Cowes Council, 1995. and reply to sender. Also copy of photo of equipment in power station.Mr and Mrs Ronald Ernest Daypower station, electricity, james norman day -

Kiewa Valley Historical Society

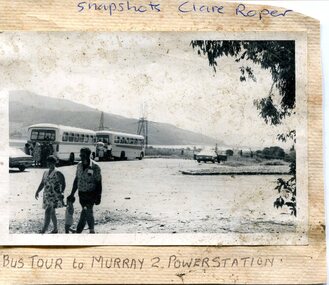

Kiewa Valley Historical SocietyPhotograph- Bus tour to Murray 2 Power Station

The Murray Region Hydroelectric Power Stations are two of seven hydro power stations, located near Khancoban in NSW. The two power stations are part of the Snowy Mountains Hydro-electricity Scheme, which is an extensive hydroelectricity and irrigation complex constructed in south-east Australia between 1949 and 1974 and now run by Snowy Hydro. Although both power stations are located in NSW, since 1 July 2008 all power generated has been allocated to the Victorian region of the National Electricity Market. Murray 2 Power Station was the first in the Snowy Scheme to use Japanese supplied large electrical and mechanical components Photographs demonstrate local Kiewa Valley residents enjoying an educational visit to Murray 2 Power Station which holds significance to the early history of the Hydro-electric Scheme in the area. Also demonstrates a pictorial history of social activities undertaken during this periodBlack and white photograph mounted on buff card Bus tour to Murray 2 Power Station showing 2 buses and group of Kiewa Valley residentsHandwritten in blue ink above photo "Snapshots Clare Roper' Handwritten in black ink below photo "Bus tour to Murray 2 Power Station'kiewa valley residents, clare roper -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyElectric Megger (Insulation Tester) and its case

Megger as the device was called, is in fact its brand name. It is a device that supplies a DC (direct current as per car batteries) voltage to enable testing of electrical apparatus. This particular device produces 250volts DC when the handle is turned vigorously. If an electrical device, such as a kettle or toaster, blew a fuse or tripped a circuit breaker, when switched on, then it must be checked electrically before any more use. Following the repair of the faulty item a megger would be used to check if either of the AC 240volt plugs leads were touching the metal case (earth). The output leads of the megger would be connected with one to the earth (metal case) and the other to each of the power connections in turn. A good megger reading of 50,000 ohms (resistance) would enable the device to be returned to service. A reading of zero ohms resistance would mean that it would again blow a fuse, and was therefore unsafe to use. In the electrical industry e.g. the former State Electricity Commission, a megger would be used to test lots of similar item in sequence. Because of the vigorous job of winding the handle, two persons were often used to save time. One would crank madly whilst the other shifted the leads. This particular megger is of a small voltage, but other meggers are bigger and have a few ranges of DC voltages able to be selected. The optimal megger for large Generating machines was motor driven megger. This was applied to the device being tested for a duration of approximately 30 minutes with reading of the resistance taken at regular intervals.All equipment belonging to the State Electricity Commission of Victoria was labelled with a metal plaque attached to it. The SECV constructed the Kiewa Hydro Electric Scheme in the Upper Kiewa Valley and on the Bogong High Plains. The scheme began in 1938 and finished in 1961 when this megger was used and also possibly later as the SECV remained to maintain and operate the Scheme. This megger is of significance in relation to the advancement of technology.A rectangular box in dark brown bakerlite casing. It has an agent's plaque fixed to the left of the face and on the right is the marker's recessed stamp. In the middle in a transparent window so the level of ohms can be read. The front also has two recessed fixing knobs in black. On one side is a crank handle with a knob that lifts up and is turned vigorously to create the voltage. The back has four recessed screws and four small leather pads. There is a hole on each side to insert wires. There are two copper insulated wires. The SECV Plaque states: State/Electricity Commission/of/Victoria/ Electrical Engineer's Section/ No.1747 The Agent's Plaque states: H. Rowe & Co. Pty Ltd/Melbourne & Sydney/Sole Agents/in Australia for/Evershed & Vignoles Ltd Maker's states: 500 volts/Megger/Regd Trade Mark/Made in England/Patent No/400728electrical meters, electrical equipment, fuses, safety, state electricity commission of victoria, mt beauty, bogong village -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyInsulator - Glass x2

Insulates electrical wire which is attached between the outside ridges. It is screwed onto the cross arm of a power pole. It is non conductive so electricity doesn't short to the ground.Used on the power poles in the Kiewa Valley.Clear tinted glass (one green & one brown) domed shaped insulator. Above centre there are 2 ridges to enable the electrical wire/cable to be fixed on. The closed end has a screw thread down to half way to enable it to be attached to a pole.Green one has 'Agee' on side of the open endkiewa hydro electric scheme. electricity. power lines. insulator -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyInsulator - Porcelain

Insulates electrical wire which is attached in the groove towards the narrow end. It is screwed onto the cross arm of a power pole. Non conductive so that electricity doesn't short out to the ground.Used on power poles in the Kiewa Valley.Cream coloured porcelain cylindrical shaped insulator with a groove towards the narrower closed end. Inside the narrow end it is threaded for screwing.On the side of the closed end - "KP / 64"kiewa hydro electric scheme. electricity. power lines. insulator -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyInsulator - Porcelain small x3

Insulates electrical wire/cable which is attached between the narrow and wide ends of the 'bell' shape (in the groove). Screwed onto the cross arm of a power pole. Non conductive so electricity doesn't short out to the ground.Used on power poles in the Kiewa Valley.White porcelain bell shaped insulator with an indent between the wide open end and the narrow closed end. The indent is for the wire/cable to be attached. The wide end is open with a white porcelain cylinder inside narrowing to thread for screwing, in the narrow section. kiewa hydro electric scheme. electricity. power lines. insulator. -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyInsulator - Porcelain large x3

Insulates electrical wire/cable which is attached between narrow and wide ends of the 'bell' shape (in a groove). Screwed onto the cross arm of a power pole. Non conductive so electricity doesn't short out to the ground. Used on power poles in the Kiewa Valley.White porcelain bell shaped insulator with an indent between the wide open end and the narrow closed end (for cable to be attached). The wide end is open with a white porcelain cylinder inside narrowing to thread for screwing in the narrow section.kiewa hydro electric scheme. electricity. power lines. insulator. -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyInsulator - Glass

Insulates electrical wire/cable which is attached in the groove. Screwed into the cross arm of a power pole. Non conductive so electricity doesn't short out to the ground.Used on power poles in the Kiewa ValleyClear blue tinted glass insulator - bell shaped at the closed end. Deep, wide groove towards the wide open end. The wide end is inscribed and opens to a decorated edge of small balls around the circumference. Inside there is a cylinder which is threaded for screwing onto a power pole. This cylinder is shorter than the outside part."Hemingray - 19" "Made in U.S.A."electricity. power lines. insulator. hemingray. -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, George Coop, Power transformer on a QB boiler/flat wagon on display at Spencer Street Railway Station during the 1954 Victorian Railways Centenary Exhibition, Sep. 1954

"V.R. Cavalcade" Centenary 1854-1954 Exhibition (11-25 Sep 1954) presented a model railway occupying about 1,400 square feet in the Lower Town Hall featuring a number of model railway working scale models. The exhibition also included a display of rolling stock, track, electrical and other railway equipment held at Spencer Street Railway Station.Digital TIFF file Scan of Kopdak 620 black and white negative transparencygeorge coop collection, display, spencer street railway station, v.r. cavalcade, victorian railways centenary 1854-1954 exhibition, power transformer, qb boiler/flat wagon, qb-13