Showing 3927 items matching "machine"

-

Damascus College

Damascus CollegePhotograph, St Paul's College woodwork machine shop 1970

As early as 1941, it was recognised that the people of Ballarat saw a need for a Catholic boys technical school. When the Bishop of Ballarat established St Paul's College in 1948, he invited the Christian Brothers to continue their work through the provision of technical education, offering a place for Catholic boys to earn their Junior Technical Certificate prior to obtaining an apprenticeship.technical education, catholic education -

National Vietnam Veterans Museum (NVVM)

National Vietnam Veterans Museum (NVVM)Book, Pollard, Rhys, The Cream Machine, 1972

The Cream Machine is at once a brilliant first novel and a social document of very great interest: for the soldier's outlook on a war is never quite the same as that of the civilian. Pollard himself, conscripted in 1967, served in Vietnam from November 1968 to July 1969.The Cream Machine is at once a brilliant first novel and a social document of very great interest: for the soldier's outlook on a war is never quite the same as that of the civilian. Pollard himself, conscripted in 1967, served in Vietnam from November 1968 to July 1969.vietnam war, 1961 - 1975, vietnam war, 1961-1975 -- fiction, rhys pollard, conscription, rifleman, long hi mountains, vung tao -

National Vietnam Veterans Museum (NVVM)

National Vietnam Veterans Museum (NVVM)Booklet, Australian Army, Australian Army: Infantry Training, Volume 1, Infantry Platoon Weapons, Pamphlet No. 6A: The General Purpose Machine Gun, 7.62mm M60, 1971 (Copy 1), 1971

A blue coloured cardboard cover with black information on the front of the cover. There is the Australian Army Insignia and under this are the details of the booklet. Top right hand corner reads DSN 7610-66-041-6416. There are two punch holes down the left hand side and the booklet is covered with a plastic cover.australia - armed forces - service manuals, infantry training, m 60 machine gun 7.62 -

National Vietnam Veterans Museum (NVVM)

National Vietnam Veterans Museum (NVVM)Booklet, Australian Army, Australian Army: Infantry Training, Volume 1, Infantry Platoon Weapons, Pamphlet No. 6A: The General Purpose Machine Gun, 7.62mm M60, 1971 (Copy 2), 1971

A blue coloured cardboard cover with black information on the front of the cover. There is the Australian Army Insignia and under this are the details of the booklet. Top right hand corner reads DSN 7610-66-041-6416. There are two punch holes down the left hand side and the booklet. Part of the spine of the booklet is torn. australia - armed forces - service manuals, infantry training, m 60 machine gun 7.62 -

Horsham Regional Art Gallery

Horsham Regional Art GalleryPhotograph, John WERRETT, May Murphy, cotton machine operator, 1987

Gift of the artist, 1990 -

Moorabbin Air Museum

Moorabbin Air MuseumBook - FLYING MACHINE, Collins Angus & Robertson Publishers Pty Ltd, The Flying Machine: From an Engineering Standpoint, 1990

-

National Vietnam Veterans Museum (NVVM)

National Vietnam Veterans Museum (NVVM)Booklet, British Army, Handbook: 303 in. Vickers Machine Gun and Tripod Mounting, Mark IV. 1930, 1930

A brown colouerd cardboard cover with black information on the front. Above the insignia (unit not known) are the details of the handbook. There are two metal staples holdong the handbook together on the inside of the cover.hanbook, british army, military books, .303in vickers machine gun, tripod, tripod mounting mark iv -

Moorabbin Air Museum

Moorabbin Air MuseumBook - TWO MEN IN A FLYING MACHINE, John Morris, 1969

-

Bendigo Military Museum

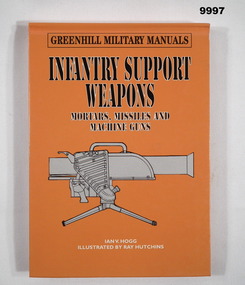

Bendigo Military MuseumBook - INFANTRY WEAPONS, Ian V Hogg et al, "INFANTRY SUPPORT WEAPONS/ MORTARS, MISSILES AND/ MACHINE GUNS", 1995

Hardcover Book. Cover - cardboard, black and white print on front, spine and back. Orange colour paper background. Illustrated - black and grey colour diagram of a weapon. 143 pages - cut, plain, white colour paper. Illustrated - black and white photographs and technical drawings.publications, books, weapons, infantry, reference -

National Vietnam Veterans Museum (NVVM)

National Vietnam Veterans Museum (NVVM)Manual, Cadillac Gage Company, Warren, Michigan USA, Manual, Technical User Handbook for Turret, Machine Gun: T-50 (Australian)

A stained dark crea coloured cardboard cover with black information on the front. Top right hand cornder reads User Handbook. Handwitten in the numbers 134360 and under this are the details of the Manual. The manual is held together by a metal slide on the inside of the cover.handbook, turret, machine gun t-50, technical manual -

National Vietnam Veterans Museum (NVVM)

National Vietnam Veterans Museum (NVVM)Booklet, Australian Army, Australian Army: Infantry Training, Volume. 1, Infantry Platoon Weapons, Pamphlet No. 4A: Sub Machine Gun 9mm F1 (Australia),1966. Copy 2, 1966

A blue coloured cardboard cover with black information on the front. Top right hand corner reads 7610-66-023-3614. Under the Australian Coat of Arms are the details of the booklet. The booklet is held together with two metal staples.australian army, infantry training, infantry platoon weapons, sub-machine gun 9mm f1, booklet -

National Vietnam Veterans Museum (NVVM)

National Vietnam Veterans Museum (NVVM)Booklet, Australian Army, Australian Army: Infantry Training, Volume. 1, Infantry Platoon Weapons, Pamphlet No. 4A: Sub Machine Gun 9mm F1 (Australia),1966. Copy 1, 1966

A blue coloured cardboard cover with black information on the front. Top right hand corner reads 7610-66-023-3614. Under the Australian Coat of Arms is the description of the booklet. There are twp metal staples down the left hand side.australian army, infantry training, infantry platoon weapons, sub-machine gun 9mm f1, booklet -

Clunes Museum

Clunes MuseumFunctional object - SEWING MACHINE/MINIATURE

MINATURE SEWING MASHINE WAS GIVEN TO JOAN SANDWITH BY HER MOTHER, WHO HAD SAVED "EGG MONEY" FOR ABOUT A YEAR TO BUY IT AS A BIRTHDAY PRESENT.MINIATURE "SINGER" SEWING MACHINE & COTTON REEL AND PACKET OF NEEDLES. GREEN FELT BASE. "TRADE MARK" SHUTTLE WITH NEEDLES AND THREADSINGER STENCILLED ON TOP OF MACHINElocal history, domestic, sewing, . -

Whitehorse Historical Society Inc.

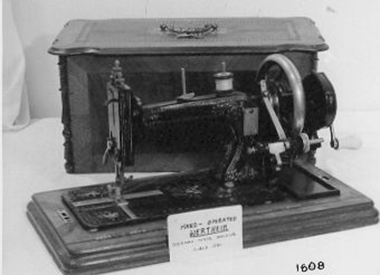

Whitehorse Historical Society Inc.Machine - Sewing Machine, 1880s

Black machine transverse shuttle Serial No. 496547, with gold and some coloured decorations. Decorations include blue and red bird and silver angels. Machine on wooden base and with wooden cover, both with inlaid decorations. Cover also has turned corner decorations. Cover can be locked to base. 'D' Syst 182.|S No. 496547'Superba' Plate with series of numbers. Card in box inscribed 'Wertheim German made machine in 1880'domestic items, sewing, textile machinery -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Page Numbering Machine, EARLY 1900’S

Antique paging or page numbering machine, also referred to as a paginater. Machine prints six digit numbers consecutively. It was used in the printing industry to number consecutive pages of journals in the early 1900’s. Alex Cowan & Sons Ltd. of Melbourne, Sydney and Adelaide supplied printing equipment to other firms. The parent company, Alexander Cowan & Sons Ltd., manufactured fine paper in Valleyfield, Penicuik, Scotland from 1814-1937. This page numbering machine or paginater is an example of mechanical technology used in the printing industry in the early 1900's.Page numbering machine, also known as a paginater or paging machine. Printing machine with six digits for numbering pages consecutively. Steel frame, wooden treadle plate and bench. Inscription of maker's name on metal plate. Made by Alex Cowan & Sons Ltd.Inscribed on maker's plate, "Alex Cowan & Sons Ltd. / Printers Furnishers / Melbourne, Sydney, Adelaide". flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, paging machine, treadle paging machine, printing machine, page numbering machine, paginater, alex cowan and sons ltd, australian printing industry -

National Wool Museum

National Wool MuseumAshtray

White ceramic square ashtray, promoting "La Laine: lavable machine" (Machine washable wool). Part of a collection of Australian Wool Corporation promotional memorabilia believed to have used in the era of Sir William Gunn.La Laine: lavable machine PURE LAINE VERGE/ 100% lavable machinewool marketing, australian wool corporation, gunn, sir william -

National Wool Museum

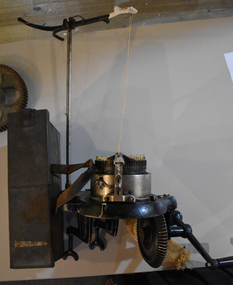

National Wool MuseumMachine - Sock Knitting Machine, G Stibbe and Co, c.1928

Knitted fabric is made with a single yarn or sets of yarns moving in only one direction. Whether done by hand or by machine, the process is the same. The knitting needle loops the yarn through itself to make a chain of stitches. These chains, or rows, are connected to produce the knitted cloth. There are two types of commercial knitting machine. A flat-bed has its needles, one for each loop, arranged in a straight line to produce a flat fabric. A circular machine has its needles arranged on a rotating circle. The cloth forms as a tube which can be made into seamless clothing. Dellruss Pty Ltd original owner Llyold Henry Coburg. Mock ribber fitted post World War 2. In use from c.1928 until 1978.Stibbe Maxim circular sock knitting machine.sock knitting machine, manufacturing, textiles, socks, machines, circular, clothing, industry, wool -

Whitehorse Historical Society Inc.

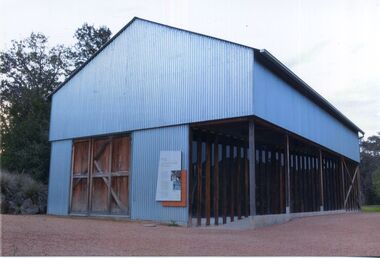

Whitehorse Historical Society Inc.Photograph, Machinery Shed, 2014

The acquisition of the apple-sorting machine was unexpected as machines of that type and age are rare19 coloured photographs ( a-s ) of machinery in the machine shed and the arrival of the apple-sorting machine from Doncastermachinery, machinery shed, orchard machinery, apple sorting machine -

Stawell Historical Society Inc

Stawell Historical Society IncPhotograph, Thresher drawn by Bullocks

Long team of bullocks pulling a threshing machine. Two people behind the threshing machine on left side.Long team of harnessed bullocks pulling machine with two people standing behind the farm machine.stawell rural harvesting -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAdding Machine

Adding machine with thirteen vertical rows of keys with clearing handle on side. Fraction keys on right hand side, and three keys missing along top row. Lever on side of machine. Two short feet at front, two long feet at back, giving slope to machine for ease of use. Serial Number "5-891861" Paper label with "Sets Mess Property" on at back of machine. Serial Number "5-891861" Paper label with "Sets Mess Property" on back of machine. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, adding machine, calculator, office equipment, commerce, business equipment -

Geoffrey Kaye Museum of Anaesthetic History

Geoffrey Kaye Museum of Anaesthetic HistoryMachine - Insufflation anaesthesia machine

In 1913, Mark Cowley Lidwill designed a machine for the purpose of mechanical or insufflation anaesthesia. The Lidwill machine was a portable machine weighing 7kg that could easily be packed into two small bags. The machine involved compressed air being delivered to an ether vaporiser. An ether/air control device allowed varying concentrations of ether to be delivered. The ether vaporiser could be immersed in hot water to prevent cooling and the ether temperature was measured. From the vaporiser, the ether/air mixture went through a trap bottle, then to a crude mercury blow-off valve and subsequently to the patient.Large leather suitcase style bag divided into two levels containing and insufflation anaesthesia machine.insufflation, mark cowley lidwill, thoracic surgery, positive pressure -

National Wool Museum

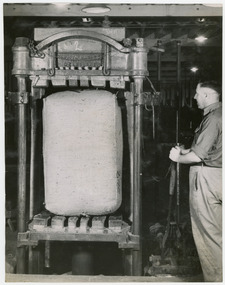

National Wool MuseumPhotograph - Bale in Dumping Machine, 1960s

One of fifty one photographs originally in a photo album found in the National Wool Museum’s office. The album was water damaged and the images were removed for conservation. The images follow the process of wool. Beginning in a sheep paddock and finishing as a folded fabric. It includes all the steps in between in this process, including shearing, transporting, selling, washing and the many different steps in the process of turning a single thread of wool into fabric.Black and white image showing a wool bale in a Robinson Bro dumping machine. A man is standing to the side of the machine.AUSTRALIAN NATIONAL PUBLICITY / ASSOCIATION / FLINDERS STREET RAILWAY BUILDING, / MELBOURNE AUSTRALIA / W4 / W4. Bale in dumping machine.wool industry, working life, women, boonoke station, farming, sheep farming, agriculture, sheep stations, transport, wool processing, shearing, textile industry, wool -

National Wool Museum

National Wool MuseumMachine - Sock Knitting Machine

Knitted fabric is made with a single yarn or sets of yarns moving in only one direction. Whether done by hand or by machine, the process is the same. The knitting needle loops the yarn through itself to make a chain of stitches. These chains, or rows, are connected to produce the knitted cloth. There are two types of commercial knitting machine. A flat-bed has its needles, one for each loop, arranged in a straight line to produce a flat fabric. A circular machine has its needles arranged on a rotating circle. The cloth forms as a tube which can be made into seamless clothing. Griswold bench-type sock knitting machine hand operated by turning the handle.sock knitting machine, textile industry, wool, fashion, clothing -

Yarrawonga and Mulwala Pioneer Museum

Yarrawonga and Mulwala Pioneer MuseumWashing machine and wringer, 1920's

significant household item for a large familyWashing Machine [Metal with plunger on leve ron a three legged base with tap at base for emptying] Wringer attachedOn the wringer :Made in Great Britain Acme Wringers Ltd Glasgow Washing Machine The Lehmann, compressed air and vacuum washing machine no.30614/30 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing Machine, early 20th century

Sewing machine, portable, hand operated, with Premier logo. Has folding crank handle, body painted black with floral design, wooden base and separate wooden cover with lock. Base has compartment with accessories, covered by curved ended, sliding wooden panel. Decorative linework on side, carvings on each corner. Wooden handle on cover is carved in rings, folds down. Below handle is decorative inlaid pattern. Serial number on plate at back of machine. Accessories include 13 attachments, key (broken), screwdriver, sewing machine needle, razor blades (2) and buttons. Attached to inside of case is a square of paper with a number on it. Instruction book for Singer Sewing Machines is included. Also with machine are white tailor's chalk and a cut out, fabric pocket with tissue paper pattern pinned to it.Serial number "579200" is stamped into plate at back of machine. Brand on transfer on front of machine is "Premier". Paper inside case has hand written number "334A". Instruction book "Instructions for using Singer Sewing Machines No. 66 - Oscillating hook for family use" flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sewing machine, permier sewing machine, hand operated sewing machine, dressmaker, fasion, singer no. 66 manual, textile, flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sewing machine, permier sewing machine, hand operated sewing machine, dressmaker, fasion, singer no. 66 manual, textile -

Australian Lace Guild - Victorian Branch

Australian Lace Guild - Victorian BranchTextile - Machine made lace, Late 19th Century

This piece of machine made lace was probably made on a Levers machine (invented 1813)Pink machine made lace edging. -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing Machine, 1911-1920s

This machine was made in Baden, Germany, for the Ward Brothers of Melbourne, who imported machines from various manufacturers and had them branded with their Ward Brothers decals. This machine is most likely dated after 1911, when the Ward Brothers became two separate businesses, as there are only remnants of two portrait decals on the machine bed. There is a fitted embedded ruler in the wood of the base. Many sewing machine manufacturers in Germany produced their machines specifically for export. A company could mass-produce its machines and give the same product several different brand names, according to their overseas buyers. There was a huge market for domestic machines as it enabled tailored clothing to be made in households at a fraction of the retail prices. Ward Brothers began in Australia in the late 1890s and early sewing machines sold by them had the three brothers on their decals. In 1911 the brothers divided into two separate firms, one operating on his own, the other two remaining together, and all still operating in Melbourne and at first still using the name Ward Brothers.This sewing machine is one of two hand-operated Ward Brothers machines in our collection that were made in Baden, Germany, and the only one that has the two Ward Brothers on its decal and that has side to side slide plates. This machine represents the early domestic market for sewing machines, making it possible for the everyday homemaker to produce fashionable garments and linen ware that was affordable. The owner of this machine could work at more than one location as it was portable and did not require a large space to set up. The machine is associated with the well-known Ward Brothers of Melbourne, who sold imported sewing machines that were branded with their own name.Sewing machine with case. The black-painted metal machine is hand-operated and the crank handle is wooden. The machine is on a wooden base and has a box included that contains many machine accessories. Made in Baden, Gemnamy, for Ward Brothers of Melbourne. There is an attached metal plate on the front with rows of groups of numbers on it. The wooden bed has an embedded ruler. The machine had decals with geometric designs and the maker's name.Printed in script: "Specially made in Baden / by Ward Broth Melbourne"flagstaff hill, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, sewing machine, hand operated, domestic sewing, homemade clothing, fashion, ward brothers, made in germany, baden, front and rear slide plates, post wwi, post 1911 -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Machine - Sewing Machine, Bootmaking, c1900

This treadle Bootmaking machine was used by early settlers and market gardeners in Moorabbin Shire, who had to be self reliant, producing their food and making and maintaining their own equipment, clothing and utensils This Claes 'Patent Elastic' boot-making machine is an example of the skills and craftsmanship of the pioneer settlers in Moorabbin Shire c1900 A black, 'Patent Elastic' treadle, boot-maker's, sewing machine.'PATENT ELASTIC' on iron framebrighton, moorabbin, pioneers, bentleigh, market gardeners, early settlers, farm equipment, sewing machine, boot-makers, leatherwork, patent elastic manufacturing company -

Bendigo Military Museum

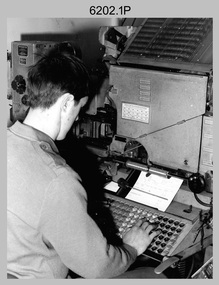

Bendigo Military MuseumPhotograph - Typesetting Equipment and Personnel, Army Survey Regiment, Fortuna, Bendigo, c1968 to 1979

This is a set of nine photographs of cartographic typesetting equipment and personnel in Cartographic Squadron at the Army Survey Regiment, Fortuna, Bendigo circa 1968 to 1979. The rooms on the top floor of Fortuna Villa where the photos were taken were formally the nursery and boys bedrooms during the Lansell family’s occupation of the building. The Fotosetter type setting machine replaced the letterpress method of type production in 1956. Its operator entered the text using a type order provided by cartographic draughtsmen/ draughtswomen. The type was output on a film positive, which was contacted onto strip film. The text was cut out by cartographic draughtsmen/ draughtswomen and affixed onto type sheets using bees wax. Cartographic Squadron’s CPL Arty Lane specialised in the operation of the Fotosetter type setting machine for many years, as shown in photos .3P and .4P. For more information on the Fotosetter, see page 71 of Valerie Lovejoy’s book 'Mapmakers of Fortuna – A history of the Army Survey Regiment’ ISBN: 0-646-42120-4. The computer based Editwriter Model 7500 typesetting system was introduced in 1975 as a replacement to the aging Fotosetter. It was operated by a specialised technician, who generated a large variety of map type styles and sizes quickly and reliably, as well as text panels. Output on Copy proof adhesive backed stripping type film replaced messy wax and spray adhesives in 1978. The Editwriter capability supported all RASvy units and its contractor type setting requirements. SGT Jim McDonald operated the Editwriter for a couple of years in the late 1970’s. He is seen in photos .7P and .8P. reading off a type order and entering text into the computer. See item 6181.23P, photo .1P for a reduced scale photo of SGT Jim McDonald undertaking this task. Also see item 6123.12P photos .1P and .2P featuring CPL Paul Richards, who was another technician that operated the Editwriter for several years in the 1980s. The Editwriter was also operated by SSGT Pat Lumsden, as featured in photo .9P taken in 1979. The Monotype Photolettering Machine seen in photos .5P and .6P is understood to be in service for a shorter period, as it was not as productive compared to the Fotosetter and Editwriter. This is a set of nine photographs of cartographic typesetting equipment at the Army Survey Regiment, Fortuna, Bendigo, c1968 to c1979. Black and white photos are on photographic paper and scanned at 300 dpi. .1) - Photo, black & white, c1960s, Fotosetter type setting machine, unidentified technician. .2) - Photo, black & white, c1960s, Fotosetter type setting machine. .3) to .4) - Photo, black & white, c1968, Fotosetter type setting machine, CPL Arty Lane. .5) to .6) - Photo, black & white, c1970s, Monotype Photolettering Machine, unidentified technician. .7) to .8) - Photo, black & white, c1979, Typesetting machine, ‘Editwriter’ Model 7500, SGT Jim McDonald. .9) - Photo, black & white, 1979, Typesetting machine, ‘Editwriter’ Model 7500, SSGT Pat Lumsden.Personnel and equipment are identified in photos .1P to .3P. on a card. A description is provided: ‘Fotosetter: This model was used from 1956 to 1974. Where photograph was taken: Army Survey Regiment. Person in Photograph: Arty Lane. Approx date photograph taken: 1968. Any Misc Information: All type on maps was set on this machine. The operator of the machine (Ex SGT Lane) joined the Army in 1956 and was discharged in 1977. Also with Survey from 1942 to 1946. Information given by: Arty Lane’. Photo .9P is dated 1979 on the back.’royal australian survey corps, rasvy, army survey regiment, army svy regt, fortuna, asr, carto -

National Wool Museum

National Wool MuseumSocks

A pair of machine knitted aqua coloured woollen socks. Probably made on the "Beehive" manual benchtop sock knitting machine.A pair of machine knitted aqua coloured woollen socks. Probably made on the "Beehive" manual benchtop sock knitting machine.SOV KNITTED BY STAN FINLAYknitting textile machinery machine knitting, hosiery, knitting, textile machinery, machine knitting