Showing 585 items matching "push"

-

Ballarat Tramway Museum

Ballarat Tramway MuseumPhotograph - Black & White Photograph/s, The Courier Ballarat, 2/11/1982 12:00:00 AM

Yields information about the recovery of No. 18 from Sebastopol, its storage facility and some of the people who were involved on the day.Black and White copy photograph of a newspaper photograph taken by The Courier of No. 18 being moved from Victory Park Sebastopol from the shed that it was sitting in. Photo has a number of BTPS members "pushing" the tram out of the shed. Photo taken 2/11/1982? published 4/11/1982. Photo used in the 1982-1983 annual report which dates the photo as the 2/11/1982. Copy of newspaper clipping photo appeared in, not held by Museum at date of cataloguing. Collected by Alan Bradley from the Ballarat Courier early 1980's. See Excel file "Record of Ballarat Courier Photos BTM era" (Archive Documents) for source of details.On rear stamped "Copyright, The Ballarat Courier Proprietary Limited." and in pencil "1 FC top"tramways, trams, btps, tram recovery, sebastopol, trams, tram 18 -

Melbourne Tram Museum

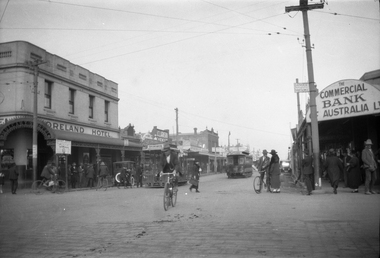

Melbourne Tram MuseumNegative, Ellis Collection, c1956

Negative (120) of the intersection of Moreland Road and Sydney Road, Brunswick, during the 1920's. In the view is a cable tram set shunting. A tramway employee and two boys at the front of the grip car seem to be manipulating something. Saloon car is No. 183 with the conductor pushing the car. The grip car has the destination of Brunswick and the saloon Flinders St? Note the two steel tramway poles and overhead for the North Coburg electric tram service from Moreland Rod into Sydney Road. In the background is the Moreland Hotel, Clarkson chemist and the Commercial Bank of Australia. An low resolution A4 laminated was received with the negatives. Hi Res image filed in the dbtext/hawthtramcoll/Large Images/htd3589large.jpgtrams, tramways, brunswick, cable trams, sydney rd, moreland rd, tram 183 -

Eltham District Historical Society Inc

Eltham District Historical Society IncNewspaper clipping, Eltham loves a parade, Diamond Valley News (Eltham), Vol. 33, No. 32, 14 August 1979, p1, 1979

Feature news story about 1979 Eltham Parade with photo of Society members Joh Ebeli and Russell Yeoman pushing Peter Bassett-Smith along in a wheelbarrow. Others featured were Eltham Rugby club float and Anne Mandel of the Slovenian Association of Melbourne. Other story on "Council elections provide shocks" featured the defeat of Eltham sitting councillors, Ken Hines and Helen Wells with Shire president Cr, Robert Marshall returned with a commanding majority. Reverse side (p2) story "Laughing cop no softy" is a feature article on Tony Zalewski of Greensborough CIB who was the key policeman involved in a hour-long siege in Norfolk Crescent, Bundoora in 1978 and for which he received the Victoria Police Valour AwardNewsprint page1979, anne mandel, ansell and muir, bundoora, elections, eltham festival, eltham rugby football club, greensborough cib, helen wells, joh ebeli, ken hines, lyon bros ford, norfolk crescent, parade floats, peter bassett-smith, robert marshall, russell yeoman, shire of diamond valley, shire of eltham, shire of eltham historical society, siege, slovenian association of melbourne, tony zalewski, victoria police valour award -

Lara RSL Sub Branch

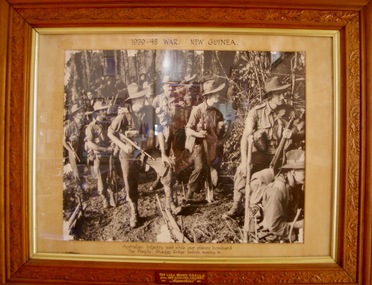

Lara RSL Sub BranchPhotograph, Australian infantry in New Guinea 1939/45 war

The Battle of the Shaggy Ridge was part of the Markham and Ramu Valley – Finisterre Range campaign, consisting of a number of actions fought by Australian and Japanese troops in Papua New Guinea in World War II. Following the Allied capture of Lae and Nadzab, the Australian 9th Division had been committed to a quick follow up action on the Huon Peninsula in an effort to cut off the withdrawing Japanese. Once the situation on the Huon Peninsula stabilised in late 1943, the 7th Division had pushed into the Markham and Ramu Valleys towards the Finisterre Range with a view to pushing north towards the coast around Bogadjim, where they would meet up with Allied forces advancing around the coast from the Huon Peninsula, before advancing towards Madang.In late December 1943, the Australian offensive to take Shaggy Ridge began, focused on an attack on The Pimple.[13] The Pimple was one of three rocky outcrops, held by the Japanese on the ridge line.Framed Photograph of Australian infantry waiting while our planes" bombard the Pimple,"Shaggy Ridge before moving in. Australian infantry waiting while our planes" bombard the Pimple,"Shaggy Ridge before moving in. THE LARA BRANCH R.S.S.I.L.A. FROM MRS HAMILTON CALVERT =MEMORIES=ww2, papua new guinea, world war 2, lara r.s.l., photographs, australian infantry, shaggy ridge -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyTape Measure, mid 1900s

This item predates the change of Imperial measure (England -1824) to decimal measure (Europe) in Australia (1970 to 1988). This item was manufactured in England as, was the majority of measuring tool and equipment. It was not until the late 1950s that other countries e.g. United States and Europe provided the same type of manufactured tools for the Australian market. World War II, when Australia had to defend its own boarders that the political push for self sufficiency of manufactured goods started local production. Workers in the Kiewa Valley had always relied on the high quality of tools and manufactured goods coming from England. From the middle to late 1950s migration by skilled workers from a war torn Europe provided the source of manpower for the expansion of the manufacturing industries in Australia.The requirement of an accurate measuring tool has always been critical. This item was used at the time when Australia was using the British Imperial measurements. Accurate measurements by carpenters and other trades people for both town and rural needs was just as critical as for the larger cities. The transition period from Imperial to metric was a period of over four years but it still presented those who had used the Imperial measurements for a longer period in their trades with a dual system of measurement for a longer time(usually up to their retirement) Other nations still using Imperial measurements kept the transition from Imperial to metric alive (the UK and USA still uses Imperial measurements in 2012)Retractable metallic wired tape measure within a leather casing. Length of tape is 66 feet. Brass fittings on casing(winder and back plate)Tape on one side marked in inches and feet and on the other in links. Winder lever marked "66ft No 401" on front and arrow with"wind this way". Leather cover marked "John R A Bone & Sons Birmingham England" on reverse side "Metallic wired tape R A Bone & Sons"wired tape measure, tool, mobile tool, construction tool -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding Plane

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. A vintage tool made by an unknown maker, this item was made commercially for firms and individuals who worked in wood and needed a tool that could produce a ornamental finish to timber. These profiled planes came in various shapes and sizes to achieve a decorative finish. This item is a significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Moulding Plane, concave cut.Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood Moulding Plane

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. A vintage tool made by an unknown maker, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use to produce a decorative moulding for a piece of furniture, door trims etc, or other timber items that had to be accomplished by using hand tools and in particular one of these types of planes. Profiled planes came in various shapes and sizes to achieve the required decorative finish. A significant tool from the mid to late 19th century that today is sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Moulding Plane W size has 4 screws holding side together (repair)J Allin GN stamped inside W size 16 one end and Inglis R F Sharp on other end.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding Plane, J Hastie, 1766-1802

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it.A vintage tool used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture was done by hand using one of these types of plane. A significant item from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture was made predominately by hand and with tools that were themselves hand made shows the craftsmanship used to make such a unique item. Moulding Plane Hollow type No15 J Hastie Stamped EG W.M flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood moulding Plane, 1890-1920

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown moulding required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it.A vintage tool made by an unknown company, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture, door trims etc. or other items had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item. Wood Moulding, plane Rabbet Hollow type Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Complex Moulding Plane, Mid to Late 19th Century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it.A vintage tool made by an unknown maker, this item was made commercially for firms and individuals who worked in wood and needed a tool that could produce a ornamental finish to timber. These profiled planes came in various shapes and sizes to achieve a decorative finish. Although the item is marked J Dixon no reference can be found at this time for a maker of complex moulding planes J Dixon of London. The plane could have been made by an unknown maker and sold through a merchandising agent of which there was one in London at the time. It is this agent J Dixon that could have stamped his mark on the item and then sold the plane on giving the impression J Dixon was the maker, this practice was quite common in the 18th & 19th centuries. This item is still regarded as a significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Panel Plough Plane white wood, blade missing. Stamped "J Dixon London" also has the letter "B" stamped flagstaff hill, warrnambool, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, wood working, cabinet making, complex moulding plane, j dixon london, mouldings -

Kiewa Valley Historical Society

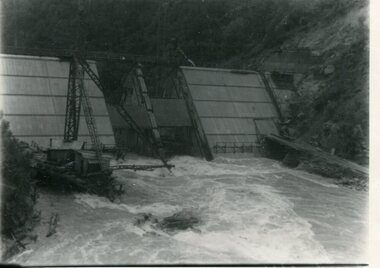

Kiewa Valley Historical SocietyPhotograph - Kiewa River in flood at Clover Dam

As part of the push to cut electricity costs and diversify supply, the Victorian Government (circa 1930) implemented the conversion strategy from mainly brown coal supply to hydro - electricity. The Kiewa Hydroelectric Scheme became the largest scheme of its kind in the State Of Victoria and the second largest scheme in Australia. Clover Dam and Power Station were built by the State Electricity Commission of Victoria as part of the Kiewa Hydro Electric Scheme from the late 1930's to the early 1940's. This dam was constructed to supply water to feed four turbines (62 mega watts) at the West Kiewa Power Station. This was at the forefront of sustainable "Green" energy. Costs associated with power supplies is still a major incentive of governments, however environmentally friendly alternatives such as wind and nuclear have also made inroads. The Kiewa valley and its surrounding alpine catchment were looked at(Victorian State Government), from the beginning of the twentieth century as a source of alternate power for an ever-increasing demand for electricity by growing population and heavy industrial areas within Melbourne City and State regions. Construction of dams, such as Clover Dam provided the large quantity holding areas of water required to turn the turbines at the various power stations to provide the electricity needed. The impact of these controls by moderating water run-off from the alpine regions is beneficial in reducing flooding from thawing of snow on the alps. This by-product allows agriculture and grazing to be less vulnerable to seasonal flooding thereby resulting in a more stable annual production level.Black and white photograph of Clover Dam with Kiewa River in flood. .5mm white boarder on 3 sides of photo.Handwritten on back of photograph in black pen - Kiewa in flood. Clover Dam.clover dam, secv -

Kiewa Valley Historical Society

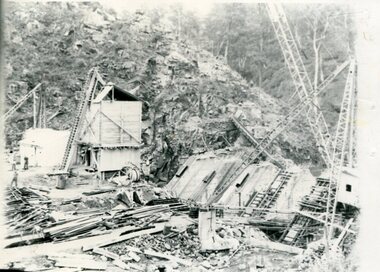

Kiewa Valley Historical SocietyPhotograph - Clover Dam

As part of the push to cut electricity costs and diversify supply, the Victorian Government (circa 1930) implemented the conversion strategy from mainly brown coal supply to hydro - electricity. The Kiewa Hydroelectric Scheme became the largest scheme of its kind in the State Of Victoria and the second largest scheme in Australia. Clover Dam and Power Station were built by the State Electricity Commission of Victoria as part of the Kiewa Hydro Electric Scheme from the late 1930's to the early 1940's. This dam was constructed to supply water to feed four turbines (62 mega watts) at the West Kiewa Power Station. This was at the forefront of sustainable "Green" energy. Costs associated with power supplies is still a major incentive of governments, however environmentally friendly alternatives such as wind and nuclear have also made inroads. The Kiewa valley and its surrounding alpine catchment were looked at(Victorian State Government), from the beginning of the twentieth century as a source of alternate power for an ever-increasing demand for electricity by growing population and heavy industrial areas within Melbourne City and State regions. Construction of dams, such as Clover Dam provided the large quantity holding areas of water required to turn the turbines at the various power stations to provide the electricity needed. The impact of these controls by moderating water run-off from the alpine regions is beneficial in reducing flooding from thawing of snow on the alps. This by-product allows agriculture and grazing to be less vulnerable to seasonal flooding thereby resulting in a more stable annual production level.Black and white photograph of Clover Dam buildings and Kiewa River. Has a .4cm white border around photograph Printed on bottom left corner of photograph in white - Clover Flatclover dam, secv -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPhotographs x 2 - Clover Dam, Circa 1940's

As part of the push to cut electricity costs and diversify supply, the Victorian Government (circa 1930) implemented the conversion strategy from mainly brown coal supply to hydro - electricity. The Kiewa Hydroelectric Scheme became the largest scheme of its kind in the State Of Victoria and the second largest scheme in Australia. Clover Dam and Power Station were built by the State Electricity Commission of Victoria as part of the Kiewa Hydro Electric Scheme from the late 1930's to the early 1940's. This dam was constructed to supply water to feed four turbines (62 mega watts) at the West Kiewa Power Station. This was at the forefront of sustainable "Green" energy. Costs associated with power supplies is still a major incentive of governments, however environmentally friendly alternatives such as wind and nuclear have also made inroads. The Kiewa valley and its surrounding alpine catchment were looked at(Victorian State Government), from the beginning of the twentieth century as a source of alternate power for an ever-increasing demand for electricity by growing population and heavy industrial areas within Melbourne City and State regions. Construction of dams, such as Clover Dam provided the large quantity holding areas of water required to turn the turbines at the various power stations to provide the electricity needed. The impact of these controls by moderating water run-off from the alpine regions is beneficial in reducing flooding from thawing of snow on the alps. This by-product allows agriculture and grazing to be less vulnerable to seasonal flooding thereby resulting in a more stable annual production level. Photographs also document early engineering and building techniques used in the construction of dams and power stations during the 1940’s and 1950’s. Note the lack of safety equipment and suitable work attire worn by construction workers on the sites 1. Black and white photograph of Clover Dam under construction. Has a .5cm white border around photo 2. Black and white photograph of Clover Dam under construction showing workmen at work. Has a .5cm white border around photo Written in pencil on back of both photographs - Clover Damclover dam, secv -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPhotograph - Folder of Photographs (KVHS 1150 A - F) – Photocopied set of black and white photographs from the display folder (pages 1 - 8) put together by KVHS to document life on the Kiewa Valley Hydro-electric Scheme

Although the Kiewa Hydro-Electric Scheme was first proposed in 1911, construction did not commence until 1938. As part of the push to cut electricity costs and diversify supply, the Victorian Government (circa 1930) initiated the conversion from primarily brown coal supply to hydro – electricity. Field investigations during the 1940’s resulted in a new proposal for a scheme that had more than double the capacity of the 1938 scheme. The Kiewa Hydroelectric Scheme became the largest scheme of its kind in the State Of Victoria and the second largest scheme in Australia. The number of personnel involved in the planning and construction of the scheme increased dramatically. During the late 1940’s, most activity centred around the construction of the West Kiewa Power Station, Rocky Valley Reservoir, McKay Creek Power Station and the Bogong Creek Aqueduct.A common thread across all the larger hydro scheme constructions was the need for workers, both qualified and unqualified who came from around the world seeking a new life for themselves and their families. New accommodation and facilities were required for the army of workers engaged in construction in often remote and wild areas. The SEC had a high demand for timber, and set up the first of a number of sawmills at Bogong Creek in 1939 and set up the first hardwood logging in the headwaters of the Kiewa River. These new ‘towns’ such as Mt Beauty and Bogong, survived, serving the needs of operational personnel and their families, and expanding with growth of new industries. Mount Beauty, and to a lesser extent Bogong, are among these places. Large A3 size spiral bound display folder containing 21 of 58 pages of photocopied black and white photographs of various aspects of the early days of the Kiewa Valley Hydro-electric scheme including equipment, various work sites and photographs of workers and their families. 1-Front page; 2-Security gate at Mt Beauty Camp; 3-Channel 1 on East Kiewa River; 4-Junction Dam – Diversion Tunnel Inlet; 5-Sawmill; 6- Homan’s Gap Sawmill; 7 Junction Dam: 8-Homan Dam Site-Diamond Drilling on River Buttress; 9- Homan Dam Site View Upstream 10-Homan Dam Investigation Camp 1-Windsor & Newton Visual Diary 60 sheet (120 pages) 11’ x 14’ 280 x 356mm 110 GSM Acid Free Drawing Paper 2-1940-Security Gate on Mt Beauty side of Kiewa River bridge. Part of old Mt Beauty camp and mess in background 3- STATE ELECTRICITY COMMISSION OF VICTORIA Date; 11.3.40 Time: 10.30am No K35 Kiewa Hydro Electric Works. Diverting East Kiewa River into Channel Page number 1 4-STATE ELECTRICITY COMMISSION OF VICTORIA Date: 5.4.40 Time: Noon No K58 Kiewa Hydro Electric Works. Junction Dam – Diversion Tunnel Inlet – Normal Flow Page number 2 5- STATE ELECTRICITY COMMISSION OF VICTORIA Date: 19.8.42 Time: 2.30pm No K883 Kiewa Hydro Electric Works. Sawmill – General View Page number 3 6- STATE ELECTRICITY COMMISSION OF VICTORIA Date: 12.1.42 Time: 2.00pm No K540 Kiewa Hydro Electric Works. Homan’s Gap Sawmill – General View Page number 4 7- STATE ELECTRICITY COMMISSION OF VICTORIA Date: 12.1.42 Time: 2.00pm No K540 Kiewa Hydro Electric Works. Junction Dam – General View looking upstream Page number 5 8- STATE ELECTRICITY COMMISSION OF VICTORIA Date: 16.11.45 Time: 10.32amm No K52153 Kiewa Hydro Electric Works Homan Dam Site – Diamond Drilling on River Buttress Page number 6 9-STATE ELECTRICITY COMMISSION OF VICTORIA Date: 15.1.45 Time: 4.10pm No K1781 Kiewa Hydro Electric Works Homan Dam Site – View Upstream Page number 7 10- STATE ELECTRICITY COMMISSION OF VICTORIA Date: 15.1.45 Time: 4.10pm No K1781 Kiewa Hydro Electric Works Homan Dam Investigation Camp 1944 – 1945 Page number 8 secv; kiewa hydro electric scheme; mt beauty; bogong; construction work; -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPhotograph - Folder of Photographs – Photocopied set of black and white photographs (pages 9 - 18) from the display folder put together by KVHS to document life on the Kiewa Valley Hydro-electric Scheme

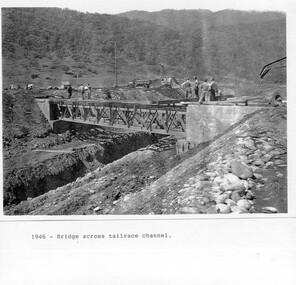

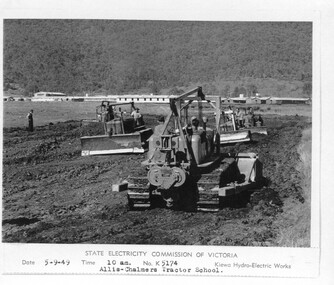

Although the Kiewa Hydro-Electric Scheme was first proposed in 1911, construction did not commence until 1938. As part of the push to cut electricity costs and diversify supply, the Victorian Government (circa 1930) initiated the conversion from primarily brown coal supply to hydro – electricity. Field investigations during the 1940’s resulted in a new proposal for a scheme that had more than double the capacity of the 1938 scheme. The Kiewa Hydroelectric Scheme became the largest scheme of its kind in the State Of Victoria and the second largest scheme in Australia. The number of personnel involved in the planning and construction of the scheme increased dramatically. During the late 1940’s, most activity centred around the construction of the West Kiewa Power Station, Rocky Valley Reservoir, McKay Creek Power Station and the Bogong Creek Aqueduct.A common thread across all the larger hydro scheme constructions was the need for workers, both qualified and unqualified who came from around the world seeking a new life for themselves and their families. New accommodation and facilities were required for the army of workers engaged in construction in often remote and wild areas. The SEC had a high demand for timber, and set up the first of a number of sawmills at Bogong Creek in 1939 and set up the first hardwood logging in the headwaters of the Kiewa River. These new ‘towns’ such as Mt Beauty and Bogong, survived, serving the needs of operational personnel and their families, and expanding with growth of new industries. Mount Beauty, and to a lesser extent Bogong, are among these places. PHYSICAL: Large A3 size spiral bound display folder containing 21 pages of photocopied black and white photographs of various aspects of the early days of the Kiewa Valley Hydro-electric scheme including equipment, various work sites and photographs of workers and their families. 1-Bridge across Tailrace Channel 1946 2-New Mess building, Mt Beauty 3-Homan’s Gap Saw Mill 4- Diamond Drilling Plant – Big Hill 5-Rocky Valley Camp-Mess Building 6-Parlimentary Party at Rocky Valley 7-No.4 Headrace Tunnel 8- Allis-Chalmers Tractor School 9- SECV Heavy Machinery lined up by road 10- No. 5 Raceline – Balasting Track with improvised truck 1-1946 – Bridge across tailrace channel Page number 9 2-New mess building, Mt Beauty 6.4.46 Page number 10 3- STATE ELECTRICITY COMMISSION OF VICTORIA Date: 10.1.47 Time: 11.40am No K2271 Kiewa Hydro Electric Works Homan’s Gap Saw Mill – Rip Saw Page number 11 4- STATE ELECTRICITY COMMISSION OF VICTORIA Date: 5.10.47 Time: 11am No K4111 Kiewa Hydro Electric Works Diamond Drilling Plant – Big Hill Page number 12 5- STATE ELECTRICITY COMMISSION OF VICTORIA Date: 11.2.48 Time: 3pm No K4277 Kiewa Hydro Electric Works Rocky Valley Camp-Mess Building Page number 13 6- STATE ELECTRICITY COMMISSION OF VICTORIA Date: 15.4.48 Time: 4.30pm No K4397 Kiewa Hydro Electric Works Parlimentary Party at Rocky Valley Page number 14 7- STATE ELECTRICITY COMMISSION OF VICTORIA Date: 22.8.48 Time: 9am No K4668 Kiewa Hydro Electric Works General view of No.4 Headrace Tunnel Page number 15 8-STATE ELECTRICITY COMMISSION OF VICTORIA Date: 5.9.49 Time: 10am No K5180 Kiewa Hydro Electric Works Allis-Chalmers Tractor School – HD 19, Mr I Crossthwaite at Controls Page number 16 9- No markings Page number 17 10- STATE ELECTRICITY COMMISSION OF VICTORIA Date: 7,12.49 Time: 4pm No K5423 Kiewa Hydro Electric Works No. 5 Raceline – Balasting Track with improvised truck. Page number 18 secv; kiewa hydro electric scheme; mt beauty; bogong; construction area -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPhotograph - Folder of Photographs – Photocopied set of 10 black and white photographs (pages 19 - 28) from the display folder put together by KVHS to document life on the Kiewa Valley Hydro-electric Scheme

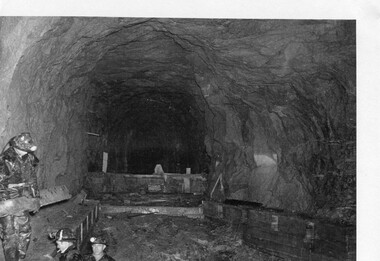

Although the Kiewa Hydro-Electric Scheme was first proposed in 1911, construction did not commence until 1938. As part of the push to cut electricity costs and diversify supply, the Victorian Government (circa 1930) initiated the conversion from primarily brown coal supply to hydro – electricity. Field investigations during the 1940’s resulted in a new proposal for a scheme that had more than double the capacity of the 1938 scheme. The Kiewa Hydroelectric Scheme became the largest scheme of its kind in the State Of Victoria and the second largest scheme in Australia. The number of personnel involved in the planning and construction of the scheme increased dramatically. During the late 1940’s, most activity centred around the construction of the West Kiewa Power Station, Rocky Valley Reservoir, McKay Creek Power Station and the Bogong Creek Aqueduct.A common thread across all the larger hydro scheme constructions was the need for workers, both qualified and unqualified who came from around the world seeking a new life for themselves and their families. New accommodation and facilities were required for the army of workers engaged in construction in often remote and wild areas. The SEC had a high demand for timber, and set up the first of a number of sawmills at Bogong Creek in 1939 and set up the first hardwood logging in the headwaters of the Kiewa River. These new ‘towns’ such as Mt Beauty and Bogong, survived, serving the needs of operational personnel and their families, and expanding with growth of new industries. Mount Beauty, and to a lesser extent Bogong, are among these places. Large A3 size spiral bound display folder containing 21 pages of photocopied black and white photographs of various aspects of the early days of the Kiewa Valley Hydro-electric scheme including equipment, various work sites and photographs of workers and their families. 1-Allis Chalmers Tractor School 2- Gardens outside Administrative Office – Mt Beauty 3- Mt Beauty house – 1950 4-Bridge over Pretty Valley River, Bogong 5-Rocky Valley Spillway Tunnel break through 6-Ni 1 Headrace Tunnel drilling face 7-No 4 Power Station Drilling 8-Clover Dam Flood Waters 9-No1 Head Race Tunnel Portal Building 10-Clover Dam 1-STATE ELECTRICITY COMMISSION OF VICTORIA Date: 5.9.49 Time: 10amm No K5174 Kiewa Hydro Electric Works Allis Chalmers Tractor School Page number 19 2-STATE ELECTRICITY COMMISSION OF VICTORIA Date: 22.2.50 Time: 3.30pm No K5601 Kiewa Hydro Electric Works Gardens outside Administrative Office – Mt Beauty Page number 20 3-Mt Beauty house – 1950 Page number 21 4-STATE ELECTRICITY COMMISSION OF VICTORIA Date: 23.10.50 Time: 11.15am No K6331 Kiewa Hydro Electric Works Bogong-Bridge over Pretty Valley River Page number 22 5-STATE ELECTRICITY COMMISSION OF VICTORIA Date: 23.6.50 Time: 2.30pm No K5844 Kiewa Hydro Electric Works ROCKY VALLEY SPILLWAY TUNNEL BREAK THROUGH Page number 23 6-20/3/52 – No. 1 Headrace Tunnel Drilling face (E.E.E. contract) Page number 24 7-6/6/52 – No 4 Power Station – Drilling Page number 25 8-STATE ELECTRICITY COMMISSION OF VICTORIA Date: 6/6/52 Time: No K7113 Kiewa Hydro Electric Works Clover Dam Flood Waters Page number 26 9-STATE ELECTRICITY COMMISSION OF VICTORIA Date: Oct 1952 Time: No K7239 Kiewa Hydro Electric Works No. 1 HEAD RACE TUNNEL PORTAL BUILDING. Handwritten underneath – This information from Ron White-the later Principal Hydro Engineer of the SEC. Oct 1952 Location incorrect? All work on No 1 had ceased after financial crash of 1951. This photo would refer to No 4 Headrace Tunnel? Page number 27 10-STATE ELECTRICITY COMMISSION OF VICTORIA Date: Jan 1953 Time: No K7307 Kiewa Hydro Electric Works CLOVER DAM Page number 28 secv; kiewa hydro electric scheme; bogong; mt beauty; construction area -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPhotograph - Folder of Photographs – Photocopied set of 10 black and white photographs (pages 29 - 38) from the display folder put together by KVHS to document life on the Kiewa Valley Hydro-electric Scheme

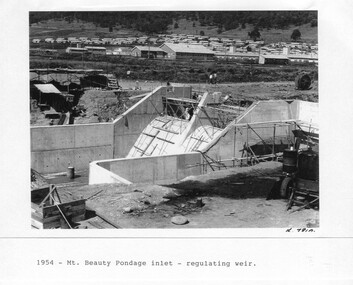

Although the Kiewa Hydro-Electric Scheme was first proposed in 1911, construction did not commence until 1938. As part of the push to cut electricity costs and diversify supply, the Victorian Government (circa 1930) initiated the conversion from primarily brown coal supply to hydro – electricity. Field investigations during the 1940’s resulted in a new proposal for a scheme that had more than double the capacity of the 1938 scheme. The Kiewa Hydroelectric Scheme became the largest scheme of its kind in the State Of Victoria and the second largest scheme in Australia. The number of personnel involved in the planning and construction of the scheme increased dramatically. During the late 1940’s, most activity centred around the construction of the West Kiewa Power Station, Rocky Valley Reservoir, McKay Creek Power Station and the Bogong Creek Aqueduct.A common thread across all the larger hydro scheme constructions was the need for workers, both qualified and unqualified who came from around the world seeking a new life for themselves and their families. New accommodation and facilities were required for the army of workers engaged in construction in often remote and wild areas. The SEC had a high demand for timber, and set up the first of a number of sawmills at Bogong Creek in 1939 and set up the first hardwood logging in the headwaters of the Kiewa River. These new ‘towns’ such as Mt Beauty and Bogong, survived, serving the needs of operational personnel and their families, and expanding with growth of new industries. Mount Beauty, and to a lesser extent Bogong, are among these places. Large A3 size spiral bound display folder containing 21 pages of photocopied black and white photographs of various aspects of the early days of the Kiewa Valley Hydro-electric scheme including equipment, various work sites and photographs of workers and their families. 1-Mt Beauty Pondage inlet-Regulating weir 2-Langfords Gap Basalt Hill-Tunnel in quarry face.3-Rocky Valley Camp-from Engineering Office 4-Basalt Hill tunnel portal 5-No 1 Pressure Shaft Works Bench 6-No 1 Power Station 7-Overturned haulage wagons on the side of an embankment 8- Group of workers dressed in wet weather gear inside a tunnel 9-Workmen and vehicle in tunnel 10-Howman’s Gap campsite at 4,150 feet 1-1954 – Mt Beauty Pondage inlet – Regulating weir Page number 29 2-28/10/54 – Langfords Gap Basalt Hill – Tunnel in quarry face K7860 Page number 30 3-STATE ELECTRICITY COMMISSION OF VICTORIA Date: 17.8.55 Time: No K8132 Kiewa Hydro Electric Works ROCKY VALLEY CAMP – FROM ENGINEERING OFFICE Page number 31 4-28/10/54 – Basalt Hill tunnel portal K7859 Page number 32 5-No.1 Pressure Shaft Works Bench 5.7.56 Page number 33 6- No. 1 Power Station 26.4.59 Page number 34 7- No markings Page number 35 8-No markings (Wooden board on ground printed with - POLAR A.N.GELATINE DYNAMITE “75” DE 28.8.40) Page number 36 9-No markings Page number 37 10-Howman’s Gap campsite at 4,150 feet Page number 38 secv; kiewa hydro electric scheme; mt beauty; bogong; construction area -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPhotograph - Folder of Photographs – Photocopied set of black and white photographs (pages 49 -58) from the display folder put together by KVHS to document life on the Kiewa Valley Hydro-electric Scheme

Although the Kiewa Hydro-Electric Scheme was first proposed in 1911, construction did not commence until 1938. As part of the push to cut electricity costs and diversify supply, the Victorian Government (circa 1930) initiated the conversion from primarily brown coal supply to hydro – electricity. Field investigations during the 1940’s resulted in a new proposal for a scheme that had more than double the capacity of the 1938 scheme. The Kiewa Hydroelectric Scheme became the largest scheme of its kind in the State Of Victoria and the second largest scheme in Australia. The number of personnel involved in the planning and construction of the scheme increased dramatically. During the late 1940’s, most activity centred around the construction of the West Kiewa Power Station, Rocky Valley Reservoir, McKay Creek Power Station and the Bogong Creek Aqueduct.A common thread across all the larger hydro scheme constructions was the need for workers, both qualified and unqualified who came from around the world seeking a new life for themselves and their families. New accommodation and facilities were required for the army of workers engaged in construction in often remote and wild areas. The SEC had a high demand for timber, and set up the first of a number of sawmills at Bogong Creek in 1939 and set up the first hardwood logging in the headwaters of the Kiewa River. These new ‘towns’ such as Mt Beauty and Bogong, survived, serving the needs of operational personnel and their families, and expanding with growth of new industries. Mount Beauty, and to a lesser extent Bogong, are among these places. Large A3 size spiral bound display folder containing photocopied black and white photographs of various aspects of the early days of the Kiewa Valley Hydro-electric scheme including equipment, various work sites and photographs of workers and their families. 1-Workmen working inside one of the tunnels. 2-Workman drilling in West Kiewa Tunnel 3-Junction Dam wall construction 4&5-2B&W photographs Kiewa House residents ready to go to a ball in Mt Beauty 6-Workmen warming up in front of a fire at No 1 bench 7-Workmen being hauled in at No 4 P.S Shaft 8-No 4 Power Station – Drilling 9-Workmen eating a hot meal in the tunnel. 10-2 photographs (a)Pretty Valley camp showing workman’s huts and construction materials & (b)Worker in Langford Gap Basalt Hill Tunnel face 11-Tunnel entrance (unlabelled) with rail tracks in foreground 12- Workmen drilling at No 1 Head race tunnel-Drilling face 13- No 1 Power Station 14-Workmen at the entrance to one of the SECV tunnels under construction 1-SECV number at bottom of picture Half obscured possibly K8461 Page number 53 2-In West Kiewa Tunnel Page number 54 3- Construction of Junction Dam wall – approximately 1941 Page number 55 4&5- Residents of Kiewa House at Bogong ready to go to the ball at Mt Beauty-1946. Handwritten on a copy of the photo on opposite page Mrs Lorna Crosset filled out the names *Dad was Des Crossett – his daughter is Gael Petcopoulis Greta engaged to John broke it off. Charlie, Rosalind, Bill, Priscilla, Max Lawrence-Dad’s Boss, Mary & Max married, Mary, Kay, Gwen McPherson Mum’s boss, John McCluskey (c) At No. 5 Bench Page number 56 6- STATE ELECTRICITY COMMISSION OF VICTORIA Date: 27.2.51 Time:2.15pm No K6373 Kiewa Hydro Electric Works No. 4 P.S. Shaft – Haulage of men in buckets (b) As above Handwritten at top of photo Appendix 4 page number 57 7- STATE ELECTRICITY COMMISSION OF VICTORIA Date: 6.6.52 Time:… No K7122 Kiewa Hydro Electric Works No. 4 POWER STATION – DRILLING page number 58 8-No markings page number 59 9-(a)Handwritten under photograph Approx. 1948/49 (b) STATE ELECTRICITY COMMISSION OF VICTORIA Date: 28.10.54 Time:.. No K7860 Kiewa Hydro Electric Works LANGFORD GAP BASALT HILL TUNNEL FACE Page number 49 10-(a) No markings 11- STATE ELECTRICITY COMMISSION OF VICTORIA Date: 20.3.52 Time: No K6979 Kiewa Hydro Electric Works No. 1 HEAD RACE TUNNEL – DRILLING FACE (E.E.E. CONTRACT) ‘The Frenchies’ (E.E.E) as they were affectionately known Page number 50 12-31.5.56 No. 1 Power Station Aggregate Stock Piles. Page number 51 13&14-No markings Page number 52 secv; kiewa hydro electric scheme; bogong; mt beauty; construction area -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood Smoothing Plane, Late 18th to Early 19th Century

A block, jack or smoothing plane is used for making a smooth finish to timber that is used to make furniture or other wooden objects. Traditionally, wood planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the intended shape of the item being worked on. The blade or iron was likewise formed to a flat shape and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers' shop might have many, perhaps hundreds, of smoothing and moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. A vintage tool by an unknown maker, this item was made for cabinet-making firms and individuals that worked in wood and needed a tool that could remove large amounts of timber. These jack, block or dressing planes as they were known came in various shapes and sizes to achieve a flat and even finish to timber surfaces before the use of mechanical smoothing planes and came in many sizes. A significant tool from the late 18th to early 19th century that's pattern or shape is still in use today. Early models of this type of woodworking plane are sought after by collectors today. This tool gives us a snapshot of how furniture and other finishes were created on timber by the use of cutting-edged hand tools used by craftsmen of the time. Tools that were themselves handmade, demonstrating the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce either a decorative or even finish for timber items. Smoothing Plane blade and wedge present. Raised handle at front end. Right-hand wedge guide broken away. Noneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane, wood plane, cabinet makers tools, furniture making -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood moulding Plane, Mid to late 19th century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it.A vintage tool made by an unknown maker, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use to produce a decorative moulding for a piece of furniture, door trims etc. or other timber items that had to be accomplished by using hand tools and in particular one of these types of planes. Profiled planes came in various shapes and sizes to achieve the required decorative finish. A significant tool from the mid to late 19th century that today is sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tongue and groove match plane with metal strip affixed with 5 screws Mc Vicar stamped on end and No 2. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Plane, James Hastie, Late 19th to Early 20th Century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it.A vintage tool used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture was done by hand using one of these types of plane. A significant item from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture was made predominately by hand and with tools that were themselves hand made shows the craftsmanship used to make such a unique item. Moulding Plane with metal blade attached. Made by J Hastie. Inscriptions stamped into wood. "J Hastie" "E G" "W.M" "EG" "11"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, j hastie, plane, wood working tool, hand tool -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Plane, Early to Mid 19th Century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it.A significant item from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture was made predominately by hand and with tools that were themselves hand made shows the craftsmanship used to make such a unique item. It also gives an insight into how many manufacturing companies bid for the rights to use prison labour to make their products at this time in our history. Moulding Plane T S Richards & Co. J Heath owner stamped. No 4/8 opposite endflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, moulding plane, plane, j heath, t s richards & co -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Plane, Mid to late 19th Century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it.A vintage tool made by an unknown company, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture, door trims etc or other items had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item. Moulding Plane 4 screws attached to wood bottom plateJ Heath. 1/2 inch on opposite end.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, j heath -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Plane, Mid to late 19th Century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it.A vintage tool made by an unknown company, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture, door trims etc or other items had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item. Circular moulding Rabbet Plane Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, circular rabbet plane, plane -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding Plane, Mid to late 19th Century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it.A vintage tool made by an unknown company, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture, door trims etc or other items had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item. Moulding Plane H Heathflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, plane -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumFolio, Garfield

GARFIELD ž Kilmartin Road, Cooma.|John Thomas Dougherty, an American, came to the Tatura area in 1874. He married Emily Whitnell from Whroo in 1883 and they had nine children.|He started building Garfield in 1886 and it was not completed until 1897. The building was named after President Garfield of America.|The building still contains the original Ericson wall telephone with its tag inside dated 1906. The house contains many features such as Jacobean over mantel and fire surround in the dining room, stained glass, a push button bell, and a stair well leading to an underground living area used in the summer for coolness. A new glass stair well was installed in the 1980®s to allow more light into the area. J.T. Dougherty died 1936.Photos and foolscap sized documents in a black A 4 size folder.documents, agreements -

Vision Australia

Vision AustraliaPhotograph - Image, Leatherwork jig, 2018

Leatherwork was offered to clients at the Ballarat office of Vision Australia, involving the use of jigs to help align punch marks. This jig was donated by "G.A. Arnold P/L 98-106 Moray St, South Melbourne" and its users were advised to "Clean and oil weekly" according to the 2 metal plates attached to the base plate that the jig was affixed to. A small metal bar runs across the middle of the base plate, to assist in correct alignment, with a black ball handle situated above a metal rod to allow users to push downwards on to a secondary rod (held in place by a cylinder) at the end of which is a punch. The cylinder that holds the punch in place is attached to a broader black metal attachment that is screwed into the base plate. The punch remains at the centre, however this image was taken before the centre's refurbishment.Metal sheet with ridges to align items above a punch activated by a lever pushed downwardsG.A. Arnold P/L 98-106 Moray St, South Melbournerecreation equipment, vision australia -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - HARRIS COLLECTION: STEAM TRACTOR DRIVING THRESHER HARRIS FAMILY AXEDALE, 1900?

Sepia tone photograph of steam tractor driving thresher, (at Axedale??) Large haystacks at rear with workmen passing down stooks of hay (perhaps oats), passed through threshing machine into bags. Two men leaning on steam engine, push bike in centre front. Men standing around thresher. Horse with rider on far right. 'Mrs Harris owned this thresher which was later burnt and a court case followed over payment of insurance'. (Black lead pencil on reverse) Inscriptions: on front - TR corner 'MP 217'. 'Royal Historical Society of Victoria, Bendigo Branch'. (circular rubber stamp), '8' on back and front TR corner (red ball point pen).person, group, employees, see also 2000.537.01 harris family axedale. -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Newspaper - LONG GULLY HISTORY GROUP COLLECTION: BENDIGO'S CENTURY VOLUME SIX: 1950 - 1959

Newspaper supplement titled Bendigo's Century Volume six: 1950 - 1959. Front page has a photo of Gillies' famous corner, 1954. Each year has heading of Who's Who, Weather, Sport and Business. First year is 1950 titled Gillies: it's a Bendigo icon. 1951 is titled It's party time. 1952 - City mourns King George. 1953 - Mining ceases. 1954 - City thrilled at royal visit. 1955 - Push to save old Joss House. 1956 - Olympic fever grips Bendigo. 1957 - State Cabinet visits Bendigo. 1958 - Plan to keep historic mine. 1959 - Water storage woes solved. Back page has the Gillies Story.bendigo, history, long gully history group, the long gully history group - bendigo's century - volume six: 1950 - 1959, gillies' corner, bendigo advertiser, john lienhop mlc, north deborah mine, les gillies, alan gillies, norm gillies, black swan hotel, sir dallas brooks, cr a g weynton, bert mundy, cr poulston, the northern district school of nursing, lister house, the bendigo free library, rev dr c irving, shamrock hotel, sir albert dunstan, the most rev dr john mccarthy, jack davey, 1950 empire games, hercules gold mines, amy castles, ben templeton, cobb & co, cr norman oliver, reg parker, fred amer, les hammer, colonel george victor lansell, john quick, mr l w galvin, mr p j clarey mhr, hanro knitting mills, flooding, bendigo pottery, snow fall, the last lamp-lighter, the north deborah, aids & appliance shop, boardwalk, the late king george vi, the north deborah, beehive building, st paul's, st kilian's, upper reserve, bendigo trades hall, bendigo blackout, bendigo hospital, shamrock hotel, gerald smith, britannia hotel, mr a j harris, william morris (billy) hughes, andrew hampson, deborah anticline, north deborah, central deborah, diamond hill mine, north nell gynne mine, robert ross haverfield, sandhurst commercial courier, arthur moore lloyd, robert ross haverfield, angus mackay, jj casey, james henderson, david stuart, bendigo independent, colonel george lansell, bendigo base hospital, bendigo town hall, victorian electric traction association, the most rev b d stewart, st vincent's memorial college, commonwealth athletic club, south atlas racetrack, harp and shamrock hotel, mr and mrs f drake, cr f w clayton, cr r poulston, j h abbott & co, sir george lansell, clan macleod, bendigo gaol, queen alexandra fountain, belfast hotel, commonwealth bank, st vincent's college, lyric threatre, des duguid, brian cahill, lord's raceway, red white & blue extended gold mining company nl, central napoleon gold miningcompany nl, joss house, harry john, bendigo advertiser, mr leggatt, university of melbourne, anz bank, golden drive-in theatre, bank of australasia, john brown industries, bendigo football league, bendigo trotting club, faith leech, racv, bendigo sewereage authority, bendigo base hospital, bendigo benevolent asylum, henry bolte, jack davey, russell oakley, neville stilwell, channel seven, bendigo's olympic pool, annie caudle centre, strathfieldsaye aerodrome committee, southern airlines, cr d j osborn, cairn curran reservoir, state savings bank, commonwealth bank of australasia, belfast hotel, bennett's arcade, eppalock weir, bendigo cenotaph, sir edmund herring, cr a s craig, bendigo creche, bendigo high school, bendigo pottery, shamrock hotel, the venerable ronald richards, bishop riley, all saints cathedral, mr albert bush, bendigo arcade company ltd, woolworths, bull's head hotel, pike's corner, arcade hotel, upper coliban reservoir, cr tom flood, crystal egg co, sailor's guide, central deborah, central nell gwynne mine, bendigo benevolent home, ron masters, george daniel, eppalock dam, water commission, public works committee, bendigo central victoria telecasters ltd, channel nine, royal princess theatre, sir george lansell, volunteer defence corps, bendigo independent, countess erna cadorin, count ettore cadorin, ernst mueller, sutex pty ltd, dick turner, marco cavasassi -

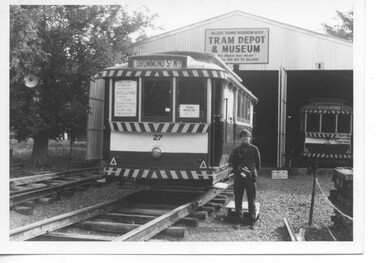

Ballarat Tramway Museum

Ballarat Tramway MuseumPhotograph - Black & White Photograph/s - set of 4, May to June 1973

Yields information about the construction of the BPTS depot in early 1974 and its appearance.Set of four Black and white photographs of how the BTPS operated during the early days of the BTPS. Based on the troughing being placed for No. 2 road only, photo dated by a list in the 1972-73 Annual Report at May to June 1973. .1 - ? Bounds standing alongside No. 27, which was operated as a Museum display. .2 - Just the tram itself - was pushed out of the shed by hand. .3 - A general scene with visitors and workers. .4 - pushing the tram back in again at the end of the day. Note the sign is different in the front of No. 27, or no sign, indicating different days. See 1972 - 1973 Annual Report which has a list of dates on page 3 of events at the depot.trams, tramways, depot fan, btps, operations, tram 27