Showing 60 items matching "metal working tool"

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Spokeshave, Mathieson and Son, 1860 to 1910

A spokeshave is a hand tool used to shape and smooth woods in woodworking jobs such as making cart wheel spokes, chair legs, paddles, bows, and arrows. The tool consists of a blade fixed into the body of the tool, which has a handle for each hand. Historically, a spokeshave was made with a wooden body and metal cutting blade. With industrialization metal bodies displaced wood in mass-produced tools. Being a small tool, spokeshaves are not suited to working large surfaces. The name spokeshave dates back to at least the 16th century, though the early history of the tool is not well documented. The name spokeshave reflects the early use of the tool by wheel wrights. The first spokeshaves were made of wood usually beech with steel blades, before being largely superseded by the development of metal-bodied spokeshaves in the latter half of the 19th century, though many woodworkers still use wooden spokeshaves. Due to their widespread use and versatility vintage wooden spokeshaves remain commonly available and relatively low in price. Spokeshaves consist of a blade or iron secured to the body or stock of the tool, which has two handles – one for each hand. The bottom surface of the tool is called the sole. The blade can be removed for sharpening, and adjusted to vary the depth of the cut. An early design consisted of a metal blade with a pair of tangs to which the wooden handles were attached, as with a draw knife. Unlike a draw knife, but like a plane, spokeshaves typically have a sole plate that fixes the angle of the blade relative to the surface being worked. There are a wide variety of different types of spokeshave, suited to different trades and applications. Company History: The firm of Alexander Mathieson & Sons was one of the leading makers of hand tools in Scotland. Its success went hand in hand with the growth of the shipbuilding industries on the Firth of Clyde in the nineteenth century and the emergence of Glasgow regarded as the "second city of the Empire". It also reflected the firm's skill in responding to an unprecedented demand for quality tools by shipyards, cooperage's and other industries, both locally and far and wide. The year 1792 was deemed by the firm to be that of its foundation it was in all likelihood the year in which John Manners had set up his plane-making workshop on Saracen Lane off the Gallowgate in the heart of Glasgow, not far from the Saracen's Head Inn, where Dr Johnson and James Boswell had stayed on their tour of Scotland in 1773. Alexander Mathieson (1797–1851) is recorded in 1822 as a plane-maker at 25 Gallowgate, but in the following year at 14 Saracen's Lane, presumably having taken over the premises of John Manners. The 1841 national census described Alexander Mathieson as a master plane-maker at 38 Saracen Lane with his son Thomas Adam working as a journeyman plane-maker. In 1849 the firm of James & William Stewart at 65 Nicolson Street, Edinburgh was taken over and Thomas was put in charge of the business, trading under the name Thomas A. Mathieson & Co. as plane and edge-tool makers. Thomas's company acquired the Edinburgh edge-tool makers Charles & Hugh McPherson and took over their premises in Gilmore Street. The Edinburgh directory of 1856/7 the business is recorded as being Alexander Mathieson & Son, plane and edge-tool makers at 48 Nicolson Street and Paul's Work, Gilmore Street. The 1851 census records indicate that Alexander was working as a tool and plane-maker employing eight men. Later that year Alexander died and his son Thomas took over the business. Under the heading of an edge-tool maker in the 1852/3 (Post-Office Glasgow Annual Directory) the firm is now listed as Alexander Mathieson & Son. By the early 1850s, the business had moved to 24 Saracen Lane. The directory for 1857/8 records that the firm had moved again only a few years later to East Campbell Street, also off the Gallowgate, and that through further diversification was also manufacturing coopers' and tin men's tools. The ten-yearly censuses log the firm's growth and in 1861 Thomas was a tool manufacturer employing 95 men and 30 boys; in 1871 he had 200 men working for him and in 1881 300 men. By 1899 the firm had been incorporated as Alexander Mathieson & Sons Ltd, even though only Alexander's son Thomas appears ever to have joined the firm.A vintage tool made by a well-known firm made for other firms and individuals that worked in wood. The tool was used to shape various items mainly in use by wheel wrights. A significant vintage item from the mid to late 19th century that today is quite sought after by collectors. It gives us a snapshot of how trade people predominately worked materials such as wood by hand and with tools that were themselves hand made shows the craftsman's art of the time. Spokeshave with blade 4 inches wide.Mathieson and Son Glasgow. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, spokeshave, mathieson and son, carpentry tools, wheel wright tools -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Plane, James Hastie, Late 19th to Early 20th Century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it.A vintage tool used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture was done by hand using one of these types of plane. A significant item from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture was made predominately by hand and with tools that were themselves hand made shows the craftsmanship used to make such a unique item. Moulding Plane with metal blade attached. Made by J Hastie. Inscriptions stamped into wood. "J Hastie" "E G" "W.M" "EG" "11"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, j hastie, plane, wood working tool, hand tool -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, steel 'C' or 'G' clamp, c1900

A clamp is a fastening device to hold or secure objects tightly together to prevent movement or separation through the application of inward pressure. The tool is for temporary use for positioning components during construction and wood working. There are many types of clamps available for many different purposes. Some are temporary, as used to position components while fixing them together, others are intended to be permanent. A C-clamp or G-clamp is a type of clamp device typically used to hold a wood or metal work piece, and often used in carpentry and welding. C-clamps or G-clamps are typically made of steel or cast iron, though smaller clamps may be made of pot metal. At the top of the "C" is usually a small flat edge. At the bottom is a threaded hole through which a large threaded screw protrudes. One end of this screw contains a flat edge of similar size to the one at the top of the frame, and the other end usually a small metal bar, perpendicular to the screw itself, which is used to gain leverage when tightening the clamp. When the clamp is completely closed, the flat end of the screw is in contact with the flat end on the frame. When the clamp is actually used, it is very rare that this occurs. Generally some other object or objects will be contained between the top and bottom flat edges. A steel ‘C’ or ‘G’ Clamp used to hold a wood or metal work piece, used in carpentry and welding.L.W.BANKtools, woodwork, metalwork, welding, carpentry, pioneers, market gardeners, early settlers, bank w.l., moorabbin, cheltenham, bentleigh, ormond -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, steel vice, c1900

Perak or State of Perak one of the 13 states of Malaysia, is the second largest state in Peninsular Malaysia. It borders Kedah and the Thai Yala Province to the north; Penang to the northwest; Kelantan and Pahang to the east; Selangor to the south, and the Straits of Malacca to the west. The state's administrative capital of Ipoh was known historically for tin-mining activities until the price of the metal dropped, severely affecting the state's economy. A vice is a tool with 2 jaws between which an object is gripped, usually by tightening a screw, so as to leave the hands free for working upon it. The vice is usually firmly attached to a bench . A steel vice THE PERAK TIN MINING COMPANYtools, vice, steel , clamps, metalwork, woodwork, carpentry, early settlers, pioneers, market gardeners, moorabbin, bentleigh, cheltenham, blacksmiths, perak tin mining co. -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tool - Horse-drawn Metal Scoop Road-working

This medium sized metal, horse-drawn, road-working scoop, with timber shafts is an example of those used in Moorabbin Shire in the late 1800s, and up until the 1940s for road-works, building dams, market-gardening work and other similar earthworks in the shire. The Box Cottage museum example would have been drawn by one horse, with the worker walking and steering the horse and scoop from behind using the timber shafts. There were even bigger metal scoops that required two or more horses to drag the scoop through the soil.Following the Dendy Special Survey 1841 allotments were sold to pioneer settlers who established market gardens in the Moorabbin area. Roads and roadside dams were needed as they transported both their stock and garden produce to markets in St Kilda and Melbourne By1880 the Shire of Moorabbin was using horse-drawn, road-working shovels on the main thoroughfares of the district.A medium sized metal, horse-drawn, road-working scoop, with timber shafts. Used by Moorabbin Shire in the late 1800s, and early 1900s for road-works, and other similar work in the shiremelbourne, shovel, brighton, moorabbin, metal, gardens, roads, markets, mckinnon, cheltenham, horse drawn, scoop, dendy henry, st kilda -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Draw Knife, Prior to 1950

A draw knife or drawing knife, draw shave, shaving knife is a traditional woodworking hand tool used to shape wood by removing shavings. It consists of a blade with a handle at each end. The blade is much longer along the cutting edge than it is deep (from cutting edge to back edge). It is pulled or "drawn" toward the user. A draw knife is commonly used to remove large slices of wood for flat faceted work, to debark trees, or to create roughly rounded or cylindrical billets for further work on a lathe, or it can shave like a spokeshave plane, where finer finishing is less of concern than a rapid result. The thin blade lends itself to create complex concave or convex curves such as in making staves for barrels.A specialised tool used in many different types of wood working and in the making of barrels, this type of tool has been used for many hundreds of years by coopers and other woodworking craftsmen all around the world. It is a tool that has not changed in design during this time and is still used today by craftsmen in the making of wooden barrels for the storage of wines etc.Draw knife with metal blade and two wooden handlesNoneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, draw knife, coopers tools, woodworking tools, knife, cooperage -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Draw Knife, Prior to 1950

A draw knife or drawing knife, draw shave, shaving knife is a traditional woodworking hand tool used to shape wood by removing shavings. It consists of a blade with a handle at each end. The blade is much longer along the cutting edge than it is deep (from cutting edge to back edge). It is pulled or "drawn" toward the user. A draw knife is commonly used to remove large slices of wood for flat faceted work, to debark trees, or to create roughly rounded or cylindrical billets for further work on a lathe, or it can shave like a spokeshave plane, where finer finishing is less of concern than a rapid result. The thin blade lends itself to create complex concave or convex curves such as in making staves for barrels.A specialised tool used in many different types of wood working and in the making of barrels, this type of tool has been used for many hundreds of years by coopers and other woodworking craftsmen all around the world. It is a tool that has not changed in design during this time and is still used today by craftsmen in the making of wooden barrels for the storage of wines etc.Draw knife with metal blade and two wooden handlesMarkings on blade unreadable flagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, draw knife, coopers tools, woodworking tools, knife, cooperage -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Fid, 1940s

A Fid is a conical tapered wooden tool used for separating the strands of rope for splicing. They were a tool traditionally made of wood or bone used to work with rope and canvas in marlinespike seamanship. A Fid differs from a marlinspike in material and purposes. A marlinspike is used in working with wire rope, natural and synthetic lines also may be used to open shackles, and is made of metal. A Fid is used to hold open knots and holes in the canvas, and to separate the "lays" (or strands) of synthetic or natural rope for splicing. A variation of the Fid, the grip fid, is used for ply-split braiding. The grip fid has a jamming cleat to pull a cord back through the cord split by the fid's point. Modern Fids are typically made of aluminium, steel, or plastic. In addition to holding rope open to assist the creation of a rope splice, modern push fid's have markings for precise measurements in a variety of sizes of rope. The length of these fid’s is typically 21 or 22 times the diameter of rope to be spliced. Fids have been used since sailing vessels were first used to travel the worlds seas the tool was invented to be used to splice rope and with working with canvas sails. A Fid is a sailors tool that has maintained its general design for hundreds of years and gives a snapshot into what the working life was like for sailors on board sailing ships for hundreds of years. The tool in its original design is still in regular use today by recreational sailors all over the world to splice and join lengths of rope.Metal Fid painted half green, flattened end with a lanyard holeNoneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, marlinspike -

NMIT (Northern Melbourne Institute of TAFE)

NMIT (Northern Melbourne Institute of TAFE)Plumbing tools: CTS and PTS 1920s onwards, Plumbing tools and texts used in teaching 1920s

A number of Plumbing tools dating from 1880s-1970s and used in teaching at Collingwood Technical School then also at Preston Technical School and at Northern Metropolitan College of TAFE's Heidelberg campus. Includes: Kerosene blow torch X 2 (1930s-); Stillson Grips; Pipe Cutter; Mash hammer; Adjustable spanner X 3 different sizes; Caulking tool; 5 way tee, 2X3 way tee, 4 way tee (1930s-); Old Handmade lead traps (student work) X 2; Metal tool tray holding; Offset adjustable spud spanner; Pear shaped lead working mallet; Bossing tool for lead work (1880s-1920s); Soldering iron (1920s-); Set square; Large screwdriver; Also Plumbing texts: • Problems for elementary physics, new rev. edn., by Thomas Tasker and Alexander Boden, Science Press, Sydney, 1966. • Gasfitting. Printed and published by McCarron Bird Pty. Ltd. [Melbourne] • Trade science for plumbing apprentices, Education Dept. Victoria, 1954 • Sanitary Plumbing and water supply, Dept. of Labour • Gasfitting, produced by members of the Colonial Gas Association Limited, Gas and Fuel Corporation of Victoria, and the Technical Division of the Education Department of Victoria. Rev metric edn. 1976 • Mechanical world year book 1953, Manchester Emmott & Co., 1953 collingwood technical school, preston technical school, northern metropolitan college of tafe, plumbing tools, plumbing texts, nmit -

Puffing Billy Railway

Puffing Billy RailwayTool - Industrial Forge, unknown

Industrial Forge from Newport Railway WorkshopsIndustrial Forge is an excellent example of equipment used in the early 19th century through to the mid 20th century for industrial iron working. It directly links a fabrication method that is widely used across several of the other collection pieces.Large Industrial Forge made of cast metal and wrought ironNo markings or inscriptions puffing billy, industrial forge -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumPlane - Wooden, 1940's

Made by internee at Camp 3 Tatura. Used there as a wood working handtoolHandmade varnished, polished wooden plane with curved, turned handle. Metal washers support centre metal barHaeringplane, wood, haering, m, camp 3, tatura, ww2 camp 3, trades, tools -

Rutherglen Historical Society

Rutherglen Historical SocietyPunches

Used for leather work1 of 2 wooden punches - pear shaped wooden handles with metal points at one endleather working, hand tools -

Rutherglen Historical Society

Rutherglen Historical SocietyPunches

Used for leather work2 of 2 wooden punches - pear shaped wooden handles with metal points at one endleather working, hand tools -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumTool - Wood Plane, 1940's

Made by internees at camp 3, using wood sourced from under the barracks ie : stumps. Wood Plane, for wood working. Has a handle at the front for pushing it through wood. Also has metal blade kazenwadel, blacksmith, wood, tools camp 3, metal, woodworking -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumTool - Wood Plane, 1940's

Made by internees at camp 3, using wood sourced from under the barracks ie : stumps. Wood Plane, for wood working. Has a handle at the front for pushing it through wood. Also has metal blade kazenwadel, blacksmith, wood, tools camp 3, metal, woodworking -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumTool - Chisel, 1940's

... kazenwadel blacksmith wood tools camp 3 metal wood working Metal ...Made by internees at camp 3, using wood sourced from under the barracks ie : stumps. Used for wood workingMetal chisel on a wooden handle, with a metal ferrule at each end of the handle. kazenwadel, blacksmith, wood, tools camp 3, metal, wood working -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumTool - Chisel Small, 1940's

Made by internees at camp 3, using wood sourced from under the barracks ie : stumps. Used for wood workingChisel with small thin blade, wood shaped handle with metal ferrule at each end of handlekazenwadel, blacksmith, wood, tools camp 3, chisels -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumTool - Chisel Medium, 1940's

Made by internees at camp 3, using wood sourced from under the barracks ie : stumps. Used for wood workingChisel, wood shaped handle with metal ferrule at blade end end of handle, partly covered with cream paintkazenwadel, blacksmith, wood, tools camp 3, chisels -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumTool - Metal Wedge, 1940's

Made by internees at camp 3, using wood sourced from under the barracks ie : stumps. Used for wood workingMetal Wedge long and tapered at one end, worn and flattened at top end ( maybe from being struck with a hammer )kazenwadel, blacksmith, wood, tools camp 3, chisels, mallets -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumTool - Metal Wedge, 1940's

Made by internees at camp 3, using wood sourced from under the barracks ie : stumps. Used for wood workingMetal Wedge long and tapered at one end, worn and flattened at top end ( maybe from being struck with a hammer )kazenwadel, blacksmith, wood, tools camp 3, chisels, mallets -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumTool - Awl, 1940's

Made by internees at camp 3, using wood sourced from under the barracks ie : stumps. Used for wood workingAwl and wooden handle with metal ferrule at end, thin metal shaft , slightly bent coming to a sharp point. Spare handle in a light wood with a brass ferrule.kazenwadel, blacksmith, wood, tools camp 3, chisels, mallets -

Bendigo Historical Society Inc.

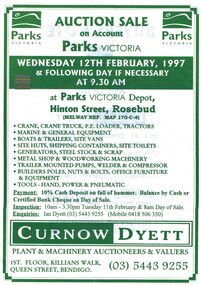

Bendigo Historical Society Inc.Document - IAN DYETT COLLECTION: AUCTION CATALOGUE - PARKS VICTORIA

White paper catalogue with green printing for a sale on account of Parks Victoria, on 12th February 1997 at Rosebud. For sale were vehicles, marine equipment, boats & trailers, metal and wood working machinery, steel and scrap, office furniture and equipment and various tools. Announcement printed in the front of catalogue mentions that J. H. Curnow & Son Pty. Ltd. Are combining their name with the Dyett family and trading as Curnow Dyett, Real Estate Agents, Auctioneers and Qualified Valuers.business, auctioneers, curnow dyett, ian dyett collection - auction catalogue - parks victoria, ian dyett, curnow dyett, j h curnow & son pty ltd, occupational health and safety act 1985, noel dyett, ian dyett, fred dyett -

![Timber maritime tool, 910mm in length and conical in shape tapering from its widest end [125mm] to its narrowest end [25mm].](/media/collectors/4f729f7e97f83e03086018d1/items/5f2e4a0746c3ab0984220566/item-media/61a1cbdf6c0d635f5cfe6cb6/item-fit-380x285.jpg) Queenscliffe Maritime Museum

Queenscliffe Maritime MuseumFunctional object - A large timber fid, 20 March 2018

A fid is a conical tool traditionally made of wood or bone. It is used to work with rope and canvas.Fids where traditionally used for working with rope and/or sails on sailing ships. They are still in use today for working with rope.Large timber fid with a metal ring attached to wide end for strength used for splicing rope or cable.fid, sail making, rope splicing -

Maldon Vintage Machinery Museum Inc

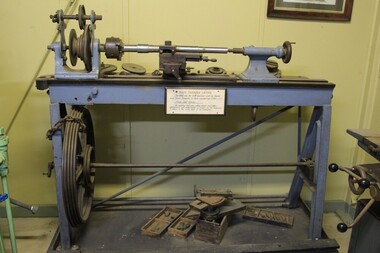

Maldon Vintage Machinery Museum IncTreadle Lathe, Post 1875

The first metal working machine used by David & James Thompson in 1878. Brought by ship by David Thompson who used it on the journey to make working models.The first machine used by David & James Thompson in their engineering section.Treadle lath for metal turning. Some brass accessories for metal working are laid out on a timber bench attached to the back of the lathe. Painted gunmetal grey and mounted on a black wooden platform for display purposes.Nonemachinery; tools; metalwork -

National Wool Museum

National Wool MuseumTool - Uster Calculator and Instructions, Zellweger Ltd

Part of a collection of books, manuals, photographs, letters and clothing relating to the working life of Stuart Ascough. Stuart's career in the wool industry spanned over 43 years from 1960 to 2003 in various roles including Topmaking Plant Manager at Courtaulds Ltd. in Spennymore, U.K., Operations Manager at Port Phillip Mills in Williamstown Victoria, Marketing Executive, Early Stage Wool Processing at the International Wool Secretariat Melbourne, Australia and General Manager of Victoria Wool Processors Pty. Ltd. in Laverton North, Victoria. Throughout his career Stuart travelled extensively, and in the 1990s worked at many topmaking mills in China on quality improvement projects. He also provided technical advice and training at mills in India, Ukraine, Lithuania, Kyrgyzstan, Russia, Latvia, Byelorussia and other parts of Europe and Asia.8347.1 Blue, yellow, white and teal circular metal calculator with four independently movable discs and black numbered measurements. 8347.2 Green booklet containing working instructions for the Uster Calculator 8347.3 Laminated comparison chart of wool finenessstuart ascough, international wool secretariat, victoria wool processors, port phillip mills pty ltd, topmaking, career, wool industry, training, technical advice, mills -

Parks Victoria - Wilsons Promontory Lightstation

Parks Victoria - Wilsons Promontory LightstationAnvil

As quoted from Wikipedia, ‘An anvil is a block with a hard surface on which another object is, struck. The block is as massive as it is practical, because the higher the inertia of the anvil, the more efficiently it causes the energy of the striking tool to be transferred to the work piece’. The lightstation’s anvil is a red-painted iron block with a conical beak or horn at one end that was used for hammering curved pieces of metal. It would have stood on a heavy free-standing pedestal, such as a large tree stump, to allow complete access to the item being hammered. Some anvils display the manufacturer’s name in the metal on the side, but this is not the case here, and its age, although unknown appears to be quite old, perhaps c.1900. It appears to have had a lot of use, and although no record of this survives, it is presumed that a forge operated on site for hammering, cutting, shaping and repairing tools such as bolts, nails, hooks, chain segments, pulley blocks, hinges, crow bars, picks, chisels, horseshoes and harness hardware. A hames hook (which forms part of the collar worn by a draught horse) survives at the lightstation as do many other heavy metal tools and pieces of equipment. The anvil is an example of the necessary resourcefulness and self sufficiency practiced by lightkeepers working and living in a remotely located workplace and home, and many of the iron items in the collection may have been repaired or even made on its working surface. As a lightstation manager Chris Richter used the anvil to manufacture pulley blocks for sash windows, repair brass door hinges & sharpen cold chisels, crowbars and picks and other lightkeepers have used this anvil for many fabricating jobs such as manufacturing ducting for the generator room ventilation system."The lightship only came in every three months with supplies and there would have been repairs to do between visits from a blacksmith - who would have had to travel on the ship. Also, the ship was only anchored in the bay long enough to unload supplies and collect and deliver lightkeeping staff – probably not enough time to get much smithy work done – especially if the weather packed it in and the ship had to depart. Lightkeepers in our time had to be self sufficient, resourceful and innovative and I imagine that would have been the case in the past." It has second level contributory significance.Red painted blacksmith's anvil. -

Mont De Lancey

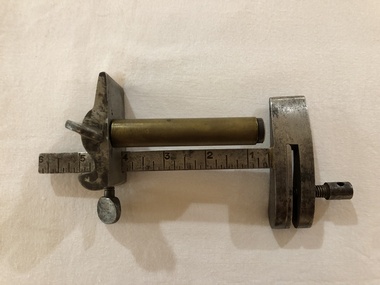

Mont De LanceyGauge

Metal gauge for working and cutting leather.Inch measurements, up to 6 inches.leatherworking tools, gauges -

Buninyong Visitor Information Centre

Buninyong Visitor Information CentreTool - Cold Chisel, 1890s Cold Chisel

... Short, heavy metal tool with fan-shaped working end.... Buninyong goldfields Metalwork Chisels Tools Short, heavy metal tool ...Short, heavy metal tool with fan-shaped working end.metalwork, chisels, tools -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Bellows, 1862-1875

This bellows was used at the Warrnambool Racecourse by Master Farrier, Brian Chapman (1931-2017), during the 1970s but its history before then is still being investigated. The bellows have continued to be used from 1978 at Flagstaff Hill's blacksmith's workshop. Even today, in 2021, this same bellows are used by a volunteer blacksmith as he demonstrate the skills and tells of the importance of the blacksmith trade to colonial Australia. This 1860s double-action bellows is a typical form of blacksmith's or shipsmith's bellows. The end is forge-fitted with an iron nozzle or tube, called a tuyere or Tue iron, which concentrates the air to fan the fire or furnace. Tuyeres were traditionally made of cow horn. The double-action design of this bellows efficiently moves air both in and out of the chambers in the one movement of the long handle. The bellows was manufactured by John C. Onions of Birmingham, England, between 1862 and 1875. The stamp with the text, Gold Medal 1862, was also used on the business’ advertising. In 1875 the company was registered and began using the name John C. Onions Limited. JOHN C. ONIONS - John C. (Collingwood) Onions (1841-1904) was the son of a bellows maker of the same name. Onions (born 1841) and his wife Helen married in 1867 and they named one of their children John Collingwood Onions (1868-1913), as was the family tradition. He was well known as a Birmingham manufacturer of patented bellows and other forge-related equipment. He sold to the wholesale and retail markets for both local and overseas customers, including the British colonies. An 1862 advertisement points out that John C. Onions was a “Bellows manufacturer and contractor to Her Majesty’s Honourable Board of Ordinance” and His Imperial Majesty the Emperor of the French [Napoleon Bonaparte]”. The advertisement includes a sketched portrait of the Emperor Napoleon III, and an Imperial Autograph Letter dated May 23, 1854, from Napoleon, Palace of the Tulleries to Mr J C Onions of Bradford Street, Birmingham. In 1863 the company registered a patent on portable forges. In 1871 there were eight employees. John C. Onions Limited became a registered company in 1875. In 1876 an advertisements included that the company were smiths for hearths and tools in general and showed a row of six medallions including one with “Napoleon III, Emperor” and his portrait, and another “ _ _ _ 1862 MEDAL”. Their advertising motto was “For Excellence of Quality”. In 1885 the company merged with William Allday and Sons to become Allday and Onions. This mid-19th century bellows has local historical significance as it were once used by blacksmiths at the Warrnambool Racecourse in the annual racing event that continues today. This bellows is significant as a working example of equipment used in the 1800 and 1900s in the trace of blacksmiths and other metal working smiths. The bellows is technologically significant as it shows the progress from simple bellows to the double-action bellows, a time saving and efficient improvement. The manufacturer John C. Onions is historically significant as a family business that began in the 1600s and continued up until the 1980s.Bellows; large, oval, mechanical double-action smith’s bellows, manually operated, in working condition. The paddles of wood that form the top, middle sections and base of the bellows have flexible leather pieces attached firmly between them, forming airtight double lungs. Cut-outs in the panels allow the bellows to fill with air then force it out. A long handle is connected to pump the bellows and control the quantity and force of the air. The blasts of air are forced through the metal nozzle or tuyere at the end of the bellows and into the forge’s fire. Inscriptions are impressed into the wood on the upper paddle or board of the bellows. There are three circular stamps containing text. Text impressed in the wooden upper paddle of the bellows has been assumed to read “JOHN C. ONIONS, PATENTEES & MANUFACTURERS, BIRMINGHAM””?” “EXTRA” “AWARDED FOR EXCELLENCE OF QUALITY”, made from the following readable text :- “JOHN C ONIONS“ “PATENT - - - & MAN - - - - - - - - -“, “BIR - - - - HAM“, “ _ ERA - - - - “- XTRA-“, “- - - - - - - FOR EXCELL-“ “OF - - - - ITY” Text in the stamp “ - - ECE - - “, “ - - - - - / 1862 / MEDAL”, “- ITY” flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, john collingwood onions, john c onions, allday and onions, bellows, smith’s bellows, 19th century bellows, double-action bellows, double-acting bellows, double lung bellows, double chamber bellows, blacksmith tools, blacksmith trade, blacksmith craft, blacksmith equipment, forging equipment, john c onions patented double-action bellows, brian chapman, warrnambool racecourse, blacksmith, shipsmith, iron smith, mechanical bellows -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Hook, Mid-20th century

A cast iron hook was made for lifting heavy loads in a marine or warehouse environment. The hook would be attached to the end of a chain or rope around a heavy load such as a pallet or container. The other end may have been joined to a pulley or crane for lifting and moving it around. The inscription on the hook shows the SWL or Safe Working Load as 3 Ton. The SWL was used in the industry for many years to rate safe loads but it is no longer used to identify the maximum capacity of equipment. In 2002 the Australian Standard AS 1418 for Cranes, Hoists and Winches changed, and the term Safe Work Load was changed to Rated Capacity, which was defined differently.The hook represents the equipment needed on a ship or at a port, railyard, transport depot or warehouse in the 19th and 20th centuries to move cargo and loads. The inscription of SWL on the hook is significant for its use as a guide for many years to work out the weight of the load the hook could safely hold. However, time and experience have led to a change in Australian Standards and the load is now measured by another formula that gives the load's Rated Capacity.Hook; large iron hook with a ring formed in the top. Inscription stamped into the metal and indicates that the Safe Working Load (SWL) for the hook to lift is 3 Ton.Marked "ani" "SWL 3TON"warrnambool, shipwreck coast, flagstaff hill, flagstaff hill maritime museum, flagstaff hill maritime village, lifting hook, maritime equipment, lifting equipment, warehousing, cargo, loads, rigging, marine technology, swl, safe working load, 3 ton, rated capacity, load limit