Showing 144 items

matching manual machine

-

Broadmeadows Historical Society & Museum

Broadmeadows Historical Society & MuseumMachine - Adding Machine

... A manually operated Burrough's adding machine... Parade Broadmeadows melbourne Burroughs Adding Machines Ltd ...Burroughs Adding Machines Ltd of Detroit Michigan was the first company to occupy a factory at Strathleven. During the European reconstruction in the late 1940's Burroughs built a major new factory at Strathleven in Scotland, initially to assemble machines from US-made parts and later to manufacture the full product range for the British and Commonwealth markets. Most of the post-war calculators and portables found in Australia are from the Strathleven factory.This manually operated calculator predates the rise of the modern computer.A manually operated Burrough's adding machine. It is a greyish green plastic and has a silver handle. It has 8 columns to add manually and has decimal currency. There is a roll of white (slightly yellowed) paper inserted in the top section.Burroughs Machine Limited, Strathleven, Scotland Made in Great Britainburroughs adding machine, office, calculator, detroit, michigan -

Yarrawonga and Mulwala Pioneer Museum

Yarrawonga and Mulwala Pioneer MuseumInstruction Manual, Alfa Laval, The Alfa Daisy Milker

... world producers of mechanical milking machines. The manual... world producers of mechanical milking machines. The manual ...The first centrifugal separator was invented in1878 by Dr. de Laval. This recognized the need for a mechanical milker for which patents were granted in 1894. Alfa Laval were leading world producers of mechanical milking machines. The manual was used in Tungamah during the 1940's and 1950'sPaper booklet describing the operation, parts and installation of the Alfa Daisy Milker. Inside front cover is listed the companies that distribute the milker. Australian capital cities. Illustration includes 12 pagesSee photos -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Voice Recorder, Thomas A. Edison, Edison Laboratory, 1916-1929

... on a manually operated mechanical machine that used wax cylinders... on a manually operated mechanical machine that used wax cylinders ...This Edison Ediphone voice recording electronic business machine is manufactured to suit a small office and is light enough to carry between work and home for use outside normal business hours. It is a dictation machine, also called by the competitor’s brand name ‘Dictaphone’, and is used for recording spoken words that would later be transcribed and typewritten. A wax cylinder would be installed onto the machine’s drum and the Reproducer on the machine would be lowered onto the cylinder. The user would speak a message into a microphone and the reproducer would then convert the sounds to scribed marks on the cylinder. Later, the cylinder could be played and the Reproducer would enable the sound to be amplified through an attached speaker. This machine is currently without its power cord, microphone and speaker horn. Thomas A. Edison extended the technology of the telegraph to his phonograph machine, invented in the late 19th century. It could record and play back sounds of music and voice on a manually operated mechanical machine that used wax cylinders to store the sound. He envisaged the way this technology could be an asset in the office, and he was right! However, most of his phonograph machines were used for entertainment, some for playing lessons, and some for-teaching languages. In 1916 Edison introduced the Ediphone, which grew in popularity after the First World War and into the late 1920s until flat round records replaced the wax cylinders. This Edison Ediphone is significant for improving the way business administration was carried out in the early 20th century, freeing up precious time for professionals and administrative personnel. It was the forerunner of audio tapes and digital technology. The Ediphone enabled letters to be dictated when the time and place suited and reduced the time professionals needed to spend with their secretaries. Secretaries were able to type the letters as they played the recording and they could replay the message if necessary.Voice recorder; a dictation machine; desktop model Edison Ediphone. The electronic machine is in a medal case with remnants of the original grey colour. It has a rectangular base with an A4-sized footprint and a domed hood that retracts halfway into the back of the base. The corners of the base have metal reinforcing, and a short metal bar is on the front centre edge of the lid and the base. A long metal drum is mounted inside the machine. A round device called a ‘reproducer’ is mounted above the drum. There is a folding handle on the left front of the machine and an angled stand with paper guides in front of the drum. A rear cover has the maker’s name stamped on it. An electrical socket with eight pins is recessed beside the cover. Made by Edison.In white letters; “EDISON”flagstaff hill, warrnambool, maritime village, maritime museum, shipwreck coast, great ocean road, edison, ediphone, dictating machine, office equipment, voice recorder, usa, dictation, communication, office machine, dictaphone, speaking phonograph, thomas edison, ediphone voicewriter, voice writer -

Bendigo Military Museum

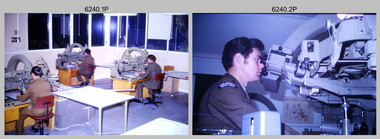

Bendigo Military MuseumPhotograph - Capturing Topographic Features with a Wild B8 – Army Survey Regiment, Fortuna, Bendigo, c1980

... and contours. These analogue machines were manually controlled... and contours. These analogue machines were manually controlled ...These four photographs of SPR Santina (Argetto) Straube capturing topographic features – plotting with a Wild B8 stereo plotter were most likely taken in c1980. Introduced in 1966, the Wild B8 stereo plotter was used for plotting topographic detail and contours. These analogue machines were manually controlled by adjusting the control knobs for the orientation of the 3D image. The B8s used a nine-inch square photo image on a film or glass diapositive which allowed highly accurate extraction of map features. At first, plotting by B8 and B9 equipment was undertaken at the aerial photography scale of 1:80,000 in pencil onto a controlled plotting sheet. Sheets were then inked up and reduced photographically to the 1: 100,000 publication scale for scribe impression production. In these photos SPR Santina (Argetto) Straube was plotting with a pencil or ink pen mounted at the far end of the pantograph arm. The plotting procedure was upgraded to direct plotting in ink with photographic reduction to publication scale. In 1975 four B8s were upgraded with tri-axis locaters as part of the Input Sub-system to enable digital extraction to AUTOMAP 1’s topographic database. When AUTOMAP 2 was introduced in 1982 these B8s were upgraded, and additional machines added to expand the Army Survey Regiment’s digital capture capability. This is a set of four photographs of a technician capturing topographic Features with a Wild B8 stereo plotter in Air Survey Squadron – Army Survey Regiment, Fortuna, Bendigo. 1980. The photographs were on 35mm negative film and were scanned at 96 dpi. They are part of the Army Survey Regiment’s Collection. .1) to .4) Photo, black & white, c1980. SPR Santina (Argetto) Straube operating a Wild B8 stereo plotter..1P to .4P – no annotations.royal australian survey corps, rasvy, army survey regiment, army svy regt, fortuna, asr, air survey, photogrammetry -

Bendigo Military Museum

Bendigo Military MuseumPhotograph - Photogrammetric Equipment – Army Survey Regiment, Fortuna, Bendigo, c1960s to c1980s

... . These analogue machines were manually controlled by adjusting the control... and contours. These analogue machines were manually controlled ...This is a set of eight photographs of technicians operating photogrammetric equipment in Air Survey Squadron, Army Survey Regiment, Fortuna, Bendigo. c1960s to c1980s. The Wild A9 Stereocomparator and Wild B9 stereo plotter were introduced in 1962. The Wild B8 stereo plotter was introduced in 1966. Technicians used the Wild A9 Stereocomparator to accurately measure between pass, tie, and survey control points on aerial photographs. The Wild B9 and B8s were used for plotting topographic detail and contours. These analogue machines were manually controlled by adjusting the control knobs for the orientation of the 3D image. The B9s used a four and a half square, and the B8s used a nine-inch square photo image on a film or glass diapositive which allowed highly accurate extraction of map features. At first, plotting with B8 and B9 stereo plotters was undertaken at the aerial photography scale of 1:80,000 in pencil onto a controlled plotting sheet. Sheets were then inked up and reduced photographically to the 1: 100,000 publication scale for scribe impression production. In the early days topographic detail and contours were plotted with a pencil or ink pen mounted at the far end of the pantograph arm. The plotting procedure was upgraded to direct plotting in ink with photographic reduction to publication scale. In 1975 four B8s were upgraded with tri-axis locaters as part of the Input Sub-system to enable digital extraction to AUTOMAP 1’s topographic database. When AUTOMAP 2 was introduced in 1982 these B8s were upgraded, and additional machines added to expand the Army Survey Regiment’s digital capture capability. This is a set of eight photographs of technicians operating photogrammetric equipment in Air Survey Squadron, Army Survey Regiment, Fortuna, Bendigo. c1960s to c1980s. Black and white and colour photos are on photographic paper and scanned at 300 dpi. .1) - Photo, black & white, c1965. Unidentified technician operating a Wild A9 Stereocomparator. .2) - Photo, black & white, c1965. Unidentified technician operating a Wild B9 stereo plotter. .3) - Photo, black & white, c1967. L to R: Unidentified technician, SPR Ken Jeffery operating a Wild B9 stereo plotter. .4) - Photo, colour, c1974. Unidentified technician, operating a Wild B8 stereo plotter. .5) - Photo, black & white, c1974. Unidentified technician operating a Wild B8 stereo plotter. .6) to .7) - Photo, black & white, c1979. Unidentified technicians operating a Wild B8 stereo plotter. .8) - Photo, black & white, c1985. Unidentified technician in AUTOMAP 2 operating a Wild B8 stereo plotter..1P, .2P, .4P, .5P, .7P – no annotations. .3P – annotated ‘Standing - , Seated SPR Ken Jefferies (sic). .6P – annotated with date ‘1979’ .8P – annotated ‘AUTOMAP 2’royal australian survey corps, rasvy, army survey regiment, army svy regt, fortuna, asr, air survey, photogrammetry -

Bendigo Military Museum

Bendigo Military MuseumPhotograph - Photogrammetric Equipment – Army Survey Regiment, Bendigo and School of Military Survey Bonegilla, c1960s to c1980s

... for plotting topographic detail and contours. These analogue machines... for plotting topographic detail and contours. These analogue machines ...This is a set of 14 photographs of RA Svy technicians operating photogrammetric equipment in Air Survey Squadron, Army Survey Regiment, Fortuna, Bendigo; and the School of Military Survey Bonegilla c1960s to c1980s. The Wild B9 stereo plotter were introduced in 1962 and the Wild B8 stereo plotter was introduced in 1966. The Wild B9 and B8 stereo plotters were used for plotting topographic detail and contours. These analogue machines were manually controlled by adjusting the control knobs for the orientation of the 3D image. The B9s used a four and a half square, and the B8s used a nine-inch square photo image on a film or glass diapositive which allowed highly accurate extraction of map features. At first, plotting with B8 and B9 stereo plotters was undertaken at the aerial photography scale of 1:80,000 in pencil onto a controlled plotting sheet. Sheets were then inked up and reduced photographically to the 1: 100,000 publication scale for scribe impression production. In the early days topographic detail and contours were plotted with a pencil or ink pen mounted at the far end of the pantograph arm. The plotting procedure was upgraded to direct plotting in ink with photographic reduction to publication scale. In 1975 four B8s were upgraded with tri-axis locaters as part of the Input Sub-system to enable digital extraction to AUTOMAP 1’s topographic database. When AUTOMAP 2 was introduced in 1982 these B8s were upgraded, and additional machines added to expand the Army Survey Regiment’s digital capture capability. There are several more photos catalogued in the Victorian Collections database of RA Svy personnel operating Wild B9 and B8 stereo plotters.Photogrammetric Equipment – Army Survey Regiment, Fortuna, Bendigo c.1981. . .7) – Unidentified technician operating Wild B8 stereo plotter in AUTOMAP 1 at ASR. .8) - Wild B8 stereo plotter in AUTOMAP 1 at ASR. Photogrammetric Equipment – Army Survey Regiment, Fortuna, Bendigo. c1981. .9) – ASR’s CPL Dave Cook in AUTOMAP 1 operating a Wild B8 stereo plotter. This is a set of 14 photographs of RA Svy technicians operating photogrammetric equipment at the Army Survey Regiment (ASR), Bendigo and the School of Military Survey (SMS) Bonegilla. c1960s to c1980s. The photographs are on 35mm colour slides and were scanned at 96 dpi. .1) - Photo, colour, c1964. Unidentified ASR technicians operating analogue Wild B9 stereo plotters. .2) - Photo, colour, c1974. ASR’s SPR Mick Minchin operating an analogue Wild B8 stereo plotter. .3) to .6) - Photo, colour, c1980. Photogrammetry Instructor SGT Neil ‘Ned’ Kelly at the SMS operating an analogue Wild B8 stereo plotter. .7) - Photo, colour, c1981. Unidentified technician operating Wild B8 stereo plotter in AUTOMAP 1 at ASR. .8) - Photo, colour, c1981. Wild B8 stereo plotter in AUTOMAP 1 at ASR. .9) to .14) - Photo, colour, c1981. ASR’s CPL Dave Cook in AUTOMAP 1 operating a Wild B8 stereo plotter..1P to .14P - Some of the equipment is annotated on the frame of the 35mm slides.royal australian survey corps, rasvy, army survey regiment, army svy regt, fortuna, asr, photogrammetry -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDrill Press, early to mid-20th century

... Post type drill press machine with gear driven flywheel... at a speed of maxim 200 r.p.m. The machine can also be manually ...This post drill press has been made by Melbourne business, Dawn Manufacturing Company. It can be operated manually or by a pulley driven flywheel, with the aid of an engine connected to a power supply. In the late 1800s early 1900s a drill press like this would have been driven by steam from a boiler, the main power source for manufacturer’s power at that time. Dawn’s Golden Anniversary 1917-1967 Catalogue describes this model 611 drill as … “Ruggedly constructed with accurately reamed bearings. The coupling between the main spindle and feed screw engages the full circumference of the spindle, and embraces a ball-bearing thrust race. The pillar, as in all “Dawn Drilling Machines” is a solid bright steel bar, in place of the usual light tubing. Adjustable automatic feed.” And “F. & l. Pulleys extra, if required”. DAWN MANUFACTURING CO. The Dawn Manufacturing Co. was founded in Coburg, Melbourne, in 1917 by the four Blake brothers, who were all engineers. After World War I Dawn was supplying drills Australia wide and the company was growing at a healthy rate. During the depression they remained busy, with employees working 60-80 hour weeks. Dawn was contracted to supply vices and clamps to the Australian Defence Department and munitions factory during the World War II. - 1959 the company was taken over by G.N. Raymond Group. - 1967 the Dawn Manufacturing Co. had distributors in Australia and overseas, including USA, Canada, New Zealand, Asia and the Middle East. - 1973 the Siddons Ramset Limited acquired Dawn. - December 1991, Dawn became a unit of the United States owned Stanley Works Pty. Ltd. - November 1998 Dawn became 100 per cent Australian owned. The drill is a typical tool of a blacksmith, cart wright, wheelwright and garage business. It is an example of the tools of the blacksmiths’ trade in Victoria in the early to mid-20th century.Post type drill press machine with gear driven flywheel. Drill press is attached to a post and is fitted with a pulley belt and will run at a speed of maxim 200 r.p.m. The machine can also be manually operated. It has an aperture in the centre, a chuck, for the drill bit and has two metal handles at the centre, on the right hand side. Gear ratio 2:1 main drive, 6" diam, 3:1 reduction gear. Made by Dawn of Melbourne, Australia. Model No. 611, Code No. 9157"DAWN MFG COY”, “MELB. AUSTRALIA", " 611"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, blacksmiths, blacksmith’s drill, blacksmith tools, dawn drill model no. 611, dawn drill code no. 9157, dawn manufacturing coy melbourne, dawn manufacturing coy coburg, dawn post drill, drilling machine, drill with gear driven flywheel, forging tool, metal working tool, post drill, steam powered drill, trade tool, warrnambool district 1900s -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing Machine, Singer Sewing Machine Company, 1907 -1920 (see note section this document for further information regards model identification)

... drawers plus instruction manual Domestic object Sewing Machine ...In 1867 the Singer Company decided that the demand for their sewing machines in the UK was sufficiently high to open a local factory. Glasgow was selected for its iron-making industries, cheap labour, and possibly because at the time the General Manager of the US Singer Sewing Machine Company was George McKenzie, who was of Scottish descent. The company obtained a lease on land near Queen Street Station and machinery and machine parts were shipped over from the US. Demand for sewing machines outstripped production at the new plant and by 1873 a new larger factory was completed near Bridgeton Cross. By now Singer employed over 2,000 people in Scotland but still, they could not produce enough machines. In 1882 George McKenzie, the soon to become President of the Singer Sewing Machine Company undertook the ground breaking ceremony on 46 acres of farmland at Kilbowie, Clydebank and the largest Singer factory in the world started to be built. Originally two main buildings were constructed. Built above the middle wing of the factory was a huge clock tower with the 'Singer' name displayed for all to see from miles around. Many miles of railway lines were laid throughout the factory to connect the different departments and to aid in the shipping of their goods. Railway lines from the factory connected Glasgow, Dumbarton, and Helensburgh stations. The factory was regarded as the most modern facility in Europe at that time. As different departments in the factory were completed, the workers moved from the old sites to the new one at Kilbowie and the factory was finally finished in 1885. With nearly a million square feet of space and almost 7,000 employees producing on average 13,000 machines a week, making it the largest sewing machine factory in the world. The Clydebank factory was so productive that in 1905 the US Singer Company set up the Singer Manufacturing Company Ltd. as a UK registered company. The invention of the sewing machine had several very significant impacts on the lives of many people. It changed the domestic life of many women as more households began to own sewing machines, women as the ones who traditionally stayed home to do chores including making and repairing clothing, found themselves with more free time. Previously several days a week would be dedicated to sewing clothing for herself and her family, a housewife could now complete her sewing in merely several hours, allowing for more free time to pursue hobbies and attain new skills. Sewing and clothing production, in general, became more industrialized activities, taking place less in the home and more in large factories. Industrial sewing machines, in combination with the cotton gin, the spinning jenny, and the steam engine, made clothing production much easier and much cheaper. Singer sewing machine treadle type wooden stand with six drawers plus instruction manual Lotus decoration to machinewarrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sewing-machine, clothes repair, singer sewing machine -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Mincer, late 19th or early 20th Century

A meat grinder, commonly known as the meat mincer, is used for chopping meat into fine pieces. Alternatively, it can be used for the mixing of raw or cooked meat, fish and vegetables. It is the best way to process meat, and is a widely used piece of equipment by butchers and in the home.. Butchers have been known to use either mincing knives or meat cleavers in the kitchen for years to produce a quantity of minced meat. This was a slow and laborious process. The advent of the meat mincer has not only made the mincing process easier but also faster. The meat mincer has slowly evolved over the years into what it is today. The first meat mixer or meat mincer was invented in the 19th century by a German inventor named Baron Karl Drais. Although some versions of the device date back to much earlier. The oldest form of meat mincer was hand cranked which forced meat through a metal plate with several small holes in it, which resulted in long and thin strands of the meat. The meat was fed into the funnel that was placed at the top of the mixer. This meat would pass through a hand cranked screw conveyor that would squash and mix the meat before passing it through the metal plate. Needless to say, this was again a slow and laborious procedure to follow to produce large quantity of meat. With passage of time, this hand cracked machine became powered by electricity. The meat mincer has a great adaptability and efficiency now. The huge variety in mincer plates allows a butcher to produce different types of minced meat in any shape desired. However, traditional manual meat mincers have not really changed a lot. They are manually operated and made of cast iron, as earlier. They are similar to the original mincer designs, dating back to the early 1900s. Some butchers still prefer using a variety of mincer knives. Adapted from: https://brennan-group.com/blogs/news/history-of-the-meat-mincerThe development of the meat mincer enabled both butchers and home cooks to process and grind meat effectively.Clamp on meat mincer with handle for rotating the mincing apparatus inside.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, meat mincer -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Breeches Buoy and Traveller Block, 1860s to 1950s

The breeches buoy and traveller block are part of the beach rescue apparatus used by lifesaving crew overseas and in Australia in the 1860s to 1960s. The breeches buoy (or chair bucket or petticoat breeches) were invented by Lieutenant Kisbee by the 1850s. It looks like a pair of canvas shorts with a cork lifebuoy ring attached around the top. The set-up works similar way to a zip wire and allows for two-way travel. Saving lives in Warrnambool – The coastline of South West Victoria has had over 600 shipwrecks and many lost lives; even in Warrnambool’s Lady Bay there were around 16 known shipwrecks between 1850 and 1905, with eight lives lost. In 1859 the first Government-built lifeboat arrived at Warrnambool Harbour and a shed was soon built to house it, followed in 1864 by a rocket house to safely store the Rocket Rescue equipment. In 1878 the buildings were moved to the Breakwater area, and in 1910 the new Lifeboat Warrnambool arrived with its ‘self-righting’ design. For almost one hundred years the lifeboat and rocket crews, mostly local volunteers, trained regularly to maintain and improve their skills, summoned when needed by alarms, gunshots, ringing bells and foghorns. Some became local heroes but all served an important role. By the end of the 1950s the lifeboat and rescue equipment had become obsolete. Rocket Rescue Method - The first use of a lifesaving rocket rescue system is often credited to Captain Manby and his invention of a life mortar, first used in 1808 to fire a line onto a ship to rescue lives. Henry Trengrouse’s invention of 1820 was the first to use a sky rocket’s power to throw a line, and his invention included a chair for carrying the shipwrecked victims to shore. In 1832 John Dennett invented a rocket specifically for shore to ship rescue. It had an iron case and an 8 foot pole attached and could shoot the line as far as 250 yards (about 230 metres). From the 1860s the rocket rescue apparatus was in use. It comprised a breeches buoy and traveller block that was suspended on a line and manually pulled to and from the distressed vessel carrying passengers and items. Colonel Boxer, who had invented an early line-thrower, designed a rocket in 1865 with a range from 300 to 470 yards. It was the first two-stage rocket, with two rockets placed one in front of the other in a tube that carried the rescue line. The hemp line was faked, or coiled, in a particular way in a faking box to prevent twists and tangles when fired, and the angle of firing the rocket was measured by a quadrant-type instrument on the side of the rocket machine. Schermuly invented the line-throwing pistol around 1920, which used a small cartridge to fire the rocket. Victoria’s Government adopted lifesaving methods based on Her Majesty’s Coast Guard in Great Britain, which used Colonel Boxer’s rocket apparatus rescue method. The British Board of Trade published instructions in 1850 for both the beach rescue crew and ship’s crew. It involved setting up the rocket launcher on shore at a particular angle measured by the quadrant, inserting a rocket that had a light-weight line attached, then firing it across the stranded vessel. A tally board was then sent out with instructions in four languages. The ship’s crew would haul on the line to bring out the continuous whip line and attach the whip block to a mast or sturdy part the ship. The rescue crew on shore then hauled out a heavier hawser line, which the ship’s crew fixed above the whip block. The hawser is then tightened using the block on the shore end of the whip. The breeches buoy and endless whip are then attached to the traveller block on the hawser, allowing the shore crew to haul the buoy to and from the vessel, rescuing the stranded crew one at a time. The rocket system could also be used from one ship to another. This item is significant for its connection with local history, maritime history and marine technology. Lifesaving has been an important part of the services performed from Warrnambool's very early days, supported by State and Local Government, and based on the methods and experience of Great Britain. Hundreds of shipwrecks along the coast are evidence of the rough weather and rugged coastline. Ordinary citizens, the Harbour employees, and the volunteer boat and rescue crew, saved lives in adverse circumstances. Some were recognised as heroes, others went unrecognised. In Lady Bay, Warrnambool, there were around 16 known shipwrecks between 1850 and 1905. Many lives were saved but tragically, eight lives were lost.Breeches buoy and traveller lock; white canvas breeches (shorts) with lifebuoy ring attached to its waistband, with ropes for attaching it to the traveller block. Wooden traveller block has double brass inline sheaves and brass rollers on each cheek of the block, and each shell is scored for the strop. The thimble attached to the strop has a wooden slat for quick release of the breeches buoy. The ropes comprise of two equal lengths of rope that have been bunched together to form two loops, then bound together just below the loops, while the four hanging ends are looped around the lifebuoy, equally spaced, with each end finished in an eye-splice. The apparatus is suspended by the loops at the top and attached to the traveller block, which has a quick release device.flagstaff hill maritime museum & village, flagstaff hill, maritime museum, maritime village, warrnambool, great ocean road, shipwreck, life-saving, lifesaving, rescue crew, rescue, rocket rescue, maritime accidents, shipwreck victim, rocket crew, beach rescue, line rescue, rescue equipment, rocket firing equipment, rocket rescue equipment, rocket apparatus, beach apparatus, petticoat breeches, breeches buoy, rocket house, rocket shed, lifeboat men, rocket equipment, rocket machine, rocket head, rocket launcher, rocket line, marine technology, william schermuly, line-firing pistol, line throwing gun, schermuly pistol, pistol rocket apparatus, beach rescue set, traveller, block, running block, pulley, hawser, faking, faking box, faked line, rescue boat, lifeboat, lady bay, warrnambool harbour, port of warrnambool, tramway jetty, volunteer lifesavers, volunteer crew, breakwater, lifeboat warrnambool, rocket rescue method, rocket rescue apparatus, captain manby, mortar, henry trengrouse, sky rocket, john dennett, shore to ship, colonel boxer, two-stage rocket, italian hemp, quadrant, schermuly, line-throwing pistol, line throwing cartridge, rocket apparatus rescue, stranded vessel, tally board, light line, whip line, endless whip, petticoat buoy, traveller chair, traveller block, her majesty’s coast guard, harbour board, line thrower, line throwing, beach cart, hand barrow, sand anchor, hawser cutter, life jacket, faking board, irish hand barrow, government of victoria -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBook - Instruction Manual, Joseph Wertheim, Instruction manual for use and management of the Wertheim High Arm Sewing Machine, 23-07-1891

... of the Wertheim High Arm Sewing Machine Book Instruction Manual Joseph ...This instruction book was donated with our collection's Wertheim sewing machine accessory box. The box contains 12 accessories, the instruction book and the receipt for the purchase of a Wertheim sewing machine. The receipt was written on July 23rd 1891 by the Wertheim distributor in Melbourne, Hugo Wertheim. His business was the Wertheim Sewing Machine and Hapsburg Piano Depot, trading at 173 Williams Street, Melbourne. The purchaser was Mrs Burrowes from Burrumbeet, Victoria, a district northwest of Ballarat. She paid £6-6 (six pounds and six shillings) in cash. The receipt was signed by H. Wertheim and the other signatory looks like John A. Cherry. Hugo Wertheim (1854-1919) was an agent for his father’s cousin Joseph Wertheim, a well-established sewing machine manufacturer in Germany. He was born in Lispenhausen, Germany, and migrated to Melbourne in October 1875, where he opened a merchandising business at 39 Flinders Lane East. He returned to Germany in 1885 to marry Joseph Wertheim's daughter Sophie Emilie. The couple came back to Melbourne, and Hugo quickly established a substantial business selling sewing machines, bicycles, pianos and other mechanical devices, under brands such as Wertheim, Electra, Planet, Griffin and Hapsburg. He exhibited at agricultural shows and in 1901 at the Pan American Exposition, Buffalo, United States of America. One of his staff was O. C. Beale, who later set up his own piano business in New South Wales. Hugo continued to own 25 per cent of one of Beale's companies, which became Wertheim's Queensland business. In 1908 Hugo Wertheim opened a piano factory in Richmond, Melbourne, aiming to produce 2000 pianos and player pianos a year, predominantly using Australian materials. In laying the foundation stone, Prime Minister Alfred Deakin observed that “few men with such opportunities for a life of ease would have embarked on such an enterprise” Hugo died of chronic hepatitis in 1919 at his home in South Yarra. His eldest son, Herbert Joseph (1886-1972), continued the business. The piano factory closed in 1935, becoming a Heinz food processing plant and in 1955, GTV Channel 9 studios and offices. The Wertheim Sewing Machine Company – Joseph Wertheim (1804–1899) founded the company in 1868 in Frankfurt, Germany. At this time Joseph was the Frankfurt city delegate for the Democratic Party. At its height, the Wertheim factory employed approximately 650 workers. The company used a trademark of a dwarf holding a hammer which is known to have been used until at least 1925, however in 1909 a Star of David was also registered. In 1870 a Wertheim subsidiary was formed in Barcelona, Spain. The business imported and sold complete machines, including the English Jones machine. Locals began calling the sewing machines “las rapidas”, and the business became known as “las casa de las rapidas”. In 1915 production began of a totally manufactured Spanish Wertheim machine. Wertheim in Germany continued manufacturing machines until 1932 when the Wertheim family fled to Spain. Despite converting to Christianity from Judaism, they feared the political unrest in Germany during that time. Wertheim Spain became Rapida SA and was then the sole manufacturer of the Wertheim machines. The factory was managed by Karl Wertheim under the alias Carlos Vallin. The item is part of a donation that connected to domestic life in 1891 during the Victorian era. It is significant for connecting the Melbourne distributor of Wertheim sewing machines, Hugo Wertheim, to Victoria’s northwest district where the purchaser lived. It is also significant for connecting the Melbourne distributor to the importing of goods from the well-known German manufacturer of early domestic sewing machines, Joseph Wertheim.Book with pale blue cover and 19 double-sided printed pages stapled together. The book is an instruction manual for using and managing the Wertheim High Arm Sewing Machine and other similar models. It was published in Frankfurt, Germany, by Joseph Wertheim, the machines' manufacturer. The Australian distributor of the machines was Hugo Wertheim, 173 William Street, Melbourne. Circa 1891.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, wertheim, sewing machine, victorian era, sewing machine accessories, sewing machine instructions, wertheim instruction book, wertheim sewing machine and hapsburg piano depot, 23-7-1891, £6 6/-, mrs burrowes, burrumbeet, h. wertheim, wertheim sewing machines, domestic machines, dressmaking, home industry, fashion -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBooks x2 - Addressograph, 1. Class 22000 Service Manual. 2. Instructions for Operating the Class 22000

The metal plate machine used plates that contained names, addresses and classifications of each State Electricity Commission of Victoria employee working on the Kiewa Hydro Electric Scheme. The plates were put through the machine onto pay envelopes. See also: KVHS 0848, KVHS 1046SECV employed many people on the KHES and used the latest technology of the time to pay each of them including each one with a pay slip.1. Thick yellowed paper. 21 pages typed one side only and 9 blank pages with 'Fig. 1' to 'Fig 12' typed. Fastened on the left side with 3 'document binders'. 1957 Issue 2. Cardboard cover with 40 pages of thick paper printed on both sides with black and white illustrations.1. Cover: Stott & Hoare. Pty Ltd. / 171 William St;, / Melbourne. C.1. / Australia / Text & Illustrations / By N.F. Vezener 2. Cover: Addressograph / Addressing Machine / Fourth Edition/ This Book is very Important / Please Read and Keep it / Addressograph - Multigraph Ltd. / Head Office & Works / 50 Oxgate Lane, Cricklewood / London. N.W. 2addressograph, secv, khes, pay slips -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyWringer - washing clothes

Wringers were used to wring clothes dry after washing. This is a manual one that can be attached to a trough or container that holds the washing. Later on washing machines were made with the wringer already attached and were operated by electricity. Afterwards washing machines spun the clothes dry as part of their cycle.This wringer was used by a resident of the Mount Beauty township during the Kiewa Hydro Electric Scheme in the 1940's and 1950's. White metal machine with 2 adjoining cloth cylinders in the middle. The metal rectangular shape forms a frame around the cylinders which have a metal shield above them and a metal flap below them. At the bottom, on each side is a protruding metal vice enabling the machine to be attached to a container. On one side is a lever with a wooden handle that can be wound around to rotate the cylinders towards each other."Acme" in red on the middle of the top front and "Acme" in white in the middle of the top of the back.washing machine; ringer; mount beauty; laundry; -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietySewing Machine

Sewing machines were used by some ladies to mend and make clothes for the family as shops were some distance away and bought clothes were much more expensive. The sewing machines were also used to sew items for fund raising e.g.. Church and School fetes.Used in the Kiewa Valley.The machine has a brown wood veneer base and a lid with a metal handle in the centre of the top. There is a long screw that fits in a hole at the top of the lid. The screw can be lifted out and used to open and take off the lid. Inside there is a black metal machine which is fitted onto the wooden base. There is a compartment in the base, right of the wheel of the machine, which holds an instruction manual and a tube of ""Singer" lubricant for electric machines". The light, above the needle is covered by bakelite. A leather belt runs around the wheel on the right to enable the machine to run. There is a foot pedal and an electric cord attached."Singer Manufacturing Company" - gold embossed "No. EL 249 355" - oval disc "99K" - disc "Singer Manfg. Co. - discsewing machine; singer manufacturing company; kiewa valley -

J. Ward Museum Complex

J. Ward Museum ComplexInstrument - Electrocardiograph Machine - Cardiotrace Heat Mark II, circa 1920

With the advent of electricity, so to came the invention of the Electrocardiograph Machine. This piece of medical equipment gave nursing staff and doctors a more precise indication of a patients heart beat and was used extensively across Victoria's medical institutions. The equipment is significant because it is a fully intact example of diagnostic equipment used in a mental health hospital in Victoria Australia.Cardiotrace Electrocardiograph Machine in blue plastic case with black handle. Contains: Electric cord Cords to link electrodes Graph paper to measure heart beats Instruments on panel marked 'stylus heat', 'off', 'run', 'position', 'test', 'record', '1', '2', '3', 'aVR', 'aVL', 'aVP', 'V', '1/2V', 'lmV', marker.Manufacturer: Medical Instrument Co. Pty. Ltd. Distributor: Watson Victor Limited Serial No: 3362 Cardiotrace Heat Mark III Electrocardiograph/Voltage 220-240 A/C /Frequency 50 cycles per second/Watts 45 serial 3362/Caution: Refer to Manual for full detail.electrocardiograph machine, medical instrument, medicine, health, mental health, ararat mental hospital, j ward -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageGestetner Machine, c. 1922 - 1929

This Gestetner Cyclostyle duplicating machine was invented and manufactured by David Gestetner. He claimed in 1922, once he had released several models, that if a Gestetner Durotype stencil was used together with his Cyclostyle machine, then 10,000 copies could be made from the one Durotype stencil, an amazing claim for office technology of that era. David Gestetner (1854-1939), was born in Csoma, Hungary. He has been called the “founder of the worldwide office copying and duplicator industry.). He moved to London and in 1879 filed his first copying patent. In 1881 he patented the Cyclostyle stylus (or pen), which was used in conjunction with his Cyclograph device for copying text and images, He established the Gestetner Cyclograph Company in England at this time (1881) to protect his inventions and to produce his products; stencils, stylos (stylus or pen) and ink rollers. HIs inventions included nail-clipper and the ball-point pen (although the latter is more commonly associated with Laszlo Biro). Gestetner’s patented Cyclograph duplicator was used with his Cyclostyle Stylus or pen to write or draw on special thin wax-coated stencil paper (originally used for kite making paper) in the following way; 1. The Cyclostyle stencil was placed on a lower, framed metal plate of the Cyclograph 2. An upper frame was clipped over the top 3. The Cyclostyle pen, with its tip being a small metal-spiked or toothed wheel, was used to write or draw on the stencil, punched small holes into the paper and removed the wax coating in those places 4. The upper frame and stencil was then removed and a piece of blank paper was placed onto the metal plate in the lower frame and the upper frame with stencil was replaced 5. A roller was given an even distribution of Cyclostyle ink and rolled by hand over the stencil in the frame. This forced the ink through the holes in the stencil to and made a copy of the stencil on the paper 6. The upper frame was raised, the printed paper removed and another blank sheet was put into place. The whole process was repeated until enough copies were made. Gestetner’s invention developed further in 1894, with a stencil that could be placed on a screen on a revolving drum. The drum was manually rotated, the stencil then wrapped around another drum and was fed between cloth-covered rollers on which ink was evenly spread. Each revolution of the drum forced ink through the holes in the stencil and transferred the ink onto paper that had been fed between rollers and pressed against the drum. The process was repeated for each page. The paper was still fed and removed manually in this earlier invention but became more automatic in later models. In 1902 Gestetner duplicator model 6 was put onto the market. This model included the improvement of an automatic paper feed that synchronised with the rotation of the stencil. The Gestetner machine was the first office printing machine. It was easily installed and it made exact copies of the sane document quickly, effectively and inexpensively. This changed the way offices operated, making information easily available to many more users. The machines were commonly used in small businesses, schools, churches, clubs and other organisations for the wide distribution of a wide variety of information in the form of worksheets, newsletters and more. In 1906 the Gestetner Works were opened in Tottenham Hale, North London, and thousands of people were employed there up until the 1970’s. Due to the fast growing success of the Gestetner Duplicator machines many international branches for sales and service centres were established. David Gestetner was succeeded by his son Sigmund, followed by his grandson’s David and Jonathan. Further advancement was made by using a manual typewriter with specifically designed stencils. The end product was a printed, typewritten copy similar to the print from newspapers and booklets. In the next few years there were further developments of this revolutionary invention. The Gestetner Cyclostyle duplicator in our Collection is dated c.1922 - 1929 and it uses Gestetner Durotype stencils The 1922 British Industries Fair’s catalogue contained advertising for the Gestetner Rotary Cyclostyle “The World’s Premier Duplicator”, demonstrated at Stand K 86.” A Notice at the foot of the advertisement’s page boasts "Important - D Gestetner's latest invention, the "Durotype" Stencil, enables you to obtain 10,000 copies from one original if desired. It contains no wax of any description, is indestructible, can be stored indefinitely and printed from as required” In 1929 the look of the Gestetner machines changed; American designer Raymond Loewy was invited by Gestetner to improve the look of his duplicators, resulting in a very streamlined appearance. Eventually, around 1960’s, offices replaced their Gestetner with small photocopying machines and printers. Gestetner took over ownership of other office machine companies over time, including Nashua, Rex Rotary, Hanimex and Savin and eventually all came under the holding company name of NRG (Nashuatech, Rex Rotary and Gestetner). In 1996 Ricoh acquired the Gestetner Company, and it was renamed the NRG Group. REFERENCES Cyclostyle, Stencil Duplicating Machines, antique Copying Machines, Early Office Museum, http://www.officemuseum.com/copy_machines.htm Duplicating machines, Wikipedia Duplicator, Collection online, Canada Science and Technology Museums Corporation http://techno-science.ca/en/collection-research/collection-item.php?id=1989.0229.001 Gestetner duplicators, Totterham-Summerhillroad.com http://tottenham-summerhillroad.com/gestetner_duplicators_tottenham.htm Gestetner Duplicator, V&A Museum http://collections.vam.ac.uk/item/O322014/gestetner-duplicator-duplicator-loewy-raymond-fernand/ Gestetner, Grace’s Guide to British Industrial History, http://www.gracesguide.co.uk/Gestetner Duplicating machines such as this one revolutionalised access to copies of printed material, changing the way that educational bodies, offices, small businesses and community clubs and charities operated.Duplicating machine, Gestetner Cyclostyle Durotype, a stencil-method duplicating machine with two rotating drums plus rollers. Hand operated, tabletop office machine. Front has folding Bakelite handle, oil filling hole, calibrating gauge with scale, and copy counting meter. Right side has printed manufacturer’s plate that slides out as a paper output tray. Left side has metal plate with protrusions and perforations, plus another similar plate that is detached. It also has a metal frame attached [that would have been used to hold a paper input board, adjusted for various sizes of paper]. Cover, metal, with folding wooden handle on top, attaches to base with metal clips. Inscriptions printed on machine, mostly in gold-coloured paint. Round metal manufacturing plate is stamped with Serial Number 95759. Made by D. Gestetner, London, c.1922-1929Maker’s plate “MANUFACTURED / BY / D. GESTETNER LTD, / No. 95759 / CYCLOSTYLE WORKS / TOTTENHAM HALE / LONDON, N” Copy counting meter shows “1 4 6 4 8 [space]“ copies. Calibrating gauge has divisions with numbers “0 1 2“, labelled “← [left arrow] “TO PRINT LOWER” and “→ [right arrow], TO PRINT HIGHER”. “The Gestetner”, “Cyclostyle”, “Gestetner” (Trade Mark), Right side print of manufacturing details includes “The / Gestetner / TRADE MARK” And “THE FOLLOWING TRAFE MARKS / - - - OF INK, STENCILS / - - - AND GUARANTEE OF PERFECT / - - - BOTH - - - AND MACHINE” and “CYCLOSTYLE / DUROTYPE / GESTETNER” and “D. Gestetner” flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, office machine, copying machine, gestetner machine, duplicating machine, duplicator, stencil machine, gestetner cyclograph company, cyclograph, cyclostyle, d. gestetner ltd, gestetner durotype stencils, gestetner cyclostyle, printing machine, office technology, durotype stencils, david gestetner, raymond loewy, roneo, rotary duplicatorten, mimeo, mimeograph machine, roneograph copier -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Codd neck bottle, E. Rowlands, 1921

The design of the bottle is called a Codd, sometimes referred to as a marble bottle or "Codd's patent bottle". During the mid-to-late 1800s, there were many inventions to keep the fizz in carbonated drinks such as ginger ale, soda water, and fruit drinks. Hiram Codd, an English engineer invented a successful process that he patented as "Codd's patented globe stopper bottle" in 1872. The Codd-neck bottle (commonly called Codd or marble bottle) is manufactured in two parts. The body of the bottle is cast in two sections. At the time of joining the sections, glass marble and rubber seal are inserted into the neck section. The lip is then applied to the top of the bottle. The Codd bottle is filled upside down as the pressure of the gas from the carbonated liquid holds the marble up and out of the way. When the bottle stands upright the gas pushes the marble up against the washer, creating a firm seal to keep the fizz inside. The bottle is opened by pushing the marble down firmly to allow some of the gas to escape. The marble drops down and is caught in a depression formed in the neck. When the bottle is tilted to pour or drink the liquid the marble rests in a dimple. Two Ballarat miners, Evan Rowland and Robert Lewis started manufacturing mineral and aerated waters, bitters, cordials, and liqueurs in 1854, in a tent on the shores of Lake Wendouree Ballarat. Another 13 firms at that time employed manual operations, whereas they introduced Taylor's No. 1 machine that speeded up the process and laid the foundation for their fortune. Evan Rowland was a pioneer in the aerated water trade in Australia. He was born on August 2, 1826, in North Wales. In 1852, during the gold rush, he emigrated to Melbourne, and in 1854 he went to Ballarat and formed a partnership with Robert Lewis, the firm being called ‘‘Rowlands & Lewis’’. Their next step was to secure a supply of pure water. Using mineral Waters that they found via a natural spring at Warrenheip, Victoria. From the outset, the beverages made from this water gained repute and were in great demand. Their business prospered so well that in 1858 they were able to build a factory at the corner of Sturt and Dawson Streets, Ballarat, and to fit with the most up-to-date machinery then in use. By 1870 their business had increased so much and demand had grown to such an extent that Mr. Rowlands erected another factory, covering over an acre of ground at the corner of Dana and Doveton Streets, costing £13,000. The factory was fitted with the most modern equipment of the time to manufacture cordials and aerated water. In 1873 Rowlands established an agency at 116 Collins St, Melbourne, because the demand for the products of the Melbourne factory became so large. The company expanded to Sydney opening a factory at the corner of Burns & Hay Streets Darling Harbour obtaining spring water to supply this plant from Katoomba in the Blue Mountains. The water was brought to Sydney by rail. In the meantime, the Melbourne concern had progressed so rapidly that in 1888 a magnificent factory embodying all the latest ideas and equipment was built in King Street Melbourne. Robert Lewis was a fellow Welshman born in 1816, and he arrived in Port Phillip in 1853 and became a partner in the early day with Evan Rowland but with lesser and shorter involvement in the firm, from which he retired in 1876. Robert Lewis was perhaps better known as Ballarat's first mayor and a Member of the Legislative Assembly. He was a strong supporter of local charities, president/treasurer of the Eisteddfod Committee, a major force in the development of the Ballarat Hospital, and he was the mayor of Ballarat five times, the first in 1863, (having been a counsellor as early as 1859) and for the last time in 1881. Lewis died in 1884 of a stroke in Ballarat. Rowlands continued in the firm and invented and patented an improved soda water bottle. The water used in Rowlands products was filtered four times but his attempts to use local corks failed on quality grounds. He was a stickler for quality, which was so good that many outside Victoria were prepared to pay the 'premium' imposed by inter-colonial customs duty payable at that time. By the 1890s, Rowlands had factories in Ballarat, Melbourne, Sydney, and Newcastle. He died in 1894 but his company continued until well after the Second World War when it was sold to Schweppes.An early manufacturing process producing the first mineral waters in Australia was invented and developed by an early Welsh migrant to Australia. The Evan Rowlands story gives an insight into the early development of manufacturing industries in Australia that allowed their workers and the towns they were situated in to prosper and develop into what they are today. Bottle; clear glass Codd neck bottle with small marble in top. Once contained soda water or soft drink. Manufactured in 1921 by E. Rowlands of Ballarat, Melbourne, Katoomba and Sydney. The bottle is 'recyclable' - the message on the base says that it remains the property of E. Rowlands Pty Ltd."E. ROWLANDS BALLARAT MELBOURNE KATOOMBA AND SYDNEY". Imprinted into bas "1921" "THIS BOTTLE REMAINS THE PROPERTY OF E. ROWLANDS PTY LTD"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, bottle, codd bottle, hiram codd, glass marble bottle, e. rowlands bottle manufacturer, soda bottle australia, early recyclable bottle, codd's patent bottle, marble bottle -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Ink Bottle, Second half of 19th Century or first half of the 20th Century

Although glass containers for wine and beer are probably 1,600 years old, much of their use began only in the late 17th century. In the United States, large-scale production of bottles was pioneered by Caspar Wistar in 1739 at his New Jersey plant. In the 1770s the carbonation process for producing soft drinks was developed, and so began an entirely new bottling industry. At the Great Exhibition of 1851 in the Crystal Palace in London, one million “pop” bottles were consumed. The first beer pasteurised in glass was produced in Copenhagen in 1870. Pasteurisation of milk followed soon after. The moulding of a screw thread on a container was invented by John Mason in 1858. The principles of the “press-and-blow” process for making wide-mouth jars were shown in the United States by Philip Arbogast in 1882, and the “blow-and-blow” process for making narrow-neck containers was demonstrated by Howard Ashley in England in 1885. These processes employed manual delivery; fully automatic jar forming by a suction-and-blow process was perfected by Michael Owens over the period 1895–1917 at the Toledo (Ohio) Glass Company, which subsequently became the Owens Bottle Machine Company. The automatic single-gob feeder was developed in 1919–22 by Karl Peiler at the Hartford-Fairmont Company in Connecticut. Fully automatic machines followed, but the true rugged survivor, utilising fully automatic gob delivery to the maximum versatility, was the Individual Section, or IS, machine invented by Henry Ingle at the Hartford Empire Company in 1925. Source: https://www.britannica.com/topic/glass-properties-composition-and-industrial-production-234890/History-of-glassmakingUnlike item 4018, this is a much smaller ink bottle, and was probably used by an individual, as against the supply of ink to pupils from a much larger bottle.Cotton Reel Ink Bottle, green glass, small, chipped around the lip, bubbles in glass.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, ink, bottle, glass -

4th/19th Prince of Wales's Light Horse Regiment Unit History Room

4th/19th Prince of Wales's Light Horse Regiment Unit History RoomBooklet (2 copies), Manual of Land Warfare Part 2 Infantry Training Vol 4 Pam 7 The General Purpose Machine Gun 7.62 mm M60 1980, 1980

Soft covered booklet. DSN 7610-66-104-8351 m60 general purpose machine gun -

4th/19th Prince of Wales's Light Horse Regiment Unit History Room

4th/19th Prince of Wales's Light Horse Regiment Unit History RoomBooklet (2 copies), Manual of Land Warfare Part 2 Infantry Training Vol 4 Pam 3 Sub Machine Gun 9 mm F1 1983, 1983

Soft covered bookletDSN 7610-66-107-6806sub machine gun f1 -

4th/19th Prince of Wales's Light Horse Regiment Unit History Room

4th/19th Prince of Wales's Light Horse Regiment Unit History RoomBooklet, Manual of Land Warfare Part 2 Infantry Training Vol 4 Pam 7 GPMG M60, Nov 1989

Green plastic loose leaf binder containing information required by all corps to conduct training in the use of the General Purpose Machine Gun 7.62 mm M 60. It describes the gun and associated equipment. The cover has a clear window through which the title is visibleMLW TWO 4.7machine gun, gpmg m60 -

4th/19th Prince of Wales's Light Horse Regiment Unit History Room

4th/19th Prince of Wales's Light Horse Regiment Unit History RoomTraining Manual, Chief Instructor, Machine Gun Training School, MGTC, Machine Gunner's Pocket Book, Nov 1917

... , 4th Light Horse Regiment ww1 chanter machine guns manual User ...Used by Capt A L Chanter, Machine Gun Section, 4th Light Horse RegimentLoose leaf pages secured in brown cloth coverUser name: A L Chanterww1, chanter, machine guns, manual -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBook - Reference Printing, Charles W. Hackleman, Commercial Engraving and Printing, Circa 1921

This item relates to methods of reproducing photos on all forms of material in an era of physical offset printing.The offset method is being replaced by digital transfer direct to the final product,(paper or other porous and non porous surfaces). Newspapers and other "paper" information publications are still producing "hard copies" but these are slowly being phased out. This item was used Circa 1920s in the peek period of paper based media. From the 1940s radio and then television stepped into the mass media revolution.This book was produced when all printing, Government and private enterprise, was using the "off set" method. This method was used to a great degree in all schools within the Kiewa Valley. It was in an era before "photo-copying machines" were available. This was a period when printing inks for larger printing machines had to be purchased from specialised outlets and printing presses required to be washed after each "run" of printing before the next plate(aluminium) could be fastened onto the "off sett" machinery. Heat infusion now used in large machines and domestic printers has superseded this task. Faded green cloth covered book with green papered front and back sleeve pages.Photos and sketches are throughout the book. Gloss paper used from page 1 one to page 400. Pages 401 to page 432 are not gloss paper. The type of paper varies throughout the book until final advertisement and index pages, from page 833 to page 846, are on gloss paperThe spine cover is badly worn and wording is faded. Front cover has"Commercial Engraving And Printing" Author and publisher details written by Charles W. Hackleman. Published by Commercial Engraving Publishing Company, "A Manual of Practical Instruction and Reference Covering" Commercial Illustrating and Printing by all Processes.technical book, reference for engraving and printing -

Cheese World Museum

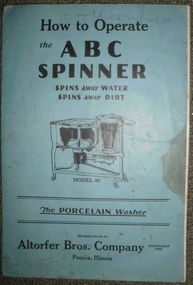

Cheese World MuseumManual, How to operate the ABC Spinner

Donated with the ABC Spinner washing machineBlue heavy paper cover with black lettering and an illustration of Model 60. Full title is 'How to operate the ABC Spinner -Spins Away Water -Spins Away Dirt. The Porcelain Washer -Manufactured by Altofer Bros Company Established 1909 Peoria Illinois Contents include parts price list and instructions for use'allansford, altofer brothers, abc spinner, washing machines, laundry aids -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Rocket set, John Dennett, ca. 1860s

This rescue line-throwing rocket set was made for the Dennett rocket system, which was used by the Rocket Rescue crews in South West Victoria from around the 1860s to the 1890s. John Dennett - John Dennett was from Carisbrooke, in the Ilse of Wight, UK. In 1826 he invented, patented and demonstrated an improved method of rocket powered, line firing rescue equipment for saving lives. The rockets had a longer range than the mortars being used, they were lighter, needed less preparation time, only needed one line for repeated shots, and fewer people were needed to move the equipment. Very favourable reports of Dennett’s rockets were received by those in charge of His Majesty’s Naval and Military services. In 1832, Dennett’s rocket-thrown line was sent out to the wreck of the ‘Bainbridge’, and was responsible for nineteen survivors coming ashore in two boatloads, along the fired line. Dennett’s rocket received national fame, and a one-year contract to supply rockets to the Coastguards. He became known as ‘Rocket Man’ and his rockets were used in rescues at least until 1890, when his son Horatio was running the business. A rocket weighing 23 lb would have a range of about 250 yards (228 metres), on average. Saving lives in Warrnambool – The coastline of South West Victoria has had over 600 shipwrecks and many lost lives; even in Warrnambool’s Lady Bay there were around 16 known shipwrecks between 1850 and 1905, with eight lives lost. In 1859 the first Government-built lifeboat arrived at Warrnambool Harbour and a shed was soon built to house it, followed in 1864 by a rocket house to safely store the Rocket Rescue equipment. In 1878 the buildings were moved to the Breakwater area, and in 1910 the new Lifeboat Warrnambool arrived with its ‘self-righting’ design. For almost one hundred years the lifeboat and rocket crews, mostly local volunteers, trained regularly to maintain and improve their skills, summoned when needed by alarms, gunshots, ringing bells and foghorns. Some became local heroes but all served an important role. By the end of the 1950s the lifeboat and rescue equipment had become obsolete. Rocket Rescue Method - The first use of a lifesaving rocket rescue system is often credited to Captain Manby and his invention of a life mortar, first used in 1808 to fire a line onto a ship to rescue lives. Henry Trengrouse’s invention of 1820 was the first to use a sky rocket’s power to throw a line, and his invention included a chair for carrying the shipwrecked victims to shore. In 1832 John Dennett invented a rocket specifically for shore to ship rescue. It had an iron case and an 8 foot pole attached and could shoot the line as far as 250 yards (about 230 metres). From the 1860s the rocket rescue apparatus was in use. It comprised a breeches buoy and traveller block that was suspended on a line and manually pulled to and from the distressed vessel carrying passengers and items. Colonel Boxer, who had invented an early line-thrower, designed a rocket in 1865 with a range from 300 to 470 yards. It was the first two-stage rocket, with two rockets placed one in front of the other in a tube that carried the rescue line. The hemp line was faked, or coiled, in a particular way in a faking box to prevent twists and tangles when fired, and the angle of firing the rocket was measured by a quadrant-type instrument on the side of the rocket machine. Schermuly invented the line-throwing pistol around 1920, which used a small cartridge to fire the rocket. Victoria’s Government adopted lifesaving methods based on Her Majesty’s Coast Guard in Great Britain, which used Colonel Boxer’s rocket apparatus rescue method. The British Board of Trade published instructions in 1850 for both the beach rescue crew and ship’s crew. It involved setting up the rocket launcher on shore at a particular angle measured by the quadrant, inserting a rocket that had a light-weight line attached, then firing it across the stranded vessel. A tally board was then sent out with instructions in four languages. The ship’s crew would haul on the line to bring out the continuous whip line and attach the whip block to a mast or sturdy part the ship. The rescue crew on shore then hauled out a heavier hawser line, which the ship’s crew fixed above the whip block. The hawser is then tightened using the block on the shore end of the whip. The breeches buoy and endless whip are then attached to the traveller block on the hawser, allowing the shore crew to haul the buoy to and from the vessel, rescuing the stranded crew one at a time. The rocket system could also be used from one ship to another.The Dennett rocket set is quite rare - there are not many examples in existence and little information is available. This Dennett's rocket set is significant for its connection with local history, maritime history and marine technology. Lifesaving has been an important part of the services performed from Warrnambool's very early days, supported by State and Local Government, and based on the methods and experience of Great Britain. Hundreds of shipwrecks along the coast are evidence of the rough weather and rugged coastline. Ordinary citizens, the Harbour employees, and the volunteer boat and rescue crew, saved lives in adverse circumstances. Some were recognised as heroes, others went unrecognised. In Lady Bay, Warrnambool, there were around 16 known shipwrecks between 1850 and 1905. Many lives were saved but tragically, eight lives were lost.A Dennett rocket set in six parts; the rocket head, three shafts (poles) and two rocket-head toting boxes. The rocket head, mounted on one of the shafts, is a long, red painted, iron tube with rounded ends and a protruding fitting around each end. The wooden rocket shafts are octagonal, with a metal sheath at the ends, carved elongated slots towards each end, and a scribed channel above the black foot. The rocket head toting boxes are thick timber, covered in fabric and painted black. They have a hinged wooden lid that slants downwards from back to front, and a metal closure. Small deliberate holes, in groups of four, on the box’s sides, indicate missing attachments, likely to have been handles. Impressed one a shaft "8"flagstaff hill maritime museum & village, flagstaff hill, maritime museum, maritime village, warrnambool, great ocean road, shipwreck, life-saving, lifesaving, rescue crew, rescue, rocket rescue, maritime accidents, shipwreck victim, rocket crew, beach rescue, line rescue, rescue equipment, rocket firing equipment, rocket rescue equipment, rocket apparatus, beach apparatus, petticoat breeches, breeches buoy, rocket house, rocket shed, lifeboat men, rocket equipment, rocket machine, rocket head, rocket launcher, rocket line, marine technology, william schermuly, line-firing pistol, line throwing gun, schermuly pistol, pistol rocket apparatus, beach rescue set, traveller, block, running block, pulley, hawser, faking, faking box, faked line, rescue boat, lifeboat, lady bay, warrnambool harbour, port of warrnambool, tramway jetty, volunteer lifesavers, volunteer crew, breakwater, lifeboat warrnambool, rocket rescue method, rocket rescue apparatus, captain manby, mortar, henry trengrouse, sky rocket, john dennett, shore to ship, colonel boxer, two-stage rocket, italian hemp, quadrant, schermuly, line-throwing pistol, line throwing cartridge, rocket apparatus rescue, stranded vessel, tally board, light line, whip line, endless whip, petticoat buoy, traveller chair, traveller block, her majesty’s coast guard, harbour board, line thrower, line throwing, beach cart, hand barrow, sand anchor, hawser cutter, life jacket, faking board, irish hand barrow, rocket head toting box, explosives, rocket shaft, rocket pole -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Wringer/Mangle, Melvin Newton Lovell, 1898 -1900

Melvin Newton Lovell was born in Allegheny, Venango county, Pennsylvania, on 31 August 1844, to Darius T. Lovell (1815-1855) and Susan B. (Conover) Lovell (1827-1883). When Melvin Lovell was a boy, the family removed to Kerrtown, a village located in the vicinity of Titusville, PA. There Melvin served an apprenticeship at the carpenter's trade, and his natural mechanical talent enabled him to become a skilled workman. He followed his trade during the major portion of his term of residence in Kerrtown. In 1861, at seventeen years of age, Melvin Lovell left his home and, without parental authority, and entered the Union army soon after the outbreak of the Civil war. In August 1862, he was enlisted as a private in the 127th Pennsylvania Volunteer Infantry and saw active service until receiving his discharge at the end of May 1863. In 1865 he took up his residence in Erie, where he worked at the carpenter's trade for several years thereafter. In 1869 Melvin Lovell invented and patented several useful articles for household use, and in that year he began the manufacturing of certain of these inventions, in partnership with Franklin Farrar Adams, another inventor. Among the principal products of the original factory were washing machines and step-ladders. In 1881 Lovell individually began manufacturing other of his patents, including spring beds, and from modest inception, his Lovell Manufacturing Company grew to be one of the largest industrial concerns of its kind in the country and was recognized as being the most extensive manufacture of clothes-wringers in the entire world. In connection with his manufacture of domestic items, Lovell established sales agencies for his products in all parts of the country, and these branches were known as the Lovell stores. These goods were sold on the instalment plan and after his business had already been established becoming a substantial concern Lovell invented and patented the famous wringer which bears his name under the “Anchor” brand, and in later years he confined his operations largely to the manufacture of this very superior household invention. Lovell was also one of the organizers and stockholders of the Combination Roll & Rubber Manufacturing Co, of New York, which was formed to manufacture his patents, with headquarters in New York and a factory at Bloomfield, New Jersey.A significant household item used in the process of washing clothes by a man who had started in 1869, as a young carpenter and later he became a successful businessman and manufacturer of household items. Lovell was granted numerous patents for various devices during his career including several patents for adding machines (cash registers).Wringer (or mangle); portable wooden washing wringer with rubber rollers, manually driven by iron set of gears and handle. Includes iron clamps and adjusting screws for attaching. Marked on frame "382", "12 x 1 3/4" Anchor Brand "Made in USA" flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, mangle, clothes wringer, washing equipment, laundry, wringer, domestic, washing mangle -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing Machine, early 20th century

Sewing machine, portable, hand operated, with Premier logo. Has folding crank handle, body painted black with floral design, wooden base and separate wooden cover with lock. Base has compartment with accessories, covered by curved ended, sliding wooden panel. Decorative linework on side, carvings on each corner. Wooden handle on cover is carved in rings, folds down. Below handle is decorative inlaid pattern. Serial number on plate at back of machine. Accessories include 13 attachments, key (broken), screwdriver, sewing machine needle, razor blades (2) and buttons. Attached to inside of case is a square of paper with a number on it. Instruction book for Singer Sewing Machines is included. Also with machine are white tailor's chalk and a cut out, fabric pocket with tissue paper pattern pinned to it.Serial number "579200" is stamped into plate at back of machine. Brand on transfer on front of machine is "Premier". Paper inside case has hand written number "334A". Instruction book "Instructions for using Singer Sewing Machines No. 66 - Oscillating hook for family use" flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sewing machine, permier sewing machine, hand operated sewing machine, dressmaker, fasion, singer no. 66 manual, textile, flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sewing machine, permier sewing machine, hand operated sewing machine, dressmaker, fasion, singer no. 66 manual, textile -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Water Canteen and Ladle, mid-to-late 19th century

The horizontal water canteen has been carefully designed to fit snugly on the hip when worn with the straps diagonally across the body. The ladle allows quick and easy scooping of the contents to refresh the lifeboat and rocket launching crew, and the survivors of the disaster Saving lives in Warrnambool – The coastline of South West Victoria is the site of over 600 shipwrecks and many lost lives; even in Warrnambool’s Lady Bay there were around 16 known shipwrecks between 1850 and 1905, with eight lives lost. Victoria’s Government responded to the need for lifesaving equipment and, in 1858, the provision of rocket and mortar apparatus was approved for the lifeboat stations. In 1859 the first Government-built lifeboat arrived at Warrnambool Harbour and a shed was soon built for it on the Tramway Jetty, followed by a rocket house in 1864 to safely store the rocket rescue equipment. In 1878 the buildings were moved to the Breakwater (constructed from 1874-1890), and in 1910 the new Lifeboat Warrnambool arrived with its ‘self-righting’ design. For almost a hundred years the lifesaving and rescue crews, mostly local volunteers, trained regularly to rehearse and maintain their rescue skills. They were summoned when needed by alarms, gunshots, ringing bells and foghorns. In July 1873 a brass bell was erected at Flagstaff Hill specifically to call the rescue crew upon news of a shipwreck. Some crew members became local heroes but all served an important role. Rocket apparatus was used as recently as the 1950s. Rocket Rescue Method - The Government of Victoria adopted lifesaving methods based on Her Majesty’s Coast Guard in Great Britain. It authorised the first line-throwing rescue system in 1858. Captain Manby’s mortar powered a projectile connected to a rope, invented in 1808. The equipment was updated to John Dennett’s 8-foot shaft and rocket method that had a longer range of about 250 yards. From the 1860s the breeches buoy apparatus was in use. The apparatus was suspended on a hawser line and manually pulled to and from the distressed vessel carrying passengers and items. In the early 1870s Colonel Boxer’s rocket carried the light line, which was faked, or coiled, in a particular way between pegs in a faking box to prevent twists and tangles when fired. The angle of firing the rocket to the vessel in distress was measured by a quadrant-type instrument on the side of the rocket machine. Decades later, in about 1920, Schermuly invented the line-throwing pistol that used a small cartridge to fire the rocket. The British Board of Trade published instructions for both the beach rescue crew and ship’s crew. It involved setting up the rocket launcher on shore at a particular angle measured by the quadrant, inserting a rocket that had a lightweight line threaded through its shaft, and then firing it across the stranded vessel, the line issuing freely from the faking board. A tally board was then sent out to the ship with instructions in four languages. The ship’s crew would haul on the line to bring out the heavier, continuous whip line, then secure the attached whip block to the mast or other sturdy part of the ship. The rescue crew on shore then hauled out a stronger hawser line, which the ship’s crew fixed above the whip block. The hawser was then tightened using the block on the shore end of the whip. The breeches buoy and endless whip are then attached to the traveller block on the hawser, allowing the shore crew to haul the breeches buoy to and from the vessel, rescuing the stranded crew one at a time. Beach apparatus equipment - In the mid-1800s the equipment could include a line throwing set, coiled line in wooden carrying case, rockets, cartridges, breeches buoy, hawser and traveller block, line-throwing pistol, beach cart, hand barrow, sand anchor, crotch pole, and tools such as spade, pick, mallet and hawser cutter. Around the 1860s Warrnambool had a Rocket House installed beside the Harbour. This water canteen is significant for its connection with local history, maritime history and marine technology. Lifesaving has been an important part of the services performed from Warrnambool's very early days, supported by State and Local Government, and based on the methods and experience of Great Britain. Hundreds of shipwrecks along the coast are evidence of the rough weather and rugged coastline. Ordinary citizens, the Harbour employees, and the volunteer boat and rescue crew, saved lives in adverse circumstances. Some were recognised as heroes, others went unrecognised. In Lady Bay, Warrnambool, there were around 16 known shipwrecks between 1850 and 1905. Many lives were saved but tragically, eight lives were lost.Water canteen and ladle; blue painted oval metal cylinder with a removable round threaded lid. Two adjustable leather shoulder straps are attached to the canteen through metal rings on the sides of the lid. A blue-painted copper ladle with a fixed, 45-degree angled handle is attached to the canteen with a length of string. The water canteen is designed to be carried horizontally.flagstaff hill maritime museum and village, flagstaff hill, maritime museum, maritime village, warrnambool, great ocean road, lady bay, shipwreck, life-saving, lifesaving, rescue crew, rescue, rocket rescue, rocket crew, lifeboat men, beach rescue, line rescue, rescue equipment, volunteer lifesavers, volunteer crew, life saving rescue crew, lifesaving rescue crew, rocket apparatus, survival canteen, rescue canteen, dipper, cup, canteen and dipper, canteen and ladle, water canteen -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Canvas Bag, mid-to-late 19th century