Showing 3983 items matching "machines"

-

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Functional object - Laundry Eqipment , 'ACME' clothes wringer, mid 20thC

This ACME portable clothes wringer could be attached to a wash trough or hand washing machine to remove excess water from the washing. It was much less cumbersome that the earlier Mangles used for this purposeMost homes of 20th C in City of Moorabbin would have had one of these ACME wringers . It greatly eased the washday burden of the women. The Exchange Hotel Nepean Highway Cheltenham was a well established meeting place for Moorabbin Shire settlers by 1915A metal clothes wringer with side hand crank and 2 rollers that could be attached by screw clamps to a wash trough or washing machine for removing excess water from washing. The pressure of 2 rollers was controlled by a screw on the top of machine that could be loosened or tightened according to the material being passed through.ACME 14 INCH / on hand crank is list of patents for Great Britain, USA, Aust. NZ, Germany, Belgium, Sweden moorabbin, bentleigh, cheltenham, laundry equipment, washing, washing mangles, washing machines -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyWringer - washing clothes

Wringers were used to wring clothes dry after washing. This is a manual one that can be attached to a trough or container that holds the washing. Later on washing machines were made with the wringer already attached and were operated by electricity. Afterwards washing machines spun the clothes dry as part of their cycle.This wringer was used by a resident of the Mount Beauty township during the Kiewa Hydro Electric Scheme in the 1940's and 1950's. White metal machine with 2 adjoining cloth cylinders in the middle. The metal rectangular shape forms a frame around the cylinders which have a metal shield above them and a metal flap below them. At the bottom, on each side is a protruding metal vice enabling the machine to be attached to a container. On one side is a lever with a wooden handle that can be wound around to rotate the cylinders towards each other."Acme" in red on the middle of the top front and "Acme" in white in the middle of the top of the back.washing machine; ringer; mount beauty; laundry; -

National Wool Museum

National Wool MuseumShearing Handpiece

Shearing handpiece with leather covered handle inscribed "THE LISTER SHEEP SHEARING MACHINE DURGLEY ENGLAND", "LISTER SHARPENED 62554". Patent 4385/25. Lister S is model after the Lister No. 3. Handpiece contains genuine rear joint, leather retaining ring, and grit proof nut that stops dirt from entering handpeice. C. 1930's.THE LISTER SHEEP SHEARING MACHINE DURGLEY ENGLAND Lister Pat. no. 4385/26shearing -

Flagstaff Hill Maritime Museum and Village

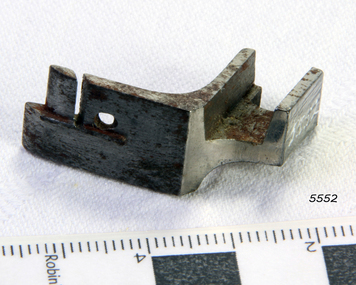

Flagstaff Hill Maritime Museum and VillageAccessory - Hemmer Foot, Joseph Wertheim, ca. 1891

This sewing machine accessory was donated with our collection's Wertheim sewing machine accessory box. The box contains twelve accessories, the instruction book and the receipt for the purchase of a Wertheim sewing machine. The receipt was written on July 23rd 1891 by the Wertheim distributor in Melbourne, Hugo Wertheim. His business was the Wertheim Sewing Machine and Hapsburg Piano Depot, trading at 173 Williams Street, Melbourne. The purchaser was Mrs Burrowes from Burrumbeet, Victoria, a district northwest of Ballarat. She paid £6-6 (six pounds and six shillings) in cash. The receipt was signed by H. Wertheim and the other signatory looks like John A. Cherry. Hugo Wertheim (1854-1919) was an agent for his father’s cousin Joseph Wertheim, a well-established sewing machine manufacturer in Germany. He was born in Lispenhausen, Germany, and migrated to Melbourne in October 1875, where he opened a merchandising business at 39 Flinders Lane East. He returned to Germany in 1885 to marry Joseph Wertheim's daughter Sophie Emilie. The couple came back to Melbourne, and Hugo quickly established a substantial business selling sewing machines, bicycles, pianos and other mechanical devices, under brands such as Wertheim, Electra, Planet, Griffin and Hapsburg. He exhibited at agricultural shows and in 1901 at the Pan American Exposition, Buffalo, United States of America. One of his staff was O. C. Beale, who later set up his own piano business in New South Wales. Hugo continued to own 25 per cent of one of Beale's companies, which became Wertheim's Queensland business. In 1908 Hugo Wertheim opened a piano factory in Richmond, Melbourne, aiming to produce 2000 pianos and player pianos a year, predominantly using Australian materials. In laying the foundation stone, Prime Minister Alfred Deakin observed that “few men with such opportunities for a life of ease would have embarked on such an enterprise” Hugo died of chronic hepatitis in 1919 at his home in South Yarra. His eldest son, Herbert Joseph (1886-1972), continued the business. The piano factory closed in 1935, becoming a Heinz food processing plant and in 1955, GTV Channel 9 studios and offices. The Wertheim Sewing Machine Company – Joseph Wertheim (1804–1899) founded the company in 1868 in Frankfurt, Germany. At this time Joseph was the Frankfurt city delegate for the Democratic Party. At its height, the Wertheim factory employed approximately 650 workers. The company used a trademark of a dwarf holding a hammer which is known to have been used until at least 1925, however in 1909 a Star of David was also registered. In 1870 a Wertheim subsidiary was formed in Barcelona, Spain. The business imported and sold complete machines, including the English Jones machine. Locals began calling the sewing machines “las rapidas”, and the business became known as “las casa de las rapidas”. In 1915 production began of a totally manufactured Spanish Wertheim machine. Wertheim in Germany continued manufacturing machines until 1932 when the Wertheim family fled to Spain. Despite converting to Christianity from Judaism, they feared the political unrest in Germany during that time. Wertheim Spain became Rapida SA and was then the sole manufacturer of the Wertheim machines. The factory was managed by Karl Wertheim under the alias Carlos Vallin. The sewing machine accessory is part of a donation that connected to domestic life in 1891 during the Victorian era. It is significant for connecting the Melbourne distributor of Wertheim sewing machines, Hugo Wertheim, to Victoria’s northwest district where the purchaser lived. It is also significant for connecting the Melbourne distributor to the importing of goods from the well-known German manufacturer of early domestic sewing machines, Joseph Wertheim. Broad Hemmer Foot for a Wertheim sewing machine. Joseph Wertheim manufacturer, Germany, distributed by Hugo Wertheim William Street Melbourne. Circa 1891flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, wertheim, sewing machine, victorian era, sewing machine accessory, wertheim sewing machine and hapsburg piano depot, wertheim sewing machines, sewing machine foot, domestic machines, dressmaking, home industry, fashion -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAccessory - Small Corder Foot, ca. 1891

This sewing machine accessory was donated with our collection's Wertheim sewing machine accessory box. The box contains twelve accessories, the instruction book and the receipt for the purchase of a Wertheim sewing machine. The receipt was written on July 23rd 1891 by the Wertheim distributor in Melbourne, Hugo Wertheim. His business was the Wertheim Sewing Machine and Hapsburg Piano Depot, trading at 173 Williams Street, Melbourne. The purchaser was Mrs Burrowes from Burrumbeet, Victoria, a district northwest of Ballarat. She paid £6-6 (six pounds and six shillings) in cash. The receipt was signed by H. Wertheim and the other signatory looks like John A. Cherry. Hugo Wertheim (1854-1919) was an agent for his father’s cousin Joseph Wertheim, a well-established sewing machine manufacturer in Germany. He was born in Lispenhausen, Germany, and migrated to Melbourne in October 1875, where he opened a merchandising business at 39 Flinders Lane East. He returned to Germany in 1885 to marry Joseph Wertheim's daughter Sophie Emilie. The couple came back to Melbourne, and Hugo quickly established a substantial business selling sewing machines, bicycles, pianos and other mechanical devices, under brands such as Wertheim, Electra, Planet, Griffin and Hapsburg. He exhibited at agricultural shows and in 1901 at the Pan American Exposition, Buffalo, United States of America. One of his staff was O. C. Beale, who later set up his own piano business in New South Wales. Hugo continued to own 25 per cent of one of Beale's companies, which became Wertheim's Queensland business. In 1908 Hugo Wertheim opened a piano factory in Richmond, Melbourne, aiming to produce 2000 pianos and player pianos a year, predominantly using Australian materials. In laying the foundation stone, Prime Minister Alfred Deakin observed that “few men with such opportunities for a life of ease would have embarked on such an enterprise” Hugo died of chronic hepatitis in 1919 at his home in South Yarra. His eldest son, Herbert Joseph (1886-1972), continued the business. The piano factory closed in 1935, becoming a Heinz food processing plant and in 1955, GTV Channel 9 studios and offices. The Wertheim Sewing Machine Company – Joseph Wertheim (1804–1899) founded the company in 1868 in Frankfurt, Germany. At this time Joseph was the Frankfurt city delegate for the Democratic Party. At its height, the Wertheim factory employed approximately 650 workers. The company used a trademark of a dwarf holding a hammer which is known to have been used until at least 1925, however in 1909 a Star of David was also registered. In 1870 a Wertheim subsidiary was formed in Barcelona, Spain. The business imported and sold complete machines, including the English Jones machine. Locals began calling the sewing machines “las rapidas”, and the business became known as “las casa de las rapidas”. In 1915 production began of a totally manufactured Spanish Wertheim machine. Wertheim in Germany continued manufacturing machines until 1932 when the Wertheim family fled to Spain. Despite converting to Christianity from Judaism, they feared the political unrest in Germany during that time. Wertheim Spain became Rapida SA and was then the sole manufacturer of the Wertheim machines. The factory was managed by Karl Wertheim under the alias Carlos Vallin.The sewing machine accessory is part of a donation that connected to domestic life in 1891 during the Victorian era. It is significant for connecting the Melbourne distributor of Wertheim sewing machines, Hugo Wertheim, to Victoria’s northwest district where the purchaser lived. It is also significant for connecting the Melbourne distributor to the importing of goods from the well-known German manufacturer of early domestic sewing machines, Joseph Wertheim. Small corder foot for a Wertheim sewing machine. Joseph Wertheim manufacturer, Germany, distributed by Hugo Wertheim William Street Melbourne. Circa 1891flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, wertheim, sewing machine, victorian era, sewing machine accessory, wertheim sewing machine and hapsburg piano depot, wertheim sewing machines, sewing machine foot, small corder foot, domestic machines, dressmaking, home industry, fashion -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAccessory - Braider foot, Joseph Wertheim, ca. 1891

This sewing machine accessory was donated with our collection's Wertheim sewing machine accessory box. The box contains twelve accessories, the instruction book and the receipt for the purchase of a Wertheim sewing machine. The receipt was written on July 23rd 1891 by the Wertheim distributor in Melbourne, Hugo Wertheim. His business was the Wertheim Sewing Machine and Hapsburg Piano Depot, trading at 173 Williams Street, Melbourne. The purchaser was Mrs Burrowes from Burrumbeet, Victoria, a district northwest of Ballarat. She paid £6-6 (six pounds and six shillings) in cash. The receipt was signed by H. Wertheim and the other signatory looks like John A. Cherry. Hugo Wertheim (1854-1919) was an agent for his father’s cousin Joseph Wertheim, a well-established sewing machine manufacturer in Germany. He was born in Lispenhausen, Germany, and migrated to Melbourne in October 1875, where he opened a merchandising business at 39 Flinders Lane East. He returned to Germany in 1885 to marry Joseph Wertheim's daughter Sophie Emilie. The couple came back to Melbourne, and Hugo quickly established a substantial business selling sewing machines, bicycles, pianos and other mechanical devices, under brands such as Wertheim, Electra, Planet, Griffin and Hapsburg. He exhibited at agricultural shows and in 1901 at the Pan American Exposition, Buffalo, United States of America. One of his staff was O. C. Beale, who later set up his own piano business in New South Wales. Hugo continued to own 25 per cent of one of Beale's companies, which became Wertheim's Queensland business. In 1908 Hugo Wertheim opened a piano factory in Richmond, Melbourne, aiming to produce 2000 pianos and player pianos a year, predominantly using Australian materials. In laying the foundation stone, Prime Minister Alfred Deakin observed that “few men with such opportunities for a life of ease would have embarked on such an enterprise” Hugo died of chronic hepatitis in 1919 at his home in South Yarra. His eldest son, Herbert Joseph (1886-1972), continued the business. The piano factory closed in 1935, becoming a Heinz food processing plant and in 1955, GTV Channel 9 studios and offices. The Wertheim Sewing Machine Company – Joseph Wertheim (1804–1899) founded the company in 1868 in Frankfurt, Germany. At this time Joseph was the Frankfurt city delegate for the Democratic Party. At its height, the Wertheim factory employed approximately 650 workers. The company used a trademark of a dwarf holding a hammer which is known to have been used until at least 1925, however in 1909 a Star of David was also registered. In 1870 a Wertheim subsidiary was formed in Barcelona, Spain. The business imported and sold complete machines, including the English Jones machine. Locals began calling the sewing machines “las rapidas”, and the business became known as “las casa de las rapidas”. In 1915 production began of a totally manufactured Spanish Wertheim machine. Wertheim in Germany continued manufacturing machines until 1932 when the Wertheim family fled to Spain. Despite converting to Christianity from Judaism, they feared the political unrest in Germany during that time. Wertheim Spain became Rapida SA and was then the sole manufacturer of the Wertheim machines. The factory was managed by Karl Wertheim under the alias Carlos Vallin.The sewing machine accessory is part of a donation that connected to domestic life in 1891 during the Victorian era. It is significant for connecting the Melbourne distributor of Wertheim sewing machines, Hugo Wertheim, to Victoria’s northwest district where the purchaser lived. It is also significant for connecting the Melbourne distributor to the importing of goods from the well-known German manufacturer of early domestic sewing machines, Joseph Wertheim.Wertheim braider; an accessory for a Wertheim sewing machine. Made by Joseph Wertheim, Germany, and distributed by Hugo Wertheim, William Street Melbourne. Circa 1891flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, wertheim, sewing machine, victorian era, sewing machine accessory, wertheim sewing machine and hapsburg piano depot, wertheim sewing machines, sewing machine foot, seamer foot, domestic machines, dressmaking, home industry, fashion -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAccessory - Sewing Machine Foot, Joseph Wertheim, ca. 1891

This sewing machine accessory was donated with our collection's Wertheim sewing machine accessory box. The box contains twelve accessories, the instruction book and the receipt for the purchase of a Wertheim sewing machine. The receipt was written on July 23rd 1891 by the Wertheim distributor in Melbourne, Hugo Wertheim. His business was the Wertheim Sewing Machine and Hapsburg Piano Depot, trading at 173 Williams Street, Melbourne. The purchaser was Mrs Burrowes from Burrumbeet, Victoria, a district northwest of Ballarat. She paid £6-6 (six pounds and six shillings) in cash. The receipt was signed by H. Wertheim and the other signatory looks like John A. Cherry. Hugo Wertheim (1854-1919) was an agent for his father’s cousin Joseph Wertheim, a well-established sewing machine manufacturer in Germany. He was born in Lispenhausen, Germany, and migrated to Melbourne in October 1875, where he opened a merchandising business at 39 Flinders Lane East. He returned to Germany in 1885 to marry Joseph Wertheim's daughter Sophie Emilie. The couple came back to Melbourne, and Hugo quickly established a substantial business selling sewing machines, bicycles, pianos and other mechanical devices, under brands such as Wertheim, Electra, Planet, Griffin and Hapsburg. He exhibited at agricultural shows and in 1901 at the Pan American Exposition, Buffalo, United States of America. One of his staff was O. C. Beale, who later set up his own piano business in New South Wales. Hugo continued to own 25 per cent of one of Beale's companies, which became Wertheim's Queensland business. In 1908 Hugo Wertheim opened a piano factory in Richmond, Melbourne, aiming to produce 2000 pianos and player pianos a year, predominantly using Australian materials. In laying the foundation stone, Prime Minister Alfred Deakin observed that “few men with such opportunities for a life of ease would have embarked on such an enterprise” Hugo died of chronic hepatitis in 1919 at his home in South Yarra. His eldest son, Herbert Joseph (1886-1972), continued the business. The piano factory closed in 1935, becoming a Heinz food processing plant and in 1955, GTV Channel 9 studios and offices. The Wertheim Sewing Machine Company – Joseph Wertheim (1804–1899) founded the company in 1868 in Frankfurt, Germany. At this time Joseph was the Frankfurt city delegate for the Democratic Party. At its height, the Wertheim factory employed approximately 650 workers. The company used a trademark of a dwarf holding a hammer which is known to have been used until at least 1925, however in 1909 a Star of David was also registered. In 1870 a Wertheim subsidiary was formed in Barcelona, Spain. The business imported and sold complete machines, including the English Jones machine. Locals began calling the sewing machines “las rapidas”, and the business became known as “las casa de las rapidas”. In 1915 production began of a totally manufactured Spanish Wertheim machine. Wertheim in Germany continued manufacturing machines until 1932 when the Wertheim family fled to Spain. Despite converting to Christianity from Judaism, they feared the political unrest in Germany during that time. Wertheim Spain became Rapida SA and was then the sole manufacturer of the Wertheim machines. The factory was managed by Karl Wertheim under the alias Carlos Vallin. The sewing machine accessory is part of a donation that connected to domestic life in 1891 during the Victorian era. It is significant for connecting the Melbourne distributor of Wertheim sewing machines, Hugo Wertheim, to Victoria’s northwest district where the purchaser lived. It is also significant for connecting the Melbourne distributor to the importing of goods from the well-known German manufacturer of early domestic sewing machines, Joseph Wertheim. Foot accessory, metal, for a Wertheim sewing machine. Made by Joseph Wertheim, Germany, and distributed by Hugo Wertheim, William Street Melbourne. Circa 1891flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, wertheim, sewing machine, victorian era, sewing machine accessory, wertheim sewing machine and hapsburg piano depot, wertheim sewing machines, sewing machine foot, seamer foot, domestic machines, dressmaking, home industry, fashion -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAccessory - Needle Plate, Joseph Wertheim, ca. 1891

This sewing machine accessory was donated with our collection's Wertheim sewing machine accessory box. The box contains twelve accessories, the instruction book and the receipt for the purchase of a Wertheim sewing machine. The receipt was written on July 23rd 1891 by the Wertheim distributor in Melbourne, Hugo Wertheim. His business was the Wertheim Sewing Machine and Hapsburg Piano Depot, trading at 173 Williams Street, Melbourne. The purchaser was Mrs Burrowes from Burrumbeet, Victoria, a district northwest of Ballarat. She paid £6-6 (six pounds and six shillings) in cash. The receipt was signed by H. Wertheim and the other signatory looks like John A. Cherry. Hugo Wertheim (1854-1919) was an agent for his father’s cousin Joseph Wertheim, a well-established sewing machine manufacturer in Germany. He was born in Lispenhausen, Germany, and migrated to Melbourne in October 1875, where he opened a merchandising business at 39 Flinders Lane East. He returned to Germany in 1885 to marry Joseph Wertheim's daughter Sophie Emilie. The couple came back to Melbourne, and Hugo quickly established a substantial business selling sewing machines, bicycles, pianos and other mechanical devices, under brands such as Wertheim, Electra, Planet, Griffin and Hapsburg. He exhibited at agricultural shows and in 1901 at the Pan American Exposition, Buffalo, United States of America. One of his staff was O. C. Beale, who later set up his own piano business in New South Wales. Hugo continued to own 25 per cent of one of Beale's companies, which became Wertheim's Queensland business. In 1908 Hugo Wertheim opened a piano factory in Richmond, Melbourne, aiming to produce 2000 pianos and player pianos a year, predominantly using Australian materials. In laying the foundation stone, Prime Minister Alfred Deakin observed that “few men with such opportunities for a life of ease would have embarked on such an enterprise” Hugo died of chronic hepatitis in 1919 at his home in South Yarra. His eldest son, Herbert Joseph (1886-1972), continued the business. The piano factory closed in 1935, becoming a Heinz food processing plant and in 1955, GTV Channel 9 studios and offices. The Wertheim Sewing Machine Company – Joseph Wertheim (1804–1899) founded the company in 1868 in Frankfurt, Germany. At this time Joseph was the Frankfurt city delegate for the Democratic Party. At its height, the Wertheim factory employed approximately 650 workers. The company used a trademark of a dwarf holding a hammer which is known to have been used until at least 1925, however in 1909 a Star of David was also registered. In 1870 a Wertheim subsidiary was formed in Barcelona, Spain. The business imported and sold complete machines, including the English Jones machine. Locals began calling the sewing machines “las rapidas”, and the business became known as “las casa de las rapidas”. In 1915 production began of a totally manufactured Spanish Wertheim machine. Wertheim in Germany continued manufacturing machines until 1932 when the Wertheim family fled to Spain. Despite converting to Christianity from Judaism, they feared the political unrest in Germany during that time. Wertheim Spain became Rapida SA and was then the sole manufacturer of the Wertheim machines. The factory was managed by Karl Wertheim under the alias Carlos Vallin. The sewing machine accessory is part of a donation that connected to domestic life in 1891 during the Victorian era. It is significant for connecting the Melbourne distributor of Wertheim sewing machines, Hugo Wertheim, to Victoria’s northwest district where the purchaser lived. It is also significant for connecting the Melbourne distributor to the importing of goods from the well-known German manufacturer of early domestic sewing machines, Joseph Wertheim. Adjustable needle plate for a Wertheim sewing machine, made by Joseph Wertheim, Germany, and distributed by Hugo Wertheim, William Street Melbourne. Circa 1891.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, wertheim, sewing machine, victorian era, sewing machine accessory, wertheim sewing machine and hapsburg piano depot, wertheim sewing machines, needle plate, domestic machines, dressmaking, home industry, fashion -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAccessory - Foot tool, Joseph Wertheim, ca. 1891

This sewing machine accessory was donated with our collection's Wertheim sewing machine accessory box. The box contains twelve accessories, the instruction book and the receipt for the purchase of a Wertheim sewing machine. The receipt was written on July 23rd 1891 by the Wertheim distributor in Melbourne, Hugo Wertheim. His business was the Wertheim Sewing Machine and Hapsburg Piano Depot, trading at 173 Williams Street, Melbourne. The purchaser was Mrs Burrowes from Burrumbeet, Victoria, a district northwest of Ballarat. She paid £6-6 (six pounds and six shillings) in cash. The receipt was signed by H. Wertheim and the other signatory looks like John A. Cherry. Hugo Wertheim (1854-1919) was an agent for his father’s cousin Joseph Wertheim, a well-established sewing machine manufacturer in Germany. He was born in Lispenhausen, Germany, and migrated to Melbourne in October 1875, where he opened a merchandising business at 39 Flinders Lane East. He returned to Germany in 1885 to marry Joseph Wertheim's daughter Sophie Emilie. The couple came back to Melbourne, and Hugo quickly established a substantial business selling sewing machines, bicycles, pianos and other mechanical devices, under brands such as Wertheim, Electra, Planet, Griffin and Hapsburg. He exhibited at agricultural shows and in 1901 at the Pan American Exposition, Buffalo, United States of America. One of his staff was O. C. Beale, who later set up his own piano business in New South Wales. Hugo continued to own 25 per cent of one of Beale's companies, which became Wertheim's Queensland business. In 1908 Hugo Wertheim opened a piano factory in Richmond, Melbourne, aiming to produce 2000 pianos and player pianos a year, predominantly using Australian materials. In laying the foundation stone, Prime Minister Alfred Deakin observed that “few men with such opportunities for a life of ease would have embarked on such an enterprise” Hugo died of chronic hepatitis in 1919 at his home in South Yarra. His eldest son, Herbert Joseph (1886-1972), continued the business. The piano factory closed in 1935, becoming a Heinz food processing plant and in 1955, GTV Channel 9 studios and offices. The Wertheim Sewing Machine Company – Joseph Wertheim (1804–1899) founded the company in 1868 in Frankfurt, Germany. At this time Joseph was the Frankfurt city delegate for the Democratic Party. At its height, the Wertheim factory employed approximately 650 workers. The company used a trademark of a dwarf holding a hammer which is known to have been used until at least 1925, however in 1909 a Star of David was also registered. In 1870 a Wertheim subsidiary was formed in Barcelona, Spain. The business imported and sold complete machines, including the English Jones machine. Locals began calling the sewing machines “las rapidas”, and the business became known as “las casa de las rapidas”. In 1915 production began of a totally manufactured Spanish Wertheim machine. Wertheim in Germany continued manufacturing machines until 1932 when the Wertheim family fled to Spain. Despite converting to Christianity from Judaism, they feared the political unrest in Germany during that time. Wertheim Spain became Rapida SA and was then the sole manufacturer of the Wertheim machines. The factory was managed by Karl Wertheim under the alias Carlos Vallin. The sewing machine accessory is part of a donation that connected to domestic life in 1891 during the Victorian era. It is significant for connecting the Melbourne distributor of Wertheim sewing machines, Hugo Wertheim, to Victoria’s northwest district where the purchaser lived. It is also significant for connecting the Melbourne distributor to the importing of goods from the well-known German manufacturer of early domestic sewing machines, Joseph Wertheim. Foot accessory tool for a Wertheim sewing machine. Mane by Joseph Wertheim, Germany, and distributed by Hugo Wertheim William Street Melbourne. Circa 1891.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, wertheim, sewing machine, victorian era, sewing machine accessory, wertheim sewing machine and hapsburg piano depot, wertheim sewing machines, domestic machines, dressmaking, home industry, fashion -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDecorative object - Sewing Machine, c 1914-1930

Sewing Machine, Medium C S. (item has 10 parts), treadle operated, in wooden cabinet. Machine body is black with floral decals in gold, cream and red. Cabinet has wheels, 4 drawers containing cylinder shuttle, 2x bobbins, handle from a drawer and a bundle of horse hair. Drive belt is missing, cabinet has evidence of borer. Ironwork on right upright has 2 splits, name on plate of treadle is worn off. Decals include English Made and Approved to Her Majesty Queen Victoria. Machine has Serial Number.Pencilled inside machine support " 11/11/10 H M X" Serial Number "66389" Decals include "MEDIUM C.S / APPOINTED TO HER MAJESTY / QUEEN VICTORIA", "ENGLISH MADE".flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, sewing machine, cylinder shuttle sewing machine, dressmaker's equipment, taylor, jones sewing machine, medium c.s. machine, medium cylinder shuttle machine -

Clunes Museum

Clunes MuseumDomestic object - SEWING MACHINE, Wertheim

Black treadle sewing machine with gold markings, on wooden base which has inlaid wood patter and inlaid ruler 2ft marked in inches, on black iron stand with wheel and treadleOn machine; Wertheim Metal plate; Wertheim Frankfurt Metal tension plate; S 524559 Stand; One plate either side of the stand with "Wertheim Frankfurt Trademark"sewing, domestic item, home sewing -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyInk Rolls - Labelling Cartridges for Addressograph Machine

The ink rolls were used in an addressograph machine. The addressograph machine used plates that contained names, addresses and classifications of each State Electricity Commission of Victoria employee working on the Kiewa Hydro Electric Scheme. The plates were put through the machine stamped in ink onto pay envelopes. See also: KVHS 0848, KVHS 1233The State Electricity Commission of Victoria employed many people on the Kiewa Hydro Electric Scheme and used the latest technology of the time to pay each of them including providing each one with a pay slip.2 large cardboard boxes, with lids, containing 3 by 4 rows of small white cardboard boxes. Inside the small boxes is a roll of ink covered by aluminium foil. Ref. KVHS 0848 which is the Addressograph MachineOn the end of one of the large boxes "For Addressograph / Purple / 1-1 and a quarter inches" / Class 22,000" Also a white label stuck on with '583' On each of the small boxes - For Addressograph / Purple / 1-1 and a quarter inches / Class 22,000 On the end of one of the lids handwritten in ink. "SF 125.7.0"addressograph machine; payroll; state electric commission of victoria; kiewa hydro electric scheme; office work; -

Orbost & District Historical Society

Orbost & District Historical SocietySewing machine, 1895 -1910

Donor, Connie Cruikshank was grand-daughter of Poppy Kerr whose father was the first doctor in Orbost. Machine belonged to her grandmother, Mrs Hilda Kerr(Temple).This item is significant for its use by an influential and well-known Orbost identity. It is also an example of a common domestic appliance of the late 19th-early 20th century.Hand-operated sewing machine. Black with gold designs, large metal turning wheel. All set on large polished block of wood.Wertheim Francfortsewing-machine kerr-dr temple-hilda cruikshank-connie wertheim -

Bendigo Military Museum

Bendigo Military MuseumPhotograph - PHOTOGRAPH, FRAMED, C.1928

Gold frame with glass front, dark green border with brown background. Photo of 6 head shots of 6th Brigade Machine Gun Team 1928 with cup in centre on white background. Frame has cardboard backing with silver wire hanging strap with 2 black cushion buttons at bottom. Cab 26 1687/1 on white tag at bottom RHS back."Dad CAPT ROY SHADFORTH" on top of background. Names of other 5 members beside each photo on background. "6th Brigade Machine Gun Team 1928 Seymour, Winners of Vickers Machine Gun Competition" on bottom.photography-photographs, frame accessories, military history - army, passchendaele barracks trust -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyNumbering Machine, Office Equipment

This numbering machine may have been used to stamp the date on documents.Used by office staff at the SECV during the construction of the Kiewa Hydro Electric Scheme.Solid stamp machine that enables changing the numbers eg. change of the date. Dipped in ink before stamping. A white bakelite knob handle at the top with stainless steel numbers able to rotate.numbering machine, office equipment -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumWeapon - Gunsight

Taken from a Japanese heavy machine gun after surrender at Lawas, British North Borneo. September, 1945Black Metal machine gunsight with spirit level and 2 X focusing wheels and sight and monocular. Metal base plate has 5 holes to secure to a benchLetters in metal: 27994 4 x 10 degrees To ? Jes 4? 154 on reverse No. 38458gunsight, gun, japan, dickinson, b, tatura, borneo, arms, firearms -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAudio - Phonograph, Thomas A. Edison, Edison Laboratory, c.1909

The Edison Fireside Phonograph Combination Type A model phonograph was an open horn model. This machine was produced around 1909, just after the introduction of 4-minute record cylinders in 1908.; the selection lever on the front was either 4 or 2-minute choice. This Fireside model has a fluted octagonal horn that attaches to the reproducer on the machine and is suspended by on ring by a horn crane attachment. The phonograph machine is powered purely by mechanical means, winding the crank handle on the side of the machine to start the belt-driven, spring-loaded motor inside. The sound comes from a pre-recorded, vertical cut record cylinder, which slides over the Mandle, a smooth rotating drum. The reproducer, an all-in-one needle, amplifier and speaker, is lowered onto the cylinder, the needle picks up the sound and plays it on the speaker and the attached horn amplifies the sound. The phonograph machine was invented by Thomas Alva Edison in the late 19th century. Edison adopted the idea from the technology of the telegraph machine. He patented the phonograph in early 1878. It was able to record sound and play it back. This amazing invention opened up a whole new world of entertainment, where wax cylinders of pre-recorded sound could be purchased with a wide variety of music and played over and over. The first wax cylinders were white and used a combination of bees' wax and animal fax or tallow. By 1892 Edison was using 'brown wax' cylinders that ranged from cream through to dark brown. The Edison Phonograph Company was formed in 1887 to produce these machines. He sold the company in 1855 to the North American Phonograph Company but bought that company in 1890. He then started the Edison Spring Motor factory in 1895, and the National Phonograph Company in 1896. In 1910 the company became Thomas A. Edison Inc. In 1898 Edison produced the Edison Standard Phonograph, the first phonograph to carry his own trade mark. He began mass producing duplicate copies of his wax cylinders in 1901 using moulds instead of engraving the cylinders. The wax was black and harder than the brown wax. The ends of the cylinders were bevelled so that the title's label could be added. The last phonograph machine to use an external open horn was produced in 1912 due to the much more robust round records being invented. In 1913 Edison started producing the Edison Disc Phonograph. The company stopped trading in 1929.This Edison Fireside Phonograph model is significant for being one of the last models to have an external horn. It is also significant for its connection with the invention of the phonograph, which made music and sound available for domestic enjoyment. It was used for entertainment and education, even teaching languages. It signalled a new era of music that could be reproduced and played anywhere. It is also significant for its short time span of popularity, just a few decades, due to the growing use of records, which gave a much higher quality sound and were more robust.Phonograph; Edison Fireside Phonograph, Combination Type, Model A. It is in a wooden case with a domed lid, metal catches on each side and a folding wooden handle. It has a metal drum and a reproducer mechanism. The metal and wood crank handle starts the machine’s motor. A sliding lever at the front selects the speed for four- or two-minute cylinders. The inscribed plate has the maker, serial number, patents and other information. The reproducer also has an inscription. It has a curved metal open horn attachment. Made in Orange, New Jersey in c.1909. NOTE: the fluted octagonal horn is catalogued separately.Case front, in script, Edison’s early ‘banner’ decal “Edison” On the front of the machine “Thomas A Edison TRADE MARK” On the maker’s plate; "Edison Fireside Phonograph Combination Type" Serial number “14718” Around sound outlet; “C 4076” “REPRODUCER LICENCED FOR USE ONLY ON EDISON PHOTOGRAPHS SOLD BYT.A. EDISON INC.” At the front edge “4 MINUTES 2flagstaff hill, maritime museum, maritime village, warrnambool, great ocean road, shipwreck coast, gramophone, phonograph, music player, entertainment, audio equipment, edison, thomas a edison, horn, phonograph horn, amplifier, audio, sound recording, sound playback, phonograph machine, phonograph cylinder, external horn, edison phonograph company, wax cylinders, sound reproduction, edison spring motor factory, national phonograph company, thomas a. edison inc, crank-operated motor, open horn phonograph, 4 speed, 2 speed -

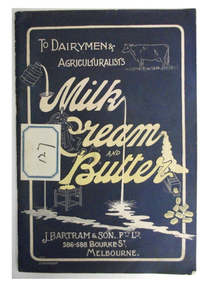

Cheese World Museum

Cheese World MuseumCatalogue, To Dairymen & Agriculturalists: Milk Cream and Butter

This catalogue belonged to Alderdice Brass Foundry in Warrnambool. It was donated to the museum by John Downing from the foundry. The catalogue is for the firm of J Bartram & Son who were suppliers of dairy equipment. They were one of the earliest suppliers of mechanical milking machines in Victoria.The catalogue is significant as it is from an early dairy supplier and shows early dairy equipment. The Alderdice Brass Foundry has been in operation since the 19th century.Blue covered catalogue booklet with white text and illustrations of a cow, separator, butter maker and butter slicer machines.To Dairymen &/Agriculturalists/Milk/Cream/and/Butter J.BARTRAM & SON. PTY. LTD./586-588 BOURKE ST./MELBOURNEcatalogues, dairy industry, j bartram & son pty ltd, dairy machinery, milk, cream, butter -

Anglesea and District Historical Society

Anglesea and District Historical SocietySewing Machine, Estimated 1890

Jones Lock-Stitch Sewing Machine made of black painted heavy metal with gold-leafed pattern on the fiddle-shaped base and along the upper arm. Four claw feet moulded on to base and handle attached to wheel - metal workings visible under hollow base.Maker's insignia on centre of base in gold and green circle reads "JONES MACHINE" around circumference and 'HAND" in central shield.machine, sewing, hand operated -

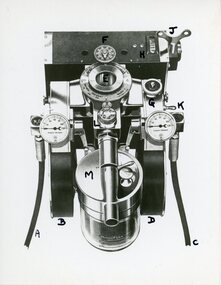

Geoffrey Kaye Museum of Anaesthetic History

Geoffrey Kaye Museum of Anaesthetic HistoryPhotograph

The McKesson Nargraf anaesthetic record was introduced in 1930, created by Dr Elmer I. McKesson.Black and white photograph of a drawing of the head of a McKesson Nargraf anaesthetic record, Model J. The view is from the top looking down onto the machine, showing a round vaporiser with a valve attached to it and two round pressure gauges on either side. The recorder on the top of the photograph does not have a chart attached to it.Each part of the machine has been labelled and handwritten in black ink the letters A - H and J - M on the surface.mckesson nargraf anaesthetic record, anaesthetic equipment -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPayroll Office Machine - S.E.C.V

This machine was used by the State Electricity Commission of Victoria on the Kiewa Hydro Electric Scheme by office workers who worked in the payroll office.The State Electricity Commission of Victoria used the latest technology available for office equipment on the Kiewa Hydro Electric Scheme. This machine was used in the payroll office.Black metal table with machine on top. Electric motor with belt drive to machine which is situated under the rear left side of the table. Safety metal mesh protects the leather belt and is at the rear of the table. The operator faces the machine which has a tray on the left and is divided longitudinally into two and holds new shiny metal plates on each side. There is a brown bakelite wheel on the left and two printing wheels inside a myriad of moving parts that enable the metal plates to be embossed with payroll information i.e. "Gang No. etc. / Names / Pay No. / Rate type. This has to be checked out each time / Date"ULQ 11 10"state electricity commission of victoria. kiewa hydro electric scheme. payroll office. office work. payroll machine. office equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAccessory - Seamer Foot, Joseph Wertheim, ca. 1891

This sewing machine accessory was donated with our collection's Wertheim sewing machine accessory box. The box contains twelve accessories, the instruction book and the receipt for the purchase of a Wertheim sewing machine. The receipt was written on July 23rd 1891 by the Wertheim distributor in Melbourne, Hugo Wertheim. His business was the Wertheim Sewing Machine and Hapsburg Piano Depot, trading at 173 Williams Street, Melbourne. The purchaser was Mrs Burrowes from Burrumbeet, Victoria, a district northwest of Ballarat. She paid £6-6 (six pounds and six shillings) in cash. The receipt was signed by H. Wertheim and the other signatory looks like John A. Cherry. Hugo Wertheim (1854-1919) was an agent for his father’s cousin Joseph Wertheim, a well-established sewing machine manufacturer in Germany. He was born in Lispenhausen, Germany, and migrated to Melbourne in October 1875, where he opened a merchandising business at 39 Flinders Lane East. He returned to Germany in 1885 to marry Joseph Wertheim's daughter Sophie Emilie. The couple came back to Melbourne, and Hugo quickly established a substantial business selling sewing machines, bicycles, pianos and other mechanical devices, under brands such as Wertheim, Electra, Planet, Griffin and Hapsburg. He exhibited at agricultural shows and in 1901 at the Pan American Exposition, Buffalo, United States of America. One of his staff was O. C. Beale, who later set up his own piano business in New South Wales. Hugo continued to own 25 per cent of one of Beale's companies, which became Wertheim's Queensland business. In 1908 Hugo Wertheim opened a piano factory in Richmond, Melbourne, aiming to produce 2000 pianos and player pianos a year, predominantly using Australian materials. In laying the foundation stone, Prime Minister Alfred Deakin observed that “few men with such opportunities for a life of ease would have embarked on such an enterprise” Hugo died of chronic hepatitis in 1919 at his home in South Yarra. His eldest son, Herbert Joseph (1886-1972), continued the business. The piano factory closed in 1935, becoming a Heinz food processing plant and in 1955, GTV Channel 9 studios and offices. The Wertheim Sewing Machine Company – Joseph Wertheim (1804–1899) founded the company in 1868 in Frankfurt, Germany. At this time Joseph was the Frankfurt city delegate for the Democratic Party. At its height, the Wertheim factory employed approximately 650 workers. The company used a trademark of a dwarf holding a hammer which is known to have been used until at least 1925, however in 1909 a Star of David was also registered. In 1870 a Wertheim subsidiary was formed in Barcelona, Spain. The business imported and sold complete machines, including the English Jones machine. Locals began calling the sewing machines “las rapidas”, and the business became known as “las casa de las rapidas”. In 1915 production began of a totally manufactured Spanish Wertheim machine. Wertheim in Germany continued manufacturing machines until 1932 when the Wertheim family fled to Spain. Despite converting to Christianity from Judaism, they feared the political unrest in Germany during that time. Wertheim Spain became Rapida SA and was then the sole manufacturer of the Wertheim machines. The factory was managed by Karl Wertheim under the alias Carlos Vallin. The sewing machine accessory is part of a donation that connected to domestic life in 1891 during the Victorian era. It is significant for connecting the Melbourne distributor of Wertheim sewing machines, Hugo Wertheim, to Victoria’s northwest district where the purchaser lived. It is also significant for connecting the Melbourne distributor to the importing of goods from the well-known German manufacturer of early domestic sewing machines, Joseph Wertheim. Seamer foot; feller single seamer for a Wertheim sewing machine. Made by Joseph Wertheim, Germany, and distributed by Hugo Wertheim, William Street Melbourne. Circa 1891flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, wertheim, sewing machine, victorian era, sewing machine accessory, wertheim sewing machine and hapsburg piano depot, wertheim sewing machines, sewing machine foot, seamer foot, domestic machines, dressmaking, home industry, fashion -

Albert Park-South Melbourne Rowing Club

Albert Park-South Melbourne Rowing ClubMoore Sculling Machine

"Grace Blake’s conversations with older members of the Club have elicited the following information during July 2014: • Don Christie recalls the machine being acquired by (or donated to) SMRC in the 1960s. SMRC later donated it to APRC. • Bob Duncan remembers it being at APRC. • Max Shaw joined the club in 1946 but doesn’t recall it at all. • Peter Watson recalls collecting the rowing machine from the old APRC club house before its demolition (c. 1995). The AP-SMRC machine carries a ‘maker’s plate’ with the name Moore... Moore Crane and Engineering Company Pty Ltd was a subsidiary of Malcolm Moore Industries Ltd whose manufacturing engineering works were located on Williamstown Road, Port Melbourne from 1927. The founder established the main business in 1921 and retired in 1953.21 The business was delisted from the Australian Stock Exchange in 1976. Grace Blake advises that some of the earlier SMRC members were plumbers and therefore worked in trades connected with engineering. She reports that Peter Watson recalls some of his contemporaries completing their engineering apprenticeships at Malcolm Moore Industries Ltd in the 1970s. There are still many unanswered questions concerning the history and provenance of the rowing machine at the time of writing this report, but the connection with a local engineering works is certainly fascinating. Questions to explore in the future include: Did Moore manufacture the machine, or import it (and perhaps assemble it) under licence? Was this machine a ‘one-off’ or did Moore make / distribute others within Australia? When, why and how did SMRC acquire the machine? Why did SMRC decide not to retain it, but to pass it over to APRC? And how did APRC use it?" 2014 Significance Assessment, pp38-40. "The ‘Moore’ Rowing Machine at the Albert Park – South Melbourne Rowing Club (AP- SMRC) is a rare example in Australia of the Kerns patent design from 1900. This machine may not, however, be that old in construction or use. The AP-SMRC machine is almost intact, appearing to lack only the leather straps for fastening the rower’s feet to the foot-rests. Spalding manufactured the design in the USA in the early decades of the 20th century, but the metal elements in its models are traditionally black. The bright red paint on the AP-SMRC machine suggests something different. The AP-SMRC machine carries a maker’s plate that associates it directly with a local engineering business, Malcolm Moore Industries Ltd of Williamstown Road, Port Melbourne. Club members recall the machine being at the South Melbourne Rowing Club in the 1960s, and being transferred at a later date to the Albert Park Rowing Club. The machine has not been used since the founding of the amalgamated AP-SMRC and requires careful conservation. The ‘Moore’ rowing machine is of national research significance as a rare survivor, in Australia, of the well-regarded Kerns patent design that was popularised by Spalding in the northern hemisphere. The English River and Rowing Museum website quotes a testimonial from an AG Spalding & Bros’ Mail Order Catalogue: ‘This machine was described by ‘an experienced oarsman’ ... “to be the most perfect rowing machine ever produced”. A feature was the adjustment of the resistance so “the weaker sex can use the machine”’. Its historic significance lies in its rarity (and perhaps uniqueness) as an aid to the training of rowers at two successful clubs on Albert Park Lake. Additional historic significance lies in the connection that the rowing machine represents between local rowing clubs and a major local manufacturing engineer. The ‘Moore’ rowing machine bridges the realms of innovation and application, of industry and recreation, of land-based and aquatic sports, and of two neighbouring rowing clubs on the Albert Park Lake." 2014 Significance Assessment, p43"A rowing machine that appears to be built to the Kerns patent design from 1900 but may not be that old in construction or use. The machine is heavy and includes parts made from cast iron. The cast iron components are painted in a distinctive bright red. The wooden seat moves on timber slides. Resistance is created by spring mechanisms at the ends of two frame elements that connect with two wooden ‘oars’, and by the central chain-driven system that co-ordinates with the rower’s movements. The machine carries a maker’s plate with the single word ‘Moore’ in an oval design, using white letters against a navy background, fastened to the base board and close to the foot-rests." 2014 Significance Assessment, p38Moorerowing, apsm rowing club, significance assessment, malcolm moore industries ltd, kerns, 1900, sculling machine, albert park rowing club, south melbourne rowing club, albert park lake, rowing machine, ergo -

Lakes Entrance Historical Society

Lakes Entrance Historical SocietyPhotograph - Elaine Benton , Anne Mills and Jane Martin, Lakes Post Newspaper, 1/04/1995 12:00:00 AM

Elaine Benton and Anne Mills receiving awards for their patchwork skills by Jane Martin of Pfaff Sewing Machines Lakes Entrance VictoriaBlack and white photograph showing Elaine Benton and Anne Mills receiving awards for their patchwork skills by Jane Martin of Pfaff Sewing Machines Lakes Entrance Victoriapeople, handcrafts -

Vision Australia

Vision AustraliaEquipment - Object, American Foundation for the Blind, Tellatouch

The Tellatouch was developed in the American Foundation research laboratory and resulted from one of the first AFB research projects, a major effort in the mid-1940s to help deaf-blind people. The device helped end social isolation for hundreds of deaf-blind children and adults. The Tellatouch provides a means of communication between a sighted (or blind) person and a deaf-blind person who can read braille. The keyboard has three rows of ten keys each and a standard braille keyboard on the fourth row. At the rear of the machine is a round metal plate with the braille cell in the center. The deaf-blind person rests a finger on the braille cell. Pins rise to form the equivalent of the letter key that is struck. The body of the device covered in beige vinyl, with a hinged lid at the front which lifts up to reveal the keyboard. The lid is secured with a metal latch at the front.Beige vinyl machine with leather carry strapbraille equipment, assistive devices -

National Wool Museum

National Wool MuseumTextile - Quilt, 1910 - 1940

Part of the "Wagga collection". Made from squares of patchwork suiting, machine stitched with red diamond and rectangle motifs at strategic positions. The diamonds look like they have been inserted in the fabric pieces where a dart has been cut and opened out.Quilt made of squares of patchwork suiting and fabric offcuts, machine stitched with red diamond and rectangle motifs at strategic positions.quilting history, patchwork history, running stitch group, running stitch collection, quilting - history, patchwork - history -

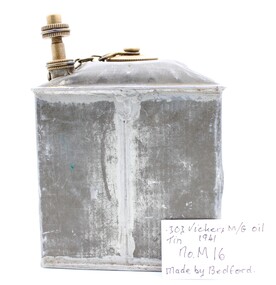

Shepparton RSL Sub Branch

Shepparton RSL Sub BranchVickers Machine gun Oil tin, 1941

Standard ww2 .303 Vickers Machine gun oil bottleWW2 Vickers Machine gun Oil Tin, 1 Quart size dated 1941, with brass oil filling plug and Brass pouring spout and Brass chain linking both. Domed top and rectangular base.11 1941 Bedford?oil bottle -

Clunes Museum

Clunes MuseumPhotograph

STAFF OF THE CLUNES KNITTING MILL 1923. INTERKNIT SPINNING MACHINE.1 B/W PHOTOGRAPH SHOWING STAFF IN FRONT OF THE CLUNES KNITTING & MFG CO. LTD. (INCLUDES SOME CHILDEN) 1923. RECEIPT ATTACHED 1992. .2 B/W PHOTOGRAPH OF SPINNING MACHINE IN THE FACTORYclunes knitting mill staff, machinery, spinning -

Australian Lace Guild - Victorian Branch

Australian Lace Guild - Victorian BranchTextile - Bonnet veil with Agentan lace motifs, Argentan motifs - mid 18th century. Bonnet veil mid 19th century

Fashion Item. Bonnet veils were very fashionable during the 19th century. At this time old lace was highly valued - in this case old Argentan needle lace motifs (mid 18th century) have been reclaimed and appliqued onto machine made cotton net to form this 19th century bonnet veil. Probably home-made.Mid 18th century Argentan needle lace motifs appliqued onto machine-made cotton net.lace veil, bonnet veil. -

Blacksmith's Cottage and Forge

Blacksmith's Cottage and ForgeSewing machine

A domestic sewing machine used for dressmaking and handcrafts which was operated by hand.A hand sewing machine with a cast metal body and gold leaf decoration on the 'arm'. It stands on four 'legs/feet' with a kidney shaped base. The driving wheel is grooved for a belt. This has no handle. All cogs move.domestic, needlework, sewingmachine, stitching, dressmaking, needlecraft