Showing 746 items

matching machine made

-

Kiewa Valley Historical Society

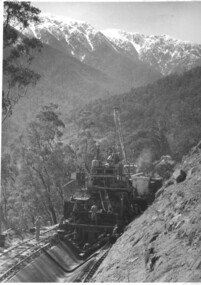

Kiewa Valley Historical SocietyPhotograph of Bogong Creek Raceline, Bogong Creek Raceline, circa 1951

A start on the construction of Bogong Creek race line was made at the commencement of winter in 1948. Work proceeded in the following years when work on the High Plains was not practicable. In January, 1951 the special trimming machine, the special slip form and concrete mixing and placing equipment was put into service. A shortage of cement caused some delays as well as a sudden financial recession. The race line was completed and put into service in 1952. An historical record showing the machinery used , the number of workers needed at any one time ( about 16 in this photo) and the mountainous terrain of the area. Black and white photograph taken during construction of Bogong Creek Raceline, showing the type of machine used for the formation of the concrete lining, the mountainous terrain, a number of workmen and a snow capped Mt. Bogong in the backgroundHandwritten on the back of photograph in black ink "Bogong Creek race line".race line, cement, machinery, bogong -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyTins - Tobacco (Lucky Hit) x4, Mid to late 1900s Possibly c1910

... smokers turning away from expensive machine (tailor) made ...The British Australasian Tobacco Co. (based in Melbourne and Sydney. The parent company was founded in England, circa 1902). This item "Lucky Hit" was the fore runner of the "Lucky Strike" brand name. The ready rubbed tobacco held within the tin was mainly used by those smokers who rolled their own cigarettes. These smokers would have mainly used their palm and formed a cup then placing their choice of the amount of tobacco to be rolled. This would then be placed on the fine cigarette paper and rolled and sealed (using saliva in the mouth) into the required shape. There were mechanical "roll you own" gadgets on the market but most rural users, especially males used their palms. The quantity of tobacco used to make up the cigarette was up to the individual user. The thinner that the cigarette was rolled the longer and more economical did the supply last. The by -products of this method were nicotine stained fingers and hands. "Chain" smokers were easily identified and could therefore be discriminated against obtaining smoke sensitive employment. The two world wars (1914-18 and1939-45) produced a significant rise in the consumption of cigarette use by men and the eventual overflow to women. Cigarette smoking before the 1900s was seen as rough and uncouth (socially frowned upon), however after the introduction of overseas films (U.K. and U.S.A.) and film stars presenting smoking as socially acceptable the rise of smoking cigarettes, especially roll you own (American western movies) in rural areas was an accepted way of life. Things however started to change in the mid 1900s when medical evidence pointed to the health problems of regular smokers. Governments were now implementing non smoking education material. Restrictions on where and when smoking was permitted and acceptable started to creep into all areas of society whether city or rural. This was the era that highlighted the use of roll your own cigarettes, especially when the costs of "tailor made" cigarettes were taxed at an increasing amount. Roll your own cigarettes also provided an avenue for the consumption of illicit drug use.The significance of this ready rubbed tobacco tin to this rural region is, stems from how much influence that the Western novels and overseas films (portraying rural lifestyles) played in shaping the rural social and working mores of the Kiewa Valley. The post war depression (financially) resulted in more smokers turning away from expensive machine (tailor) made cigarettes to the roll your own, using ready rubbed tobacco. This tobacco tin relays a long ago era, when personal contact, and not something that has been written down by some "unknown", was valued as the true appraisal of a member of the community. This was especially relevant in a small regional area such as the Kiewa Valley. Although social networking was not as fast then as the internet provides now, appearances, manners, fashion and etiquette with first impressions high on the order of evaluating someone in the community. Pointer such as the brand of tobacco smoked was part of the rural assessment method. Up until the demise of the Australian Tobacco Industry, circa 2004, the Kiewa Valley and surrounding district was part of a vibrant producer of tobacco leaves. The remnants of this industry still remain today but the drying sheds (for tobacco leaves) are now used to store hay for the valley's dairy and beef cattle industries. Tins 2,3 and 4 were found (in 2009) at Wallace's Hut on the Bogong High Plains. This tobacco tin is constructed from tin plated thin rolled steel. The lid is attached by two pressed and formed (from the main frame) hinges using the nip and tuck construction method. The lid and outside frame have been gold & silver anodised. Tins 2,3 and 4 have the Union Jack on the front lid. One is too rusty to read. The other two have "A blend containing choice selected Australian grown leaf" in white across the bottom on the red border and above the "2oz net weight when packed". In the centre and on the outside of the lid and surrounded by a reproduction of the "Union Jack" is stamped, "Lucky Hit Tobacco" within these words are also stamped "Ready Rubbed". The bottom of the lid is stamped (in smaller script) "2oz NET WEIGHT WHEN PACKED" and underneath this and on the rim of the lid is "THE BRITISH AUSTRALASIAN TOBACCO CO. PTY. LTD. MELBOURNE" on the inside of the lid and stamped in black print on a gold anodised lid is " NOTICE "(underlined) "Every tin of genuine "Lucky Hit has the name of the Manufacturing Company printed on wax paper lining; also on the band or wrapper with which the tin is sealed. THE BRITISH-AUSTRALIAN TOBACCO CO. PTY. LTD., MELBOURNE" and underneath this and underlined is " None genuine without the band or wrapper" On the hinge side of the lid is "LUCKY HIT READY RUBBED TOBACCO" Tins 2,3 and 4 Vary to the above inscription.roll your own, cigarette tins, smoking accessories, personal effects, tobacco containers, tobacco -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyTin Tobacco, Mid to late 1900s

... smokers turning away from expensive machine (tailor) made ...The British Australasian Tobacco Co. (based in Melbourne and Sydney. The parent company was founded in England, circa 1902). This item "HAVELOCK" is one of many ready rubbed tobacco tins produced by the British Australasian Tobacco Company.The ready rubbed tobacco held within the tin was mainly used by those smokers who rolled their own cigarettes. These smokers would have mainly used their palm and formed a cup then placing their choice of the amount of tobacco to be rolled. This would then be placed on the fine cigarette paper and rolled and sealed (using saliva in the mouth) into the required shape. There were mechanical "roll you own" gadgets on the market but most rural users, especially males used their palms. The quantity of tobacco used to make up the cigarette was up to the individual user. The thinner that the cigarette was rolled the longer and more economical did the supply last. The by -products of this method were nicotine stained fingers and hands. "Chain" smokers were easily identified and could therefore be discriminated against obtaining smoke sensitive employment. The two world wars (1914-18 and1939-45) produced a significant rise in the consumption of cigarette use by men and the eventual overflow to women. Cigarette smoking before the 1900s was seen as rough and uncouth (socially frowned upon), however after the introduction of overseas films (U.K. and U.S.A.) and film stars presenting smoking as socially acceptable, the rise of smoking cigarettes, especially roll you own (American western movies) in rural areas was an accepted way of life. Things however started to change in the mid 1900s when medical evidence pointed to the health problems of regular smokers. Governments were now implementing non smoking education material. Restrictions on where and when smoking was permitted and acceptable started to creep into all areas of society whether city or rural. This was the era that highlighted the use of roll your own cigarettes, especially when the costs of "tailor made" cigarettes were taxed at an increasing amount. Roll your own cigarettes also provided an avenue for the consumption of illicit drug use.The significance of this ready rubbed tobacco tin to this rural region is, stems from how much influence that the Western novels and overseas films (portraying rural lifestyles) played in shaping the rural social and working mores of the Kiewa Valley. The post war depression (financially) resulted in more smokers turning away from expensive machine (tailor) made cigarettes to the roll your own, using ready rubbed tobacco. This tobacco tin relays a long ago era, when personal contact, and not something that has been written down by some "unknown", was valued as the true appraisal of a member of the community. This was especially relevant in a small regional area such as the Kiewa Valley. Although social networking was not as fast then as the internet provides now, appearances, manners, fashion and etiquette with first impressions high on the order of evaluating someone in the community. Pointer such as the brand of tobacco smoked was part of the rural assessment method. Up until the demise of the Australian Tobacco Industry, circa 2004, the Kiewa Valley and surrounding district was part of a vibrant producer of tobacco leaves. The remnants of this industry still remain today but the drying sheds (for tobacco leaves) are now used to store hay for the valley's dairy and beef cattle industries.This tobacco tin is constructed from tin plated thin rolled steel. The lid is attached by two pressed and formed (from the main frame) hinges using the nip and tuck construction method.The lid and outside frame have had a green "weave" pattern anodised to the metal.On the outside of the lid and at the top left is stamped, in gold coloured letters "HAVELOCK". The bottom of the lid is stamped (in smaller script) "READY RUBBED TOBACCO" and below this in smaller lettering "2oz NET WEIGHT WHEN PACKED". On the rim of the lid is "THE BRITISH AUSTRALASIAN TOBACCO CO. PTY. LTD." Inside of the lid and stamped in black print on a gold anodised lid is "Every tin of genuine HAVELOCK Ready Rubbed Tobacco has the mane Havelock printed on the paper lining, and also on the band or wrapping sealing the tin. On the hinge side of the lid is "HAVELOCK READY RUBBED"roll your own, cigarette tins, smoking accessories, personal effects, tobacco containers -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyTelephone - Wall Mounted 184, Circa mid 1900s

This handset appeared via Australia Post Office and was to some degree manufactured in Britain just prior to 1939. During and after World War II these handsets were made in Australia. The handset belonged to the SEC Victoria and later the Kiewa Hydro Electricity Scheme. As this unit has a winder arm (to notify the switchboard) it would have resided in a workshop/machine shop and not in an office. The durability of the bakelite covering gave good protection in any environment. In years later the bakelite came in colours. This type of handset being able to endure rough handling was ideal for the surroundings of the alpine terrain. It would have been at the various outside outposts or foreman posts as swift communications was essential and communications with all sectors of work in the Hydro Electricity Scheme was mandatory, not only for safety reasons but also for efficient operational day to day progress. Also refer to article in "This Week" Newsletter 30th June 2023. Article attached to paper copy.This Australian Post Office 184 black coloured bakelite wall mounted phone was initially developed by Ericsson Telephones Ltd Britain. It was used by the SEC Office based at Mount Beauty and therefore has a winder (for power and notification to the switchboard. The hand piece (large ear and voice receptors)is placed vertically above the dial up winder.On the winder plate in hand writing is" turn handle lift handset" and below the handle "when finished replace handset turn handle"sec communications, wall telephone, internal communications kiewa hydro electricity scheme -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Memorial Tower, Kangaroo Ground c.1934, 1934c

Sepia photograph of Joyce McMahon and 'Tiny' Carroll at the War Memorial Tower, Kangaroo Ground c.1934. The guns were installed in 1934 and removed in 1942. Taken in the early 1930s, the photograph ... shows the Kangaroo Ground Tower of Remembance with Joyce McMahon, daughter-in-law of Mr. P. J.McMahon, the then Shire of Eltham Secretary, her horse and a very tall person patting the horse. He is ex-serviceman W. "Tiny" Caroll who was the council's caretaker of the surrounding War Memorial Park. He lived in the stone cottage which still stands in the park. "Tiny" is seen as the fictional character "Tiny Bourke" who, in author Alan Marshall's book "This is the Grass", "was a giant of a man, well over six feet high, with huge hands that completely encircled the cup of tea". The bronze casting, which shows the 79 names of those who paid the "supremen sacrifice" in World War 1 (1914-1918), was erecfed above the entrance to the Tower in September, 1930. The Monterey cypress trees which now form the windbreak around the park's fenceline, were just knee high in this photograph. They were planted in August 1926, with all the plantings paid for, and done, by the public as the Tower was being erected. The two field guns have been identified as of German origin, Krupp 77 mm calibre captured on October 4, 1918 at Geneve, France. They were removed in 1943/44 as a wartime requirement of the Australian Govenment. A public notice dated October 16, 1926 by Cr. H Rutter, Chairman of the Eltham Soldiers War Memorial League stated: "On the summit of that central and conspicuous landmark, Garden Hill, there is being erected a massive memorial tower which will, for all time, remind every passerby of the part played by the men of the Shire of Eltham in the Great War. The work has been undertaken by the people of the Shire a a tribute of love and admiration for those who were known and dear to use in the days of their youth and early manhood, who went out from amongst us, never to return, and whose self-sacrifice has made us, each and all, thier ever-lasting debtors" Harry Gilham, Eltham District Historical Society Kangaroo Ground Tower of Remembrance, A Journey in Time: a column about Nillumbik's history, Nillumbik Mail, 9th August, 2000 Since that research the following has been sourced from Eltham and Whittlesea Shires Advertiser and Diamond Creek Valley Advocate, April 8, 1921, p. 3 Retrieved April 25, 2020, from http://nla.gov.au/nla.news-article57639687 Eltham Shire Council From Town Clerk, Melbourne, stating that a light machine-gun captured by the 22nd battalion, A.I.F. at La Motte Farm, near Beaurvoir, on Oct. 3rd, 1918, during the operations which won the Beauvoir line and completed the smashing of the great Hindenburg defence-system, has been alloted to the Shire of Eltham. - On the motion of Crs Hubbard and Smedley, it was decided to have the gun placed in the Memorial Park. Sepia Photographgarden hill, gun, joyce mcmahon, kangaroo ground, memorial tower, shire of eltham war memorial tower, tiny carroll, war memorials, war trophy, william carroll -

Warrnambool RSL Sub Branch

Warrnambool RSL Sub BranchArmy Uniform, shirt, Fletcher Jones & Staff, 1983

This uniform was worn by Bernie Farley, present secretary of Warrnambool RSL (2019). The uniform was made by Fletcher Jones & Staff, Warrnambool in 1998.Long sleeve Khaki shirt, two long sleeve button down breast pockets, six button fastenersPrinted on collar "SIZE 40 84" Printed on tag"A.G.C.F. VIC 1983 [ARROW MOTIF] 8405.66.088.7064 Size 40/84 SERVICE NO. NAME. DO BOIL OR WRING, MACHINE WASHABLE, DRIP DRY, IRON LIGHTLY WITH WARM IRON Patch on Left shoulder with rising sun, crown and cross. THE AUSTRALIAN ARMY.army uniform, military uniform, warrnambool ex service -

Warrnambool RSL Sub Branch

Warrnambool RSL Sub BranchTrousers, Australian Defence Apparel, 2015

These trousers are part of a General Purpose Uniform issued by the Australian Airforce to Bernard Farley during service. This uniform type was developed in 2014 and replaced camouflage as the uniform worn during general base duties and in non-warlike environments. Although a camouflage pattern, this design is not intended for use as camouflage. This item has social significance, as an item of uniform worn by Warrnambool RSL community member and Secretary (2019), Bernard Farley during service with the Australian Airforce. The item is a representative example of current Airforce General Purpose Uniform and is in excellent condition. As a set, the uniform has aesthetic significance in it’s design, incorporating GPU uniform design from the Army alongside the colours and motifs of the Australian Airforce. General Purpose Uniform (GPU) trousers in Airforce colours of blue and grey in camouflage pattern. Long pants with elasticised drawstring fastener at ankle and velcro adjustment fasteners at the waist. Pants take a straight leg style and bears several pockets: two thigh level pockets with zippered horizontal opening, two open hip pockets on the front, one open pocket on the reverse right hand side with blue plastic button fastener. Five large belt loops encircle the waist and there is a zippered fly, secured at the top with a blue plastic button.Label on interior front right of trousers reads: “A193/ADA/MADE IN AUSTRALIA/JUL 2015/ PO: CC2X91/NSN: 8415 66 161 4017/SIZE: 95 R/(broad arrow)/NAME:............/PM KEYS NO:............./75% COTTON 25% POLYESTER/WARM MACHINE WASH 40*C/RINSE WELL, WARM IRON/DO NOT IRON OVER HOOK AND PILE/DO NOT BLEACH/DO NOT STARCH/MAY BE TUMBLE DRY 40*C/DRYCLEANABLE (P)”camouflage, general purpose uniform, airforce, uniform, australian defence force -

Warrnambool RSL Sub Branch

Warrnambool RSL Sub BranchTrousers, Australian Defence Apparel, 2015

These trousers are part of a Disruptive Pattern Combat Uniform issued by the Australian Airforce to Bernard Farley during service. This uniform type was used in base and field activities and was replaced in 2014 by the General Purpose Uniform as the uniform worn during general base duties and in non-warlike environments.This item has social significance, as an item of uniform worn by Warrnambool RSL community member and Secretary (2019), Bernard Farley during service with the Australian Airforce. The item is a representative example of previously standard issue Airforce uniform and is in excellent condition. As a set, the uniform has aesthetic significance in it’s design, incorporating the Disruptive Pattern style of camouflage which has its roots in the 1980s and continues to be adapted into uniform design by the Defence Force.Disruptive Pattern trousers in five colours of green and brown. Long pants with elasticised drawstring fastener at ankle and velcro adjustment fasteners at the waist. Pants take a straight leg style and bears several pockets: two thigh level pockets with zippered horizontal opening, two open hip pockets on the front, one open pocket on the reverse right hand side with blue plastic button fastener. Five large belt loops encircle the waist and there is a zippered fly, secured at the top with a blue plastic button.Label on interior front right of trousers reads: “A13/ADA/VICTORIA 2008/(broad arrow)/SPECIFICATION ARMY (AUST)6542/NSN: 8415 66 152 1059/SIZE: 95 S/NAME/SERVICE NO/75% COTTON 25% POLYESTER/WARM MACHINE WASH 40*C/RINSE WELL, WARM IRON/DO NOT IRON OVER HOOK AND PILE/DO NOT BLEACH/DO NOT STARCH/MAY BE TUMBLE DRY 40*C/MADE IN AUSTRALIA” The name “FARLEY” is also handwritten on the back interior waist band of the trousers. camouflage, general purpose uniform, airforce, uniform, australian defence force -

Warrnambool and District Historical Society Inc.

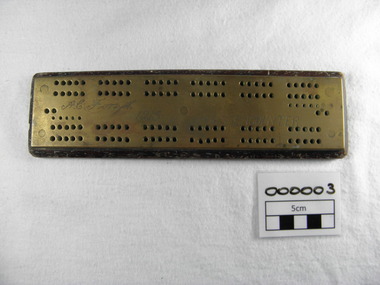

Warrnambool and District Historical Society Inc.Domestic object - Game, Cribbage board, Prior to 1913

This item is linked to the 'HMAS Encounter', possibly made on the ship c. 1913. In 1916 this ship visited a then unnamed island off the Western Australian coast, where the crew discovered two bronze cannons protruding from the sand. These cannons now in the WA Maritime Museum, Fremantle, have been linked to the "Mahogany Ship" legend by historian K.G. MacIntyre. Cribbage is a very popular card game, particularly with naval personnel. This cribbage score board belonged to Alexander Charles Forsyth who used it aboard H.M.A.S. Encounter in 1913. He was a stoker, service number 3086, from New South Wales. H.M.A.S Encounter, the fourth warship of that name, was built at Devonport Dockyard, Tasmania, for the Royal Australian Navy in 1905. She was a second class protected cruiser and in 1909 was lent for three years to the British Admiralty. In 1913 (the year marked on this cribbage board) she was in New South Wales and Queensland waters and in World War One she served in the Pacific region, taking part in the capture of German New Guinea. She was finally scuttled in 1932.Social significance: an example of leisure activities in early C20th. Historical significance: link to "Mahogany Ship" legend through H.M.A.S. Encounter. This is an interesting item with social significance as cribbage was a popular game, particularly in the 20th century, and it illustrates the pastimes of a generation past. It was given to Warrnambool and District Historical Society by a Wangoom couple and so may have local significance if A.C. Forsyth was related to this couple. H.M.A.S. Encounter was important in Australia’s naval history. Rectangular brass plate with rows of holes, grouped in tens. Plate mounted with 5 brass studs to a rectangular wooden base. 134 holes in brass, grouped in tens. Three holes in each end of wooden base. Board used for scoring made out of brass for game of cribbage Burnished gold on playing surface Reddish-brown on base 144 main indentations, 10 minor indentations Machine engraved "A.C. Forsyth" (in script)/ "1913"/ "H.M.A.S. ENCOUNTER" across middle of the plate, between the rows of holes. brass, ships, leisure, royal australian navy, cribbage board, games, mahogany ship, a s forsythe, encounter, alexander charles forsyth, warrnambool -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Textile - Work Apron, 1883-1899

The personal 'carry-all', a cloth apron like article was utilised by Thomas Hamilton Osborne in his work with the Warrnambool Steamship Navigation Company. He was Company manager in 1883 until its dissolution in 1899. Osborne wrote many articles on early Warrnambool, particularly maritime material under the name of " Sliding Gunter". When he died he was buried at sea off the breakwater.His sister Mrs Annabella Kell is thought to have made this article.This is a significant item as T.H.Osborne was a key figure in 19th Century Warrnambool history, particularly in maritime affairs. Six sided, scalloped edges, four pockets, two metal hooks, purple woven fabric with yellow and gold embroidery, lifebuoy outline with W.S.N.Co and THO initials embroidered and two flags. Machine sewing of pockets and tab to base apron.W.S.N.Co THO initials on top of each other Two metal hookswork apron, warrnambool steamship navigation company, wsnc, thomas hamilton tracey osborne, annabella kell, sliding gunter -

Orbost & District Historical Society

Orbost & District Historical Societycape, Before 1922

This cape comes from the estate of James Cameron who was one of the first Snowy River councillors for the Tambo Shire. He selected land at Lochiel in 1892. From 1902-1920 he was the Assembly member for East Gippsland.A black shoulder cape made of crepe silk. It has scalloped edges and is probably hand-made. It fastens with press studs and the hems have been machined.cape silk clothing -

Orbost & District Historical Society

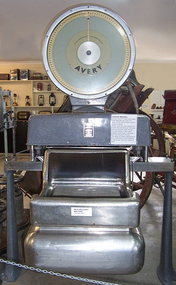

Orbost & District Historical Societyscales, circa 1930's

These scales were in the Dicken building in Nicholson Street Orbost. Frank B. Dicken and his son, Selwyn, were General Merchants. These scales are an example of a commercial measuring instrument used in Orbost before the common use of the metric system and digital scales.A large set of commercial scales painted white. The measuring scale gives the weight in pounds and the price per pound. There is a brass plate with NO A572/19951 W. & T. AVERY LTD.On front in green print - AVERY Beneath scale in green print - SOLE AGENTS On a brass plate - MACHINE ??????? "WHITE KNIGHT" AUSTRALASIAN FNO4 BRITISH MADE SCALE CO LTD TRULY LEVEL BIRMINGHAM ENGLANDscales measuring-machines weights dicken-frank -

Orbost & District Historical Society

Orbost & District Historical Societychristening robe, C 1900

... christening robe made of fine cotton. It is hand made edged... robe made of fine cotton. It is hand made edged with machine ...Christening gowns are traditional outfits made just for baby’s baptism. They are almost always white and can be very ornate, highly decorated garments. Usually, the christening gown is quite long – much longer than the baby being christened, particularly when it is worn by a young or very small baby. Many families keep a “family” christening gown that has been passed down through various family members and is used for the baptism ceremony. This christening robe was probably used by the Cameron family.The christening gown was a late 18th century innovation usually made of white lawn, muslin or net, longer than the baby and fancier than a day gown. The design was a more moderate version of contemporary adult fashion. Most 19th century christening gowns featured lace. All, until the end of the century, had low necklines and short sleeves. This gown reflects the style of christening robes in the early 20th century. A high waisted, short-sleeved long white broderie anglaise christening robe made of fine cotton. It is hand made edged with machine stitched cut work lace. The bodice is pin tucked.christening-robe clothing-childhood -

Cheese World Museum

Cheese World MuseumButter Churn, Taco butter churn, 1880 (estimated)

These glass churns came in several different sizes. A 3 and 1/2 pint vessel could churn 2 pints of cream into butter. A similar glass churn is advertised in the mail order catalogue for D & W Chandler Ltd, Melbourne. Issue No.49, page 168. Listed as 'Butter machines (Glass) Makes butter equal to the best wooden churn, and quicker. Prices-2 qts, 9/6; 3 quts, 13/3; 4 qts, 14/6 each.'Taco butter churn with square clear glass jar with round mouth and round green painted metal lid with a small wedge of airholes. The lid has a round turning mechanism with attached wooden handle. A shaft with a metal paddle goes down into the jar to beat the cream. A paper label is attached to the bottom.'Taco Burnley England' on turning mechanism on lid, 'British Foreign Pats Pending' on reverse. 'Made in England' imprinted on base. Paper label attached to base 'Kraft Foods Ltd' 'M.G.'butter, allansford, dairy industry, dairy utensils, butter churns, kraft foods ltd, taco -

Cheese World Museum

Cheese World MuseumPump, dairy vacuum

From the dairy farm of Leon Miller, Swans Lane, AllansfordMilking machine chain driven vacuum pump made of cast iron, marked on the circular cylinder cap with an identification number.209allansford, machinery, dairy machinery, dairying, pumps, milking machines, leon miller -

Cheese World Museum

Cheese World MuseumCentrifuge, electric

This Babcock tester was used in the laboratory at the Kraft cheese factory, Allansford. When it was superseded it was passed to one of the users of the machine, Les O'Callaghan, president of the Warrnambool & District Historical Society who placed it in the historical society collection. In 2009 when the historical society premises were upgraded there was insufficient room to store the tester so it was donated to Cheese World Museum. The machine was used to test the butterfat content of milk. Prior to dairy factories coming into existence farmers made butter individually on farms. There was no need for milk testing until farmers supplied factories for payment. Payment was based on a gallon of milk weighing 10lbs (pounds) and this led to richer milk, containing a high degree of butterfat for use in buttermaking, being paid at the same rate as lesser quality milk. In 1890 Stephen Moulton Babcock, an American professor at the University of Wisconsin-Madison, developed a method of determining the amount of butterfat in milk, thus providing a standardised and fairer system for payment. Babcock Test Process 1. 18 grams of milk (17.6ml) was put into a test tube 2. The same amount of sulphuric acid was added 3. A centrifuge at 50ºC was rotated at more than 900 revs per minute 4. The fat floating on top of the liquid in the test tube was measured The Babcock Test provided fairer compensation to farmers and also helped produce a consistent product for consumers. It also allowed for selective breeding when dairy herd testing evolved. ‘The Babcock Test is so simple that it can be used by any careful person, and it is inexpensive to operate. From the very beginning it was so complete in every detail that no change has had to be made in it.’ (Babcock Test http://www.en.wikipedia.org/wki/Babcock_test 31 March 2009) Round green metal container with opening lid. Inside houses a spinning rotor with 20 test tube holders around the outside in two circular rows.7173 BABCOCKTESTER 190allansford, dairy manufacturing, milk testing, babcock test, babcock, stephen moulton, butter, warrnambool cheese and butter factory company -

Cheese World Museum

Cheese World MuseumMilk weighing machine, Perfect Cheese company weighing machine

Perfect Cheese Company was founded in 1930 by newly-arrived Italian migrant Natale Paquale Italiano. The company specialised in traditional Italian-style cheese but also produced Greek, Cypriot and Maltese origin cheeses. The cheeses were sold in Australia and Italy with all products being matured and non-processed. The company remained in operation until the early 2000s.This weighing machine is significant as it represents the machinery used by an early cheese production company.Large metal machine with cast iron with a cast iron frame and a stainless steel rectangular bowl in a cradle. The round weighing scale at the top shows a weight scale up to 1100 pounds. A mesh stainless steel baffle strains the milk.Made in England Birmingham - AVERY SOLE AGENTSallansford, perfect cheese company, avery, cheese manufacturing, dairy industry -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Dowel Maker (Moot), Mid to late 19th Century indication of this date range is due to the engraved handles and brass ferrules often used on hand tools of this era

A dowel is a cylindrical rod, usually made of wood. In its original manufactured form, a dowel is called a dowel rod. Dowel rods are often cut into short lengths called dowel pins.These are commonly used as structural reinforcements in cabinet making and in joining large timbers together. To make a dowel, a piece of wood is split or whittled to a size slightly bigger than desired and to place the stock into a vice then rotate past a fixed knife, or alternatively, to rotate the knife around the stock such as the subject tool was used. Machines based on this principle emerged in the 19th century. Frequently, these are small bench-mounted tools, prior to this time dowels had to be cut by hand. The tool is an example of early to late 19th century hand tool used to make timber dowels. It is not associated with an historical event, person or place, makers provenance is unable to be determined at this time. Many small American and British tool manufactures were taken over by Stanley tools after 1843 when the company was established and this item could have been made by one of these. However the subject item appears to be rare and would be regarded as a collector's item.An adjustable woodworking tool know as a Moot, used for making Trunnels or Treenails (Dowels) for fastening joints in timber. Noneflagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, moot, trunnels, treenails, circular, dowels, woodworking tool -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Lawn Mower, Alex Shanks & Sons Ltd Engineers Arbroth London, 1903-1925

The firm of Alexander Shanks & Sons Ltd of Arbroath, were engineers, founders and boiler makers the company was incorporated in the year 1893. At the Dens Iron Works, purchased by the firm in the same year, a wide variety of products was manufactured including cranes, hoists, pumps and lawnmowers. In the 1960s the firm was taken over by Alexander Shanks (1801-1845) was an Inventor of the modern lawnmower, who lived in Arbroath Scotland. While credit is usually given to the Englishman Edwin Budding (1795-1846) for the invention of the lawnmower, it is Shanks' machine which was the direct predecessor of the modern mower. Shanks' innovation was a machine which rolled the grass as well as mowing it. Although Shanks himself died at a young age, his son showed the mowers at the Great Exhibition in 1851 which led to a successful business that continued into the 20th century, supplying mowers to cut the tennis courts of Wimbledon, the cricket grounds at Lords and the Old golf course at St Andrews. The firm was also well known for the manufacture of portable steam engines and steam cranes. In 1968, the company was taken over by Giddings & Lewis Fraser Ltd, Engineers of Arbroath. The subject item is a good example of an early lawn mower made by the company that is credited with being the first to patent and manufacture such a machine. The company Alexander Shanks founded was known throughout the world as significant manufactures of large steam machines used from the middle of the 19th century to the first quarter of the 20th century. The subject item is now regarded as a collector's item.Lawnmower, cast iron handles has two wooden ends and two wooden rollers at front. Blades driven by chain fixed to metal roller. Shanks's Standard Chain. Shanks's Standard Chain Arbroth London. Alex Shanks & Sons Ltd Engineers Arbroth Londonflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, hand mower, lawn mower, mower, shanks, arboth -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Treadle Scroll Saw, Hobbies Ltd, Manufactured by Hobbies in England from 1928- 1965

Since 1895, Hobbies Ltd have been supplying model makers and enthusiasts throughout the world with a wide range of quality model kits, accessories, tools, components and handbooks. The Hobbies Company began life in Dereham, Norfolk in 1881 with a London Office opened later (1922) at 65 New Oxford Street, WC1. In 1895 Hobbies began supplying model makers with their products and in 1897 were incorporated into a Public company. In 1922 at a British Industries Fair the company had a stand advertising their products as "The All-British Firm with a World reputation". Fretwork Outfits. Fretwork Machines. Carpentry Outfits. Strip work Outfits. Also manufactures of Fretwork Tools and Benches, Wood, Circular Saws, Lathes, Picture Framing Outfits, Tools, etc. In 1947 the company had expanded and was still making tools and materials for the amateur craftsman in wood. They had acquired a reputation as manufacturers of quality Fretwork Outfits, Tools, Treadle Machines, Model Maker's Tool Kits. The company also publishers of ‘Hobbies Weekly magazine’ and also sold plans for fretwork, model making and wooden toys. In 1961 they were still manufacturers and retailers of craft tools and materials, timber merchants, light engineers and Government contractors with around 500 employees. A vintage tool made for hobbyists and distributed throughout the world by a British company that is still in existence today. The item is significant as it catalogues the manufactures history at a specific time in the company's development.Foot operated treadle Fret saw called "GEM" subject item is a short saw , the stand in the background is the base for a Delta Q3 model scroll saw. Gem inscription cast into the cast iron frameworkflagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, saw, treadle saw, fret saw, pedal saw, the gem, tool, hobbies ltd, treadle, foot operated -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Balance Scale, 1850s

A Large Rare mid 19th Century Balance Scale (also called a Beam Scale) Made in England by W&T Avery a British manufacturer of weighing machines. The company was founded in the early 18th century and took the name W & T Avery in 1818. The undocumented origin of the company goes back to 1730 when James Ford established the business in the town of Digbeth. On Joseph Balden the then company’s owner’s death in 1813 William and Thomas Avery took over his scale making business and in 1818 renamed it W & T Avery. The business rapidly expanded and in 1885 they owned three factories: the Atlas Works in West Bromwich, the Mill Lane Works in Birmingham and the Moat Lane Works in Digbeth. In 1891 the business became a limited company with a board of directors and in 1894 the shares were quoted on the London Stock Exchange. In 1895 the company bought the legendary Soho Foundry in Smethwick, a former steam engine factory owned by James Watt & Co. In 1897 the move was complete and the steam engine business was gradually converted to pure manufacture of weighing machines. The turn of the century was marked by managing director William Hipkins who was determined to broadening the renown of the Avery brand and transforming the business into a specialist manufacture of weighing machines. By 1914 the company occupied an area of 32,000m² and had some 3000 employees. In the inter-war period the growth continued with the addition of specialized shops for cast parts, enamel paints and weighbridge assembly and the product range diversified into counting machines, testing machines, automatic packing machines and petrol pumps. During the second world war the company also produced various types of heavy guns. At that time the site underwent severe damage from parachute mines and incendiary bombs.Then from 1931 to 1973 the company occupied the 18th-century Middlesex Sessions House in Clerkenwell as its headquarters. Changes in weighing machine technology after World War II led to the closure of the foundry, the introduction of electronic weighing with the simultaneous gradual disappearance of purely mechanical devices. The continued expansion was partly achieved through a series of acquisitions of other companies. After almost a century of national and international expansion the company was taken over by GEC in 1979. Keith Hodgkinson, managing director at the time, completed the turn-around from mechanical to electronic weighing with a complete overhaul of the product range of retail scales and industrial platform scales. In 1993 GEC took over the Dutch-based company Berkel and the Avery-Berkel name was introduced. In 2000 the business was in turn acquired by the US-American company Weigh-Tronix, who already owned Salter, and is today operating as Avery Weigh-Tronix. Item made and used possibly around the 1850s by Victorian colonial government to check weights of goods being sold by early shop keepers on the gold fields item is very rare.James McEwan & Co were the retailers of W & T Avery scales in Victoria from 1852. A very rare item used probably to check weights used by merchants during colonial times by government inspectors in Victoria. A similar example exist in a NSW museum, the item is believed to have been made before W & T Avery expansion to the Soho foundry in Birmingham in 1885 and after 1818.Beam balance scale suspended from a wooden tripod, with metal trays suspended by three chain lengths. embossed on the balance beam W T Avery, Birmingham,flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, scale, avery -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Spring Balance Scale, George Salter & Co, 1920s

Scales such as the subject item were used to measure commercial quantities, possibly grains and farm produce for quite large amounts of product. Bags of grain etc would have been hooked up and weighed. Salter has been a name long associated with weights and measures. The firm began life in the late 1760s in the village of Bilston, England when Richard Salter, a spring maker, began making the first spring scales in Britain. He called these scales "pocket steelyards", though they work on a different principle from steelyard balances. By 1825 his nephew George had taken over the company, which became known as George Salter & Co. George later established a manufacturing site in the town of West Bromwich, about 4 miles (7 km) from Bilston. West Bromwich Albion football club was formed from workers at this works site. From here the company produced a wide variety of scales including the UK's first bathroom scales. Other items were added to the range, including irons, mincers, potato chippers, coin-operated machines and the first typewriters made in the UK. The business thrived throughout the 1900s, and by 1950 it employed over 2000 people, still in the same area and owned by the same family.Salter is a British housewares brand developing products that span a wide range of core product categories, including scales, electrical, cookware. It is a market leader in kitchen and bathroom scales and one of the UK’s oldest consumer brands. Established in 1760, Salter has been developing precision products for over 260 years. It was acquired by Manchester-based consumer goods giant Ultimate Products in 2021 after they had previously licensed the brand for cookware and kitchen electrical since 2011.Balance scale Salters Spring Balance consisting of a circular, bronze face engraved with measurements in pounds, with an iron hand, weighing mechanism and hanging loop. Engraved on the face: "Class III Salter's Spring Balance Silvester's Patent To Weigh 300lbs".flagstaff hill, warrnambool, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, salter balance scale, weight measuring scale, weighing dry goods -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Guillotine, c. 1880's

This guillotine is a hand operated machine specifically designed to cut through multiple sheets of paper or card. It has a very heavy and sharp single blade knife mounted between vertical guides or runners. The main users of a machine like this is in by the printing and publication binding industry. Book binding companies use a guillotine to evenly trim the pages of a book after it has been bound. The way the guillotine is used is - paper or card is stacked squarely on the flat table and pushed firmly against the back guide - the handle below the table at the front of the machine is wound around, which brings the back guide forward, pushing the paper stack forward and positioning the centre of the stack below the vertical frame - the upper wheel is wound around, which brings the clamp and firmly in position on top of the paper, to hold it very firmly - the large wheel on the side of the machine is turned around to lower the long sharp blade down onto the pages and cut them through. The sharp edge of the blade is protected somewhat from becoming blunt; a block of wood sits in the table under the stack of paper An early model of a guillotine was patented in 1837 by Thirault, who built a model with a fixed blade. Guillotines similar in principal to this one were patented by Guillaume Massiquot in 1844 and 1852. Over the years many improvements have been made and operation has moved from man power to electricity. Oscar Friedheim Ltd. was the importer and wholesaler of a large range of machinery and equipment for the printing and bookbinding industry. He sold most of his equipment under his own name. On this guillotine or paper cutter he refers to the origin of the guillotine’s manufacture only as “German Manufacrure”. A reference book “Commercial Bookbinding: a description of the processes and the various machines used" by Geo. Stephen, 1910, recommends Oscar Friedheim, amongst others, for the supply of “reliable cutting machines for hand or power”. It also recommends Oscar Friedheim’s for a wide range of other printing machinery and processes. OSCAR FRIEDHEIM LIMITED, LONDON Oscar Friedheim Ltd. was established in 1884 and operated from Ludgate in London. The company was an importer and wholesale supplier in the 1880’s, offering machinery and equipment for the printing and packaging industry for the UK and Ireland. The company became incorporated in 1913. An advertisement of 1913 includes a telegraphic code plus two telephone numbers for Oscar Friedheim Ltd and invites readers to call at the Ludgate, London, showrooms to see the machines working. The company later became Friedheim International Ltd. The book titled “Friedheim, A Century of Service 1884-1984 by Roy Brewer, celebrates Oscar Friedheim’s achievements. Friedheim International currently operates from Hemel Hempstead, on the northern outskirts of London UK. It promotes itself as “… the leading supplier of finishing, converting and packaging machinery to the printing, graphic arts, and highly varied packaging industries in the UK and Ireland. The company’s policy is simple – “employ the best people, work with the best equipment manufacturers in the world, and treat our customers as partners!” The company still sells guillotines. The guillotine is significant for its ability to represent aspects of the printing trade in Warrnambool and in a typical port town circa 1850 to 1910. It represents communication methods and processes used in the time before electrically powered equipment became common in industry.Guillotine (or paper cutter), hand operated. Metal framework with vertical guides, stand and metal mechanical parts including wheels and gears. Table with back guide; handle below front of table winds to move the back guide. A wheel at top of machine winds to adjust pressure of the clamp on the work on the table below it. The cutting blade fits between vertical guides; a timber insert in the table below the blade helps minimise the loss of sharpness of the blade. A handle on the side of the machine turns a large spoked wheel, which rotates a large gear, causing the blade to move up and down. Makers details are on a small oval plaque with embossed maker’s details is screwed onto main body. Maker is O Friedheim, London, and the machine is of German manufacture, circa late 1880’s.Maker’s plaque inscribed "O. FRIEDHEIM / London / German Manufacture"flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, printing machinery, printer’s guillotine, paper guillotine, paper cutter machine, oscar friedheim ltd london, friedheim international ltd, bookbinding industry, printing industry -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Knife Sharpener, Johann Friedrich Dick, 1873 to 1900

Johann Friedrich Dick founded the company in 1778 to manufacture files, the company continued in the manufacture of files as its main product line until 1873, when Paul Friedrich Dick took over the company and began the production of sharpening steels, with the logo of “F Dick” on their products. One hundred years after the founding of the company, a factory in Esslingen began construction. At that time the company had 20 employees. In 1881, company commissioned Germany's first file production machine. In 1889, Friedrich Dick built a new factory in Kollwitz/Fleischmannstrasse in Esslingen, employing 100 people and expanding the product line to include knives for butchers and chefs, cleavers and other specialized tools. Files manufactured ranged from the smallest watchmaker's file to the largest (over 45 cm in length) square file. In 1997, the F Dick company moved to a new headquarters in Deizisau, Germany. The old factory in Esslingen is now a class listed monument and the town's landmark.An item made by a world class manufacture of cutlery for chefs, the subject item is significant as its manufacture was probably early in the firms beginnings when Friedrich Dick took over in1873 when he specialised in making sharpening steels. The company is still producing these items today as well as other specialised knives for professionals. Early manufactured steels such as the subject item are sought after today by collectors and quite rare. Sharpening Steel or Knife sharpener with bone handle with ribbed pattern, brass knobs and ring at end of handleMarked F Dick Esslingenflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, sharpening steel, knife sharpener, kitchen tool, carving, kitchen utensil, cooking, f dick -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Scale, Computing Scale Company, 1897-1900

In 1885 Julius Pitrat of Gallipolis, Ohio, patented the first computing scale. Six years later, Edward Canby and Orange Ozias of Dayton, Ohio, purchased Pitrat's patents and incorporated The Computing Scale Company as the world's first computing scale vendor. And four years after that, The Computing Scale Company introduced the first automatic computing scale In 1911. the Computing Scale Company merged with the International Time Recording Company and Tabulating Machine Company to form the Computing-Tabulating-Recording Company, a business that was renamed IBM in 1924. An early example of a hanging clock face scale patented in October 1897 and made by a company that pioneered the first computing scales used in retail businesses. This company went on to become incorporated with IBM that late became an international computer manufacturer.Scale, patented Oct 12, 1897. Measures in pounds and ounces, up to 10lb. Red indicator needle. Two adjustment screws. Ring on the top for mounting. Marked "The Computing Scale Co Dayton Ohio"Marked "The Computing Scale Co Dayton Ohio"flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, scale, computing scale, computing scale company, weighing instrument -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Wringer/Mangle, Melvin Newton Lovell, 1898 -1900

Melvin Newton Lovell was born in Allegheny, Venango county, Pennsylvania, on 31 August 1844, to Darius T. Lovell (1815-1855) and Susan B. (Conover) Lovell (1827-1883). When Melvin Lovell was a boy, the family removed to Kerrtown, a village located in the vicinity of Titusville, PA. There Melvin served an apprenticeship at the carpenter's trade, and his natural mechanical talent enabled him to become a skilled workman. He followed his trade during the major portion of his term of residence in Kerrtown. In 1861, at seventeen years of age, Melvin Lovell left his home and, without parental authority, and entered the Union army soon after the outbreak of the Civil war. In August 1862, he was enlisted as a private in the 127th Pennsylvania Volunteer Infantry and saw active service until receiving his discharge at the end of May 1863. In 1865 he took up his residence in Erie, where he worked at the carpenter's trade for several years thereafter. In 1869 Melvin Lovell invented and patented several useful articles for household use, and in that year he began the manufacturing of certain of these inventions, in partnership with Franklin Farrar Adams, another inventor. Among the principal products of the original factory were washing machines and step-ladders. In 1881 Lovell individually began manufacturing other of his patents, including spring beds, and from modest inception, his Lovell Manufacturing Company grew to be one of the largest industrial concerns of its kind in the country and was recognized as being the most extensive manufacture of clothes-wringers in the entire world. In connection with his manufacture of domestic items, Lovell established sales agencies for his products in all parts of the country, and these branches were known as the Lovell stores. These goods were sold on the instalment plan and after his business had already been established becoming a substantial concern Lovell invented and patented the famous wringer which bears his name under the “Anchor” brand, and in later years he confined his operations largely to the manufacture of this very superior household invention. Lovell was also one of the organizers and stockholders of the Combination Roll & Rubber Manufacturing Co, of New York, which was formed to manufacture his patents, with headquarters in New York and a factory at Bloomfield, New Jersey.A significant household item used in the process of washing clothes by a man who had started in 1869, as a young carpenter and later he became a successful businessman and manufacturer of household items. Lovell was granted numerous patents for various devices during his career including several patents for adding machines (cash registers).Wringer (or mangle); portable wooden washing wringer with rubber rollers, manually driven by iron set of gears and handle. Includes iron clamps and adjusting screws for attaching. Marked on frame "382", "12 x 1 3/4" Anchor Brand "Made in USA" flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, mangle, clothes wringer, washing equipment, laundry, wringer, domestic, washing mangle -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, Late 19th century or early 20th century

Glass manufacturing has evolved over thousands of years. Glass making has been traced back to 3500 BC in Mesopotamia. The earliest known glass objects were beads, perhaps made by accident while working with metal. In the late Bronze Age, several civilizations discovered how to make vessels and glass bottles by wrapping threads of melted glass around cores of sand or clay. Later, moulds were used to form dishes and table wares. Around the 1st century BC, glassblowing was discovered. This made glass containers less expensive than pottery. Mould-blown glass, the process of blowing a piece of molten glass into a wooden or metal mould, was invented during the 1st century AD. This technique was faster with more consistent results. It paved the way for mass production. It wasn’t until the late 1800s that the production process to become more efficient. In 1887, a company in England created a semi-automatic process that could produce up to 200 bottles an hour. This process has been refined to the point where modern machines can yield more than 600 containers per minute. Blown vs. Manufactured Glass Bottles Nowadays, glass bottles, jars, and cups are usually manufactured on a bigger scale than is found in individual glassblowing studios. If we still depended on hand-blown glass for all of our glass containers, we would see some major differences in the process of creating bottles and jars. First, there's the time. Hand blowing glass takes a significant amount of time, even for one simple container. In contrast, hundreds of jars per minute can be made using modern technology. This leads to the second advantage: price. Because of the automated and streamlined process, the price for manufactured containers is much lower than that of hand-blown glass. Third, manufactured bottles will be much more consistently uniform than bottles blown by hand. Automated glass manufacturing produces nearly identical batches of jars. Glass blowing is awesome for unique, beautiful pieces of art. But for lots of lower priced and uniformly shaped containers, automatic manufacturing is the preferred method to create glass bottles and jars. https://www.containerandpackaging.com/resources/glass-bottles-brief-history The invention and development of glass for domestic items including bottles, has been nothing short of revolutionary. The use of glass bottles, that could be easily washed, led to improved hygiene, and mass manufacturing of drinks of all types, including milk, cordial and alcoholic beverages.Green Glass Bottle Possibly a ginger beer bottle.Concave indentation at the base. Also on base are two raised lumps. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, glass -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Wooden Bread Board, Not known

In the high tech, fast paced society that we live in, it’s easy to take some things for granted. Case in point: the wood cutting board on which you’ll probably be preparing the evening’s dinner. Have you ever taken the time to think about the history of the cutting board? Where did it come from, and what did ancient civilizations use to cut their meats, fruits and vegetables? Wood throughout the ages Since the dawn of time, wood has been one of the most available materials used by mankind to build tools and lodgings, so it’s not really surprising to know that wood has been used in the preparation of food since the prehistoric ages. Of course, back then, cavemen probably used an unpolished slab of tree trunk to cut the kill of the day on and they probably didn’t think twice about saving it once the meal was over. Chances are they probably threw it in the fire with the rest of the wood needed to kindle it. Advances in technology Throughout the centuries, mankind evolved and started creating machines from steam, electricity and metal. When the circular saw was invented, nicer, cleaner slabs of wood were cut and used as cutting boards. Since soft wood was the most available type of wood at the time, it was the material of choice for to be used for cutting boards. Boards were made smaller since the slab of wood could now be cut to any desired size. Since they were made smaller, they were also used to eat off of and some people referred to them as trenchers. Trenchers were originally pieces of stale hard bread that were used as substitute plates. Wood trenchers quickly became the replacements of the eatable dinnerware. The butcher block: the cutting board’s larger cousin In the industrial ages, many industries rapidly developed, and the butchery industry followed this trend as well. Before the invention of the cutting board, butchers used tree rounds to carve their meat on. The rounds were often too soft and they rapidly became unsanitary. Hard maple wood butcher blocks were the preferred choice of the industry. They were made to be extremely thick and durable, so durable in fact, that a butcher could use the same block for almost his entire career. Cutting boards around the world As cutting boards began to be more and more used in kitchens around North America, the rest of the world crafted such boards from different materials. The East used thick bamboo as their material of choice. Despite its frail appearance, bamboo is quite strong and made durable cutting boards and butcher blocks. Europe used maple in the crafting of their cutting boards while Persia used flat pieces of polished wood in their kitchens. The world then saw cutting boards that were being made from other materials like plastic and they came in all shapes and sizes, but they always served the same purpose, to provide a household with a safe, clean surface on which to prepare meals for their friends and family members. https://www.woodcuttingboards.com/news/quick-history-of-the-cutting-board-47.aspxThe use of the wooden chopping board over time. Wooden Rectangular Bread board . Worn (concave in centre). Raw wood.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, chopping board, cooking -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bread Board

In the high tech, fast paced society that we live in, it’s easy to take some things for granted. Case in point: the wood cutting board on which you’ll probably be preparing the evening’s dinner. Have you ever taken the time to think about the history of the cutting board? Where did it come from, and what did ancient civilizations use to cut their meats, fruits and vegetables? Wood throughout the ages Since the dawn of time, wood has been one of the most available materials used by mankind to build tools and lodgings, so it’s not really surprising to know that wood has been used in the preparation of food since the prehistoric ages. Of course, back then, cavemen probably used an unpolished slab of tree trunk to cut the kill of the day on and they probably didn’t think twice about saving it once the meal was over. Chances are they probably threw it in the fire with the rest of the wood needed to kindle it. Advances in technology Throughout the centuries, mankind evolved and started creating machines from steam, electricity and metal. When the circular saw was invented, nicer, cleaner slabs of wood were cut and used as cutting boards. Since soft wood was the most available type of wood at the time, it was the material of choice for to be used for cutting boards. Boards were made smaller since the slab of wood could now be cut to any desired size. Since they were made smaller, they were also used to eat off of and some people referred to them as trenchers. Trenchers were originally pieces of stale hard bread that were used as substitute plates. Wood trenchers quickly became the replacements of the eatable dinnerware. The butcher block: the cutting board’s larger cousin In the industrial ages, many industries rapidly developed, and the butchery industry followed this trend as well. Before the invention of the cutting board, butchers used tree rounds to carve their meat on. The rounds were often too soft and they rapidly became unsanitary. Hard maple wood butcher blocks were the preferred choice of the industry. They were made to be extremely thick and durable, so durable in fact, that a butcher could use the same block for almost his entire career. Cutting boards around the world As cutting boards began to be more and more used in kitchens around North America, the rest of the world crafted such boards from different materials. The East used thick bamboo as their material of choice. Despite its frail appearance, bamboo is quite strong and made durable cutting boards and butcher blocks. Europe used maple in the crafting of their cutting boards while Persia used flat pieces of polished wood in their kitchens. The world then saw cutting boards that were being made from other materials like plastic and they came in all shapes and sizes, but they always served the same purpose, to provide a household with a safe, clean surface on which to prepare meals for their friends and family members. https://www.woodcuttingboards.com/news/quick-history-of-the-cutting-board-47.aspxThe bread board is an example of kitchen equipment used during Victorian times and similar to those used today.Bread board. Wooden, octagonal, plain sanded light wood. Has decoration around edge and indented circular line to delineate round cutting board section.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, bread board, cutting board, pastry board, kitchen utensil, kitchen equipment, baking equipment, food preparation -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Ink Bottle, Caldwell’s Ink Factory, Late 19th to early 20th centuries

This design of the bottle is sometimes called a ‘cottage’ or ‘boat’ shape. The Caldwell’s handmade glass ink bottle was mouth-blown into a three-piece mould, a method often used in the late 19th and early 20th centuries, with the maker's name engraved into the mould section for the base. The glass blower would cut the bottle off the end of his blowpipe with a tool and join a mouth onto the top, rolling the lip. The bottle was then filled with ink and sealed with a cork. This method of manufacture was more time-consuming and costly to produce than those made in a simple two-piece mould and 'cracked' off the blowpipe. The capacity for a bottle such as this was about 3 ½ oz (ounces) equal to about 100 ml. This particular bottle is unusual as it has four sloping indents at the corners of the shoulder, most likely for resting a pen with its nib upwards and the handle resting on a flat surface. Most of the bottles made during this era had horizontal pen rests that were indented into both of the long sides of the shoulder. Pen and ink have been in use for handwriting since about the seventh century. A quill pen made from a bird’s feather was used up until around the mid-19th century. In the 1850s a steel point nib for the dip pen was invented and could be manufactured on machines in large quantities. This only held a small amount of ink so users had to frequently dip the nib into an ink well for more ink. Handwriting left wet ink on the paper, so the blotting paper was carefully used to absorb the excess ink and prevent smudging. Ink could be purchased as a ready-to-use liquid or in powdered form, which needed to be mixed with water. In the 1880s a successful, portable fountain pen gave smooth-flowing ink and was easy to use. In the mid-20th century, the modern ballpoint pen was readily available and inexpensive, so the fountain pen lost its popularity. However, artisans continue to use nib pens to create beautiful calligraphy. Caldwell’s Ink Co. – F.R. Caldwell established Caldwell’s Ink Company in Australia around 1902. In Victoria, he operated from a factory at Victoria Avenue, Albert Park, until about 1911, then from Yarra Bank Road in South Melbourne. Newspaper offices were appointed as agencies to sell his inks, for example, in 1904 the New Zealand Evening Star sold Caldwell’s Flo-Eesi blue black ink in various bottle sizes, and Murchison Advocate (Victoria) stocked Caldwell’s ink in crimson, green, blue black, violet, and blue. Caldwell’s ink was stated to be “non-corrosive and unaffected by steel pens”. A motto used in advertising in 1904-1908 reads ‘Makes Writing a Pleasure’. Stationers stocked Caldwell’s products and hawkers sold Caldwell’s ink stands from door to door in Sydney in the 1910s and 1920s. In 1911 Caldwell promised cash for returned ink bottles and warned of prosecution for anyone found refilling his bottles. Caldwell’s Ink Stands were given as gifts. The company encouraged all forms of writing with their Australian-made Flo-Eesi writing inks and bottles at their impressive booth in the ‘All Australian Exhibition’ in 1913. It advertised its other products, which included Caldwell’s Gum, Caldwell’s Stencil Ink (copy ink) and Caldwell’s Quicksticker as well as Caldwell’s ‘Zac’ Cough Mixture. Caldwell stated in a 1920 article that his inks were made from a formula that was over a century old, and were scientifically tested and quality controlled. The formula included gallic and tannic acids and high-quality dyes to ensure that they did not fade. They were “free from all injurious chemicals”. The permanent quality of the ink was important for legal reasons, particularly to banks, accountants, commerce, municipal councils and lawyers. The Caldwell’s Ink Company also exported crates of its ink bottles and ink stands overseas. Newspaper advertisements can be found for Caldwell’s Ink Company up until 1934 when the company said they were the Best in the business for 40 years.This hand-blown bottle is significant for being the only bottle in our collection with the unusual sloping pen rests on its shoulder. It is also significant for being made in a less common three-piece mould. The method of manufacture is representative of a 19th-century handcraft industry that is now been largely replaced by mass production. The bottle is of state significance for being produced by an early Melbourne industry and exported overseas. This ink bottle is historically significant as it represents methods of handwritten communication that were still common up until the mid-20th century when fountain pens and modern ballpoint pens became popular and convenient and typewriters were becoming part of standard office equipment.Ink bottle; rectangular base, hand-blown clear glass bottle with its own cork. The bottle has side seams from the base to the mouth, an indented base and an applied lip. The corners of the shoulder sides have unusual diagonal grooves that slope down and outwards that may have been used as pen rests. Inside the bottle are remnants of dried blue-black ink. The glass has imperfections and some ripples on the surface. The bottle has an attached oval black label label with gold-brown printed text and border. The base has an embossed inscription. The bottles once contained Caldwell’s blend of blue black ink.Printed on label; “CALDWELL's BLUE BLACK INK” Embossed on the base "CALDWELLS"flagstaff hill, warrnambool, maritime village, maritime museum, shipwreck coast, great ocean road, ink, nib pen, writing ink, writing, copying, banks, lawyers, commerce, student, permanent ink, blue black ink, stationery, record keeping, handwriting, writing equipment, writing accessory, office supply, cottage bottle, boat bottle, mouth-blown bottle, cork seal, f r caldwell, caldwell’s ink company, albert park, south melbourne, inkstands, stencil ink, copy ink, quicksticker, zac cough mixture, three part mould, cauldwells, cauldwell's