Showing 808 items matching "large plate"

-

4th/19th Prince of Wales's Light Horse Regiment Unit History Room

4th/19th Prince of Wales's Light Horse Regiment Unit History RoomPrincess Mary Gift Tin, 1914

In November 1914, an advertisement was placed in the national press inviting monetary contributions to a 'Sailors & Soldiers Christmas Fund' which had been created by Princess Mary, the seventeen year old daughter of King George V and Queen Mary. The purpose was to provide everyone wearing the King's uniform and serving overseas on Christmas Day 1914 with a 'gift from the nation'. The response was truly overwhelming, and it was decided to spend the money on an embossed brass box, based on a design by Messrs Adshead and Ramsey. The contents varied considerably; officers and men on active service afloat or at the front received a box containing a combination of pipe, lighter, 1 oz of tobacco and twenty cigarettes in distinctive yellow monogrammed wrappers. Non-smokers and boys received a bullet pencil and a packet of sweets instead. Indian troops often got sweets and spices, and nurses were treated to chocolate. Many of these items were despatched separately from the tins themselves, as once the standard issue of tobacco and cigarettes was placed in the tin there was little room for much else apart from the greeting card All boxes, irrespective of recipient, contained a Christmas card and a picture of the Princess. Those which were not distributed until after Christmas were sent out with a card wishing the recipient a 'victorious new year'. The wounded on leave or in hospital, nurses, and the widows or parents of those killed were also entitled to the gift. Prisoners of war at the time had theirs reserved until they were repatriated. Great efforts were made to distribute the gifts in time for Christmas, and huge demands were made on an already stretched postal service. More than 355,000 were successfully delivered by the deadline. As time pressed on, a shortage of brass meant that many entitled personnel did not receive their gift until as late as the summer of 1916, and in January 1919 it was reported that 'considerable' numbers had still not been distributed. Orders for brass strip were placed with the USA, who were not yet involved in the war, and a large consignment was lost with the ship 'Lusitania'. As so much brass was being consumed in the production of weapons and munitions, the quality of the boxes which were manufactured late on was poor, being of a plated inferior alloy, when compared with the earlier pure brass examples. When the fund finally closed in 1920, almost £200,000 had been donated for the provision of more than two and a half million boxes with contents. The 'tin' is approximately 5" long by 3¼" wide by 1¼" deep with a double-skinned, hinged, lid. The surface of the lid depicts the head of Princess Mary in the centre, surrounded by a laurel wreath and flanked on either side by the 'M' monogram. At the top, a decorative cartouche contains the words 'Imperium Britannicum' with a sword and scabbard either side. On the lower edge, another cartouche contains the words 'Christmas 1914', which is flanked by the bows of battleships forging through a heavy sea. In the corners, small roundels house the names of the Allies: Belgium, Japan, Montenegro and Servia; France and Russia are at the edges, each superimposed on three furled flags or standards. -

4th/19th Prince of Wales's Light Horse Regiment Unit History Room

4th/19th Prince of Wales's Light Horse Regiment Unit History RoomPhotograph, Australian Lighthorseman, abt 1915

Large black & white photograph of mounted Australian Lighthorseman. Soldier is wearing WW1 uniform, with 4 Light Horse colour patch. He is holding aq .303" rifle. Photo is in wooden frame with glass front On brass plate: "No 1008 Tpr E H T Cross C Squadron 4th L H Regt" Nothing written on backtrooper cross, 4th light horse -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyWheelchair

... "Sibbing / Melbourne" on the foot plates 2 large wheels - The outer ...After WWII demand for wheelchairs increased. The original wheelchairs were driven by the patient's hands pushing the wheels. Later a motor was added. Then the motor and battery were built into the chair under the seat. This was followed by developments in ergonomics (comfort), controls, comfort and performance.See KVHS 1796, KVHS 1797Used by Wilma Davies, a Kiewa Valley resident, who suffered from polio from the early 1950s.2 large wheels - The outer wheel is steel and the inner is rubber with metal spokes attached. The foot plates are of ribbed steel. The ribbed seat is blue made of thick canvas as is the back of the chair. Some plastic has been glued on the back. The arm rests are also covered with old torn plastic. There is a metal stick on the side used to brake the chair by being pulled enabling it to touch the wheel and slow it down or stop it from turning."Sibbing / Melbourne" on the foot platespolio, wheelchair, pandemic -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyStove - electric

Simpson was founded in 1853 by Alfred M. Simpson. It was a manufacturer of household appliances based in Adelaide, Australia. This stove has only 3 hotplates (not the usual 4) and may have been used in the 1950s.Used by a resident of the Kiewa Valley.Green ceramic stove with 3 hot plates - 2 solid (one small and one large) at the back and one at the front with coils (large). 5 black knobs - 2 for the oven and 3 for the hotplates. The oven has a tray and adjustable shelving. At the bottom there is a warming drawer. The stove is electric and has a warming drawer at the bottom. The handles are black."Simpson" on the front on the vertical panel and also on the control panel.ceramic stove, simpson stove -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyScales Balance Pocket, Circa 1900

Historically this item would have been used by gold miners, rabbit shooters, mobile "Rag and Bone" traders and other mobile(in caravans and/or horse drawn cart) traders of various small goods and haberdashery. Although marked as not to be used as trade, the isolation and sometimes difficult terrain rules out using larger and more delicate scales. In the early 1900s rough roads and severe weather conditions forced traders to be more flexible in trading with weights and measures. The "close enough is good enough" doctrine was the Australian outback rule of thumb. The significance of this item in the Kiewa Valley during this period demonstrates the slower acceptance of accurate trading measure using the country side principle "my hand shake is my bond". In the Kiewa Valley small quantity commercial undertakings e.g. gold mining, fur pelts and rabbit meat trade did not require bulk weight type scales. Commerce in rural production e.g. fruit and vegetables involved more farmers and their staff in a barter and/or "in kind" payments. This was more so in the depression years 1929 to late 1930s. Self sufficiency was to a large extent more attainable in this region than in the city/ large country town environment. The Australian "fair go" ethical approach to life and commerce was very much ingrained in those living in country regions, like Kiewa Valley as is demonstrated by the not so accurate hand balance, spring loaded scales. Portable Pocket Balance with front plate made from brass. Spring mechanism enclosed by black painted medium gauge steel cover( three quarters cylindrical). Front scale face and rear spring casing fastened by three rivets. Spring loaded marker blade is located in the centre of the front plate. See item KVHS 0224 for a similar scales.Front plate marked: at top "Not legal for use in trade", below this in larger print "Pocket Balance", under and to the right in smaller print "lbs" under this graded marks, first marked with a Zero, then every second mark in ascending order up to 25. At the bottom of the front plate is marked "Made in Germany"antique pocket balance, scales, mobile weights, vintage appliances -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBook - Reference Printing, Charles W. Hackleman, Commercial Engraving and Printing, Circa 1921

This item relates to methods of reproducing photos on all forms of material in an era of physical offset printing.The offset method is being replaced by digital transfer direct to the final product,(paper or other porous and non porous surfaces). Newspapers and other "paper" information publications are still producing "hard copies" but these are slowly being phased out. This item was used Circa 1920s in the peek period of paper based media. From the 1940s radio and then television stepped into the mass media revolution.This book was produced when all printing, Government and private enterprise, was using the "off set" method. This method was used to a great degree in all schools within the Kiewa Valley. It was in an era before "photo-copying machines" were available. This was a period when printing inks for larger printing machines had to be purchased from specialised outlets and printing presses required to be washed after each "run" of printing before the next plate(aluminium) could be fastened onto the "off sett" machinery. Heat infusion now used in large machines and domestic printers has superseded this task. Faded green cloth covered book with green papered front and back sleeve pages.Photos and sketches are throughout the book. Gloss paper used from page 1 one to page 400. Pages 401 to page 432 are not gloss paper. The type of paper varies throughout the book until final advertisement and index pages, from page 833 to page 846, are on gloss paperThe spine cover is badly worn and wording is faded. Front cover has"Commercial Engraving And Printing" Author and publisher details written by Charles W. Hackleman. Published by Commercial Engraving Publishing Company, "A Manual of Practical Instruction and Reference Covering" Commercial Illustrating and Printing by all Processes.technical book, reference for engraving and printing -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyTypewriter Mechanical Portable, 1950s

The Olivetti company was founded in Italy in 1908.This particular typewriter is a Olivetti Lettera 22, oblique front stroke and portable manufactured after 1950. The 1950s and 1960s was a time when British manufactured goods were still purchased by many Australian consumers. The later 1960s onwards, there was a shift, mainly in the cities, to European made goods. The invasion of Japanese manufactured goods was relatively slower, especially in rural areas. The demand for long lasted and dependable merchandise was in the rural area still the most important criteria. The ease of setting up this typewriter and its compact mobility was its major benefit to trades people and travelling professionals, e.g. rural doctors, other medical professionals, accountants, lawyers and educators. This item facilitated the growing numbers of professional nomads requiring a relatively light office stationery package e.g. travelling novelist, writer, businessman and academics. This typewriter needed no electrical or battery power to operate it. Outback Australia, where at this point in time, was still relatively isolated from a good available electrical power reticulation and battery power, and therefore could not be totally measured as a highly efficient office environment.Although this typewriter was purchased from a business in Penrith, Sydney, N.S.W., it is significant that it travelled easily to the Kiewa Valley, demonstrating the mobility of certain sections of the community. This typewriter was designed by an Italian industrial designer, Marcello Nizzoli, in line with the art deco style of the 1930s and the colour and flexibility of the vibrant 1950s. The underlying theme of manufacturing in the 1950s was to produce equipment that was more efficient than what was inherited from the earlier period of 20th century. Improvements were made to this Olivetti typewriter by Giuseppe Beccio by reducing the number of parts made from 3,000 to 2,000. This reduction of parts and therefore cost of production was the major principle of the Japanese manufacturing juggernauts of the post World War II era. Efficiency and low costs material was becoming prime factors in the success of rural industries from the 1960s. Competition from overseas producers was starting to affect rural industries and the removal of the large range of tariff protection, especially rural products, required not only a shift of farm management but a more efficient cost savings modus operandi. This Olivetti Lettera 22, oblique front stroke portable (weighs 4kg) mechanical typewriter has a coral coloured plastic casing. The keys are made of black hardened plastic with white lettering, numbers and symbols (imperial fractions, and pound). It has a QWERTY keyboard as opposed to the Italian QZERTY. It has a lever to move the ribbon between black, neutral (for mimeograph stencils)and red colours (a red key is provided for highlighting specific words,letters or symbols) . This machine is fitted with only a black ribbon. It has a black rubber paper rollers and chromed metal parts on the carriage way. It has four rubber feet underneath the main body. On the left side of the roller there is a lever to adjust the roller from fixed (when mobile) through 1,2 and 3 line space gradients. This model has a key for zero but not one for the number one (uppercase letter l is used) see KVHS 0459 for the carrying bag.On the cover over the ribbon wheels letter strikers has a plate marked "Lettera 22" and the back plate behind the paper roller and in front of the paper supports has a silver metal label marked "olivetti made in great britain".commercial, mobile office equipment, mechanical typewriter -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyTin Tobacco / Cigarette, Circa 1900s

This particular brand of tobacco (State Express 555) was first made in 1915, and was most popular in Asia and China. The number triple 5 was mooted as a sacred number, and may have contributed to its high level of demand by Asian smokers. This would have been a favourite "smoke" for the Chinese emigrants, and especially those who settled in rural areas of Australia. In the era where 'male' type of activities such as motor racing, were sponsored by tobacco companies, roll your own cigarettes was ingrained as a macho male requirement. It was only in the early 2000s, when cigarette advertising had greater restrictions attached to the product, that the roll your own, and cigarettes in general, became less "cool". This particular cigarette tin would have also been useful for roll your own (ready rub tobacco)The significance of this particular Qantas cigarette tin to this rural region is that it demonstrates that overseas travel by plane was not only for the affluent city dweller but also available, and not impossible to the inhabitants of the Kiewa Valley. This cigarette tin also may hint that the influx of Asian immigrants into this region where able to visit relatives back in Asia without too much effort. The use of a Qantas cigarette tin in the Kiewa Valley also suggests a degree of affluent there or tourists from elsewhere. This tobacco tin relays a long ago era, when personal contact, and not something that has been written down by some "unknown", was valued as the true appraisal of a member of the community. This was especially relevant in a small regional area such as the Kiewa Valley. Although social networking was not as fast then as the internet provides now, appearances, manners, fashion and etiquette with first impressions high on the order of evaluating someone in the community. Pointer such as the brand of tobacco smoked was part of the rural assessment method. Up until the demise of the Australian Tobacco Industry, circa 2004, the Kiewa Valley and surrounding district was part of a vibrant producer of tobacco leaves. The remnants of this industry still remain today but the drying sheds (for tobacco leaves) are now used to store hay for the valley's dairy and beef cattle industries.This tobacco/cigarette tin is constructed from tin plated thin rolled steel. The lid is attached by two pressed and formed (from the main frame) hinges using the nip and tuck construction method.The outside lid and frame has a yellow colour anodised to the metal.On the front of the lid are the following printed: "STATE EXPRESS" ,in yellow print, and below this are two horizontal lines in brown and central to these are the numbers "555" . Below this appears and within a 'royal' crest, in yellow writing on a brown circular background "STATE EXPRESS". Below this, in brown print, "PICCADILLY, LONDON". On each side of the tin are printed in brown colour: front side" ARDATH TOBACCO CO. LTD. PICCADILLY, LONDON" . On the left and right sides are printed in brown colour "20 STATE EXPRESS 555". On the rear side is with smaller print "MANUFACTURED UNDER ARRANGEMENTS WITH THE POPRIETORS". On the inside of the lid printed in red colour, are the following words, the royal crest and sketch of the winged kangaroo(symbol of the QANTAS logo). Within a red elongated square border, are the Royal Crest and in very small red print "BY APPOINTMENT TO HER MAJESTY THE QUEEN" underneath in slightly larger print "STATE EXPRESS" The print underneath this and in smaller print is "CIGARETTE MANUFACTURERS ARDARTH TOBACCO CO. LTD." Next to the royal crest and in much larger print is "STATE EXPRESS" and underneath this ,the numerals 555 with the words "CIGARETTES" below. The lower half of the inside lid has the following words and the "flying" kangaroo(winged). These words in written (running free hand) style "Specially packed for QANTAS(in red print). Underneath and in smaller print is "AUSTRALIA'S OVERSEAS AIRLINE". On the bottom of this tobacco tin is stamped into the metal surface, the number"704"qantas supplied cigarettes, roll your own, cigarette tins, smoking accessories, personal effects, tobacco containers, tobacco -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyTelephone - Wall Mounted 184, Circa mid 1900s

This handset appeared via Australia Post Office and was to some degree manufactured in Britain just prior to 1939. During and after World War II these handsets were made in Australia. The handset belonged to the SEC Victoria and later the Kiewa Hydro Electricity Scheme. As this unit has a winder arm (to notify the switchboard) it would have resided in a workshop/machine shop and not in an office. The durability of the bakelite covering gave good protection in any environment. In years later the bakelite came in colours. This type of handset being able to endure rough handling was ideal for the surroundings of the alpine terrain. It would have been at the various outside outposts or foreman posts as swift communications was essential and communications with all sectors of work in the Hydro Electricity Scheme was mandatory, not only for safety reasons but also for efficient operational day to day progress. Also refer to article in "This Week" Newsletter 30th June 2023. Article attached to paper copy.This Australian Post Office 184 black coloured bakelite wall mounted phone was initially developed by Ericsson Telephones Ltd Britain. It was used by the SEC Office based at Mount Beauty and therefore has a winder (for power and notification to the switchboard. The hand piece (large ear and voice receptors)is placed vertically above the dial up winder.On the winder plate in hand writing is" turn handle lift handset" and below the handle "when finished replace handset turn handle"sec communications, wall telephone, internal communications kiewa hydro electricity scheme -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyIron Hand Kerosene, mid to late 1900s

The 1950's saw a revolution in small appliances for use in the average household. This hand held self heating(kerosene) iron was introduced as a time saving and more convenient iron for pressing clothes and other cloth fabrics. It replaced irons needing a separate fire source to heat the ironing plate. These irons continued to be in service, even when electricity was available in cities and larger rural towns (domestic electric steam irons were invented in 1938). This item was used before and during the electricity supplies available from the Kiewa Hydro Electricity Scheme. These irons remained in use within regional rural areas that had limited or unreliable electrical reticulation.In the 1950s and later the Kiewa Valley was still a relatively isolated region which was home to rural properties and small settlements. The availability of electricity and or the financial means to afford new types of electric hand irons ensured that older and sometimes less efficient ironing remained for an extended period covering the 1960s to 1970s. Kerosene products, such as this kerosene iron was a cheaper method for farm based domestic and other rural activities requiring a heat source. The use of kerosene as a heat/light source was able to be supplied in bulk and able to be used when floods severed vital roads into this region. The supply of electricity was in summer time subject to interruption from bush fire damaged wooden poles carrying the electrical cables. Self sufficiency by rural populations was the backbone of survival and the ability to store energy sources "on the farm" was a prerequisite of isolated regions, such as the Kiewa Valley, circa 1950s.This Coleman kerosene iron has a solid steel chrome plated(press) base with a painted (blue) wooden handle. The handle is stud fastened onto an oblong shaped rolled steel handle frame and screwed (two screws) onto the base plate. Both the heating plate and the top securing plate are shaped similar to a river boat. The main housing enclosing the heating element is enamel coated(blue in colour) steel and has a half hole for lighting the kerosene at the rear end. Behind the handle and protruding upwards is a stainless steel fully enclosed container (bowl shaped) for the main supply of kerosene to the burner or generator(enclosed within the main body of the iron. The bowl has an air valve and inlet for pressurised air intake (hand pump) On the bottom rear of the fuel bowl there is a screw regulated fuel pump. The fuel heated base plate provides the heat for this advertised "self heating iron(instant lighting). See KVHS 0347B- Instruction sheet; KVHS 0347C- Wrench; and KVHS 0347D Fuel can.Stamped on the base plate of the handle, front region "COLEMAN LAMP & STOVE CO." below this "WICHITA KAN" below this"TORONTO CAN". In the middle of the handle base and in larger print "COLEMAN Instant-Lite" At the rear location in large print "MODEL 4" in smaller print below "MADE IN U.S.A." below this "PAT#1718473"household appliances, alternative non electrical ironing appliances, domestic appliances, kerosene appliances -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyCan Fuel Measuring, circa 1950

The 1950's saw a revolution in small appliances for use in the average household. The hand held self heating(kerosene) iron for which this filling can was provided ,was introduced as a time saving and more convenient iron for pressing clothes and other cloth fabrics. It replaced irons needing an external fire source to heat the ironing plate. These irons continued to be in service, even when electricity was available in cities and larger rural towns. This item was used before and during the electricity supplies available from the Kiewa Hydro Electricity Scheme. These irons remained in use within regional rural areas that had limited or unreliable electrical reticulation and the ability to service them from this filling can was an essential part.n the 1950s and later the Kiewa Valley was still a relatively isolated region which was home to rural properties and small settlements. The availability of electricity and or the financial means to afford new types of electric hand irons ensured that older and sometimes less efficient ironing appliances remained for an extended period covering the 1960s to 1970s. Kerosene products, such as the kerosene self heating (KVHS 0347A) iron and this kerosene filling item, was a cheaper method for farm based domestic and other rural activities requiring a heat source. The use of kerosene as a heat/light source was able to be supplied in bulk and able to be used when floods severed vital roads into this region. The supply of electricity was in summer time subject to interruption from bush fire damaged wooden poles carrying the electrical cables. Self sufficiency by rural populations was the backbone of survival and the ability to store energy sources "on the farm" was a prerequisite of isolated regions, such as the Kiewa Valley, circa 1950s.This specially spout fitted can was provided with the Coleman self heating kerosene iron (see KVHS 0347A). On one side of the half enclosed top of the can there is a small spout(for poring the appropriate liquid into the egg shaped fount container) at the rear end of the hand iron. The can is made from tin. See KVHS 0347B- Instruction sheet; KVHS 0347C- Wrench.On one side of the can in black print on yellow background is "FUEL MEASURING CAN" underneath is "For Coleman Instant-Lite Iron" underneath are four numbered paragraphs detailing the use of this can. Below this is the name and places of manufacture. On the other side of the can is printed "BE SURE" with filling and maintenance instructionskerosene can, ironing, domestic appliances, household appliances -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Brass Plate, Dr H I Holmes, Circa 1905

Doctor Horace Iles Holmes was born at Launceston Tasmania 09/08/1877. He was educated at Launceston High School and Tasmanian University and later at Melbourne University. After graduation he came to Warrnambool in 1905 and worked in the practice of Dr T F Fleetwood and took over the practice shortly afterwards along with the position of Honorary medical officer at Warrnambool Hospital and also health officer until 1944 and as an Honorary consulting medical officer from then until 1958. His practice which was located at " Ierne" opposite the Presbyterian Church in Spence St Warrnambool. He later moved to a new home and surgery at the corner of Spence Liebig st and Raglan parade which was later sold to Dr C B Berryman. A large medical clinic still operates from this site. Dr Holmes was a keen fisherman and a member of Rotary serving as district governor.This plate is a connection to a long standing doctor in the Warrnambool district. In his practice he would have treated many district people and as such this item has strong social and historical connections to the district. Rectangular brass plate engraved with name which has been coloured in black. There are six screw holes around the outer edge of the plaque. The back is plain .H.I. Holmes M.D. Surgeon & Physician. A stamped name at middle bottom edge is unreadablewarrnambool, warrnambool doctors, dr h i holmes, warrnambool history -

Victoria Police Museum

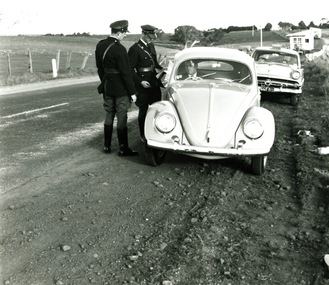

Victoria Police Museumphotograph (police car)

Police pulling over a Volkswagon without any registration plates on the front. There are two uniformed police standing at the driver's window of the Volkswagon with the police car being a Ford Customline. There are two large trucks in the background hauling houses. Circa 1954. The Policeman are wearing a "Sam Browne" belt and equipment, apparently as a trial.police vehicles; wireless patrol; motor transport branch; motor transport section; ford customline car -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Domestic object - Plate, side, C1920

The Ozone Hotel was formerly the Grand Ozone Coffee Palace which was erected in 1890 at a cost of around ten thousand pounds. Coffee Palaces were temperance hotels which were popular in the latter part of the 19th century which offered recreation and superior accommodation. The coffee palace operated until 1915 and was then closed before re-opening in 1920 as Hotels Mansions. It had major renovations including a large theatre area. February 23rd 1929 saw the most spectacular fire in Warrnambool's history when the Hotel mansions was burnt to the ground. Evelyn O'Brien was granted a temporary licence and in September 1930 she was given permission to rebuild. The new hotel named Hotel Warrnambool was opened in March 1931. This item has local significance having come from one of Warrnambool's grandest buildingsSide Plate with Hotel Mansions crest in black, with Warrnambool in banner underneath and a black line around rim of plate. Loftus Moran Pty Ltd Melbourne stamp on back (distributor?)Hotel Mansions crest on front of plate, with Warrnambool in banner underneath.grand ozone coffee palace, hotel mansions warrnambool, ozone hotel warrnambool, warrnambool -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Plaque - Nameplate, marble, Ozone Hotel, C 1900

The Ozone Hotel was formerly the Grand Ozone Coffee Palace which was erected in 1890 at a cost of around ten thousand pounds. Coffee Palaces were temperance hotels which were popular in the latter part of the 19th century which offered recreation and superior accommodation. The coffee palace operated until 1915 and was then closed before re-opening in 1920 as Hotels Mansions. It had major renovations including a large theatre area. February 23rd 1929 saw the most spectacular fire in Warrnambool's history when the Hotel mansions was burnt to the ground. Evelyn O'Brien was granted a temporary licence and in September 1930 she was given permission to rebuild. The new hotel named Hotel Warrnambool was opened in March 1931. The name plate is visible in photographs of the original Directors of the Grand Ozone. Mrs Lilias Euphemia Thom was a licensee of the Ozone hotel from 1907-1910.A link to a significant part of Warrnambool's streetscape and grand buildings.Marble name plate Ozone Hotel, with a shallow decorative groove 30mm in from edge, 4 mounting holes in each corner, an inscription L E Thom has 6 holes in lower portion perhaps used to attach the name of subsequent licensees. Ozone Hotel L E Thom grand ozone coffee palace, warrnambool history, hotel warrnambool, hotel mansions warrnambool, l thom -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Domestic object - China bowl, Gibsons and Paterson Limited, St Ann's College, Mid 20th Century

St. Anns College had its beginnings in the arrival in May 1872 of a group of nuns from Ireland. They were the third group of Sisters of Mercy to come to Victoria. The Warrnambool nuns worked hard to establish a school and orphanage for the socially disadvantaged children of the district. They purchased Wyton from Captain Ardlie that year and also Amhurst later on. The Nazareth sisters of Ballarat took over the orphanage in the late 1880's and moved the children to Ballarat but the school continued to develop an expanding curriculum. A chapel was built in 1887 and a school wing in 1906. They survived on tuition fees and the generosity of benefactors though the early and middle part of the 20th century including a large bequest by Mrs Vera Kenna in the 1960's. Boarders were a regular part of convent life until the 1970's which is probably the source of this plate. St Ann's College was combined with St Joseph's CBC college as Emmanuel College and operates today as the largest Catholic college in the district.This has significance as it is associated with one of the longest running schools in the district and hence would have a connection to many Warrnambool people as well as district people who boarded at the college.White bowl, with green and yellow stripe around edge and emblem. Surface is quite scratched on front and bottom of bowl.Inscription on emblem. " St. Anns Warrnambool around edge of logo with Omnia Vincit Labor on banner through the middle with four stars in the background. Printed in green. Inscription on base Grindley Hotel Ware England . Vitrified . Gibson and Paterson Limited New Zealand. CIR stamped into china on base.secondary school, catholic, warrnambool, st ann's college, sisters of mercy, education, emmanuel college -

Orbost & District Historical Society

Orbost & District Historical Societyscales, 1930's

... Underneath weights plates - 1lb 14oz Large black kitchen scales ...These cast iron scales were made for domestic use as they are quite basic and not accurate enough for commercial use.This item is an example of a common domestic kitchen appliance no longer in use.Large black kitchen scales with large dish that sits in metal claw.Underneath weights plates - 1lb 14ozscales instruments-weighing domestic kitchen -

Orbost & District Historical Society

Orbost & District Historical Societycup and saucer

This was used at Dr Kerr's tennis court. Dr James Kerr visited Orbost on Govt vaccinating job and settled in Orbost the next year. He served in Orbost for 40 years travelling everywhere on horseback.Dr James Kerr was Orbost's first doctor.Cup and saucer set. White cup with delicate floral pattern. Large saucer with extra section for biscuit in same floral pattern has cut-out section on saucer/plate.Bottom - Victoria, Australiakerr-james crockery china cup saucer -

Orbost & District Historical Society

Orbost & District Historical Societywriting desk, before 1888

This was presented to Mr A.D. Munro by the residents of Orbost on his retirement as postmaster in 1888. In 1883 the mail terminus was at Newmerella. In July 1883 it was extended to the north side of the river and Archie Munroe became Acting Post Master. He was Post Master until 1885 when the telegraph line came to Orbost.Archie Munro was a well-known Orbost identity who first operated a boot shop in Cameron's barn. He was also active in the promotion of the first brass band in Orbost. He was the son of Hector Munro.A large brown leather portable writing desk. It has a brass handle on the top. Inside are copies of some Munro family documents in a document folder.On a brass plate-Presented to Mr A.B. Munro by the RESIDENTS OF ORBOST on his retirement as Post Master. A.D. 1888munro-archie writing-desk post-office -

Orbost & District Historical Society

Orbost & District Historical Societyscales, circa 1930's

These scales were in the Dicken building in Nicholson Street Orbost. Frank B. Dicken and his son, Selwyn, were General Merchants. These scales are an example of a commercial measuring instrument used in Orbost before the common use of the metric system and digital scales.A large set of commercial scales painted white. The measuring scale gives the weight in pounds and the price per pound. There is a brass plate with NO A572/19951 W. & T. AVERY LTD.On front in green print - AVERY Beneath scale in green print - SOLE AGENTS On a brass plate - MACHINE ??????? "WHITE KNIGHT" AUSTRALASIAN FNO4 BRITISH MADE SCALE CO LTD TRULY LEVEL BIRMINGHAM ENGLANDscales measuring-machines weights dicken-frank -

Orbost & District Historical Society

Orbost & District Historical Societyboard game, 1930-1950

The National Bicycle Game is an Australian-made and designed board game for 2, 3 or 4 players made by The National Game Company of Ballarat and Melbourne between 1930 and 1950. The earliest board games date from the mid-18th century and were printed on copper or steel plates and coloured by hand. By 1839 lithography was first used, making it possible for publishers to produce larger quantities of all types of toys. By the 1890s the games were mounted on to a folded board. Popular subjects were of an historical or geographical nature, as well as transport including motoring, aviation and railways and various sports. The board game 'A Motor Ride' ,made by The National Game Company, was possibly the first large-scale manufacturer of locally-designed board games in Australia. The firm was established in Ballarat, Victoria, at the beginning of the twentieth century by W. Owen. Other board games made by National include the 'Victory-United Nations" game, 'Fairyland', 'Yacht Race', 'Golf Game', 'Bicycle Game', Steeple Chase', 'Our Great Game' about football, 'Courtship and Marriage', 'Around the Commonwealth by Aeroplane', and 'Dugouts and Trenches' as well as the more traditional games such as Ludo, Snakes and Ladders, and Noughts and Crosses. This game board has been well-used. The game is significant because it uses scenarios familiar to Australian children in the first half of the twentieth century. This game board reflects the experience of being a child in the twentieth century. Toys were how children were socialised and taught. Most toys mimic the adult world, and looking at them can tell us something about how the world has changed. A folding game board for The national Bicycle Game for 2,3 or 4 players. It has a yellow spiral track on which the player progresses at the throw of the die, starting at the clubhouse until reaching home. In the background are pictures of rural scenes.board-games recreation cycling national-game-company -

Orbost & District Historical Society

Orbost & District Historical Societyshield, 1984

Air Vice Marshal (Rtd) John Douglas Gordon Lessels, Marshal in charge of disaster relief, was a municipal councillor at Mallacoota where he had a holiday house.A wooden shield with a badge in the centre. Inside an orange circle is " in paratus adversitatem" with a larger CD inside a blue triangle. It has gold coloured decorations . around the circle. There are two small metal plates above and below this badge. On the back is a cut out for hanging.On plate at top : "NATURAL DISASTERS ORGANISATION CANBERRA ACT" On plate below badge : " ORBOST & TOURIST ASSN PRESENTED BY AVM JOHN LESSELS DGNDO 30 NOV 84" shield disaster-organisation orbost-tourism -

Orbost & District Historical Society

Orbost & District Historical Societyscales, 19th century

This is a MANCUR spring balance. They were used for rough weighing on farms, in kitchens, on hunting trips for animals or hides. Large numbers of Mancur scales were made in America and Europe during the latter half of the nineteenth century, and they were generally used by farmers.This item is an example of an early type of hanging scale.A set of small round hanging scales with a hanging hook. It has two suspension rings and two load hooks. It has a brass crescent shaped plate in the centre calibrated in lbs, a needle as pointer which is hinged to the C spring. It has double sided measurements with graduations in pounds. scale-mancur measurement weight hanging-scales -

Cheese World Museum

Cheese World MuseumPlate, 2009

The plate was presented to WCB on the occasion of the official opening of the joint project Great Ocean Ingredients.Large blue and white porcelain plate with a floral border and finished with a fine blue line around the rim. An inscription sits in the centre of the plate. The base has three fine lines around the rim and two holes on the rim to hang the plate.Congratulations on the official opening of Great Ocean Ingredients Friesland Campina Dorno 27th May 2009allansford, warrnambool cheese & butter factory company ltd, great ocean ingredients, trophies, presentations, awards, friesland, porcelain -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Syringe

In 1821 the French otologist Jean Marc Itard irrigated the ear canal to remove hard wax, by using a syringe prototype designed for enemas which was made from tin and brass. This glass and cork ear syringe was manufactured by the Ambson Company in the United Kingdom, about eighty years afterwards. Its lightweight properties would have been ideal for application to the sensitive regions of the ear canal. https://www.racgp.org.au/the-racgp/history/the-racgp-museum-collection/syringes/ambson-ear-syringe Otology is a branch of medicine which studies normal and pathological anatomy and physiology of the ear (hearing and vestibular sensory systems and related structures and functions) as well as their diseases, diagnosis and treatment. Otologic surgery generally refers to surgery of the middle ear and mastoid related to chronic otitis media, such as tympanoplasty, or ear drum surgery, ossiculoplasty, or surgery of the hearing bones, and mastoidectomy. Otology also includes surgical treatment of conductive hearing loss, such as stapedectomy surgery for otosclerosis. https://en.wikipedia.org/wiki/Otology The ear syringe was donated to Flagstaff Hill Maritime Village by the family of Doctor William Roy Angus, Surgeon and Oculist. It is part of the “W.R. Angus Collection” includes historical medical equipment, surgical instruments and material once belonging to Dr Edward Ryan and Dr Thomas Francis Ryan, (both of Nhill, Victoria) as well as Dr Angus’ own belongings. The Collection’s history spans the medical practices of the two Doctors Ryan, from 1885-1926 plus that of Dr Angus, up until 1969. ABOUT THE “W.R.ANGUS COLLECTION” Doctor William Roy Angus M.B., B.S., Adel., 1923, F.R.C.S. Edin.,1928 (also known as Dr Roy Angus) was born in Murrumbeena, Victoria in 1901 and lived until 1970. He qualified as a doctor in 1923 at University of Adelaide, was Resident Medical Officer at the Royal Adelaide Hospital in 1924 and for a period was house surgeon to Sir (then Mr.) Henry Simpson Newland. Dr Angus was briefly an Assistant to Dr Riddell of Kapunda, then commenced private practice at Curramulka, Yorke Peninsula, SA, where he was physician, surgeon and chemist. In 1926, he was appointed as new Medical Assistant to Dr Thomas Francis Ryan (T.F. Ryan, or Tom), in Nhill, Victoria, where his experiences included radiology and pharmacy. In 1927 he was Acting House Surgeon in Dr Tom Ryan’s absence. Dr Angus had become engaged to Gladys Forsyth and they decided he further his studies overseas in the UK in 1927. He studied at London University College Hospital and at Edinburgh Royal Infirmary and in 1928, was awarded FRCS (Fellow from the Royal College of Surgeons), Edinburgh. He worked his passage back to Australia as a Ship’s Surgeon on the on the Australian Commonwealth Line’s T.S.S. Largs Bay. Dr Angus married Gladys in 1929, in Ballarat. (They went on to have one son (Graham 1932, born in SA) and two daughters (Helen (died 12/07/1996) and Berenice (Berry), both born at Mira, Nhill ) According to Berry, her mother Gladys made a lot of their clothes. She was very talented and did some lovely embroidery including lingerie for her trousseau and beautifully handmade baby clothes. Dr Angus was a ‘flying doctor’ for the A.I.M. (Australian Inland Ministry) Aerial Medical Service in 1928 . Its first station was in the remote town of Oodnadatta, where Dr Angus was stationed. He was locum tenens there on North-South Railway at 21 Mile Camp. He took up this ‘flying doctor’ position in response to a call from Dr John Flynn; the organisation was later known as the Flying Doctor Service, then the Royal Flying Doctor Service. A lot of his work during this time involved dental surgery also. Between 1928-1932 he was surgeon at the Curramulka Hospital, Yorke Peninsula, South Australia. In 1933 Dr Angus returned to Nhill and purchased a share of the Nelson Street practice and Mira hospital (a 2 bed ward at the Nelson Street Practice) from Dr Les Middleton one of the Middleton Brothers, the current owners of what previously once Dr Tom Ryan’s practice. Dr Tom and his brother had worked as surgeons included eye surgery. Dr Tom Ryan performed many of his operations in the Mira private hospital on his premises. He had been House Surgeon at the Nhill Hospital 1902-1926. Dr Tom Ryan had one of the only two pieces of radiology equipment in Victoria during his practicing years – The Royal Melbourne Hospital had the other one. Over the years Dr Tom Ryan had gradually set up what was effectively a training school for country general-practitioner-surgeons. Each patient was carefully examined, including using the X-ray machine, and any surgery was discussed and planned with Dr Ryan’s assistants several days in advance. Dr Angus gained experience in using the X-ray machine there during his time as assistant to Dr Ryan. When Dr Angus bought into the Nelson Street premises in Nhill he was also appointed as the Nhill Hospital’s Honorary House Surgeon 1933-1938. His practitioner’s plate from his Nhill surgery is now mounted on the doorway to the Port Medical Office at Flagstaff Hill Maritime Village, Warrnambool. When Dr Angus took up practice in the Dr Edward and Dr Tom Ryan’s old premises he obtained their extensive collection of historical medical equipment and materials spanning 1884-1926. A large part of this collection is now on display at the Port Medical Office at Flagstaff Hill Maritime Village in Warrnambool. In 1939 Dr Angus and his family moved to Warrnambool where he purchased “Birchwood,” the 1852 home and medical practice of Dr John Hunter Henderson, at 214 Koroit Street. (This property was sold in1965 to the State Government and is now the site of the Warrnambool Police Station. and an ALDI sore is on the land that was once their tennis court). The Angus family was able to afford gardeners, cooks and maids; their home was a popular place for visiting dignitaries to stay whilst visiting Warrnambool. Dr Angus had his own silk worm farm at home in a Mulberry tree. His young daughter used his centrifuge for spinning the silk. Dr Angus was appointed on a part-time basis as Port Medical Officer (Health Officer) in Warrnambool and held this position until the 1940’s when the government no longer required the service of a Port Medical Officer in Warrnambool; he was thus Warrnambool’s last serving Port Medical Officer. (Masters of immigrant ships arriving in port reported incidents of diseases, illness and death and the Port Medical Officer made a decision on whether the ship required Quarantine and for how long, in this way preventing contagious illness from spreading from new immigrants to the residents already in the colony.) Dr Angus was a member of the Australian Medical Association, for 35 years and surgeon at the Warrnambool Base Hospital 1939-1942, He served with the Australian Department of Defence as a Surgeon Captain during WWII 1942-45, in Ballarat, Victoria, and in Bonegilla, N.S.W., completing his service just before the end of the war due to suffering from a heart attack. During his convalescence he carved an intricate and ‘most artistic’ chess set from the material that dentures were made from. He then studied ophthalmology at the Royal Melbourne Eye and Ear Hospital and created cosmetically superior artificial eyes by pioneering using the intrascleral cartilage. Angus received accolades from the Ophthalmological Society of Australasia for this work. He returned to Warrnambool to commence practice as an ophthalmologist, pioneering in artificial eye improvements. He was Honorary Consultant Ophthalmologist to Warrnambool Base Hospital for 31 years. He made monthly visits to Portland as a visiting surgeon, to perform eye surgery. He represented the Victorian South-West subdivision of the Australian Medical Association as its secretary between 1949 and 1956 and as chairman from 1956 to 1958. In 1968 Dr Angus was elected member of Spain’s Barraquer Institute of Barcelona after his research work in Intrasclearal cartilage grafting, becoming one of the few Australian ophthalmologists to receive this honour, and in the following year presented his final paper on Living Intrasclearal Cartilage Implants at the Inaugural Meeting of the Australian College of Ophthalmologists in Melbourne In his personal life Dr Angus was a Presbyterian and treated Sunday as a Sabbath, a day of rest. He would visit 3 or 4 country patients on a Sunday, taking his children along ‘for the ride’ and to visit with him. Sunday evenings he would play the pianola and sing Scottish songs to his family. One of Dr Angus’ patients was Margaret MacKenzie, author of a book on local shipwrecks that she’d seen as an eye witness from the late 1880’s in Peterborough, Victoria. In the early 1950’s Dr Angus, painted a picture of a shipwreck for the cover jacket of Margaret’s book, Shipwrecks and More Shipwrecks. She was blind in later life and her daughter wrote the actual book for her. Dr Angus and his wife Gladys were very involved in Warrnambool’s society with a strong interest in civic affairs. He had an interest in people and the community They were both involved in the creation of Flagstaff Hill, including the layout of the gardens. After his death (28th March 1970) his family requested his practitioner’s plate, medical instruments and some personal belongings be displayed in the Port Medical Office surgery at Flagstaff Hill Maritime Village, and be called the “W. R. Angus Collection”.The W.R. Angus Collection is significant for still being located at the site it is connected with, Doctor Angus being the last Port Medical Officer in Warrnambool. The collection of medical instruments and other equipment is culturally significant, being an historical example of medicine from late 19th to mid-20th century. Dr Angus assisted Dr Tom Ryan, a pioneer in the use of X-rays and in ocular surgery.Glass ear syringe. Has cork stopper at top and cotton wrapped at base of plunger. Has a curved end.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, otology, ears, ear syringe, deafness, ear wax -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, Late 19th or early 20th Century

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/ The bowl is an example of kitchenware used in the 19th century and still in use today.Bowl white ceramic. Crack on side. Badly stained.Backstamp very faint and unable to be read.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, mixing bowl, food preparation, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/ This bowl is an example of kitchenware used in the 19th century and still in use today.Bowl white ceramic plain that has two sets of edging around lip. Inside bowl has plaster designed to look like cooking mixture.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, J & G Meakin, Late 19th or early 20th Century