Showing 53 items matching "hand spinning"

-

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Leisure object - TOYS AND GAMES COLLECTION: SPINNING TOPS, early 1900s

Toys and Games Collection. Three children's wooden spinning tops with metal tips. 1. Light coloured wooden top. Machine turned. 2. Red painted wooden top. Machine turned. 3. Wooden top. Possibly hand-made, with uneven shape and surface.toys, general -

Dutch Australian Heritage Centre Victoria

Dutch Australian Heritage Centre VictoriaTop (tol)

These tops normally driven by small whips. Thin string was wound around from the bottom up up to the groove. Then a sharp pull on the whip would start the top spinning. It was kept going by whipping. Wooden top, hand turned, traces of red paint. Pear shape with groove at widest diameter, stem at top. At bottom, small iron knob. Slightly damaged.toy -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumToy - Spinning top, 1940's

Made by internee at Camp 3, Tatura and used by children there as a spinning top toy.Hand turned wooden ridged and tapering to metal tip, spinning toptop, bissinger g, wied g, camp 3, tatura, ww2, toys, general -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumToy - Spinning top, 1940's

Made by internee and used by children at Camp 3Hand turned wooden, tapered to tip, spinning top. 1 ridge around centre. 3 ridges around the topspinning top, wied l, camp 3, tatura, ww2, toys, general -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumToy - Spinning top, 1940's

Made by internee and used by children at Camp 3Hand turned wooden tapered to a tip, spinning top. A single ridge around the centrespinning top, wied l, camp 3, tatura, ww2, toys, general -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumToy - Spinning top, 1940's

Made by internee and used by children at Camp 3Hand turned wooden, tapered to a tip, spinning top. 2 ridges around centrespinning top, wied l, camp 3, tatura, ww2, toys, general -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumToy - Spinning top, 1940's

Made by internee and used by children at Camp 3Hand turned wooden, tapered to a tip spinning top. 3 ridges around the centre and 3 around the topspinning top, wied l, camp 3, tatura, ww2, toys, general -

Tatura Irrigation & Wartime Camps Museum

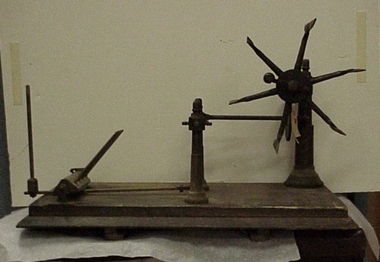

Tatura Irrigation & Wartime Camps MuseumWool winder, 1940's

... camp 3 tatura ww2 camp 3 textile machinery spinning handcrafts ...Made by Internee at Camp 3Superb hand tooled red gum wool winder on a base of 2 hexagonal pieces, 2 small hexagonals on the top piece of wood support one fixed position spool whilst the upper spool is adjustable up or downwool, hoefer r, wood, camp 3, tatura, ww2 camp 3, textile, machinery, spinning, handcrafts, woodwork -

Robin Boyd Foundation

Robin Boyd FoundationDocument - Script, Robin Boyd, The Flying Dogtor. Episode 8 The Dog Fight, 1963

The Flying Dogtor and Elvis Evil Eagle crashed mid air and the Dogtor helped Elvis gain control and rescued him. Thee Dogtor then tried to loosen a pile of logs that were blocking the creek and making the flood worse, but the effort sent his plane into a spin.The Flying Dogtor" series was broadcast on Australian Television Network (later becoming the Seven Network) between February and April 1964 (see item D254 for schedule).Typewritten, carbon copy, foolscap, 3 pagesPage 1: spelling correction, hand writtenthe flying dogtor, robin boyd, crawford productions, manuscript -

National Wool Museum

National Wool MuseumDrum carder, 1990s

Made by Ashford in New Zealand, possibly in the 1990s. Ashford would make and sell various wool-related machines (carders, weavers, spinning wheels, etc) as kits which the purchaser would then assemble.Small drum carder, natural wood colour. Rectangular base with two sides, the right side has a handle with which to rotate the carding rolls. The left side has four cogs (one large, three small) joined with a green rubber band. There are two carding rolls, one large, one small, both are an orange/red colour and covered in steel.wire bristles. There is a hand-written tag tied to the handle.ASHFORD/ MADE IN NEW ZEALANDwool, carding -

National Wool Museum

National Wool MuseumMini drum carder

Manufactured by Ashford of New Zealand, probably sometime in the 1990s. Ashford would produce various wool-related machines (weavers, carders, spinning wheels, etc) as kits which the purchaser could then assemble.Mini drum carder, assembled from kit. Carder is a natural wood colour. Has a base with two sloping sides, the right side has two cogs and a handle to drive the carders. The carder rolls are a red/orange covered in steel bristles. A hand-written tag is tied to the handle.ASHFORD / MADE IN NEW ZEALANDcarding, wool -

National Wool Museum

National Wool MuseumMachine - Wrap Reel

Wrap reel manufactured at Valley Worsted Mill and possibly used in the laboratory. "Wrap reels were used to check the yarn count in a spinning mill. A set length of yarn was wound off several test bobbins and weighed, if the weight was not the correct amount expected the spinning machines draft could be re calculated and the machine draft wheel ( cog ) changed to achieve the required count". - Greg AldridgeA small hand operated wrap reel. The reel is on a wooden base, the winding mechanism is metal and turned by a wooden handle. There is a metal plaque on the base inscribed MAKERS VWM. A wood and metal yarn feeder has broken off its mount.MAKERS/ VWMtextile machinery textile production weaving, valley worsted mill valley worsted mill, warping machinery, textile machinery, textile production, weaving, wrap reel, skein winder -

National Wool Museum

National Wool MuseumClothing - Suit, 1987

Hand spun, hand dyed, hand woven and hand sewn suit which won best garment in the 1987 Geelong show. Size 12 in a design by Chanel. It was spun with variegated natural greys on a Sheridan horizontal spinning wheel. It was then dyed pink using natural dyes. The jacket had commercially brought warp and hand spun weft in twill on a 24” loom. All spinning, dyeing and weaving was by Jean Inglis of Geelong. The suit was sewn by Caroline Mogic of Geelong, with iron on interfacing, commercially brought trim. It was worn only once in the parade at the Geelong show. The pink suit jacket has four pockets with gold buttons on front, size 12. The jacket has a checker-plate pattern in which the predominate pink is always present and is accompanied in areas which have grey or white showing through the pink. This checker plate pattern continues down the sleeves of the jacket. The edge of the jacket has a lighter pink trim. A pink skirt accompanies the suit jacket. It has horizontal lines with pink as the predominate colour and areas of grey and white showing through in sections. geelong show, hand spun, hand dyed, hand woven, hand sewn, channel -

National Wool Museum

National Wool MuseumPicker

Wool picking machine designed to separate locks of wool before it is carded and spun. The picker opens the wool’s locks which makes it easier to send the fleece through a carding machine. It does this by teasing the fibres (which can also be done by hand just by pulling the lock structure apart), but a picker does this in bulk and much quicker than what can be done by hand. It is possible to spin fibres directly after the picking stage; however, it is usually more desirable to card and blend them with other fibres. Typically, at a textile mill, a picking machine can separate enough lengths of fibre for a full day’s work after just a single hour. It will also help to remove any vegetation matter or other any unwanted elements that may be present in the wool. The quality of the casting on this machine suggest that it was made locally, either in Australia or New Zealand. Mike Leggett, the donor of the machine, acquired it from New Zealand where the seller said it had been used by his father to pick wool to make hand stuffed horse saddles. Mike attempted to used it a couple of times to pick alpaca hair, but the speed of the attached motor caused damage to the fibres. The motor is thought to be an added attachment, sometime around the 1960s judging by its age, while the machine itself is thought to be dated around the 1920s. The machine works by inserting wool through the rollers. Initially there was a conveyor belt feeder system which was powered by the handle on the side. This conveyor belt has been removed however, most likely due to age and deterioration. Wool is now fed through the initial teeth and is met by a spiked rotating drum which works to separate the fibres. The separated fibres would then complete a loop of the drum before being dispatched somewhere below, around where the motor presently sits, at a rapid rate of speed. Typically this wool will be collected in a closet or large catchment area, as can be seen from the 8:47 minute marker in the linked video (link - https://www.youtube.com/watch?v=kMjx-t3tH3A). It is not apparent how the wool is collected with this machine. Red and green machine with four green legs currently attached to a wooden pallet with wheels for easy movement. The green legs lead up to a red central circular barrel from which many attachments are present. Also present on the wooden pallet is a small black motor which is attached by a rubber belt to the central drum inside the red barrel. The belt spins the wooden drum via a dark red circular plate attached to the side of the drum. On the other side of the red barrel, a green handle extends for turning the picker’s conveyor belt feeder system. Two green walls extend forward from the central red barrel, guarding either side of where the conveyor belt would have been. At the start of these walls is a wooden cylinder, which the conveyor belt would have wrapped around, followed by two interlocking gears which rotate and accept the fed wool. The red roof extends over the central cylinder from here, securing the wool inside and protecting hands from the heavily spiked internal wooden cylinder which rotates and separates (picks) the wool. Extending over the top of this red roof is a green handle which reaches to the back of the machine (not pictured). Here it accepts a weight to ensure pressure is always present for the initial feeder interlocked gear teeth. There are two large gear cogs on the rubber belt side of the machine and 3 small gear cogs on the handle side of the machine, all coloured green. A green handle is also present at the rear of the machine, below the location from which the weight is hanging. A power cable extends from the motor and there are two adjustable metal rods on the top of the machine, the purpose of these rods is presently unknown. Black texter. On top of drum. Wording: HG3707 Wording. Imprint: BRACEWIND BLYN On motor. Wording AEIwool picking, textile manufacturing, wool processing -

National Wool Museum

National Wool MuseumTextile - Travel Rug, Onkaparinga Woollen Mill Company, 1960s

Collector says: I can still recall one of my earliest childhood memories, of my nana's bright aqua shoes against the checks of our family travel rug on summer picnics. Maybe that's when this collection planted its seed in me - 40 years later I start my first blanket collection after stumbling across old Onkaparinga travel rugs. I would go to a vintage market in Collingwood every month and almost always found a good one, amassing enough for the entire household. Everyone had their favourite, even the cat had his own – a small red tartan one just for him.Collector's note: "For more than 100 years blankets were made all over Australia in over 100 woollen mills. My aim, is to preserve 100 examples of these wonderful pieces of history. Ten years ago I started collecting the iconic Onkaparinga travel rugs, so that on movie nights at home there would be plenty to go around. Everyone had their favourite; even the cat had his own – a small red tartan one. Keeping an eye out for those travel rugs at op-shops and markets, collectable stores and bazaars, led to noticing vintage blankets. I'd never really thought about them before or paid much attention though of course I had grown up with them at my grandmother's. When I discovered my first Laconia cream blanket with blue stripes, my eyes just went gaga. Well that was it, I was hooked and since then over 500 blankets have passed through my hands. These common, everyday items, found in all households for so many decades, were traditional engagement gifts. Pairs were prized wedding presents turning into family heirlooms. They were fashionable dressers of beds, givers of warmth, bestowers of security and reliability. The comfort found in these objects resonates with almost all of us; we grew up with them ourselves or fondly recall them in a grandparent’s home. There is no modern replacement with the integrity of these old blankets, many of them now older than most of us. They are romantic, sensible, special, familiar, nostalgic and nothing else feels so appropriate in so many situations. No offense to the great Aussie doona, but from hippie to hipster, at a music festival, picnic, campsite or couch, a vintage blanket is something coveted by all. This industry that employed tens of thousands and must have been such a huge contributor to the economy is almost completely lost now. Blanket Fever is an ode to everything that came before: the land, the sheep, the shearers, the hands, the mills, the weavers, the designers, the distributors, the department stores. To the grandparents that gave them, the people that received them, the families that kept them; thank you. I’m passionate about my collection of Australian blankets manufactured in mostly Victoria, South Australia and Tasmania from the 1930s to the end of the 1960s. The collection has blankets from each of these four decades representing the styles and fashions of their time and includes dated advertisements which help determine the eras the blankets are from."Fringed plaid travel rug, brown, yellow and blue Onkaparinga/washing instructions/use A.W.C. approved wool detergent/warm machine wash on short gentle cycle/or warm hand wash/DO NOT BLEACH/warm rinse well on gentle cycle/normal spin/DO NOT TUMBLE DRY/dry in shade - gently pull to shape/dry cleanable (A) - in emblems: The Woolmark pure new wool, Woven in Australia, F 472wool, blanket, blanket fever, travel rug, onkaparinga -

National Wool Museum

National Wool MuseumTextile - Travel Rug, Onkaparinga Woollen Mill Company

Collector says: "I can still recall one of my earliest childhood memories, of my nana's bright aqua shoes against the checks of our family travel rug on summer picnics. Maybe that's when this collection planted its seed in me - 40 years later I start my first blanket collection after stumbling across old Onkaparinga travel rugs. I would go to a vintage market in Collingwood every month and almost always found a good one, amassing enough for the entire household. Everyone had their favourite, even the cat had his own – a small red tartan one just for him."Collector's note- "For more than 100 years blankets were made all over Australia in over 100 woollen mills. My aim, is to preserve 100 examples of these wonderful pieces of history. Ten years ago I started collecting the iconic Onkaparinga travel rugs, so that on movie nights at home there would be plenty to go around. Everyone had their favourite; even the cat had his own – a small red tartan one. Keeping an eye out for those travel rugs at op-shops and markets, collectable stores and bazaars, led to noticing vintage blankets. I'd never really thought about them before or paid much attention though of course I had grown up with them at my grandmother's. When I discovered my first Laconia cream blanket with blue stripes, my eyes just went gaga. Well that was it, I was hooked and since then over 500 blankets have passed through my hands. These common, everyday items, found in all households for so many decades, were traditional engagement gifts. Pairs were prized wedding presents turning into family heirlooms. They were fashionable dressers of beds, givers of warmth, bestowers of security and reliability. The comfort found in these objects resonates with almost all of us; we grew up with them ourselves or fondly recall them in a grandparent’s home. There is no modern replacement with the integrity of these old blankets, many of them now older than most of us. They are romantic, sensible, special, familiar, nostalgic and nothing else feels so appropriate in so many situations. No offense to the great Aussie doona, but from hippie to hipster, at a music festival, picnic, campsite or couch, a vintage blanket is something coveted by all. This industry that employed tens of thousands and must have been such a huge contributor to the economy is almost completely lost now. Blanket Fever is an ode to everything that came before: the land, the sheep, the shearers, the hands, the mills, the weavers, the designers, the distributors, the department stores. To the grandparents that gave them, the people that received them, the families that kept them; thank you. I’m passionate about my collection of Australian blankets manufactured in mostly Victoria, South Australia and Tasmania from the 1930s to the end of the 1960s. The collection has blankets from each of these four decades representing the styles and fashions of their time and includes dated advertisements which help determine the eras the blankets are from. "Fringed travel rug, red, blue, green and blackOnkaparinga/washing instructions/use A.W.C. approved wool detergent/warm machine wash on short gentle cycle/or warm hand wash/DO NOT BLEACH/warm rinse well on gentle cycle/normal spin/DO NOT TUMBLE DRY/dry in shade - gently pull to shape/dry cleanable (A) - in emblems: The Woolmark pure new wool, Woven in Australia, F 472wool, blanket, blanket fever, travel rug, onkaparinga -

National Wool Museum

National Wool MuseumTool - Grinder, 1960-69

Cooper S.E. Ball Bearing Grinder made and guaranteed by Sunbeam Corporation Limited. Grinders like this example have been made the same since the early 1900s, with this grinder thought to have been produced in the 1960s. It is belt driven, with the other end of the belt being attached to an engine; the same engine that would have powered the overhead shearing equipment in shearing sheds. It was common for shearing teams to bring their own equipment, especially pre-1960 as most shearing sheds were not connected to power, and shearers preferred to work with their own equipment. The engines that powered the shears and grinder were typically fuelled with kerosene or petrol. The large circular disks are attached to the bolt that protrudes from the grinder and fastened tightly with a nut. An example of seeing a similar grinder in action can be found on the following link - https://www.youtube.com/watch?v=O7eimI_Gm9o. Inventor Frederick Wolseley made the world's first commercially successful power-shearing system in Australia in 1888. US company Cooper, which had been founded in 1843 as a maker of sheep dip, began selling Wolseley equipment in the USA in 1895. The Chicago Flexible Shaft Company successfully entered the power-shearing market a few years later and entered a joint venture with Cooper. It set up a branch in Sydney and sold shearing sets, and engines to power them, into the Australian market. In 1921 the US parent company, realising it needed to make products whose sales were not as seasonal as those of shearing equipment, made its first household appliances and branded them Sunbeam. In 1933, changes in exchange rates and taxes led the company to manufacture engines and shearing equipment in Australia via subsidiary Cooper Engineering, which changed its name to Sunbeam in 1946. Although most Australians know of this company as a major manufacturer of household appliances, its rural division flourished and retained the Sunbeam name for shearing equipment even after it was taken over by New Zealand company Tru-Test in 2001. The grinder is formed from a central arch shaped block of green painted metal. Much of this paint has been lost to age, leaving the grinder in a ‘farm used’ condition with much surface oxidation present. On the front of the arch is a specification plate, reading “Cooper S.E. ball bearing grinder. Made and guaranteed by Sunbeam”. At the foot of the arch, three bolt holes are found for securing the grinder to the base of a solid wooden surface. Two of the bolt holes are found on the front of the grinder, with another found on the rear. From the central arch, a bolt protrudes to the right of the grinder. This large bolt is for securing a grinding plate to the grinder. Above the central arch is a pendulum which holds the comb / cutter that is being sharpened. From the pendulum, a large arm extends down (not pictured) to meet and strike the plate spinning at a rapid speed. On the left-hand side of the central arch of the grinder, a wheel is found which a belt is attached to for power. This belt is then attached to a separate engine, spinning the wheel and hence powering the grinder. The wheel is partially covered with a section of protective bent tube, designed to provide protection from the rapidly spinning wheel. Below this wheel is the belt shifter. It is designed to move the protective bent tube from one side of the grinder to the other, to accommodate the grinder in the setup of different shearing sheds. The two separate grinding plates are identical. They have a slight slope for sharpening the comb and cutters in the correct method, with a slight bias towards the base, or “tooth”, of the equipment. The disks have a large central bolt for attaching to the grinder. They have tags on the horizontal axis of the grinding plates, for securing the plates in transportation, and to help with initial alignment when setting up the grinder. The reverse of these grinding plates has the same green painted metal finish found on the grinder. This paint is also in a ‘farm used’ condition, with surface oxidation present. The grinder would be provided from the factory with a comb holder, shifter for securing the grinding plates, emery cloth and emery glue. The emery cloth is what does the actual grinding and is applied to the grinding disks, replacing once well worn. These items can be seen in the final images in the multimedia section, showcasing advertising for this grinder. Plate. Inscribed. “Cooper / S.E. BALL BEARING GRINDER / MADE AND GUARANTEED BY / Sunbeam / CORPORATION LIMITED / SYDNEY MELBOURNE / ADELAIDE BRISBANE ”sheep shearing, shearing equipment, sunbeam, grinder -

National Wool Museum

National Wool MuseumSpinning Wheel

Part of the Zakrzewski Collection of spinning wheels donated to the National Wool Museum by Mr Wlodzimierz Zakrzewski. For many years, Mr Zakrzewski collected, researched and repaired spinning wheels from all over the world. This wheel is from Yugoslavia and dates from the early 20th century. It is made from Poplar Alba. The treadle bar runs obliquely from beneath the right arm of the T-shaped base to beneath the stem of the T. The mounting of the wheel and the flyer mechanism are reversed. This is in order that flax may be spun with one hand or that plying may be done. It was purchased by Sobieski Galleries, Glen Iris.Part of the Zakrzewski Spinning Wheel collection.handicrafts - history flax, spinning wheels, highlights of the national wool museum: the zakrzewski spinning wheel collection - exhibition (28/07/2001 - 02/12/2001), zakrzewski, mr wlodzimierz, handicrafts - history, flax -

National Wool Museum

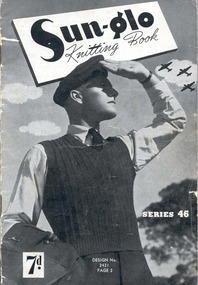

National Wool MuseumBook, Knitting, Sun-glo Knitting Book series 46

This book and a number of others like it were owned by the mother and aunts of the donor, Mrs Dorothy Boyle. They were prolific producers of hand knitted and hand made items of clothing and also knitted and sewed for the armed forces during the Second World War. This books contains patterns for items that could be knitted for the armed forces. It was produced by the Alexandria Mills in Sydney who made Sun-glo and Sunbeam knitting wools.Knitting Book (front cover) - "Sun-glo Knitting Book series 46", WWII.Sun-glo / Knitting Book / SERIES 46 / 7d. / DESIGN No. / 2421 / PAGE 2knitting handicrafts - history world war ii, alexandria spinning mills pty ltd, knitting, handicrafts - history, world war ii -

Beechworth Honey Archive

Beechworth Honey ArchiveExtractor

Frames are uncapped with an uncapping knife, and placed into a holding spot or basket. The handle is then turned, spinning the frames inside. Eventually, the centrifugal force drains the honey from the frames. The honey can be poured from the drum via the tap. The empty frames go back into beehives to be filled with honey again.Antique two frame manual extractor. Metal 44 gallon drum with external tap, handle and hole. Inside; rotating two-frame honey extractor. The two frames are attached to a square metal structure. Each frame is only attached by one end. Each frame is a rectangular metal construction with square wire panels on two sides. Internal frame rotates freely. Other two sides and base solid. On top of drum is a hand-driven metal crank for turning internal frames.two, frame, hand, manual, extractor, honey, beechworth honey -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncCarder, Not known

Green painted, hand operated, floor standing drum carder. Metal guard badly corroded. Four legs. Three meshing gearwheels. Large spikes on drum. Wooden roller to feed fleece.Ruben Sutcliffe / Maker / Manchester. In relief on topside of frame.textile machinery; spinning; wool carding; metalcraft; cast iron -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionPrint, D. Higgins, Clouds, 1975

NoneSeveral plate print. Background images are embossed, showing clouds and abstract water patterns. At centre left is an embossed women's head in profile. Central image is a man in what appears to be a monkey skin. He has a cap on his head and is spinning a barrel-shaped object with the fingers of his right hand. Below him is a light brown etching of grass. Below the grass is a blue etching of water ripples. Mounted in cream matt with blue edging. Wooden frame with glass.Front: "Clouds" 26/65 (centre left) D. Higgins '75 (centre right) (pencil) Back: (no inscriptions) -

Bendigo Military Museum

Bendigo Military MuseumUniform - DRESS, SERVICE DRESS, ARMY, Australian Government Clothing Factory, 1980

Dress - garment part of Women's Service Dress Uniform. Item issued to "BALAAM" Service No. "F3205719"Dress - light green colour wool/polyester fabric dress with wide collar, front opening with five buttonholes, no buttons, short sleeves with self cuff, two inset front pockets. Pale green colour Rank Insignia - Corporal stripe. Manufacturers label back below collar. White cotton fabric with handwritten information.Manufacturers label - black ink print. "A.G.C.F./ VICTORIA/ 1980/ 8410-66-097-0793/ SIZE 12 AVE HEIGHT/ AV HIP/ 85cm BUST? 65 cm WAIST/ 90 cm HIPS/ LAUNDRY INSTRUCTIONS/ MACHINE/ HAND HOT/ 40c/ HANDWASH/ HAND HOT/ 40c/ USE GOOD QUALITY/ SOAP FLAKES/ COLD RINSE/ SHORT SPIN/ DO NOT WRING/ OR TUMBLE DRY/ DRY CLEANABVLE S or P/ FABRIC/ WOOL/POLYESTER/ NAME/ SERVICE NO." "BALAAM/ F3205719"uniform, women's dress, army, balaam, passchendaele barracks trust