Showing 50 items matching "test tube"

-

Royal Australian and New Zealand College of Obstetricians & Gynaecologists (RANZCOG)

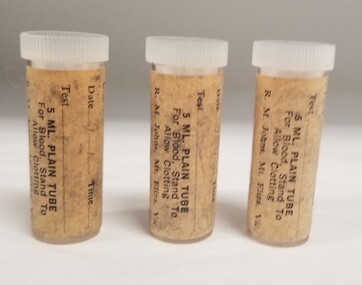

Royal Australian and New Zealand College of Obstetricians & Gynaecologists (RANZCOG)Equipment - Group of 5ml plastic medical collection tubes

... attached to each of the tubes reads 'P2/Name/Date/Time/Test/5 ML... attached to each of the tubes reads 'P2/Name/Date/Time/Test/5 ML ...Used to collect medical samples, including blood.Three plastic medical collection tubes, with caps. Labels attached to each of the tubes reads 'P2/Name/Date/Time/Test/5 ML PLAIN TUBE/For Blood, Stand To/Allow Clotting/ R.M. Johns, Mt. Eliza, Vic.'pathology -

Federation University Art Collection

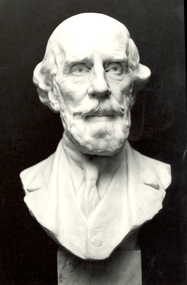

Federation University Art CollectionSculpture - Marble sculpture, 'Professor Alfred Mica Smith' by Paul Montford, 1924

... eyes. He then took a test tube and added a little colourless... and a white bead appeared in front of my eyes. He then took a test ...Paul Raphael MONTFORD (1868 - 1938) Paul Montford moved to Australia to carve four buttress groups in granite for the Melbourne Shrine of Remembrance. In 1924 he was teaching at Geelong Technical College. Professor Alfred Mica Smith was a long term lecturer at the Ballarat School of Mines. The sculpture was commissioned by former Students of the Ballarat School of Mines working in Western Australia. One of those former students, William Corbould, remembered his first encounter with the professor fondly:- 'From the Registrar's Office I was led to be introduced to the Professor of Chemistry, one Mica Smith. The initial encounter gave me little encouragement - his large laboratory was filled with hundreds of bottles bearing strange labels with queer symbols on them. My heart sank. At the first opportunity I grabbed my hat and made for the door, but the good professor called me back. I pointed out that I was never any good at school ... so it was no use pretending to be clever enough to understand all those weird symbols! The Professor told me not to worry about that and took me to one of the benches where he found a blowpipe and a charcoal block. Mixing together two powders from bottles on the shelf he transferred a sample to the charcoal and directed the bunsen flame onto it. Soon it began to melt and a white bead appeared in front of my eyes. He then took a test tube and added a little colourless liquid from each of two bottles. A beautiful dark blue colour appeared. My interest was won.' Alfred Mica Smith was the well-loved Professor of Chemistry and Metallurgy at the Ballarat School of Mines between 1881 and 1922. Upon reaching the age of 78 Mica Smith retired having influenced generations of miners. At the time of his death Ballarat School of Mines Students’ Magazine reported: "In the annals of the School, the year 1922 will be noted chiefly as the last year in which Professor Mica Smith taught here. With his retirement, a memorable epoch closed. The Professor has served the School for 42 years with a service, the length and thoroughness of which are unique. … It is not quite realised in this city how famous the School became throughout the world, nor to what extent the Professor was responsible for its high position in the mining and metallurgical world. … This item is part of the Federation University Art Collection. The Art Collection features over 2000 works and was listed as a 'Ballarat Treasure' in 2007.Marble bust of Ballarat School of Mines Professor Alfred Mica Smith by Paul Montford. The bust is mounted on a jarrah pedestal made from timber donated by the Millar Timber and Trading Company. The bust was formally presented to the Ballarat School of Mines on Saturday 13 December1924 in front of Alfred Mica Smith and a large gathering. It is signed 'Paul R. Montford, Sc, 1924' at the back.Professor A. Mica Smith, 1924, Presented by His Old Students Associated with Western Australia as a Token of Affectionate Esteemart, artwork, ballarat school of mines, montford, paul montford, alfred mica smith, mica smith, marble, bust, sculpture -

Federation University Historical Collection

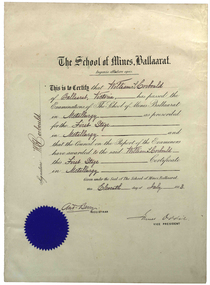

Federation University Historical CollectionCertificate, Ballarat School of Mines, William Corbould's Ballarat School of Mines Metallurgy Certificate, 11/07/1883

... eyes. He then took a test tube and added a little colourless... eyes. He then took a test tube and added a little colourless ...William Corbould was the son of a Ballarat tailor. He attended Ballarat College, and obtained certificates in assaying and metallurgy at the Ballarat School of Mines (SMB) in 1883, studying under the revered Professor Mica Smith. Corbould was not a born student and remembered his first experience at SMB: 'From the Registrar's Office I was led to be introduced to the Professor of Chemistry, one Mica Smith. The initial encounter gave me little encouragement - his large laboratory was filled with hundreds of bottles bearing strange labels with queer symbols on them. My heart sank. At the first opportunity I grabbed my hat and made for the door, but the good professor called me back. I pointed out that I was never any good at school ... so it was no use pretending to be clever enough to understand all those weird symbols! The Professor told me not to worry about that and took me to one of the benches where he found a blowpipe and a charcoal block. Mixing together two powders from bottles on the shelf he transferred a sample to the charcoal and directed the bunsen flame onto it. Soon it began to melt and a white bead appeared in front of my eyes. He then took a test tube and added a little colourless liquid from each of two bottles. A beautiful dark blue colour appeared. My interest was won.' During Corbould's mining career he travelled to Europe twice, and visited most of Australia's main mining fields. Corbould started his career as an assayer at Pinnacle Silver Mine, Silverton, and was then a self-employed assayer at Broken Hill. Corbould became an assayer for the infant BHP mine, and later worked in Kalgoorlie and Coolgardie, including managing Hannan's Reward, the oldest gold mine on the Kalgoorlie gold field. He spent 13 years at the Mount Elliott copper fields as general manager. In 1923, at the age of 57, Corbould went to Mount Isa and reported on options, experimented with new metallurgical processes and floated a company. John Carden of CRA said: 'Corbould was the man who brought Urquhart to Mount Isa. He was the man who made it all possible. He is tremendously important in the Mount Isa story, because he was the first technical man, the first professional man on the scene. He was responsible as I said, for bringing finance to the place, but I think even more importantly he was the first man to recognise the need to put all the little claims in the Mount Isa discovery together. I think perhaps his major contribution to Mount Isa was this amalgamation on the various claims. He recognised that the ore bodies at Mount Isa were not as rich as Broken Hill and they would never have survived had it been fragmented, so he was terribly important.' After completing major financial negotiations for Mt Isa Mine from London in 1927 Corbould remained in Europe where he remained until his death. Corbould was awarded the Legion of Honour of the American Institute of Mining and Metallurigical Engineers for fifty years service. Corbould died at Monaco in 1949 at the age of 82. (http://guerin.ballarat.edu.au/curator/honour-roll/honourroll_Corbould,William.shtml)A white paper certificate with black printed and handwritten text, and a blue Ballarat School of Mines seal. The certificate is signed by Andrew Berry (Registrar) and James Oddie (Vice-President).Signed on the left 'W.H. Corbould'mining, ballarat school of mines, mining alumni, metallurgy, james oddie, andrew berry, william corbould, corbould, berry, oddie -

Federation University Historical Collection

Federation University Historical CollectionPhotograph, Ballarat School of Mines Corbould Building

... appeared in front of my eyes. He then took a test tube and added... eyes. He then took a test tube and added a little colourless ...Corbould Hall was named after Ballarat School of Mines alumni WIlliam Corbould. William Corbould was the son of a Ballarat tailor. He attended Ballarat College, and obtained certificates in assaying and metallurgy at the Ballarat School of Mines (SMB) in 1883, studying under the revered Professor Mica Smith. Corbould was not a born student and remembered his first experience at SMB: 'From the Registrar's Office I was led to be introduced to the Professor of Chemistry, one Mica Smith. The initial encounter gave me little encouragement - his large laboratory was filled with hundreds of bottles bearing strange labels with queer symbols on them. My heart sank. At the first opportunity I grabbed my hat and made for the door, but the good professor called me back. I pointed out that I was never any good at school ... so it was no use pretending to be clever enough to understand all those weird symbols! The Professor told me not to worry about that and took me to one of the benches where he found a blowpipe and a charcoal block. Mixing together two powders from bottles on the shelf he transferred a sample to the charcoal and directed the bunsen flame onto it. Soon it began to melt and a white bead appeared in front of my eyes. He then took a test tube and added a little colourless liquid from each of two bottles. A beautiful dark blue colour appeared. My interest was won.' During Corbould's mining career he travelled to Europe twice, and visited most of Australia's main mining fields. Corbould started his career as an assayer at Pinnacle Silver Mine, Silverton, and was then a self-employed assayer at Broken Hill. Corbould became an assayer for the infant BHP mine, and later worked in Kalgoorlie and Coolgardie, including managing Hannan's Reward, the oldest gold mine on the Kalgoorlie gold field. He spent 13 years at the Mount Elliott copper fields as general manager. In 1923, at the age of 57, Corbould went to Mount Isa and reported on options, experimented with new metallurgical processes and floated a company. John Carden of CRA said: 'Corbould was the man who brought Urquhart to Mount Isa. He was the man who made it all possible. He is tremendously important in the Mount Isa story, because he was the first technical man, the first professional man on the scene. He was responsible as I said, for bringing finance to the place, but I think even more importantly he was the first man to recognise the need to put all the little claims in the Mount Isa discovery together. I think perhaps his major contribution to Mount Isa was this amalgamation on the various claims. He recognised that the ore bodies at Mount Isa were not as rich as Broken Hill and they would never have survived had it been fragmented, so he was terribly important.' After completing major financial negotiations for Mt Isa Mine from London in 1927 Corbould remained in Europe where he remained until his death. Corbould was awarded the Legion of Honour of the American Institute of Mining and Metallurigical Engineers for fifty years service. Corbould died at Monaco in 1949 at the age of 82. He bequested 6000 pounds to the Ballarat School of Mines, his will stating 'for the purpose of founding a scholarship to commemorate the memory of the late Alfred Mica Smith'. The accumulated income from this sum provides the Mica Smith travelling scholarship, enabling successful students in mining, metallurgy or chemistry to undertake a year's travelling abroad. The first award was made in 1957. In the same year a general purpose hall at SMB was named the Corbould Hall as a tribute to a distinguished former student and generous benefactor.ballarat school of mines corbould building, corbould hall, corbould building -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyMilk and Cream Fat Tester Centrifuge

In 1890 D. Babcock invented a test for measuring the amount of butter fat in milk, either on the farm or in the dairy or creamery. Samples of milk were put in the glass vial and then spun (by cranking the handle) causing the cream to separate from the non-fat milk thus determining the percentage of cream in the milk. The product was then priced accordingly.Dairy farming in the Kiewa Valley was the main industry with farmers keen to test the quality of their milk before selling it. This centrifuge enabled them to test the amount of milk and cream being produced by their herd. This '1903 Butter Fat Tester' made 100 turns per minute. Early hand crank centrifuge for measuring the butterfat content of milk in the farm dairy or creamery. It has 4 brass / copper removable canisters with glass vials and tubes that fit inside. The glass vials bulge at the bottom and are marked with measurements 1, 2 etc.Numbers on the glass vialsmilk and cream tester, dairy farming, centrifuge -

Orbost & District Historical Society

Orbost & District Historical Societythermometer, c. 1950s-1980s

Used at Orbost Hospital where it was used for testing the temperature of bath water. It was donated to Orbost Historical Society in 1991. This is a floating bath thermometer made in Germany for the British market.This item is associated with Orbost Hospital and is an example of an early medical instrument.A glass tubed thermometer in a wooden case with temperatures for bath water written on it. Has a red "Orbost" label glued to it indicating that it was used at Orbost Hospital. The thermometer is housed inside a wooden frame that is stoppered with a cork at the base. It is in degrees Fahrenheit and includes water and spirit boiling temperatures, as well as hot, warm, tepid and freezing points. Can be hung.Made in Germany. Dr Forbes specifications.thermometer-medical -

Federation University Historical Collection

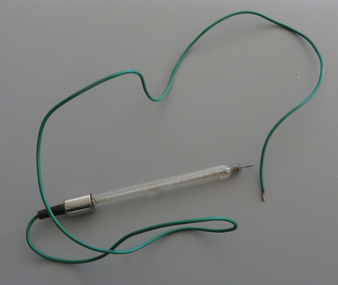

Federation University Historical CollectionScientific Instrument

... laboratory testing graham hood Glass tube attached capped with metal ...Glass tube attached capped with metal and with a green plastic coated copper wire attached to conduct electricity. The other end of the tube narrows and has a metal 'prod' attached. The tube as a nother tube inside it which includes a spring made of fine wire. A small amount of thick liquid is present between both tubes.laboratory, testing, graham hood -

Royal Australian and New Zealand College of Obstetricians & Gynaecologists (RANZCOG)

Royal Australian and New Zealand College of Obstetricians & Gynaecologists (RANZCOG)Rubin's tubal insufflator apparatus associated with St Vincent's Hospital, c1919

"Potential blockage in the Fallopian tubes was assessed using this apparatus. It was developed by American gynaecologist Isidor Clinton Rubin (1883-1958). It blows carbon dioxide, via a cannula, into the uterus. The ease with which gas escaped through the Fallopian tubes was reflected by pressure changes on an instrument called a manometer. Blockage of the tubes is often due to previous infection or surgery. It is a common cause of infertility. Rubin’s test formed a standard part of infertility investigations for many years. It was gradually replaced by an X-ray technique involving radio-opaque ‘dye’ injected into the uterus." Source: Science Museum Group. Rubin’s apparatus for uterotubal insufflation, New York, United States, 1928. A639503Science Museum Group Collection Online. Accessed 12 June 2024. https://collection.sciencemuseumgroup.org.uk/objects/co96774/rubins-apparatus-for-uterotubal-insufflation-new-york-united-states-1928-tubal-insufflator. There is no manometer to monitor gas pressure on this model so it is either incomplete or a manometer was not available in this possibly early model. This device may be dated c1919, 1920s, or 1930s. 1919 was the year Isidor Clinton Rubin (1883-1958) introduced this apparatus. Rubin's tubal insufflator apparatus. Consists of a large cylindrical glass canister, with three glass nozzles at top with long rubber tubing attached to each. The device is inside a portable plywood box with two door. One surgical steel introducer, and one glass introducer, are also attached to the device. -

Australian Gliding Museum

Australian Gliding MuseumMachine - Glider – Sailplane, March 1964

The Schleicher K7 is a high wing tandem two-seat sailplane designed in the late 1950s by Rudolf Kaiser for the Alexander Schleicher company in Germany. The fuselage is built using steel tube framing covered with fabric. The swept-forward cantilever wing is of wood and fabric construction with a single spar and a plywood covered leading edge “D” box for strength. The wing is equipped with Schempp-Hirth airbrakes. The K7 first flew in 1959. It is a versatile design that can be used for both basic and more advanced training of pilots. Over 500 were built. VH-GNX was manufactured in Germany and imported into Australia by Edmund Schneider Limited. It was test flown by them at Parafield Aerodrome, Adelaide, South Australia in March 1964. The original owner of VH-GNX was the Adelaide Soaring Club and it was maintained by Edmund Schneider Limited until May 1971. It appears that about this time it was transferred to the Gold Coast Soaring Club. In July 1974, after it had flown for an aggregate 3075 hours from 13919 flights, it was purchased by the Bundaberg Soaring Club. About 10 years later, it was acquired by the Bendigo Gliding Club. At that stage it had recorded over 4600 hours flying time from 21546 launches. When it was retired from service by the Bendigo Gliding Club in June 2006 due to age related defects the hours flown had reached 7259 from 31820 flights. It appears that the airframe has had a relatively trouble free life with only minor damage from storage / ground handling incidents, a heavy landing (January 1987) and a bird strike (January 2002). It was donated to the Museum in April 2007.This exhibit is an example of the Schleicher K7 two seat sailplane type.Two seat high wing glider sailplane finished in white with red detailing.Serial Number 7134, registered as VH-GNX. The registration appears on each side of the Fin / Rudder in red letteringaustralian gliding, glider, sailplane, schleicher, k7, schneider, adelaide soaring club, gold coast soaring club, bundaberg soaring club, bendigo gliding club -

Royal Australian and New Zealand College of Obstetricians & Gynaecologists (RANZCOG)

Royal Australian and New Zealand College of Obstetricians & Gynaecologists (RANZCOG)Tubal insufflator associated with Dr Lorna Lloyd-Green, c1919

"Potential blockage in the Fallopian tubes was assessed using this apparatus. It was developed by American gynaecologist Isidor Clinton Rubin (1883-1958). It blows carbon dioxide, via a cannula, into the uterus. The ease with which gas escaped through the Fallopian tubes was reflected by pressure changes on an instrument called a manometer. Blockage of the tubes is often due to previous infection or surgery. It is a common cause of infertility. Rubin’s test formed a standard part of infertility investigations for many years. It was gradually replaced by an X-ray technique involving radio-opaque ‘dye’ injected into the uterus." Source: Science Museum Group. Rubin’s apparatus for uterotubal insufflation, New York, United States, 1928. A639503Science Museum Group Collection Online. Accessed 12 June 2024. https://collection.sciencemuseumgroup.org.uk/objects/co96774/rubins-apparatus-for-uterotubal-insufflation-new-york-united-states-1928-tubal-insufflator. Model may be dated c1919 or 1920s or 1930s. 1919 was the year Isidor Clinton Rubin (1883-1958) introduced the apparatus. Instrumant has a label with Cyrus Jones monogram " Donated by Dr Lorna Lloyd Green, 1986/ Rubin's Insufflator/ NB "sparklet holder separate" missing?Rubin's tubal insufflator apparatus, large cylidrical glass canister inside a portable carry box with two doors with three glass nozzels at top with long rubber tubing attached on each. One surigical steel introducer, one glass introducer attached. A blood pressure manometer is fixed on the inside door. infertility -

Royal Australian and New Zealand College of Obstetricians & Gynaecologists (RANZCOG)

Royal Australian and New Zealand College of Obstetricians & Gynaecologists (RANZCOG)Cannula, Spackman's, c1969

Part of the laparoscopy equipment donated by Dr Geoff Bishop. Dr Geoffrey Bishop, whilst at the Department of O and G, University of Liverpool, UK, began laparoscopy in 1969. On returning to Australia, Bishop and Grimwade together with Mr Peter Paterson introduced gynaecological laparoscopy to Melbourne, practising at the Queen Victoria Memorial Hospital (QVMH), Melbourne in 1969. The College, through the Victorian State Committee of the Australian Council, RCOG, ran training courses in laparoscopy for local and interstate gynaecologists. These were conducted by Bishop, Grimwade and Paterson. They established protocols, with particular reference to safety, for the conduct of laparoscopy. Laparoscopy was used initially for diagnosis and for limited treatment using diathermy for conditions such as endometriosis. The real impetus came with the great upsurge of tubal sterilization in the early 1970s. Early techniques included diathermy and division of the Fallopian tubes using the Palmer forceps. [Dr Peter Renou, former honoury curator.]This Spackman's cannula was used by Dr Geoff Bishop during gynaecological laparscopioc surgery.He used this decice as a uterine elevator. Also, for testing tubal patency by inserting dye through it. Manufacturers stamp: ANAX.laparoscopy, tubal ligation, infertility investigation -

Royal Australian and New Zealand College of Obstetricians & Gynaecologists (RANZCOG)

Royal Australian and New Zealand College of Obstetricians & Gynaecologists (RANZCOG)Cannula, infertility, c1969

Part of the laparoscopy equipment donated by Dr Geoff Bishop. Dr Geoffrey Bishop, whilst at the Department of O and G, University of Liverpool, UK, began laparoscopy in 1969. On returning to Australia, Bishop and Grimwade together with Mr Peter Paterson introduced gynaecological laparoscopy to Melbourne, practising at the Queen Victoria Memorial Hospital (QVMH), Melbourne in 1969. The College, through the Victorian State Committee of the Australian Council, RCOG, ran training courses in laparoscopy for local and interstate gynaecologists. These were conducted by Bishop, Grimwade and Paterson. They established protocols, with particular reference to safety, for the conduct of laparoscopy. Laparoscopy was used initially for diagnosis and for limited treatment using diathermy for conditions such as endometriosis. The real impetus came with the great upsurge of tubal sterilization in the early 1970s. Early techniques included diathermy and division of the Fallopian tubes using the Palmer forceps. [Dr Peter Renou, former honoury curator.]This cannula has two points for tubal attachments at one end. At yhe other end, a bell cap with a nossel.This was used by Dr Geoff Bishop during gynaecological laparscopioc surgery. This instrument is commonly used for suction. Also, for testing tubal patency by inserting dye through it. Manufacturers stamp: PRECIOUS.laparoscopy, tubal ligation, infertility investigation -

Moorabbin Air Museum

Moorabbin Air MuseumManual (item) - RAAF School Of Technical Training, Testing and Calibration of Bourdon Tube Pressure Gauges

RAAF Technical Training -

Ballarat Base Hospital Trained Nurses League

Ballarat Base Hospital Trained Nurses LeagueGlass Test Tubes - Small

... Street Nth Ballarat goldfields Glass Test Tubes - Small Glass ...glass test tubes - small -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Milk testing apparatus

Bought by Mrs Tate, mother of the donor in the 1920's and used by her.Fine glass tube inserted with larger coloured tube. On the finer tube indicators for milk, water and (between the two) degrees of adulteration. Accompanying, a printed sheet ('A Novelty Tester') giving instructions on how to determine whether milk is adulterated. The kit housed in a cardboard box on which drawings of tester in applicationdomestic items, food preparation -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Equipment - Natural Gas Conversion Testing Kit

All items belonged to Harold Victor Allen who worked for Colonial Gas Association Ltd. Firstly at Footscray and then Box Hill in the 1960's. Retired in 1971. Born in Ballarat in 1906. Apprenticed and worked there till 1945, then moved to Footscray. Eileen, his wife, worked with Harold, helping with the Natural Gas Conversion during Harold's Box Hill time.Change over in Victoria from Gas fired gas supply to Natural Gas supply to Victoria from about 1965 -1. Gas testing kit in green metal box, with silver handle and clasp (silver colour)|2. Suction ball and pump body.|3. Detector tubes of glass capillary. 4. Instruction Manual. 5. Sealing cap ( box of 10) All spare parts |6. Natural Gas Conversion Badge.H.V.Allen MSAgas technology, appliances & accessories -

Ballarat Tramway Museum

Ballarat Tramway MuseumBook, Australian Commonwealth Engineering Standards Association, "AC Electric Arc Welding Plant - Transformer type", "Brass water fittings - stop, bib, globe and ferrule or main taps", "Vegetable tanned leather belting", "Rubber Conveyor and Power Transmission Belting", "Maintenance of Portable Chemical Fire Extinguishers of the Acid-Alkali and Foam Types", "Copper Tubes", "Portland Cement", 1928 - 1942

.1 - Book - 12 pages + brown covers, side stapled, issued by the Australian Standards Association, "AC Electric Arc Welding Plant - Transformer type", C97-1942, July 1942. .2 - Book - 40 pages + grey covers, side stapled, issued by the Australian Commonwealth Engineering Standards Association, Tentative Australian Standard B1 - "Brass water fittings - stop, bib, globe and ferrule or main taps", B1-1928, August 1928. .3 - Book - 20 pages + grey covers, side stapled, issued by the Australian Commonwealth Engineering Standards Association, Tentative Australian Standard B4 - "Vegetable tanned leather belting", B4 - 1929, January 1929. .4 - Book - 16 pages + grey covers, side stapled, issued by the Australian Commonwealth Engineering Standards Association, Tentative Australian Standard B3 - Rubber Conveyor and Power Transmission Belting", B3 - 1929, March 1929. .5 - Book - 8 pages + green covers, side stapled, issued by the Australian Standards Association, "Maintenance of Portable Chemical Fire Extinguishers of the Acid-Alkali and Foam Types", CA 18-1941, May 1941. .6 - Book - 16 pages + grey covers, side stapled, issued by the Australian Commonwealth Engineering Standards Association, Tentative Australian Standard B2 - "Copper Tubes", B2 - 1928, July 1928. .7 - Book - 28 pages + grey covers, side stapled, issued by the Australian Commonwealth Engineering Standards Association, Australian Standard A2 - "Portland Cement", includes tests, A2-1926, December 1926. On top right hand corner has the date stamp of the "The Electric Supply Co. of Victoria Ltd Ballarat" .2 - 3 Sep 1928 .3 - 19 Jan 1929 .4 - 3 Apr 1929 .5 - SEC Stamp - ? 1941 .6 - 20 July 1928 .7 - 17 Apr 1934trams, tramways, power station, standards, materials -

Moorabbin Air Museum

Moorabbin Air MuseumBook - Scanning generators, Time Bases Scanning Generators Their Design and Development With Notes on the Cathode Ray Tube

Desctription of the construction, testing & uses of Time Bsses circa 1947non-fictionDesctription of the construction, testing & uses of Time Bsses circa 1947time bases & cathode ray tubes -

Ringwood and District Historical Society

Ringwood and District Historical SocietyPhotograph, Boiler explosion at Ringwood station 20th June 1894 for engine 297R. "Heard in Box Hill"

Black and white photographs - 2 copiesTyped below photograph, "Boiler explosion at Ringwood station 20/6/1894. Heard in Box Hill". Article from newspapers:- Weekly Times (Melbourne, Vic. : 1869 - 1954), Saturday 27 January 1894, page 21 Official enquiry. The Board of Enquiry appointed by the Railway Commissioners to enquire into the causes of the boiler explosion which shattered the locomotive at Ringwood on Saturday night, assembled at the Railway department on Wednesday to commence its deliberations, The board consisted of Mr R. Fulton, engineer, C. W. McLean; engineer to the Marine Board, and Mr Mephan Ferguson, iron-founder. There is some difficulty at the outset about the constitution of the board; It was suggested that the Apt of Parliament contemplated that boards of experts, after the manner of the present one, needed, to have their appointments confirmed by the Governor-in-Council. The point, however, was not considered sufficiently important to prevent the board from proceeding with evidence. Robert Greyford, stationmaster at Ringwood, was the first witness. He said he saw the explosion on Saturday night at about twenty minutes to 8. There was a rush to the engine to see what had happened, and the driver and fireman were both found on the platform of the engine. The driver seemed badly hurt, but the fireman, to all appearances, was not so badly injured. They were both attended to and sent up to Melbourne by the last suburban train. Witness had a look at the engine and found the dome and all the plates round the boiler blown clean, away. The springs were also blown clean away. The Chairman (Mr Fulton) : Did you measure the distance ? Witness: Yes; one of the plates was 209 yards away. A piece from the top of the boiler 15 pounds in weight he found driven into the hard beaten track 410 yards away. Several pieces of boiler plate were found scattered at various distances. The buildings roundabout were injured. The Chairman; Did you notice anything peculiar about either of the driver or the fireman ? — No ; nothing wrong, with either of them. If the engine was blowing off at all, it must have been very light. In your opinion, were they perfectly sober ? — Perfectly. In approaching the station, is there a down or an up grade? — A very slight down grade. How is the road from Healesville ? — Up and down all the way. It is down, grade for about 200 yards coming into Ringwood station. They shut off ; steam about a quarter of a mile away, and come in at a good pace. They generally put on 15 pounds of steam while they are in the station. Mr Ferguson : Had the driver the usual load on ? — Yes ; about the usual load. Witness added that he had known the driver personally for about 10 years, and he had always been a careful, steady, sober man. He did not know the fireman so well. John Palmer, porter at Ringwood station, also saw the explosion. He was attending to the train on its arrival. He was knocked down by the force of the explosion. When he got up he saw the engine driver being carried into the office covered in blood. He noticed nothing peculiar about the driver and fireman, nor about the engine. Mr McLean : How far were you from the engine when you were knocked down ? — From ten to fifteen yards. William Paul, the guard of the train to which the injured locomotive Was attached, said he was looking at the engine at the very moment the explosion occurred. It seemed to come from exactly under the dome. The force of it took him off his feet. He was about 15 yards from the tender. When he rose he tried to reach the engine, but could not do so on account of the steam and coal dust. He called out to know whether any of the passengers were injured, and got no response, so that he concluded they were all right. All the lamps but about half dozen were extinguished by the force of the explosion, although the glass was not broken. He could testify most distinctly that the driver and fireman were both sober. The driver was a man who never drank. The steam started to blow off about a minute and a half before the explosion took place. The last place at which the engine took water was Healesville. The Chairman : Do yon know anything of the quality of the water there ? Is it creek water ? — Yes ; it comes from the Graceburn River. You never heard of its quality ?— No. How long have you known this engine on the road— About 13 months. Hew long have you known the driver on this line ? — About six weeks. I have known the fireman several years. The driver was a strict teetotaller, and I never saw the fireman take anything to drink in his life. Mr T. H, Woodroffe, chief mechanical engineer of the Victorian Railways, produced a report he had written to the secretary, about this explosion. The document gave facts concerning the engine and the explosion. It stated that the rapture seemed to have occurred at the rim of the plates adjoining the fire box. The engine was built at the Phoenix Foundry, Ballarat, in 1883. It was repaired at various times, the last time being in July of last year when it was sent to the Port Melbourne shops, and was then tested to a cold water pressure of 195 and found all right. It was the custom to overhaul all locomotives about every five years. The Chairman : There were no very heavy repairs in July, 1893; were there? — Not to the boilers. The shop manager's report says that the plug and safety tap holes were repaired, five new copper studs put in firebox, ash-pan door repaired, tender cleaned and overhauled, and studs re-rivetted, and boiler tested to pressure of 195, cold water. Mr Woodroffe read the report of the repairs effected to the boiler in December, 1888. That would be the time the plate was put in the boiler. On that occasion three new plates were put in the bottom and the boiler tested up to 195. The Chairman: Do you keep a record of the water used ?— Yes, the water in this case, I think, came from the Maroondah scheme. Mr Woodroffe said boilers were examined front time to time in the running sheds. In his opinion every possible care had been taken to keep the engine in proper care. There might, however, be lessons learnt from this. The Chairman: No doubt. From his examination of the plates [the] witness did not think the state of them could have been detected from the outside. There were no signs of leakage or sweating or anything of that sort. The next witness- was Walter Stinton, workshop manager at Newport and he said that the injured engine had been repeatedly repaired under his charge. He gave a technical account of the repairs effected on various occasions. The testing of locomotives was under his special notice. They had a high pressure pipe running; round the works, and a pump set at 2001b. When the boiler was pumped full of water the pressure when applied up to 1951b. The board appointed by the department to inquire into the Ringwood locomotive boiler explosion sat again at Spencer street on 25th inst. Mr R. Fulton presided and the other members of the board were. Mr Mephan Ferguson and Mr C. W. McLean. Charles Grubb, foreman of the boiler-makers at the Newport workshops, said he had inspected the pieces of plate that had been blown out of the engine, and after examining them, pointed out to the Chief Mechanical Engineer the portion where the plate had started to burst. It was under the lap, on the right hand side of the boiler. The grooving might be accounted for by bad water. During the past twenty years he had examined all the boilers that came into the Williamstown workshops, and while some were hardly marked at all, others were very badly eaten away. The practice was to cut out the defective portions. In this case the boiler was repaired in a similar manner. The Chairman : Can you suggest any other way of repairing so as to prevent accident ? — No, unless by taking out a plate on one side from the joint, and carrying it further up so as to avoid the joints meeting, or by taking out the plate altogether. What would.be the cost .of putting in a new " plate I—Perhaps about double the price; but I wouldn't recommend that course. It would be putting a new plate against plates that have been in use ten years or so and that would not be advisable. I think the present system better. I consider the present system of repairing the best. This is the first we have had so bad like that, to my knowledge. You attributed this to bad water. Is there no other probable cause ? — Well; unless the iron be bad. This was Lowmoor iron. I think this accident was caused by the eating away of plates. This one was the worst I have seen, for the short time it had been running. We use three classes of iron — Lowmoor, Monkbridge and Bowling. By Mr Woodroffe (Chief Mechanical Engineer) ; There are engines still running that were repaired at the same time as this one, in 1888, and. in the same way. These are engines 339 and 333. They have been recently examined and are in splendid order. What in your experience, is the age of a boiler on the Victorian railways? — From 17 to 20 years our earlier boilers stood. The later boilers don't stand so well. How is that? — There is difference in construction, and the material is lighter. The old boilers had thicker plates. Have you been asked in any way to curtail boiler affairs? — No, sir; nor in any way. You have never hesitated to carry out any necessary repairs? — Never. Our orders have been to exercise every care in examining, repairing and renewing boilers. Witness said that his practice was when an engine came into the workshop to find out how long she had been running. If over five years, he informed the workshop manager, and they thought it necessary the tubes were taken nut. If everything was in good order witness reported to the manager. The cost of taking out the tubes and putting them in again was about L20. Mr Woodroffe : Have you ever hesitated to repair a boiler on the score of expense ? — No, never. Mr McLean : Hew do yon ascertain whether a boiler requires repairs?— I keep a record of every boiler examined. From every boiler that comes in I have the dome covers taken off, and when it is practical I get inside. l can almost tell from the top of a boiler what the bottom is like. If there is any doubt about it I have the tubes taken out. If I have suspicion of defective plate I cause to have bored a triangle in the plate at the point where there is the most wear. There is a travelling inspector who visits all the running sheds of the colony except Port Melbourne and tests the boilers. He reports to us and we note what he points out. Alfred Thompson, locomotive inspector of the eastern section, said he knew this engine, 297R. He read a list of her repairs. He heard of the accident on Saturday night and went up to Ringwood. The Chairman : Did you ever notice anything peculiar about the engine? — No, I considered her A1 and would not have hesitated to have put on 140lb pressure owing to the repairs she had undergone. Witness considered that the explosion was caused by the expansion and contraction of the plates ; and, no doubt, the plate had been eaten away through bad water. The other side of the boiler showed: signs of corrosion: By Mr Woodroffe ; Is every care taken with the boilers ? — Yes, every possible care is taken for the safety of boilers, Weekly Times (Melbourne, Vic. : 1869 - 1954), Saturday 27 January 1894, page 7 EXPLOSION OF A LOCOMOTIVE BOILER, NARROW ESACPE FROM FATALITIES. THE DAMAGED ENGINE. [See drawing of loco – saved in “Railways” folder] The explosion of a locomotive boiler at Ringwood on Saturday evening, formed the subject of much discussion in railway circles on Monday. The Minister arrived at the office at an unusually early hour and immediately entered into a consultation with the acting chairman, Mr Kibble, and Mr Commissioner Murray. As the result of the interview it was resolved to ask three gentlemen of acknowledged engineering experience to sib as a board with the . object of inquiring into the cause of the accident and furnishing a report. Mr Richardson and the Commissioners are tally seized of the importance of having a searching investigation into the accident, and, with Mr Murray, the former went to Ringwood to inspect the scene of the disaster. They will he accompanied by Mr Woodroffe. During the morning no official report had come to hand from the driver or fireman of the engine in reference to the accident, but that is thought to be due to the circumstance that they have not sufficiently recovered to be able to give a circumstantial account of what occurred. The engine was one of the old R's, and, Mr Kibble pronounced them to be about the best class of engines used. So far nothing can be said as to the probable cause of the accident, as the broken plating of the engine has not been submitted to the inspection of experts. Weekly Times (Melbourne, Vic. : 1869 - 1954), Saturday 27 January 1894, page 7 STATEMENT BY THE FIREMAN. This morning Thomas Miles, fireman on the engine the boiler of which exploded on Saturday night, is suffering from an injury to the spine, as well as a very severe shaking to the system. He states that he was fireman on the engine attached to the train which left Healesville on Saturday evening, at ten minutes to 8. Everything went all right until Ringwood was reached, when, .just as the train was about to continue its journey, a load explosion took place and Miles remembers nothing more until he was picked np on the platform ; and found himself suffering from a pain in the back, and an injury to his arm. He cannot think of any reason which could have caused the explosion, as there was plenty of water in the boiler, and everything seemed working all right. Mr R. Fulton, consulting engineer, of Queen street; Mr McLean, a member of the Marine Board ; and Mr Mephan Ferguson, engineer, have consented to act as a board to inquire into the cause of the engine boiler explosion at Ringwood on Saturday evening. The board has been appointed under section 117 of Act 1135, which provides that the Governor-in-Council may direct the taking of a such a step. Mr1 Fulton will act as chairman of the board, which met for the first time at the railway offices, Spencer street, this forenoon. Before separating the members of the Board paid a visit to the Prince's Bridge locomotive sheds in company with Mr Woodroffe, the chief mechanical engineer, for the purpose of inspecting the shattered boiler. It has been stated that the explosion is known to have been caused by a flaw in a plate which was put on the boiler about four years ago, but enquiries have tailed to elicit anything in support of that view. The engineers connected with the department are not inclined to say anything on the subject. Weekly Times (Melbourne, Vic. : 1869 - 1954), Saturday 14 April 1894, page 20 The Ringwood Boiler Explosion, The Minister of Railways has received the supplementary report of the board appointed by him to investigate the circumstances connected with the explosion of a locomotive boiler at Ringwood. In their first report the board did not attach blame to anyone. Mr Richardson felt satisfied that the responsibility of having the engines properly inspected and overhauled periodically could be fixed if the inquiry were extended. He therefore referred the matter again to the Board, who took further evidence. In the report now furnished, the Board hold Loco. Inspector Thompson blameable, but point out as a mitigating circumstance that he had not received "written instructions" respecting inspections and overhauls. Weekly Times (Melbourne, Vic. : 1869 - 1954), Saturday 7 July 1894, page 32 The Ringwood Boiler Explosion. The Minister of Railways takes exception to the tone of a paragraph appearing in a morning contemporary respecting the Ringwood boiler explosion. It makes it appear that Mr Richardson has referred the report of the board which considered the facts connected with the explosion to the Crown solicitor simply because he differed from the finding of the board. The Minister explains that when he received the report he found that the responsibility for having boilers properly inspected and overhauled had not been clearly fixed. He personally obtained farther evidence on that point, and arrived at a conclusion, from which the commissioners differed. As he did not like to take upon himself the responsibility of deciding upon the effect of the evidence, he submitted the matter to the Crown Solicitor, but that officer did not furnish him with the information sought. He has, therefore, referred the question to the Attorney-General, together with the draft of a regulation respecting boiler inspections and overhauls in the future. Mr Richardson says that his whole aim is to have the responsibility positively fixed. Weekly Times (Melbourne, Vic. : 1869 - 1954), Saturday 28 April 1894, page 23 The Minister of Railways has completed his consideration of the supplementary report received by him from the Ringwood Boiler Explosion Board. The report, it will be remembered, held Loco-Inspector Thompson blameable for the non-inspection of the boiler, but considered there was extenuating circumstances. There was a certain amount of doubt as to the absolute instructions given for overhauling engines periodically. Mr. Richardson is sending the report on to the Commissioners with instructions that the responsibility respecting inspection of boilers shall be made clear for the future. -

Alfred Hospital Nurses League - Nursing History Collection

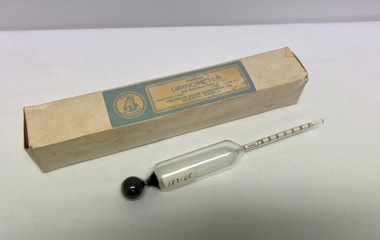

Alfred Hospital Nurses League - Nursing History CollectionInstrument - Specific gravity urinometer, Diabetes Urinometer

Glass urine specific gravity measure.Cream coloured manufacturers box labelled with a pale blue and cream label: "Diabetes Urinometer and Specimen Tube. Manufacturer Precision Glass Instrument Co, Melbourne". Blown glass urinometer used to measure the specific gravity of urine. It consists of 3 parts: I. The float: is the air containing part II. Weight: the lower end of urinometer (metal ball bearings) III. Stem- Has calibrations with numbers marked to measure the specific gravity Missing urine holding specimen tubeHospital type diabetes urinometer 60 degrees F Precision Glass Instrument Co. Melb. Measurements on stem from 000 to 030 urine specific gravity measure, urine testing