Showing 107 items

matching timber cutting

-

Orbost & District Historical Society

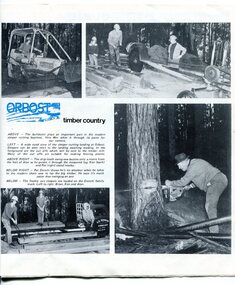

Orbost & District Historical Societypamphlet, VR Printing Works, Railways, 1975

This pamphlet was produced by Victorian Railways. In 1976 the name Victorian Railways was replaced by Vicrail.Railways have played a key role in Victorian transport especially in linking regional towns to the cities. The railways have provided jobs for many Orbost people. This item is associated with the history of the Orbost-Bairnsdale railway line and therefore reflects the role that the rail line played in the social and economic history of Orbost.A pamphlet produced for Victorian Railways. On the front is a coloured photograph of a train. It contains photographs and an article about Orbost as "Timber Country" and a detailed article titled, " Cutting Sleepers is a Family Business" which tells about the Donchi family.pamphlet-victorian-railways sleeper-cutting donchi -

Orbost & District Historical Society

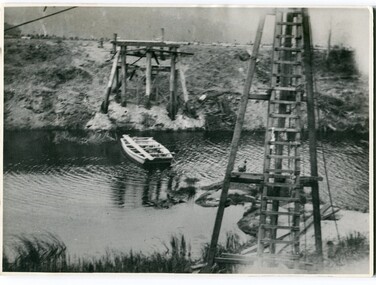

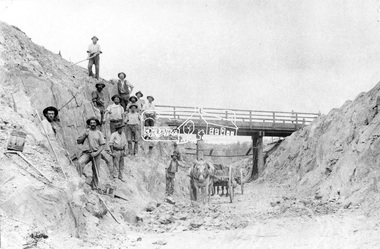

Orbost & District Historical Societyblack and white photographs, 1915

This photograph is of the construction of the first road bridge over the Genoa River - 1915. Before today's timber truss and concrete bridge was constructed between 1926-1928 by contractor J.T. Noble Anderson, two earlier bridges crossed the Genoa River at this location. They provided crucial links in the Princes Highway route from Melbourne to Sydney. The letter on the back of the postcard was written by Gordon ? to Alex ? on 2nd October 1917. "this represents the opening of Genoa Bridge. Mrs Alexander cutting the ribbon and Mr Martin holding it at the other side. Did most of the speaking. The gent holding the roll of paper is who came to open the bridge. I can't think of his name. Hubert is standing up at the right / Gordon " This is a pictorial record associated with the history of Genoa in East Gippsland.1100 -A large black / white photograph on a cream coloured buff card. It is of an unfinished bridge with men working there. A small rowboat can be seen on the far side of the river. 1100.1 - A photograph / postcard of the opening of "Genoa Bridge 1917". There is a ribbon stretched across the timber decking road in front of a group of people. 1100.2 - A black / white photograph of a road bridge across a river.on back - "Princes Highway - the 1st bridge over the Genoa River - 1915" on back of 1100.1 is a hand-written letter.genoa-bridge princes-highway-east-gippsland -

Orbost & District Historical Society

Orbost & District Historical Societycross cut saw, first half 20th century

... activity. Timber cutting tools are reminders of this history. saw ...Crosscut saws are used to cut down trees and to saw the trunks to length. This is a two man cross cut saw. The two-man crosscut saw has wooden handles that fit into a steel socket at each end. The teeth are designed to enable both users to have equal strength.Orbost has historically been based on the timber industry and it remains an important but diminishing economic activity. Timber cutting tools are reminders of this history.A steel bladed cross cut saw with wooden handles that fit into a steel socket at each end. The blade has one straight edge and a toothed curved edge. saw timber cross-cut-saw tool -

Orbost & District Historical Society

Orbost & District Historical Societyraker saw, c 1880 - 1940

... for cutting planks. timber-industry-tool raker-saw pit-saw A long ...Used in the timber industry in the Orbost district. This is a two person operated cross cut saw which functions as a pit saw. A log is placed over a pit lengthways. The man on the top walks along the log and pulls the saw upwards, and he man below pulls the saw downwards. This saw therefore cuts in both directions. This type of saw was often used in the ship building industry for cutting planks.A long raker saw which has been installed into the Slab Hut Shed in a vertical position as a pit saw. It has a metal handle extension at the top which has a wooden handgrip attached. Towards the bottom of the saw, a wooden handle had been added to the saw. timber-industry-tool raker-saw pit-saw -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Plane, Mid to late 19th Century

A jack plane (or fore plane) is a general-purpose woodworking bench plane, used for dressing timber down to the correct size in preparation for truing and/or edge jointing. It is usually the first plane used on rough stock, but in exceptional cases can be preceded by the scrub plane. Jack planes are 300–460 mm long and 64–76 mm wide, with wooden-stocked planes sometimes being slightly wider. The blade is 44–57 mm wide that is often slightly convex (or ground with rounded corners) to prevent digging in to or marking the work. The cut is generally set deeper than on most other planes as the plane's purpose is to remove stock rather than to gain a good finish (smoothing planes are used for that). In preparing stock, the jack plane is used after the scrub plane and before the joiner plane and smoothing plane. The carpenters' name for the plane is related to the saying "jack of all trades" as jack planes can be made to perform some of the work of both smoothing and joiner planes, especially on smaller pieces of work. Its other name of the fore plane is more generally used by joiners and may come from the fact that it "is used before you come to work either with the Smooth Plane or with the Joiner". Early planes were all wood, except for the cutter, or combined a wood base with a metal blade holder and adjustment system on top. Although there were earlier all-metal planes, Leonard Bailey patented many all-metal planes and improvements in the late 19th century. A jack plane came to be referred to as a "No. 5" plane or a "Bailey pattern No. 5" at the end of the 19th century. A vintage tool made by an unknown company, this item was made commercially for firms and individuals that worked in wood and needed a tool that could remove large amounts of timber. These jack or dressing planes came in various shapes and sizes to achieve a flat and even finish to timber surfaces before the use of smoothing planes and came in many sizes. A significant tool from the mid to late 19th century that is still in use today with early models sought after by collectors. It gives us a snapshot of how furniture and other finishes were created on timber by the use of cutting edged hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative or even finish that was needed for the finishing of timber items. Jack Plane handle is attached by large screw there is a round piece of wood tacked to front. noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, jack plane -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Bow Saw, Prior to 1950

... old tool used for cutting timber for hundreds of years before ...A coopers turning or bow saw is a woodworking tool used for straight or curved cuts. A bow saw is a type of frame saw with a thin toothed blade that is held in tension by a frame with two long narrow handles called "cheeks" that are supported and separated by a thin stretcher in the center of the handles, making a wide H shape (the cheeks form the uprights of the H, the stretcher the crossbar of the H). The blade is kept in tension with a turnbuckle that runs parallel to the blade between the two cheeks but on the opposite side of the stretcher.An age old tool used for cutting timber for hundreds of years before the modern cross cut saws were invented. This design of saw was part of a Coopers tool kit and used in the production of making barrels. However this item at this time cannot be associated with an historical event, person or place, provenance is unknown, item assessed as a collection asset as it is believed to have been produced before 1950.Bow saw wooden handle with metal blade missingNonewarrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, bow saw, turning saw, coopers tools, cutting wood, sawing timber, coopering -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood moulding Plane, Christopher Gabriel, 18th Century

The story of Christopher Gabriel born on April 2, 1746, in Falmouth England is a tale of a poor boy who made good. Shortly before he turned thirteen years of age in 1759 he was apprenticed to a local master carpenter, recorded as a Mr Barnicot the master trained his apprentice well as we can assume by Christopher's later successes. The apprenticeship ended in 1766 after seven years when Christopher reached twenty. Then in 1768, he relocated to London walking the two hundred miles from Falmouth carrying his possessions in a sack. He no sooner arrived in London when he met Alice Trowell who became his wife in March 1769. They set up house on Albermarie Street Clerkenwell and by the first of 1770, Gabriel had begun his business of plane making. It has been speculated that Gabriel took over the shop of John Cogdell aided with an investment from his in-laws of 131 pounds. He went on to prosper as a plane maker and lumber merchant over the next forty years. His business did well and in 1774 Gabriel moved to a house in Golden Lane, London and 1779 moved again to a home in Ould Street London. By now Gabriel was making a name for himself and his business at this time was located at 32 Banner Street Golden Lane, the following year he purchased another home in Banner Street and 1793 purchased the house next door. At the time of his death in 1808, he owned twenty-seven houses and commercial building. Christopher Gabriel s descendants became quite prominent in England and his grandson, Sir Thomas Gabriel became the Sheriff of London and Middlesex in 1859 and the Lord Mayor of London 1866 and 1867. Gabriel was an extremely prolific plane maker with a lot of examples made in the 18th century can still be found today. He made good quality tools and was an innovator of several new plane designs. A vintage tool made by a well-known plane maker, this item was made commercially for firms and individuals that worked in wood and needed a tool that could give a decorative finish to timber. These planes came in various shapes and sizes to achieve a finish to timber surfaces and came in many sizes. A significant Christopher Gabriel plane from the mid to late 18th century that after 200 years can still be used today. Planes made by Gabriel are eagerly sought after by collectors. The tool gives us a snapshot of how furniture and other finishes were created on timber by the use of cutting edged hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative or even finish that was needed for the finishing of timber items. Plane Moulding Reverse Ogee with two squares type Maker stamped Gabriel also stamped JB & No 9flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Orbost & District Historical Society

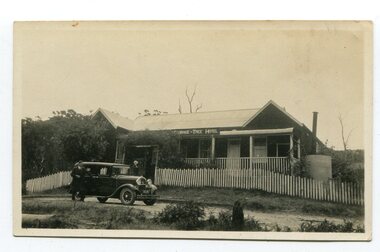

Orbost & District Historical Societyblack and white photograph, 1920s -1930s

The Cabbage Tree Creek township was originally established to support the booming timber industry of the mid 20th century. Five timber mills worked full time supporting the families that were drawn to the area's wealth of natural resources. The settlement of Cabbage Tree Creek is located on the Princes Highway, 27 km east of Orbost in East Gippsland. The first white settler arrived in the valley in 1887 cutting a dray track from Marlo to the south-west. Several families cleared the alluvial flats, growing maize, peas and beans and raising pigs, cattle and sheep. Later the farmers milked cows, sending cream to Orbost. In the late 1890s, small quantities of alluvial gold were found in the creek. A school commenced classes in 1913, but enrolment was small and at times the school operated part time with several other small schools in the area. The school building served as a hall for the district. From the 1920s the Cabbage Tree Hotel catered to drivers on the improved Princes Highway. (info. from Victorian Places)This is a pictorial record of Cabbage Tree, East Gippsland in the late 20th century. It shows a building that no longer exists.A small black / white photograph of a single storey timber building. On a sign below the roof is "Cabbage Tree Hotel". The hotel is surrounded by a wooden picket fence. A man and woman are standing on either side of a motor car parked on the roadway in front of the building.on back - on label - Cabbage Tree Hotelcabbage-tree-hotel -

Bendigo Military Museum

Bendigo Military MuseumNewspaper - NEWSPAPER CUTTING, FRAMED, Melbourne Herald, c1942

Relates to an ANTI AIRCRAFT PREDICTOR - VICKERS NO.1 MK111 - piece of Military equipment on display in the museum. Refer Cat No. 4591.Newspaper extract - facsimile copy on paper, black print on off white paper. Illustrated with photograph. Small typewritten label on paper attached to top of facsimile with metal staples. Frame - timber with mid brown stain, heavy plastic front and cardboard backing with paper tape. - handwritten information on cardboard.Top of facsimile - typewritten label - black ink. "Believed to be an extract from a "Melbourne Herald" early December 1942". On cardboard - handwritten - black ink "NEWSPAPER ARTICLE/ Newspaper article and photograph explaining how the PREDICTOR on/display in the main hall operated./ See Catalogue No: 4591"framed accessories, newspaper, military equipment, anti-aircraft, predictor -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Cross cut saw

... This saw is used for cutting curved edges of timber... is used for cutting curved edges of timber. It could have been ...This saw is used for cutting curved edges of timber. It could have been used in the home or for commercial building purposes. The hand-held saw has largely now been replaced by electrically-operated machines. This item has no known local provenance but it is an interesting example of a hand-held tool of the past.This is a hand saw with a thin serrated metal blade. The blade is affixed to the bottom end of a wooden frame with two upright pieces and a cross piece affixed to the upper part of the frame. The top part of the frame has a piece of plaited rope stretched across. The top part of the frame has two wooden handles. The blade is somewhat rusted and the wooden parts and the rope are stained. vintage tools, history of warrnambool -

Eltham District Historical Society Inc

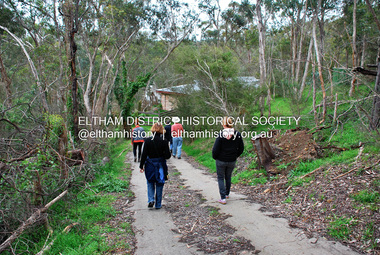

Eltham District Historical Society IncPhotograph - Digital Photograph, Jim Connor, River Bend House, 130 Laughing Waters Road, Eltham, 7 September 2013

Laughing Waters Walk, 7 Sep 2013 This Society excursion was a follow up to the Laughing Waters Story told to us by Jane Woollard at our Annual General Meeting in March 2013. It involved a walk commencing from the corner of Laughing Waters and Overbank Roads along Laughing Waters Road to its eastern end and returning partly over the same route - a total distance of about 2.5km. On the way we visited the two artist in residence properties, River Bend and Birrarung, to view the houses on them that are associated with Alistair Knox, Gordon Ford and others in the local mud brick and artistic community. We also able to walk around the derelict ruin which was once home to Gordon and Sue Ford, Boomerang House. An unexpected afternoon tea was offered to us by the artists in residence at Birrarung House and we had a brief opportunity to view inside the house. River Bend was designed and built by Alistair Knox for Rosemary and Bill Cuming in 1968. It sits in a deep cutting on a steep slope above the Yarra River and features floor to ceiling windows and glass doors set into mission brown timber frames and walls of reclaimed bricks in pinkish hue. Rosemary laid the brick paving around the house, a copy of the shell paving found in the ancient French town of Colmar, where the family had lived for a period. The kitchen was equipped with a 1960s stove as well as a cast iron wood stove reclaimed from Rosemary's sister's home in Armadale. Max and Tini Huygens, migrants from Holland, purchased the property in 1975 and named it Tilwinda from an Aboriginal word meaning 'hole in a rock'. In late 1981 Tini died after a short illness, but Max continued to live at Tilwinda until he moved to a retirement village in 2000 and the property was sold to Parks Victoria. Renamed River Bend, the property became part of the Laughing Waters Artist in Residency Program in 2008. Nillumbik Shire Council upgraded the property in 2012 with solar panels, a heat pump for hot water and double glazing to improve the comfort of the artists in residence and make the house more energy efficient. For a more in-depth description of the property and biographies of the various artists in residence commencing from 2008 to 2015, see Jane Woollard's book, "Laughing Waters Road; Art, Landscape & Memory in Eltham" published 2016.2013-09-07, activities, artists in residence, eltham district historical society, heritage excursion, jim connor collection, laughing waters road, river bend house -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood Moulding Plane, 1770-1809

The story of Christopher Gabriel born on April 2, 1746, in Falmouth England is a tale of a poor boy who made good. Shortly before he turned thirteen years of age in 1759 he was apprenticed to a local master carpenter, recorded as a Mr Barnicot the master trained his apprentice well as we can assume by Christopher's later successes. The apprenticeship ended in 1766 after seven years when Christopher reached twenty. Then in 1768, he relocated to London walking the two hundred miles from Falmouth carrying his possessions in a sack. He no sooner arrived in London when he met Alice Trowell who became his wife in March 1769. They set up house on Albermarie Street Clerkenwell and by the first of 1770, Gabriel had begun his business of plane making. It has been speculated that Gabriel took over the shop of John Cogdell aided with an investment from his in-laws of 131 pounds. He went on to prosper as a plane-maker and lumber merchant over the next forty years. His business did well and in 1774 Gabriel moved to a house in Golden Lane, London and 1779 moved again to a home in Ould Street London. By now Gabriel was making a name for himself and his business at this time was located at 32 Banner Street Golden Lane, the following year he purchased another home in Banner Street and 1793 purchased the house next door. At the time of his death in 1808, he owned twenty-seven houses and commercial building. Christopher Gabriel s descendants became quite prominent in England and his grandson, Sir Thomas Gabriel became the Sheriff of London and Middlesex in 1859 and the Lord Mayor of London 1866 and 1867. Gabriel was an extremely prolific plane-maker with a lot of examples made in the 18th century can still be found today. He made good quality tools and was an innovator of several new plane designs. A vintage tool made by a well-known plane-maker, this item was made commercially for firms and individuals that worked in wood and needed a tool that could give a decorative finish to timber. These planes came in various shapes and sizes to achieve a finish to timber surfaces and came in many sizes. A significant Christopher Gabriel plane from the mid to late 18th century that after 200 years can still be used today. Planes made by Gabriel are eagerly sought after by collectors. The tool gives us a snapshot of how furniture and other finishes were created on timber by the use of cutting edged hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative or even finish that was needed for the finishing of timber items. Moulding multi patterned plane has a "5" long bladeStamped Maker C Gabriel (owner JB).flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, side rabbet plane, gabriel m hobling -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionPhotograph - Photograph, framed collection - Early harbour facilities in Portland, n.d

UnknownFramed collection of black and white photographs in brown timber frame, under glass. 1. Lighthouse and staff building - Battery point; 2. Official opening - Ocean Pier; 3. Official opening - Ocean Pier, cutting the ribbon; 4. Henty's House (101 Bentick St); 5. Lighthouse - Battery Point; 6. Lighthouse quarters, Battery Point; 7. View from London Hotel of Henty Piers; 8. Portland early 1860s from Whalers Point; 9 & 10. First piles being driven for the ocean pier.Front: Lighthouse and staff building - Battery point/ Official opening - Ocean Pier/ Official opening - Ocean Pier, cutting the ribbon/ Henty's House (101 Bentick St)/ Lighthouse - Battery Point/ Lighthouse quarters, Battery Point/ View from London Hotel of Henty Piers/ Portland early 1860s from Whalers Point/ First piles being driven for the ocean pier. Back: (no inscriptions)port of portland -

Halls Gap & Grampians Historical Society

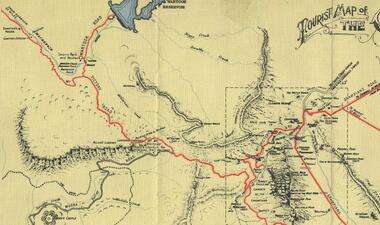

Halls Gap & Grampians Historical SocietyMap - Coloured

Background on Bridle Path up Stony Creek Gorge Pre 1840 C. B. Hall, squatter on Mokepilly Run 1841-1842, first European to discover the Fyans Creek valley, the entrance of which became known as Hall's Gap. He later recorded that he followed a number of tracks which he assumed had been made by the Aboriginies and described one as "leading up a wild romantic glen and over on to the source of the Glenelg River". This could well have been the route taken up Stony Creek gorge by the first timber-cutters in this part of the Grampians to the saddle between the Wonderland and Mt. Difficult ranges known as Valley Gap 1850s/60s Timber cutters and shingle splitters were reported to be moving into the eastern side of the Grampians and by the mid 1860s there were a number of families connected to the supplying of timber to Pleasant Creek living in the "Hall's Gap ranges". John Wakeham, the first store owner in Pleasant Creek in 1854, established a timer-mill in upper Stony Creek Gorge in the late 1850s. Wakeham is credited for the clearing and levelling of the first bridle-path up the gorge. 1870s By the mid 1870s the track had been extended over Valley Gap to the Victoria Forest (the upper region of the Victoria Valley). McKeon's bullock team was known to have hauled red gum from the Valley to Stawell in the late 1870s and the 1880s. 1880s In 1887 an article in the Pleasant Creek news describes the Stony Creek Gorge track as "being a ledge alongside the mountain range, formed in the early days with the aid of earth and timber, along which the bullock teams used to travel to Horsham and plains of the Wimmera beyond." 1890s Gold was discovered in the catchment area of Stony Creek and by the end of the 1890s a new track was built from "near the junction of Fyan's and Stony Creeks, up the gorge to the diggings settlement. The mining Department had paid L300 for its construction and, when completed, the track was "three miles and 30 chains in length, the side cuttings at the narrowest part being 10 feet between" and "the watercourses which cross the track at various points" having been "filled up with rocks rolled down the sides of the hills, and consequently there can be no damage caused by bushfires which destroyed the former wooden bridges erected on the old track to Wakeham's saw-mill, the remains of which are still to be seen at the side of the diggings" The article goes on to further describe the track as one which "can with ease travel with a two horse conveyance either up or down" and that the workmen engaged in the construction of the track would be attending "a ball that night at McKeon's farm near the mouth of the gap to celebrate the successful completion of the undertaking". 1900s At what time the bridle path was extended beyond Valley Gap to the Wartook basin on the Mt. Difficult Range has not yet been determined. However, it is known that, by the turn of the century, people were travelling between Halls Gap and the caretakers' residence at Wartook Reservoir along what was now known as the "Bluff Road. Wartook's embankment had been constructed in 1887 and at that time there was already a track from Rosebrook Station homestead (near the present day Wartook Pottery) to the reservoir. Philip Rose owned both Rosebrook and Wartook Stations from the mid 1840s to the late 1850s and had regularly leased the Wartook basin to Cobb & Co. to rest horses there. 1920s Following the war of 1914-1918, tourism really took off in the Grampians, and Halls Gap rapidly grew. People would travel as far as they could on the many tracks then hike to the many lookouts being discovered by local tour guides. This led to the need for access across the range so that horse riders and the increasing number of vehicles could travel between Horsham and Halls Gap. To this end, the Bluff Road was improved and extended on 1929 and at its opening in March, 1930, by Lady Somers it was renamed the Mt. Victory Road.Map of Mt Victory Road and othersaccess routes, mt victory rd, bridle path, roads -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietySaw Logging, circa early 1900's

This item can be seen as a hand piece belonging to a logger or farmer spanning over one hundred or more years. The equipment was made to perfection as a hand tool and has not been improved upon since its introduction into the logging industry or farming fraternity. It can be used by one person or two (husband and wife or father and child). Its versatility is ageless. It can be used for domestic clearing of the paddocks, or for domestic fire places and stoves or commercial logging up until the 2000s (introduction of specific logging trucks that cut and treat the trees in one process).This item is very significant to the rural and logging regions within the Kiewa Valley. It has been used for domestic wood cutting and for industrial logging in the mid to late 1900s. It was used when clearing land for the SEC Hydro scheme and to allow for the introduction of the Mount Beauty construction workers' village (later developed into the town) The great advantage of this saw was that it uses only muscle power and can be located where ever a lumber "Jack" or property owner can venture. either by foot or by horse.This saw is a Warranted Superior One/Two Man Logging Saw. It has 68 teeth and is 42 inches long. At a position of one inch (2.5cm) from the end is a hole one inch down from the leading edge. There is another hole 45 cm in front of the handle. Both these holes are for a "helper handle" which when in use renders this logging saw fit for a two man operation. This is a cross cut saw for cutting down vertical trees (horizontal cut) The handle is made from wood and fastened to the blade by three heavy duty screws. The one helper handle stands 150mm high and has a 150mm wooden hand grip.The central screw has 25mm manufacturers' identification logo stamped "WARRANTED SUPERIOR".one or two man cross cut saws, forestry, timber industry -

Orbost & District Historical Society

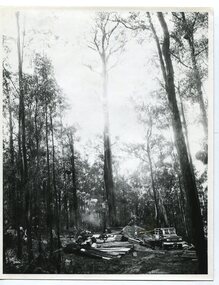

Orbost & District Historical Societyblack and white photograph, 1975

... sleeper-cutting-orbost donchi-orbost timber-industry-orbost... and sleeper-cutting industry in the Orbost Region. Timber sleepers ...The Donchi family has been cutting sleepers since the 1890s in the Orbost area. This photograph , one of a set of six, was taken for an article in the Victorian railways Magazine in 1975. This was a pamphlet produced for Victorian Railways. . It contains photographs and an article about Orbost as "Timber Country" and a detailed article titled, " Cutting Sleepers is a Family Business" which tells about the Donchi family.This item is associated with the timber and sleeper-cutting industry in the Orbost Region. Timber sleepers were superceded by concrete sleepers in c. 1970s. Orbost has historically been based on the timber industry, but that industry has declined considerably over the last 20 years..The number of locals involved in the timber industry has declined and many of the mills have closed. This item reflects a time when that industry was a significant contributor to the economy of the district.A black / white photograph of a bush scene of a timber harvesting coupe used by the Donchi family.on back - Pr 8766sleeper-cutting-orbost donchi-orbost timber-industry-orbost -

Orbost & District Historical Society

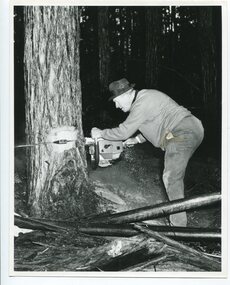

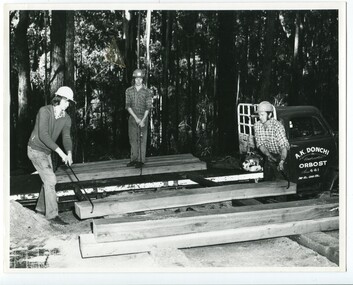

Orbost & District Historical Societyblack and white photograph, VR Printing Works, 1975

... with the timber and sleeper-cutting industry in the Orbost Region. Timber ...Pat Donchi's grandfather came to Orbost to cut sleepers in the 1890s. Pat and his sons have carried on since then. This photograph, one of six, was taken for the Victorian railways Magazine in 1975, a pamphlet produced for Victorian Railways. It contains photographs and an article about Orbost as "Timber Country" and a detailed article titled, " Cutting Sleepers is a Family Business" which tells about the Donchi familyThis item is associated with the timber and sleeper-cutting industry in the Orbost Region. Timber sleepers were superceded by concrete sleepers in c. 1970s. Orbost has historically been based on the timber industry, but that industry has declined considerably over the last 20 years. The number of locals involved in the timber industry has declined and many of the mills have closed. This item reflects a time when that industry was a significant contributor to the economy of the district.A black / white photograph of Pat Donchi, a local sleeper cutter, falling a tree with a chainsaw.on back - Pr 8708timber-industry-orbost donchi-orbost sleeper-cutting-orbost -

Orbost & District Historical Society

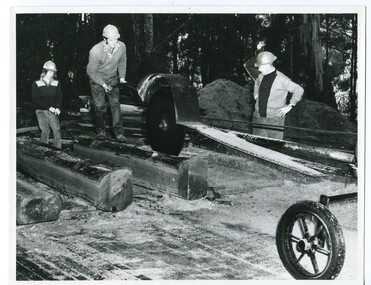

Orbost & District Historical Societyblack and white photograph, VR Printing Works, 1975

... timber-industry-orbost sleeper-cutting-orbost donchi-family... with the timber and sleeper-cutting industry in the Orbost Region. Timber ...The Donchi family has ben involved in sleeper cutting in the Orbost district since the 1890s. This phootograph , one of a set of six, was taken for the Victorian Railways Magazine, August,1975, a pamphlet produced for Victorian Railways. It contains photographs and an article about Orbost as "Timber Country" and a detailed article titled, " Cutting Sleepers is a Family Business" which tells about the Donchi family.Name Associated with the timber and sleeper-cutting industry in the Orbost Region. Timber sleepers were superceded by concrete sleepers in c. 1970s. Orbost has historically been based on the timber industry, but that industry has declined considerably over the last 20 years. The number of locals involved in the timber industry has declined and many of the mills have closed. This item reflects a time when that industry was a significant contributor to the economy of the district.A black / white photograph of Pat, Ken and Alan Donchi working a large saw at a timber coupe in Orbost.on back - Pr 8767timber-industry-orbost sleeper-cutting-orbost donchi-family -

Orbost & District Historical Society

Orbost & District Historical SocietyVR Printing Works, 1975

... timber-industry-orbost sleeper - cutting donchi-family... and sleeper-cutting industry in the Orbost Region. Timber sleepers ...The three men in this photograph, one of a set of six), are all from the Donchi family who have been involved in sleeper - cutting since the 1890s. From left to right they are Brian, Ken and Alan Donchi. The photograph was taken for an article in the Victorian Railways Magazine in 1975, a pamphlet produced for Victorian Railways. It contains photographs and an article about Orbost as "Timber Country" and a detailed article titled, " Cutting Sleepers is a Family Business" which tells about the Donchi family.This photograph is associated with the timber and sleeper-cutting industry in the Orbost Region. Timber sleepers were superceded by concrete sleepers in c. 1970s. Orbost has historically been based on the timber industry, but that industry has declined considerably over the last 20 years..The number of locals involved in the timber industry has declined and many of the mills have closed. This item reflects a time when that industry was a significant contributor to the economy of the district.A black / white photograph of three members of the Donchi family working at sleeper - cuttingin a timber coupe in Orbost.on back - Pr 8764timber-industry-orbost sleeper - cutting donchi-family-orbost -

Orbost & District Historical Society

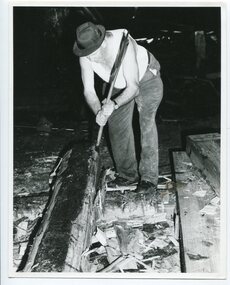

Orbost & District Historical Societyblack and white photograph, VR Printing Works, 1975

... timber-industry-orbost sleeper-cutting-orbost donchi-family... as "Timber Country" and a detailed article titled, " Cutting Sleepers ...This is one of a set of six photographs taken for the Victorian Railways Magazine, a pamphlet produced for Victorian Railways. t contains photographs and an article about Orbost as "Timber Country" and a detailed article titled, " Cutting Sleepers is a Family Business" which tells about the Donchi family The man in the photograph is Pat Donchi, a member of the Donchi family, who have been involved in the sleeper - cutting industry since the 1890s. This item is associated with the timber and sleeper-cutting industry in the Orbost Region. Timber sleepers were superceded by concrete sleepers in c. 1970s. Orbost has historically been based on the timber industry, but that industry has declined considerably over the last 20 years.The number of locals involved in the timber industry has declined and many of the mills have closed. This item reflects a time when that industry was a significant contributor to the economy of the district.A black / white photograph of a sleeper cutter at work swinging a broad axe.on back - Pr 8765timber-industry-orbost sleeper-cutting-orbost donchi-family -

Orbost & District Historical Society

Orbost & District Historical Societypaling knife, c. 1890s to 1960s

Used in the timber industry for making split palings. The palings are shaped by hand with the bottom edge put onto the timber and a mallet hit onto the top of the blade. This pre-dates sawn palings. Associated with the timber and household building industry in the Orbost region.A rectangular flat iron blade attached to a wooden handle. The cutting edge of the knife is along the bottom (rather than the end as with an axe). The wooden handle appears to be made from a small tree branch.paling-knife splitting-timber -

Orbost & District Historical Society

Orbost & District Historical SocietyD.V.D, Laurie Popeye Light, 1950-1992

... sleeper-cutting Light-Laurie timber-industry-Orbost.... sleeper-cutting Light-Laurie timber-industry-Orbost On disc in red ...The video shows Laurie LIght, a sleeper cutter for 42 years, using a swing saw. There is also a video of a lyre bird display. Laurie Light was born on May 12, 1938 to parents, Arthur Vernon Light and Nellie Hall. He started work with his father, a sleeper cutter for the Victorian Railways, at the age of 16. (More info. from newsletter LAURIE LIGHT, SLEEPER CUTTER - Heather Terrell)This item is associated with the history of the Orbost-Bairnsdale railway line and therefore reflects the role that the rail line played in the social and economic history of Orbost. It is also associated with the timber industry of East Gippsland.A D.V.D. of pictures and a video on Laurie Light, a sleeper cutter from 1950-1992. The disc is in a clear plastic case with a black insert. It is a copy of the original. this copy was probably made in 2016.On disc in red marker : "LAURIE LIGHT SLEEPER CUTTING with swing saw and lyre bird display"sleeper-cutting light-laurie timber-industry-orbost -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Joiner or Jack Plane, Late 19th to first quarter of the 20th century

A jack plane (or fore plane) is a general-purpose woodworking bench plane, used for dressing timber down to the correct size in preparation for truing and/or edge jointing. It is usually the first plane used on rough stock, but in exceptional cases can be preceded by the scrub plane. Jack planes are 300–460 mm long and 64–76 mm wide, with wooden-stocked planes sometimes being slightly wider. The blade is 44–57 mm wide that is often slightly convex (or ground with rounded corners) to prevent digging in to or marking the work. The cut is generally set deeper than on most other planes as the plane's purpose is to remove stock rather than to gain a good finish (smoothing planes are used for that). In preparing stock, the jack plane is used after the scrub plane and before the jointer plane and smoothing plane. The carpenters' name for the plane is related to the saying "jack of all trades" as jack planes can be made to perform some of the work of both smoothing and jointer planes, especially on smaller pieces of work. Its other name of the fore plane is more generally used by joiners and may come from the fact that it "is used before you come to work either with the Smooth Plane or with the Jointer". Early planes were all wood, except for the cutter, or combined a wood base with a metal blade holder and adjustment system on top. Although there were earlier all-metal planes, Leonard Bailey patented many all-metal planes and improvements in the late 19th century. A jack plane came to be referred to as a "No. 5" plane or a "Bailey pattern No. 5" at the end of the 19th century. A vintage tool made by an unknown company, this item was made commercially for firms and individuals that worked in wood and needed a tool that could remove large amounts of timber. These jack or dressing planes came in various shapes and sizes to achieve a flat and even finish to timber surfaces before the use of smoothing planes and came in many sizes. A significant tool from the mid to late 19th century that is still in use today with early models sought after by collectors. It gives us a snapshot of how furniture and other finishes were created on timber by the use of cutting edged hand tools. Tools that were themselves handmade shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative or even finish that was needed for the finishing of timber items. Jack or Fore plane with blade and wedge. Marked "D Morris" (owner)flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, plane, fore plane, d morris, jack plane, wood working tools -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood Smoothing Plane, Late 18th to Early 19th Century

A block, jack or smoothing plane is used for making a smooth finish to timber that is used to make furniture or other wooden objects. Traditionally, wood planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the intended shape of the item being worked on. The blade or iron was likewise formed to a flat shape and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers' shop might have many, perhaps hundreds, of smoothing and moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. A vintage tool by an unknown maker, this item was made for cabinet-making firms and individuals that worked in wood and needed a tool that could remove large amounts of timber. These jack, block or dressing planes as they were known came in various shapes and sizes to achieve a flat and even finish to timber surfaces before the use of mechanical smoothing planes and came in many sizes. A significant tool from the late 18th to early 19th century that's pattern or shape is still in use today. Early models of this type of woodworking plane are sought after by collectors today. This tool gives us a snapshot of how furniture and other finishes were created on timber by the use of cutting-edged hand tools used by craftsmen of the time. Tools that were themselves handmade, demonstrating the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce either a decorative or even finish for timber items. Smoothing Plane blade and wedge present. Raised handle at front end. Right-hand wedge guide broken away. Noneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane, wood plane, cabinet makers tools, furniture making -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Guillotine, c. 1880's

This guillotine is a hand operated machine specifically designed to cut through multiple sheets of paper or card. It has a very heavy and sharp single blade knife mounted between vertical guides or runners. The main users of a machine like this is in by the printing and publication binding industry. Book binding companies use a guillotine to evenly trim the pages of a book after it has been bound. The way the guillotine is used is - paper or card is stacked squarely on the flat table and pushed firmly against the back guide - the handle below the table at the front of the machine is wound around, which brings the back guide forward, pushing the paper stack forward and positioning the centre of the stack below the vertical frame - the upper wheel is wound around, which brings the clamp and firmly in position on top of the paper, to hold it very firmly - the large wheel on the side of the machine is turned around to lower the long sharp blade down onto the pages and cut them through. The sharp edge of the blade is protected somewhat from becoming blunt; a block of wood sits in the table under the stack of paper An early model of a guillotine was patented in 1837 by Thirault, who built a model with a fixed blade. Guillotines similar in principal to this one were patented by Guillaume Massiquot in 1844 and 1852. Over the years many improvements have been made and operation has moved from man power to electricity. Oscar Friedheim Ltd. was the importer and wholesaler of a large range of machinery and equipment for the printing and bookbinding industry. He sold most of his equipment under his own name. On this guillotine or paper cutter he refers to the origin of the guillotine’s manufacture only as “German Manufacrure”. A reference book “Commercial Bookbinding: a description of the processes and the various machines used" by Geo. Stephen, 1910, recommends Oscar Friedheim, amongst others, for the supply of “reliable cutting machines for hand or power”. It also recommends Oscar Friedheim’s for a wide range of other printing machinery and processes. OSCAR FRIEDHEIM LIMITED, LONDON Oscar Friedheim Ltd. was established in 1884 and operated from Ludgate in London. The company was an importer and wholesale supplier in the 1880’s, offering machinery and equipment for the printing and packaging industry for the UK and Ireland. The company became incorporated in 1913. An advertisement of 1913 includes a telegraphic code plus two telephone numbers for Oscar Friedheim Ltd and invites readers to call at the Ludgate, London, showrooms to see the machines working. The company later became Friedheim International Ltd. The book titled “Friedheim, A Century of Service 1884-1984 by Roy Brewer, celebrates Oscar Friedheim’s achievements. Friedheim International currently operates from Hemel Hempstead, on the northern outskirts of London UK. It promotes itself as “… the leading supplier of finishing, converting and packaging machinery to the printing, graphic arts, and highly varied packaging industries in the UK and Ireland. The company’s policy is simple – “employ the best people, work with the best equipment manufacturers in the world, and treat our customers as partners!” The company still sells guillotines. The guillotine is significant for its ability to represent aspects of the printing trade in Warrnambool and in a typical port town circa 1850 to 1910. It represents communication methods and processes used in the time before electrically powered equipment became common in industry.Guillotine (or paper cutter), hand operated. Metal framework with vertical guides, stand and metal mechanical parts including wheels and gears. Table with back guide; handle below front of table winds to move the back guide. A wheel at top of machine winds to adjust pressure of the clamp on the work on the table below it. The cutting blade fits between vertical guides; a timber insert in the table below the blade helps minimise the loss of sharpness of the blade. A handle on the side of the machine turns a large spoked wheel, which rotates a large gear, causing the blade to move up and down. Makers details are on a small oval plaque with embossed maker’s details is screwed onto main body. Maker is O Friedheim, London, and the machine is of German manufacture, circa late 1880’s.Maker’s plaque inscribed "O. FRIEDHEIM / London / German Manufacture"flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, printing machinery, printer’s guillotine, paper guillotine, paper cutter machine, oscar friedheim ltd london, friedheim international ltd, bookbinding industry, printing industry -

Eltham District Historical Society Inc

Eltham District Historical Society IncNegative - Photograph, Construction of Railway Line, Greensborough to Eltham, 1901

The Silver Street Bridge, 1901 Butty Gang workers excavate a rock cutting near the Silver Street bridge prior to laying of track. The Butty Gang system versus the Contract System was subject to public debate regarding cost benefits at the time of the Eltham line construction. Butty gang workers were a group of men who take a contract for a part of a work, as in the construction of railroads, etc., the proceeds being equally divided between them, with something extra to the foreman. Some hold picks, a couple of horses and carts are lined up probably for carting the broken rock away, dirt, rocks and shale lay at the bottom. A pair of small wooden buckets are evident, most likley to provide drinking water. The timber Silver Street bridge crosses the cutting in the background. The opening of the railway line from Heidelberg to Eltham took place on the 6th June 1902. Similiar to 810. Source: Mrs. Dandy, Montmorency and Miss McColl, 8 Anderson St., HeidelbergThis photo forms part of a collection of photographs gathered by the Shire of Eltham for their centenary project book,"Pioneers and Painters: 100 years of the Shire of Eltham" by Alan Marshall (1971). The collection of over 500 images is held in partnership between Eltham District Historical Society and Yarra Plenty Regional Library (Eltham Library) and is now formally known as the 'The Shire of Eltham Pioneers Photograph Collection.' It is significant in being the first community sourced collection representing the places and people of the Shire's first one hundred years.Digital image 120 format B&W negativeshire of eltham pioneers photograph collection, eltham, railway workers, 1901, butty gang, overpass, railway construction, railway line construction, silver street bridge -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Taps and Dies set, Wiley and Russell Mfg. Co, C. 1884

This set of taps and dies tools was owned by Frederick William McDowell (Fred) (1880 to 15-6-1967). He was a wheelwright by trade. He made and repaired vehicles such gigs, buggies, jinkers, sulkeys, spring carts and farm wagons. His workshop was on the corner of Cramer Street and Raglan Parade in Warrnambool., previously the site of Fotheringhams, and after McDowell's, and still in 2023, occupied by Reece Plumbing Fred's workplace prior to retiring was at Bryant & Waterson's in Kepler Street, opposite the Criterian Hotel, making rubber tyred horse-driven farm wagons. This Wiley and Russell hand operated, thread cutting Die and Stock, or Die and Tap, set’s patent carries the description “The taper-headed screws adjust the size; the four side screws hold the cutters firmly in the holder. Marketed as the Wiley & Russell LIGHTNING SCREW PLATE. The taper-headed screws are carried over from the J.J. Grant October 21, 1871 patent (no. 120,266). This patent was improved by Smart's Oct. 21, 1884 patent (no. 306,783).” Dies are used to cut external screw thread, stocks are the tools that hold the dies in place with countersunk adjustable screws, and taps are the tools that make the internal threads. The tools would be used by farriers, blacksmiths, wheelwrights sailing and steam ship engineers for making new, or repairing old, threads in metal. WILEY AND RUSSELL Manufacturing Company The company Wiley and Russell was established in 1872 by Solon Wiley and Charles P Russell, whose uncle founded the J. Russell Cutlery Co. The company began with the purpose of manufacturing thread cutting tools in Green River U.S. This tap and die set is an example of tools used by blacksmiths, farriers, wheelwrights and engineers on sailing and steam ships. It is also an example of early U.S. made engineering tools.Tap, Die, Die Stock set of industrial tools, fitted inside original timber box with three instruction labels attached inside lid. The set is the “Wiley and Russell LIGHTNING SCREW PLATE Pat. Aug. 5, 1884”. The lid has three metal hinges and is secured by two metal hook and eye fittings. This set of Whitworth standard threads has metal die and stocks (seven), and taps (three - the case has provision for four more die). The manufacturer’s details and the sizes of the threads are impressed into the tools. The paper labels have instructions and a diagram for the use and care of the tools. Tools have a protective oil coating. Made by Wiley and Russell Manufacturing Co. of Greenfield, Massachusetts, U.S., c. 1884; the tools were patented in August 1884, U.S. Patent 303,060. “Wiley & Russell MFG.CO, Greenfield, Mass, Pat Aug 5 1884.” “WHIT. STD.”flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, tap and die set, 1884 engineering tools, wiley and russell mfg co, lightning tap and die set, tap, die and stock set, screw thread cutting tools, taps and dies, stocks and dies, lightning screw plate, cutters, j.j. grant, patent no. 120266, solon wiley and charles p russell, wiley and russell, j. russell cutlery co, green river u.s, whitworth thread, fred mcdowell, frederick mcdowell, wheelwright, gig, buggy, jinker, sulkey, spring cart, farm wagon, 2-wheeled cart, horse cart, horse cart parts, jinker buggy, transport, vehicle, horse drawn, horse jinker, bryant & waterson -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood Plane, Late 19th to early 20th century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers' shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. John Moseley & Son: Records indicate that before 1834, the firm is listed at number 16 New Street, London and according to an 1862 advertisement the shop had been established in New Street since 1730, The Sun insurance records from the time show that John Moseley was the possessor of a horse mill in the yard of his premises, which means that some kind of manufacturing was taking place, as the mill would have provided power to run a saw or perhaps a grinding wheel so the probability is that he did not just sell tools, he made them as well. John Moseley died in 1828 and his will named his four sons: John, Thomas, William and Richard. To complicate matters he also had brothers with the same first names; brothers Richard (of Piccadilly) and William (of Peckham Rye) are named as two of the executors. Brother Thomas is not mentioned in this will, but became a minister and was one of the executors of brother Richard's estate when he died in 1856. From John's will, we also learn that, although the shop was in New Street, he resided in Lympstone, Devon. The family must have had a house in that county for quite some time as both sons Richard and William are baptised in Devon, although John and Thomas were baptised in London. In the 1841 and 1851 census records, we just find William in New Street, but in 1861 both William and Richard are listed there as toolmakers. That Richard was staying overnight at New Street was probably just accidental as in 1851 and 1871, we find him with his wife Jane and children in Clapham and Lambeth respectively. In 1851 Richard is listed as “assistant clerk cutlery warehouse” and in 1871 as “retired plane maker and cutler”. Although the actual place of work is not stated, one may assume he worked in the family business. 1862 is a year full of changes for the firm. In that year, William had a new property built at 27 Bedford Street. In the catalogue for the 1862 International Exhibition, 54 Broad Street (later 54-55 Broad Street) is listed for the first time, which may very well coincide with the split of the business into a retail and a wholesale branch. Around the same time, they must have moved from New Street to 17 & 18 King Street because their manufacturing premises had been pulled down to form the New Street from Cranbourne Street to King Street. In January 1865, William died and Richard continued the business. In 1867, the partnership he had with his son Walker and Thomas Elis Hooker, is dissolved. Richard continued tool-making at King Street and Bedford Street. Richard retired somewhere between 1867 and 1871, but the business continued. The business is taken over by W M Marples & Sons and tools continued to be made in London until 1904 when manufacturing relocated to Sheffield.A vintage tool made by a well-known company, this item was made commercially for firms and individuals that worked in wood and needed a tool that could remove large amounts of timber. These jack or dressing planes came in various shapes and sizes to achieve a flat and even finish to timber surfaces and came in many sizes. A significant tool from the mid to late 19th century that is still in use today with early models sought after by collectors. It gives us a snapshot of how furniture and other finishes were created on timber by the use of cutting-edged hand tools. Tools that were themselves handmade show the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative or even finish that was needed for the finishing of timber items.Jack Plane metal body with rose wood filler.Mosley & Sons London No 2flagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, john moseley & son, jack plane, woodworking tool, carpenders tools, cabinet makers tools -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Mallet, Prior to 1950

Wooden mallets are usually used in carpentry or by a cooper to knock wooden pieces together, or to drive barrel bungs, dowels or chisels. A wooden mallet will not deform the striking end of a metal tool, as most metal hammers would. It is also used to reduce the force driving the cutting edge of a chisel, giving better control. Hardwood mallets are also used by a cooper to knock bungs or other wooden parts of a barrel in place.A significant tool a carpenter or cooper would use to knock wooden staves or furniture parts in place without damaging the soft surface of the timber being used. Item at this time cannot be associated with an historical event, person or place, provenance is unknown, item assessed as a collection asset as it is believed to have been produced before 1950.Mallet large with wooden handle attached to wooden head with 2 metal ferrules at top and bottom of head Nonewarrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, coopers tools, wooden mallet, barrel bung, carpenters tool, hammer -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding Plane, 1770-1809

The story of Christopher Gabriel born on April 2, 1746, in Falmouth England is a tale of a poor boy who made good. Shortly before he turned thirteen years of age in 1759 he was apprenticed to a local master carpenter, recorded as a Mr Barnicot the master trained his apprentice well as we can assume by Christopher's later successes. The apprenticeship ended in 1766 after seven years when Christopher reached twenty. Then in 1768, he relocated to London walking the two hundred miles from Falmouth carrying his possessions in a sack. He no sooner arrived in London when he met Alice Trowell who became his wife in March 1769. They set up house on Albermarie Street Clerkenwell and by the first of 1770, Gabriel had begun his business of plane making. It has been speculated that Gabriel took over the shop of John Cogdell aided with an investment from his in-laws of 131 pounds. He went on to prosper as a plane-maker and lumber merchant over the next forty years. His business did well and in 1774 Gabriel moved to a house in Golden Lane, London and 1779 moved again to a home in Ould Street London. By now Gabriel was making a name for himself and his business at this time was located at 32 Banner Street Golden Lane, the following year he purchased another home in Banner Street and 1793 purchased the house next door. At the time of his death in 1808, he owned twenty-seven houses and commercial building. Christopher Gabriel s descendants became quite prominent in England and his grandson, Sir Thomas Gabriel became the Sheriff of London and Middlesex in 1859 and the Lord Mayor of London 1866 and 1867. Gabriel was an extremely prolific plane-maker with a lot of examples made in the 18th century can still be found today. He made good quality tools and was an innovator of several new plane designs. A vintage tool made by a well-known plane-maker, this item was made commercially for firms and individuals that worked in wood and needed a tool that could give a decorative finish to timber. These planes came in various shapes and sizes to achieve a finish to timber surfaces and came in many sizes. A significant Christopher Gabriel plane from the mid to late 18th century that after 200 years can still be used today. Planes made by Gabriel are eagerly sought after by collectors. The tool gives us a snapshot of how furniture and other finishes were created on timber by the use of cutting edged hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative or even finish that was needed for the finishing of timber items. Side Rabbet Plane Stamped Maker Gabriel (owner M Hobling).flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, side rabbet plane, gabriel m hobling