Showing 143 items

matching textile world

-

Kew Historical Society Inc

Kew Historical Society IncClothing - Silver Tinsel Yarn on Tulle Scarf, 1970s

... includes examples of textiles dating from the 18th, 19th and 20th... diverse community in Kew after the Second World War, textiles ...The Fashion & Design collection of Kew Historical Society includes examples of textiles dating from the 18th, 19th and 20th centuries. Some of the textiles, were used as items of clothing, others as items of household decoration, or simply as travel souvenirs. These textiles were created both domestically and internationally. Predictably with the growth of an ethnically and culturally more diverse community in Kew after the Second World War, textiles, clothing and objects in the collection inevitably reflected this diversity. The item was purchased and donated by Rosemary Vaughan-Smith.A tulle scarf using beaten silver tinsel yarn on a net base, with pattern of lozenges, from Baalbek (Lebanon)scarfs, metal-thread weaving, lebanese textiles, rosemary vaughan-smith -

Kew Historical Society Inc

Kew Historical Society IncClothing - Lace Pelerine, 1900s

... includes examples of textiles dating from the 18th, 19th and 20th... diverse community in Kew after the Second World War, textiles ...The Fashion & Design collection of Kew Historical Society includes examples of textiles dating from the 18th, 19th and 20th centuries. Some of the textiles, were used as items of clothing, others as items of household decoration, or simply as travel souvenirs. These textiles were created both domestically and internationally. Predictably with the growth of an ethnically and culturally more diverse community in Kew after the Second World War, textiles, clothing and objects in the collection inevitably reflected this diversity. A pelerine is a small cape that covers the shoulders. It was most popular during the mid- to late nineteenth century. Cream net machine embroidered collar with ruffle of chemical lace. Machine constructed post World War 1. Worn in the evening women's clothing, lace, collars, pelerines -

National Wool Museum

National Wool MuseumFunctional object - Yarn Spinner and Accessories, John Nesbitt, 19th Century

... at various textile mills between 1957 & 2003. He travelled the world... for the world of textiles provided energy and knowledge to the visitors ...Nino Corda was a Geelong based textile designer who worked at various textile mills between 1957 & 2003. He travelled the world in search of the latest fashions and techniques and developed timeless designs that were much loved by Australians. These items are on rotational display at the National Wool Museum’s ‘In the Factory’ exhibition. For many years, Nino also worked as part of the Honorary Staff of the National Wool Museum. His passion for the world of textiles provided energy and knowledge to the visitors and staff of the museum. Although Nino has now retired from his honorary position and has hung up his Australian Tartan vest, these items will continue to serve the community in sharing the stories of Australian Textile design.Custom made wooden hinged box with a hook latch. Brass yarn spinner, attached to a mahogany wood plinth base, which spins fibre into cord/yarn/thread. It has dials to set the rate that it spins. Metal plaque with black inlaid enamel lettering. Small cork inlay. Brass rod with hinge and wingnut, and ball at end. Ball at end has an adjustment mechanism. Rod also has an adjustable circular collar. Pair of curved tweezers. Circular magnifying glass on long thin handle. Glass has two concave lenses. Weaving sample in shades of blue, green and brown. Twill weave. Alternate pattern samples separated by red thread.Brass plaque on base of spinner: 42 MARKET St / John Nesbitt / REGd TRADE MARK / LIMd / MANCHESTER Underside of wooden plinth: 4976apparatus, textile, testing, spinning, nino corda, magnifyer, tools, brass, mahogany, tweezers, yarn, spinner, design, john nesbitt, manchester, england, 19th century, engineering, manufacturing -

National Wool Museum

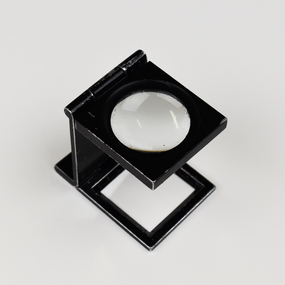

National Wool MuseumTool - Lens, c.1960

... at various textile mills between 1957 & 2003. He travelled the world... for the world of textiles provided energy and knowledge to the visitors ...Nino Corda was a Geelong based textile designer who worked at various textile mills between 1957 & 2003. He travelled the world in search of the latest fashions and techniques and developed timeless designs that were much loved by Australians. These items are on rotational display at the National Wool Museum’s ‘In the Factory’ exhibition. For many years, Nino also worked as part of the Honorary Staff of the National Wool Museum. His passion for the world of textiles provided energy and knowledge to the visitors and staff of the museum. Although Nino has now retired from his honorary position and has hung up his Australian Tartan vest, these items will continue to serve the community in sharing the stories of Australian Textile design. Textile designers used viewing lenses such as this to see how many threads are within a textile sample. It was important to count correctly, otherwise the enlarged final pattern would be out of alignment. Before compact lenses such as this, specialised glasses were used such as 8039.The viewing lens has a 3 fold design in order to fold up to be compact and easily transportable in a pocket while also working to provide its own stand when unfolded. The lens is black and contains one circular piece of magnifying glass on the top panel.Top panel. Words, scratched. NINOtextile calculations, textile design -

National Wool Museum

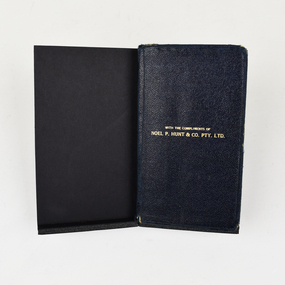

National Wool MuseumBook - Notebook, Collins Textile Diary - 1958, 1958

... at various textile mills between 1957 & 2003. He travelled the world... for the world of textiles provided energy and knowledge to the visitors ...Nino Corda was a Geelong based textile designer who worked at various textile mills between 1957 & 2003. He travelled the world in search of the latest fashions and techniques and developed timeless designs that were much loved by Australians. These items are on rotational display at the National Wool Museum’s ‘In the Factory’ exhibition. For many years, Nino also worked as part of the Honorary Staff of the National Wool Museum. His passion for the world of textiles provided energy and knowledge to the visitors and staff of the museum. Although Nino has now retired from his honorary position and has hung up his Australian Tartan vest, these items will continue to serve the community in sharing the stories of Australian Textile design. This notebook contains information on how to calculate and enlarge a small sample pattern into a larger textile. The equations would provide answers to the required length of thread (often measured in weight as opposed to distance) of a selected textile. The sample and appropriate thread would be needed for mass production at a commercial mill.Blue textured vinyl forms the covers of this notebook. On the front of the inscription is visible in gold text. Internally, small font black writing on yellowing pages forms most of this notebook. Pp.128 published pages with calendar and spare pages for notes forming the second half of this notebook. Front Cover. Words, printed. WITH THE COMPLIMENTS OF / NOEL P. HUNT & CO. PTY. LTD.textile design, textile calculations -

National Wool Museum

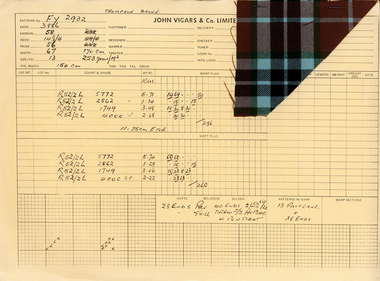

National Wool MuseumDocument - Mastercard, 1970-1975

... at various textile mills between 1957 & 2003. He travelled the world... for the world of textiles provided energy and knowledge to the visitors ...Nino Corda was a Geelong based textile designer who worked at various textile mills between 1957 & 2003. He travelled the world in search of the latest fashions and techniques and developed timeless designs that were much loved by Australians. These items are on rotational display at the National Wool Museum’s ‘In the Factory’ exhibition. For many years, Nino also worked as part of the Honorary Staff of the National Wool Museum. His passion for the world of textiles provided energy and knowledge to the visitors and staff of the museum. Although Nino has now retired from his honorary position and has hung up his Australian Tartan vest, these items will continue to serve the community in sharing the stories of Australian Textile design. Once a pattern has been selected for mass production, a master card is produced. A mastercard shows exactly how to replicate the designs and colours depicted on the sample attached. “Ends” is the technical word to describe a vertical band and “picks” describes a horizontal band.Brown card with fabric sample stapled to the top right. Writing is present on the left and bottom of the card detailing the information applicable to the design of attached fabric. 14 individual Masetercards in collectiontextile calculations, textile design -

National Wool Museum

National Wool MuseumClothing - Suit Jacket, c.1970

... at various textile mills between 1957 & 2003. He travelled the world... for the world of textiles provided energy and knowledge to the visitors ...Nino Corda was a Geelong based textile designer who worked at various textile mills between 1957 & 2003. He travelled the world in search of the latest fashions and techniques and developed timeless designs that were much loved by Australians. These items are on rotational display at the National Wool Museum’s ‘In the Factory’ exhibition. For many years, Nino also worked as part of the Honorary Staff of the National Wool Museum. His passion for the world of textiles provided energy and knowledge to the visitors and staff of the museum. Although Nino has now retired from his honorary position and has hung up his Australian Tartan vest, these items will continue to serve the community in sharing the stories of Australian Textile design. This Suit Jacket was tailored from fabric designed by Nino while he was working at the Foster Valley Mill. Nino developed a Mastercard such as w8043, which was sent to a mill in order to produce bolts of the desired fabrics w8044. These fabrics were then given to tailors where the final product was produced, such as this Suit Jacket.Single breasted suit jack with two buttons and notched lapel. Jacket is predominantly grey with black buttons and a silver silk interior lining. Four darker grey vertical and horizontal lines make up the design of the fabric on the exterior of the suit jacket. suit jacket, weaved, tailored -

National Wool Museum

National Wool MuseumTool - Glasses, c.1950

... at various textile mills between 1957 & 2003. He travelled the world... for the world of textiles provided energy and knowledge to the visitors ...Nino Corda was a Geelong based textile designer who worked at various textile mills between 1957 & 2003. He travelled the world in search of the latest fashions and techniques and developed timeless designs that were much loved by Australians. These items are on rotational display at the National Wool Museum’s ‘In the Factory’ exhibition. For many years, Nino also worked as part of the Honorary Staff of the National Wool Museum. His passion for the world of textiles provided energy and knowledge to the visitors and staff of the museum. Although Nino has now retired from his honorary position and has hung up his Australian Tartan vest, these items will continue to serve the community in sharing the stories of Australian Textile design. Textile designers used glasses such as these to see how many threads are within a textile sample. It was important to count correctly, otherwise the enlarged final pattern would be out of alignment. These glasses were popular in the 1950s but were replaced by viewing lens, such as item 8040 (in the National Wool Museum's Collection) in the 1960s because of their compact nature.Thin metal wire makes up the frame of the glasses. The metal is a standard metallic silver. The piece to sit on-top of the ear is excessively curved to hook around the ear. This is done to ensure the glasses do not fall off the face while looking down to view thread counts in a textile sample. The glasses are lacking lenses in their usual place. This has been replaced by another thin wire frame which protrudes an extra inch in front of the frame, almost like an additional layer of the glasses. Where this layer / frame ends, two lenses can be found which are square and much smaller than typical glasses lenses. This has been done to allow for powerful magnifying glass which would be ill-suited if it sat too close to the face / eyes. The glasses are also accompanied by their original box. The box is blue and has a large rectangle running through its centre. This rectangle works as a cushion for the glasses and is required as a result of their unusual shape.textile design, textile calculations -

National Wool Museum

National Wool MuseumTextile - Fabric Bolt, c.1970

... at various textile mills between 1957 & 2003. He travelled the world... for the world of textiles provided energy and knowledge to the visitors ...Nino Corda was a Geelong based textile designer who worked at various textile mills between 1957 & 2003. He travelled the world in search of the latest fashions and techniques and developed timeless designs that were much loved by Australians. These items are on rotational display at the National Wool Museum’s ‘In the Factory’ exhibition. For many years, Nino also worked as part of the Honorary Staff of the National Wool Museum. His passion for the world of textiles provided energy and knowledge to the visitors and staff of the museum. Although Nino has now retired from his honorary position and has hung up his Australian Tartan vest, these items will continue to serve the community in sharing the stories of Australian Textile design. These three bolts of fabric come from the same run of fabric used to tailor Suit Jacket 8045. All fabrics were designed by Nino Corda while he was working at the Foster Valley Mill. The bolts of fabric have an attached swing tag. This swing tag details information such as composition of the fabric, total amount of fabric and the design number.Three bolts of fabric with repeating pattern in 100mm grid. All three bolts have frayed edges, indicative of their need to be sent for finishing. The dominant colour in all three fabrics is grey. 8044.1 has red and green lines running vertically and horizontally and an attached swing tag. 8044.2 has red and orange lines running vertically and horizontally and an attached swing tag. Fabric bolt has yellow label attached to one edge of fabric, depicting the fabric’s number. 8044.3 has orange and blue lines running vertically and horizontally. No swing tag is attached.8044.1. Swing tag. Typed wording. Front. foster / valley / Pty / Ltd. / (Incorporated in Victoria) 8044.1. Swing tag. Typed and handwritten wording. Reverse. JONO TAILORING / CALL NO……………. / DESIGN 6302-49-5 / PIECE NO 9528 / METERS 3.5 STRINGS…………… / NET METERS…………… / COMPOSITION / 70% WOOL 30% POLYESTER 8044.2. Swing tag. Typed wording. Front. foster / valley / Pty / Ltd. / (Incorporated in Victoria) 8044.2. Swing tag. Typed and handwritten wording. Reverse. left over (?unknown handwriting?) / CALL NO…………… / DESIGN 6302-49-2 / PIECE NO…………… / METERS 6.0 STRINGS…………… / NET METERS…………… / COMPOSITION / 70% WOOL 30% POLYESTER.textile design -

National Wool Museum

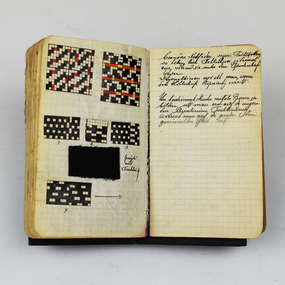

National Wool MuseumBook - Notebook, c.1920

... at various textile mills between 1957 & 2003. He travelled the world... for the world of textiles provided energy and knowledge to the visitors ...Nino Corda was a Geelong based textile designer who worked at various textile mills between 1957 & 2003. He travelled the world in search of the latest fashions and techniques and developed timeless designs that were much loved by Australians. These items are on rotational display at the National Wool Museum’s ‘In the Factory’ exhibition. For many years, Nino also worked as part of the Honorary Staff of the National Wool Museum. His passion for the world of textiles provided energy and knowledge to the visitors and staff of the museum. Although Nino has now retired from his honorary position and has hung up his Australian Tartan vest, these items will continue to serve the community in sharing the stories of Australian Textile design. This notebook contains information on how to calculate and enlarge a small sample pattern into a larger textile. It is a hand-written notebook that was passed from a master to an apprentice. This notebook is written in German and belonged to George Snchabel and was given to Nino Corda, who eventually donated it to the National Wool Museum. Nino only spoke basic German so many of the passages of writing were lost to him, regardless the illustrations and little bits of German he did know made this a useful resource which was often looked upon for inspiration and guidance.The notebook has a black cover on both the front and back with no writing. The spine is in bad condition and is being held together by three strips of tape. Internally, the pages have faded to a pale peach colour with a background blue square pattern. The notebook is completed with black ink used for writing and illustration. Occasional red ink is used for highlighting and illustration.textile calculations, textile design -

Kew Historical Society Inc

Kew Historical Society IncTextile - Lace Edging

... includes examples of textiles dating from the 18th, 19th and 20th... diverse community in Kew after the Second World War, textiles ...The Fashion & Design collection of Kew Historical Society includes examples of textiles dating from the 18th, 19th and 20th centuries. Some of the textiles, were used as items of clothing, others as items of household decoration, or simply as travel souvenirs. These textiles were created both domestically and internationally. Predictably with the growth of an ethnically and culturally more diverse community in Kew after the Second World War, textiles, clothing and objects in the collection inevitably reflected this diversity. This form of bobbin lace is made in Malta. It is a guipure style of lace. Maltese lace is worked as a continuous width tape lace on a tall, thin, upright lace pillow called a "Trajbu" and the Bobbins are called "Combini" . Bigger pieces are made of two or more parts sewn together. Lace made in Malta was originally needle lace, from the 16th to the 19th century, when the economic depression in the islands nearly led to the extinction of lacemaking there. But in the mid 1800s, Lady Hamilton Chichester sent lacemakers from Genoa to Malta. They used the old needle lace patterns and turned them into bobbin lace, which was quicker. It was not long after its introduction that the Maltese lace developed its own style from Genoese lace. Maltese lace was shown at The Great Exhibition of 1851 and it became popular in Britain. The style was copied by lacemakers in the English Midlands, and it was one of the sources for Bedfordshire lace. Maltese lace usually has the following characteristics which are useful for identification: It is usually made from cream silk. There is often the 8 pointed Maltese cross as part of the pattern, worked in whole or cloth stitch.The pattern may also have closely worked leaves known as “wheat ears” or “oats”. These are plump and rounded in shape, rather than the long narrow leaves of other types of bobbin lace. Maltese lace edging. It shows the Wheat ears, characteristic of Maltese lacelace, maltese lace, lace tape -

Kew Historical Society Inc

Kew Historical Society IncClothing - Maltese Lace Chemisette, 1900s

... includes examples of textiles dating from the 18th, 19th and 20th... diverse community in Kew after the Second World War, textiles ...The Fashion & Design collection of Kew Historical Society includes examples of textiles dating from the 18th, 19th and 20th centuries. Some of the textiles, were used as items of clothing, others as items of household decoration, or simply as travel souvenirs. These textiles were created both domestically and internationally. Predictably with the growth of an ethnically and culturally more diverse community in Kew after the Second World War, textiles, clothing and objects in the collection inevitably reflected this diversity. This form of bobbin lace is made in Malta. It is a guipure style of lace. Maltese lace is worked as a continuous width tape lace on a tall, thin, upright lace pillow called a "Trajbu" and the Bobbins are called "Combini" . Bigger pieces are made of two or more parts sewn together. Lace made in Malta was originally needle lace, from the 16th to the 19th century, when the economic depression in the islands nearly led to the extinction of lacemaking there. But in the mid 1800s, Lady Hamilton Chichester sent lacemakers from Genoa to Malta. They used the old needle lace patterns and turned them into bobbin lace, which was quicker. It was not long after its introduction that the Maltese lace developed its own style from Genoese lace. Maltese lace was shown at The Great Exhibition of 1851 and it became popular in Britain. The style was copied by lacemakers in the English Midlands, and it was one of the sources for Bedfordshire lace. Characteristics of Maltese lace. Maltese lace usually has the following characteristics which are useful for identification. It is usually made from cream silk. There is often the 8 pointed Maltese cross as part of the pattern, worked in whole or cloth stitch.The pattern may also have closely worked leaves known as “wheat ears” or “oats”. These are plump and rounded in shape, rather than the long narrow leaves of other types of bobbin lace. Camisole, made of silk thread Maltese bobbin lace that is constructed of lengths of lace forming two rectangles with a hole for the neck. Shows the characteristic Maltese cross and wheat ears. Fabric is made of tape lace joined togethercamisoles, maltese lace, bodices -

National Wool Museum

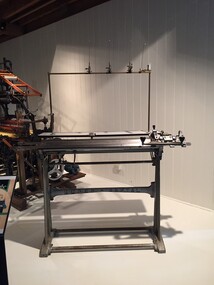

National Wool MuseumMachine - Knitting Machine, Coppo, 1960s

... to be the best in the world of textiles and knitwear. Through emigration... artisans were seen to be the best in the world of textiles ...The knitting machine is a recently designed instrument, especially when it is compared with its ancient counterpart, the loom. It enables the creation of many metres of fabric very quickly. A knitting machine is composed of a series of needles which mimic the process of manual knitting. The mechanism engages numerous mechanical elements simultaneously and enables the creation of many metres of fabric very quickly. In addition, a knitting machine can be setup to produce unique bolts of fabric. The density of the fabric may be modified and a knitting machine can produce double-faced effects. A doubled-faced effect creates colour combinations through the introduction of an additional colour to the knitting pattern. This knitting machine is a Coppo brand. It contains over five hundred needles and was produced in the 1960s. It is a representation of the best available in the world at that time. Originating from Italy, it was designed for commercial use. Through both precision and capacity, Italian artisans were seen to be the best in the world of textiles and knitwear. Through emigration, globalisation and the regularly available quantities of wool, Australia came to compete on this stage. The owner of this particular machine migrated from Italy in 1959. When she did, she brought with her a Dubied knitting machine. She later replaced it with this Coppo. When in Australia the owner began work as a piece worker, knitting jumpers and worked for some of the iconic names in the Australian knitting trade including ES Poratt and Alpin Manufacturing. The owner’s role progressed from a piece worker to a wool garment designer and she won many Wool Industry Awards in the 1970s and 1980s. Her high quality of work using and her individual custom designs were spoken about by many of her customers and she had a very large private clientele. She designed and knitted fully fashioned tailored jumpers for people for around 30 years.Knitting table sits on a stand with wide metal legs. Legs contain lettering 'COPPO torino'. Legs are connected via three thin metal poles as well as a metal band and the bed of knitting table at top. The connecting metal band has the lettering 'SUPER - COPTAL' attached. The Knitting table itself contains two beds and a bench at the rear. Attached to the bench is a thin metal structure for the elevation of yarn. It has four crane esk structures above on this metal structure. The bench is covered in a pale grey laminate in the imitation of wood. Attached to the knitting bed is a sliding contraptions containing two handles at the front followed by a complex semi-circle sliding mechanism used to move the knitting mechanism front and back.Left Stand. Lettering: Coppo Torino Right Stand. Lettering: Coppo Torino Centre Stand. Lettering SUPER - COPTALcoppo, knitting machine, design, italy, wool, business, migrants -

The Beechworth Burke Museum

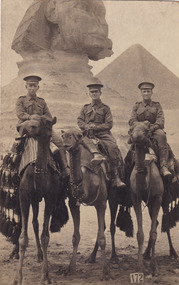

The Beechworth Burke MuseumPostcard, 1916

The photograph on the obverse side of the postcard was taken in Egypt on 4 March 1916, during World War I. Depicted are three unidentified Australian soldiers part of the Australian Imperial Force. They are dressed in military uniforms. Each of these men are seated atop a camel's back. All three camels are draped in - what are believed to be - traditional Egyptian textiles, including tassels, carpets and beads. In the background, we can see a triangular pyramid and the Great Sphinx of Giza. The Australian Imperial Force (AIF) were established by the Australian government in August 1914. This announcement marked the beginning of Australia's involvement in World War I. Immediately, men were recruited to serve the British Empire in the Middle East and on the Western Front. The first contingent of the AIF departed Australia by ship in November 1914. England was their destination. Although, their convoy was diverted to Egypt after the Australian High Commissioner in London, Sir George Reid, and the British military authorities unanimously agreed that the overcrowded military camps in England were unsuitable for so many men over winter. The AIF disembarked in Alexandria, Egypt on 3 December 1914, and the men moved to training camps near Cairo. It was in Egypt that the AIF and the New Zealand Expeditionary Force (NZEF) formed one united corps - the Australian and New Zealand Army Corps (ANZAC). This group of troops trained in the desert beneath the pyramids until March 1915.The record is historically significant due to its connection to World War I. This conflict is integral to Australian culture as it was the single greatest loss of life and the greatest repatriation of casualties in the country's history. On 25 April 1915, members of the Australian Imperial Force landed on Gallipoli in Turkey with troops from New Zealand, Britain, and France. This specific event holds very strong significance within Australian history. The record has strong research potential. This is due to the ongoing public and scholarly interest in war, history, and especially the ANZAC legend, which is commemorated annually on 25 April, known as ANZAC Day. The record's unique research potential is strengthened by its relationship to a historically significant site: the Egyptian pyramids. Since the postcard was produced in 1916, the record can be used as primary evidence for historians and conservationists studying these sites, or how these sites have evolved over time. The record may also be a useful resource for those interested in the history of Egyptian textiles. Furthermore, it may also provide insight into international relations between Egypt and Australia in the past and present.Sepia rectangular postcard printed on paper.Obverse: 172 / Reverse: 6536 / CARTE POSTALE / 4/3/16 / Rough riders under / the shadow of the / pyramids /military album, army, war, wwi, world war i, egypt, pyramid, great sphinx of giza, textiles, australian imperial force, aif, uniform -

Warrnambool and District Historical Society Inc.

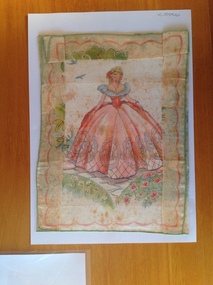

Warrnambool and District Historical Society Inc.Accessory - Textile Handkerchief painted lady, C 1910

Handkerchiefs have been used for centuries as a piece of cloth deemed useful for personal hygiene. They are usually kept in one's pocket but at times through history have been fluttered to attract attention or send a message. In harder times they proved to be a cheap item often used to add interest to an outfit. This item is one of five handkerchiefs which were brought back from France after WW1 by great uncles of Gloria Redman and have been passed down through her grandmother and mother.This item has significance as an item linked to a local family and World War 1 and as such has social, and historical significance. It is well provenanced and can be used to provide interest to the relating of a fairly common story whereby many soldiers brought or sent back small items such as handkerchiefs to their loved ones at home.White linen painted with an image of a lady in red crinoline dress with black lined pattern around bottom of dress. Three blue birds on the left side.and surrounded by semicircles of flowers around bottom half of hankerchief. Bordered with pink printed line and hemmed in green stitching.warrnambool,, world war 1 hankerchief, printed silk hankerchief, redman hankerchief, crinoline lady hankerchief -

Warrnambool and District Historical Society Inc.

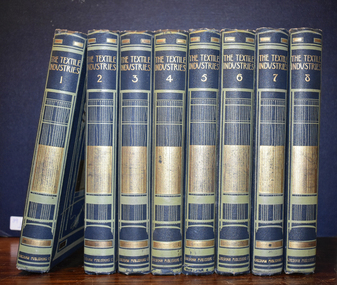

Warrnambool and District Historical Society Inc.Book, William S. Murphy, The Textile Industries ( eight volumes)

Technical information on the textile industryThese volumes have blue hard covers with pale green printing and stylised images of a loom and spindles in gold. The spines also feature a loom. The pages contain printed text, a colour photo, diagrams and black and white illustrations on inserted pages.non-fictionTechnical information on the textile industrywarrnambool woollen mill, textile industries -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Textile - Silk Handkerchiefs, 1940s

These three souvenir handkerchiefs were brought back to Australia after World War Two by James Godfrey. Flight Lieutenant James John Godfrey enlisted in World War Two in the Australian Air Force from Bessiebelle in western Victoria. He was attached to the British 8th Army under General Montgomery in North Africa and then took part in the landing in Sicily and the subsequent campaign through Italy. Before returning to Australia he travelled to Israel and Austria. These handkerchiefs are retained, firstly as examples of souvenirs brought back to Australia from returning military personnel after World War Two and secondly as souvenirs belonging to James Godfrey who had connections with the Warrnambool district. .1 This is a small pink silk handkerchief with a fluted edge and with some embroidery in one corner with flowers and wording in green, yellow and orange. .2 This is a small aqua-coloured silk handkerchief with a stitched edge and some stitched wording in one corner. Much of the edge stitching has been lost. .3 This is a white silk handkerchief with a stitched edge and a stencilled image in one corner. .1 Till we meet again .2 Bethlehem .3 Souvenir of Egypt world war two, history of warrnambool, james john godfrey -

Eltham District Historical Society Inc

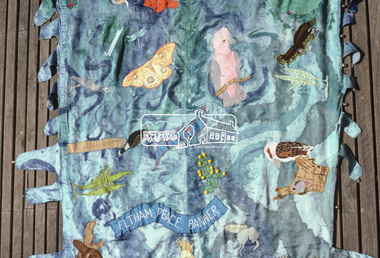

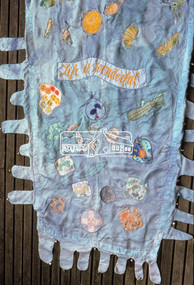

Eltham District Historical Society IncPhotograph, "As we are" Community Banner Project, c.Oct. 1986

River of Life and Hiroshima Day Banners The River of Life and Hiroshima Day banners were specific peace projects initiated by the CAO and taken up by Eltham Living & Learning Centre and funded by the Victorian Peace Secretariat for IYP. The project was transferred from the Centre to Tracey as part of her artist in the community portfolio. Tracey, as CAO, employed Jacky Talbot, who was not familiar with Eltham but was an experienced community arts worker personally interested in textiles and peace. The project was publicised and a peace banner group formed. Only two of the women knew each other. They had come together from a need to do something for peace, rather than to learn about textiles. Jacky Talbot shared Elizabeth Savage's approach to the banner. She was not 'a peace-expert' and did not want to be seen as such by the group. Like Elizabeth Savage she wanted to encourage an expression of peace as it was perceived by the group. Jacky showed slides of peace images and peace banners. Textile workshops were interspersed with discussions about peace, one of which was led by a local People for Nuclear Disarmament member. The idea for the banner occurred during one of these discussions. One of the women began to talk about feeling like a drop of water lost in the river of life - yet rivers were made of countless droplets which, when joined together, became the powerful force of the river. This group quickly established a commitment, not only to peace, but to the group itself, and this has continued beyond the project. The women, as is the case with many of the groups in the Banner Project, were really surprised at their increasing textile skills and self-confidence. But they were more concerned with their commitment to peace. Each is continuing to find ways in which she can continue to work for peace, and activities are undertaken on a group basis as well. The decision to participate in the group based activities is up to each woman as the time arises. The banner and some members of the group have now participated in the Peace Boogie at the World Trade Centre, the Peace Arts Conference organised by Art Action for Peace, Melbourne City Council's Peace Vigil weekend, Women's Precious Things for Peace Day exhibition and the banner was ' hung at the Footscray Community Arts Centre when the other textile peace mural Jacky co-ordinated was opened. One woman wrote a poem about the project and peace; others have sent telegrams and letters to politicians about peace. A great deal of information about peace and other activities, articles, books, media programs were circulated amongst the group. The Hiroshima Day Banner was made by Jacky Talbot as part of the project. The women wanted to do something for Hiroshima Day and suggested that a workshop be set aside to make a banner. The artist was concerned about the remaining time scheduled for the project and spent several days "whipping" up the banner herself. For the artist this banner was to prove quite significant. The women hung it at the Community Notice Board on Hiroshima Day and were photographed by the local newspaper publicising the group and drawing wider community attention to the remembrance of the day. Although no new members joined the group from this activity, the artist felt that she was more fully accepted by the group afterwards. This banner has initiated a small group of women committed to peace. The artist has also continued to liaise and meet with the women as time permits. Future group plans include: making kimonos to wear when carrying the banner, participating in the Palm Sunday March, an observance of Hiroshima Day activity, which is yet to be decided, establishing contact with a sister-town in USA and USSR and supporting Eltham Council's stance as a Nuclear Free Zone. (Source: The banner habits of the Eltham tribes : Eltham Shire "as we are" Community Banner Project report / by Jacky Talbot, Shire of Eltham, Feb. 1987, pp43-46)35mm colour positive transparency (1 of 2) Mount - Kodak KodachromeProcess Date OCT 86Mbanner project, community banner project, tracey naughton, eltham living and learning centre, eltham peace banner, jacky talbot, river of life banner -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, "As we are" Community Banner Project, c.Oct. 1986

River of Life and Hiroshima Day Banners The River of Life and Hiroshima Day banners were specific peace projects initiated by the CAO and taken up by Eltham Living & Learning Centre and funded by the Victorian Peace Secretariat for IYP. The project was transferred from the Centre to Tracey as part of her artist in the community portfolio. Tracey, as CAO, employed Jacky Talbot, who was not familiar with Eltham but was an experienced community arts worker personally interested in textiles and peace. The project was publicised and a peace banner group formed. Only two of the women knew each other. They had come together from a need to do something for peace, rather than to learn about textiles. Jacky Talbot shared Elizabeth Savage's approach to the banner. She was not 'a peace-expert' and did not want to be seen as such by the group. Like Elizabeth Savage she wanted to encourage an expression of peace as it was perceived by the group. Jacky showed slides of peace images and peace banners. Textile workshops were interspersed with discussions about peace, one of which was led by a local People for Nuclear Disarmament member. The idea for the banner occurred during one of these discussions. One of the women began to talk about feeling like a drop of water lost in the river of life - yet rivers were made of countless droplets which, when joined together, became the powerful force of the river. This group quickly established a commitment, not only to peace, but to the group itself, and this has continued beyond the project. The women, as is the case with many of the groups in the Banner Project, were really surprised at their increasing textile skills and self-confidence. But they were more concerned with their commitment to peace. Each is continuing to find ways in which she can continue to work for peace, and activities are undertaken on a group basis as well. The decision to participate in the group based activities is up to each woman as the time arises. The banner and some members of the group have now participated in the Peace Boogie at the World Trade Centre, the Peace Arts Conference organised by Art Action for Peace, Melbourne City Council's Peace Vigil weekend, Women's Precious Things for Peace Day exhibition and the banner was ' hung at the Footscray Community Arts Centre when the other textile peace mural Jacky co-ordinated was opened. One woman wrote a poem about the project and peace; others have sent telegrams and letters to politicians about peace. A great deal of information about peace and other activities, articles, books, media programs were circulated amongst the group. The Hiroshima Day Banner was made by Jacky Talbot as part of the project. The women wanted to do something for Hiroshima Day and suggested that a workshop be set aside to make a banner. The artist was concerned about the remaining time scheduled for the project and spent several days "whipping" up the banner herself. For the artist this banner was to prove quite significant. The women hung it at the Community Notice Board on Hiroshima Day and were photographed by the local newspaper publicising the group and drawing wider community attention to the remembrance of the day. Although no new members joined the group from this activity, the artist felt that she was more fully accepted by the group afterwards. This banner has initiated a small group of women committed to peace. The artist has also continued to liaise and meet with the women as time permits. Future group plans include: making kimonos to wear when carrying the banner, participating in the Palm Sunday March, an observance of Hiroshima Day activity, which is yet to be decided, establishing contact with a sister-town in USA and USSR and supporting Eltham Council's stance as a Nuclear Free Zone. (Source: The banner habits of the Eltham tribes : Eltham Shire "as we are" Community Banner Project report / by Jacky Talbot, Shire of Eltham, Feb. 1987, pp43-46)35mm colour positive transparency Mount - Black and Whitebanner project, community banner project, tracey naughton, eltham living and learning centre, eltham peace banner, jacky talbot, river of life banner -

Federation University Historical Collection

Federation University Historical CollectionArticle - Article - Women, Ballarat School of Mines, Girls' School: Women of Note; Valda D'Angri, Teacher, (1930 - )

Val grew up in Ballarat and started school in the early 1940s, during World War II. Her mother was a teacher and her father worked in Melbourne on war-related business. She attended kindergarten, which she recalled was unusual for the time. She attended Humphrey Street State School and her secondary schooling was at Ballarat Girls' School. Val completed her secondary school education at 15 years of age and went on to tertiary study at The School of Mines, where she trained in art and dressmaking. After completing her education, she worked as draughtswoman before becoming a teacher. The remainder of her career was spent teaching art and textiles at both secondary and tertiary levels. She taught at the secondary school that she had attended.women of note, valda d'angri, teacher, kindergarten, humphrey street state school, ballarat girls' school, ballarat school of mines, art, dressmaking, draughtswoman -

Cheese World Museum

Cheese World MuseumTextile, Camisole

Possibly worn by Mrs Myrtle Uebergang. Part of the Uebergang Collection.White cotton camisole with crocheted front and back yoke. The yoke has a floral design with crocheted lace border edging and capped sleeves. The square neckline is decorated with picot crochet lace.textiles, uebergang, allansford, tooram park, camisole, female costume accessories, handcrafts, needlework -

Cheese World Museum

Cheese World MuseumTextile, Bed jacket

The Uebergang family lived at Tooram Park, Allansford from 1912 to 1992. The bed jacket is part of a collection of items relating to rural life in the mid 20th century.White cotton bed jacket with scalloped satin stitch edging and cut work with butterfly motif lace insertions. Front closing with press studs and a tie. Cap sleeves with a V-shaped slit and butterfly motifs either side.201 (on tape at the side)costume accessories, female costume, uebergang, allansford, women's bed wear -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Hand operated embossing document press, 1910

The woollen mill was a vital part of Warrnambool for all but 22 years of the town’s history since it's the establishment in 1847 when the first land sales were held and white settlement began. In 1869 the Warrnambool Meat Preserving Company began operations on the mill site, in 1875, shareholders of the then defunct Warrnambool Meat Preserving Company happily sold the land and buildings on the Merri river to Warrnambool Woollen Mill Company Ltd for £5,000. The site was sold again in 1876 to grazer Robert Hood of Sherwood, who was chairman of directors of the failed company, which couldn’t raise sufficient capital to keep the works operating. The entrepreneurial Hood then used the existing plant to turn his own wool into tweed cloth. But just as the mill was starting to show a profit, a fire destroyed the building and plant on the night of 25 March 1882. So again, the mill was operational for six short years. Insurers only paid a fraction over 10% of the damage, Hood couldn't raise sufficient capital to rebuild on his own, and so the site lay unused until 1910. In 1908 Marcus Saltau and Peter John McGennan convinced the Warrnambool Chamber of Commerce to invest in a secondary industry with local capital. A public meeting in September 1908 agreed to raise £40,000, electing Saltau chairman of directors, a post he held for 34 years. A year later, using mostly local money, the Warrnambool Woollen Mill Company dispatched its first manager, John E. Bennett, to buy a plant and recruit 20 experienced staff from the Yorkshire woollen industry in December 1909. Another year more, the new mill was officially opened on 14 November 1910 by Marcus Saltau as company chairman and town mayor. Eighteen months on, in May 1912, the mill paid its first half-yearly dividend of 2 ½%. It was now working two shifts, with a year's orders to fill. In 1914 the mill ordered its own generator, providing the town with electricity and effectively doubling its plant size by October 1915, six months after Gallipoli. Thereafter, government orders for cloth and military supplies assured the mill’s success right through the First World War and on until 1923. A plant upgrade in 1922 for machinery to make worsted fabric drained profits, which, with a fall in demand, led to a loss in 1925. Profits were restored by the 1930s, despite the Depression, mostly due to tight management and robust marketing. Production boomed again during the Second World War, but soon foreign competition bit into profits, forcing the company to consolidate operations. The ‘50s and ‘60s were golden years for the mill. Security and growth gave the company confidence to trial Australia’s first electric blanket in 1958 and to install Swiss Sulzer looms in 1965. Over time, the building facades took on the modern look that the mill presented until it closed. The Dunlop company bought the mill in 1968, fending off a challenge from Onkaparinga in South Australia, and continued to expand by adding Wendouree Woollen Mill in the same year and Dream-spun Textiles a decade later, in 1979. Soon after that purchase, however, the mill began its slippery slide into decline. Dunlop sold to its former rival bidder Onkaparinga Woollen Co. Ltd in 1982, which in turn was taken over by Macquarie Worsted's only a year later, in 1983. Operations remained stable for a decade until 1994 when the Macquarie Group signaled that its newly rationalised operations left no room for the Warrnambool investment. The final operator of the mill was The Smith Family charity group, which ran the site by agreement with the Warrnambool City Council and a state government grant in that same year, 1994. The mill became more of a fabric recycler than a manufacturer. The site was sold to private operators in February 2003 and rezoned four months later to allow for the mixed housing development. The embossing press is significant for its association with the Warrnambool Woollen Mills 1910-1968, a major employer in the Warrnambool district. The press is also significant as an example of commercial office equipment used in the 19th and 20th century.Press, metal, for Company seal of Warrnambool Woollen Mill, stamping their brand as Western District Worsted Mills Pty Ltd. Metal is black with red and gold floral markings. Inscription of stamp reads "WESTERN DISTRICT WORSTED MILLS PROPRIETRY LIMITED" flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, warrnambool woollen mills, western district worsted mills proprietry limited, worsted fabric, printing press, logo printing press, stamp printing press, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined

Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070.Whale bone was an important commodity, used in corsets, collar stays, buggy whips, and toys.Whale bone in two pieces. Advanced stage of calcification as indicated by deep pitting. Off white to grey.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whale bones, whale skeleton, whales, whale bone, corsets, toys, whips -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined

Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070.Whale bone was an important commodity, used in corsets, collar stays, buggy whips, and toys.Whale bone piece. Advanced stage of calcification as indicated by deep pitting. Off white to grey.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whales, whale bone, corsets, toys, whips -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined

Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070. Whale bone was an important commodity, used in corsets, collar stays, buggy whips, and toys.Whale bone vertebrae. Advanced stage of calcification as indicated by deep pitting. Off white to grey.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whales, whale bone, corsets, toys, whips -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined