Showing 863 items

matching metal container

-

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyAsh Tray Pocket

This flip top pocket aluminium ash tray was at the beginning of the social "cleaning up" of cigarette ash and related products. This cigarette waste container was for those occasions when it was polite not to throw the cigarette ash and used up cigarettes "buts" on the ground, or if working in any rural area during a dry fire prone season, when discarding burning cigarette waste could set up a severe "bush" fire. It was also at the beginning of an intensive look at the affects of smoking upon the health of users. Later in the 1900s was a time when medical evidence supported a ground swell of the anti smoking movement which resulted in further restrictions of the use cigarette smoking in public places. Before the anti cigarette smoking revolution, it was both fashionable and manly to either roll your own cigarette or open up a packet of "tailor made's". In the rural and man's man environment the roll your own provided a visual acknowledgement that the user was "true blue" Aussie male and not a city boy. The cycle of use of cigarettes has drastically changed from when this item was first used. Today's society (post 2000) has produced a ground swell of government and non government organisations whose aim is provide a cigarette "ash" free environment and society. This is highlighted in the beginning of the 2000 millennium by a cigarette "Free" Australia campaign, and the pocket flip top personal ash tray as a practical solution for butt litter disposal.This light weight aluminium pocket ash tray not only was used when social graces required it to, but also provided a container for any unfinished cigarettes or stogies (cheap half used cigars). In rural areas (open fresh air countryside), where time was always made available for the "smoko" (Australian rest period), at any time, especially after some hard physical work, the ability to have a self contained ashing apparatus, not to offend the gentler folk, was a pre-requisite . The rural environment, in the days of these cigarette ash containers,was one which could range from harsh and unforgiving to mild and relaxing. Smoking could be enjoyed anywhere and at any time without too much "fussing" around. This ash tray was mobile, convenient, unobtrusive and regarded by the user as being considerate to those around. It also eliminated the tell tale evidence that the "no smoking" signs had been ignored. The Kiewa Valley was like many rural ares that found it hard for smokers to come to grips with a governmental "non smoking policy" to indoor recreational and other "confined space" environments. The covered lid reduces odors and eliminates ashes from being blown around.Aluminium round container with a lid. The opening lid is spring loaded, hinged top, circular and fixed by a clasp, pop- riveted (4) onto the main housing. Opposite the hinge the lid is held closed by a small metal ball fitting tightly to the top wall of the container. The lid is opened by the use of a fingernail positioned at junction of lid to body. This edge is bevelled to allow access.personal effects, tobacco waste products, smoking accessories, tobacco -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyTin Tobacco, early to mid 1900s

This early tobacco tin was manufactured in England and imported to the "colony" Australia at the beginning of the 1900s. This manufacturer had won the Gold Medal at the Liverpool International Exhibition in 1884. This tobacco would have therefore been very expensive to purchase making it a must for the wealthier client of the Kiewa Valley. The Golden Flake Cavendish smells of the man of wealth and position. In this era the type of dress and the brand of tobacco smoked showed everyone at first glance where the man using it was on the social ladder and his pecking order. With the demise of tobacco smoking in the early 2000s clothes themselves do not show the pecking order in that quickly visualised manner, as at the time of manufacture of this tobacco tin. In the 21st century the level that men are in the socio economic field is realized on "the social information" available on the internet.This tobacco tin relays a long ago era, when personal contact, and not something that has been written down by some "unknown", was valued as the true appraisal of a member of the community. This was especially relevant in a small regional area such as the Kiewa Valley. Although social networking was not as fast then as the internet provides now, appearances, manners, fashion and etiquette with first impressions high on the order of evaluating someone in the community. Pointer such as the brand of tobacco smoked was part of the rural assessment method. Up until the demise of the Australian Tobacco Industry, circa 2004, the Kiewa Valley and surrounding district was part of a vibrant producer of tobacco leaves. The remnants of this industry still remain today but the drying sheds (for tobacco leaves) are now used to store hay for the valley's dairy and beef cattle industries.A dark metal tobacco tin covered in a bright metallic gold fleck pattern with a black frame on the lid around a drawing of a woodsman with a musket and axe sitting on a stump overlooking a valley that reads "Pioneer Brand", next to a company seal incorporating a wreath, eagle and shield. The front side reads "Richmond Cavendish Co./ Limited/ Liverpool." and the right and left side "Golden Flake Cavendish". The bottom has the same woodsman feature as the lid. The back side is an elongated diagram featuring tobacco leaves and plant summit. Inside lid surface has a half torn coloured (red, black and green) sketch on paper of the woodsman scene depicted on the top lid.The following inscriptions are displayed on the top and inside lid and on the bottom tobacco tin: "PIONEER BRAND" and to the left of the scene the "SEAL OF THE COMPANY TRADE MARK" Both side of the ens have the following words in large thick print "GOLDEN FLAKE CAVENDISH" and each is contained withih a black boarder.pipe tobacco, cigarette tins, smoking accessories, personal effects, tobacco containers -

Orbost & District Historical Society

Orbost & District Historical Societyplant holder, Wilkinson, Dick

This item was made by Dick Wilkinson as a copy of simuilar article made during the Depression.Handmade ornamental metal pot plant holder made from painted milk tins. Curled metal decorations. Lined with milk tin.FRESH FROZEN PASTEURISED HOMOGENISED MILK. PRODUCT OF AUSTRALIA -inside DAIRY FARMERS CO-OPERATIVE LTD.container milk-tin plant-holder handcrafts -

Orbost & District Historical Society

Orbost & District Historical Societypurse

From the estate of Elsie Cooke who was the Orbost librarian for many years before 1940's. Elsie Cooke lived all her life in Gippsland,. She was born at Brodribb in 1895 and died in 1970, Elsie Cooke lived at Bruthen for a short time and, in 1937, moved to live with her aunt, Miss Jean Munro. Miss Cooke was Librarian at the Mechanics Institute for many years. Kindness and consideration for other were Miss Cooke’s attributes and she endeared herself to all who knew her. She was a loyal member of the Presbyterian Church and a stalwart of the Ladies’ Guild, an energetic worker for the Municipal Auxiliary and a member of the Red Cross. (ref. Mary Gilbert) Elsie Cooke was a well-respected Orbost identity. This item is an example of a fashionable accessory used by women in the first half of the 20th century.Small black velvet lady's change purse. Metal clasp and black holding string. Velvet has floral design. Purse has two coins inside - 1938 threepence (3d) and 1918 sixpence (6d) purse personal-effects money-containers -

Orbost & District Historical Society

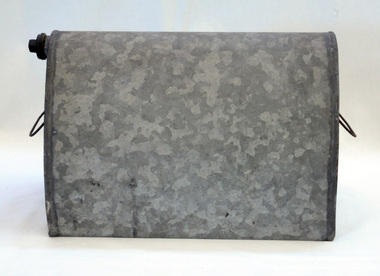

Orbost & District Historical Societyfoot warmer

This container could be filled with hot water and put on the floor of a train so that passengers could warm their feet by placing their feet near the container. A blanket could be put over the warmer to contain the heat. This foot warmer was used on trains. A galvanised iron container with a screwable stopper at the top and metal handles on both ends. foot-warmer metal-foot-warmer -

Orbost & District Historical Society

Orbost & District Historical Societyjug

... gippsland jug container domestic A cylindrical metal jug ...A cylindrical metal jug with a handle and metal lid. It contains seeds.jug container domestic -

Orbost & District Historical Society

Orbost & District Historical Societybottle

... gippsland bottle personal-effects travel container Large metal ...Large metal drinking bottle covered and laced up in leather. It was used by horsemen and has a long leather carrying strap. It has a cork stopper. The cover is handmade.bottle personal-effects travel container -

Orbost & District Historical Society

Orbost & District Historical Societycontainers, 1970s

These items were used or were available for sale by chemists in Orbost. Chemists who worked in Orbost included Henry Cottman; James Alfred Dubois Williams; Harry Arthur Murray; Miss P.E .Mason (Phyllis Estelle?); Miss Sybil Monica Buzza; Thomas James Frayer; Australia Shaw; James David Torley; John William Zimmer; Dalkeith William Steele; William Thomas Hollingsworth; E.E. Cohen; R.S. Anderson; Frances John Perry Faith Everard Pardew and Charles Anthony Wurf. The tin was designed and used by the Colonial Sugar Refining Co. to store and sell golden syrup which is a by-product of cane sugar, molasses and treacle. The practices of early pharmacists are revealed through these items. The items have a clear association with Orbost.3210.15 is a rusty tin of CSR Golden Syrup. It is a yellow, red, brown, white tin with a black lid. used to sell and store golden syrup. The kilogram tin has the words 'golden syrup' printed in large red letters. There is a recipe for ANZAC BISCUITS on the back of the tin. Inside two concentric circles - "FROM THE AUSTRALIAN CANEFIELDS NATURALLY GOLDEN" around a drawing of a sugar refinery. 3210.16 is a glass jar with a black metal lid. It contains small beakers, rubber tubing, stoppers and vials. on front in red print - "FROM THE AUSTRALIAN CANEFIELDS NATURALLY GOLDEN ; CSR GOLDEN SYRUP ; GUARANTEED PREMIUM QUALITY ; NET 1KG ; SEE BACK FOR DELICIOUS RECIPE"pharmacies-orbost zimmer-john tin-golden-syrup medical-equipment -

Orbost & District Historical Society

Orbost & District Historical Societyglue pot, early 20th century

This glue pot would have been used in woodwork projects. The glue used was probably an animal based glue.This item is an example of an accessory used by a trades person before the widespread availability of the modern liquid adhesivesA cast iron glue pot consisting of two separate pots - the larger of the two is designed to hold water and be hung over a fire. The smaller pot is placed inside so the glue can melt. each pot has a metal hanging / lifting hook / bail handle.glue-pot trades carpentry cast-iron container -

Orbost & District Historical Society

Orbost & District Historical Societypurse, first half 20th century

This item is an example of a fashionable accessory used by women in the first half of the 20th century.A coin purse made of light blue dyed sheepskin. It has a gold coloured metal frame and clasp and is a rectangular shape.coin-purse accessories-women's sheepskin purse personal-effects money-containers -

Orbost & District Historical Society

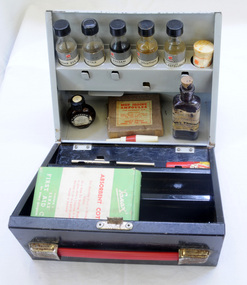

Orbost & District Historical Societyfirst aid kit, first half 20th century

This item was used at Orbost Hospital.This item reflects the changes and development in medicine over the last century.A first aid kit in a metal carry case. It contains bottles, containers a thermometer, cotton bandages and iodine ampoules.TRAFALGAR (in red) FIRST AID KIT ( in green) Inside a green circle is a white cross. medical health orbost-hospital trafalgar-first-aid -

Orbost & District Historical Society

Orbost & District Historical Societymetal butter churn, first half 20th century

Used domestically, though any extra butter could have been sold to neighbours. Many families kept a cow or two for milk etc. Cream needed to be at least 2 days old - the thicker the better. The handle was turned until the cream turned to butter,the whey was poured off and the butter washed in cold water until the water ran clear. Generally salt and bicarbonate of soda were added. Two pats were used to form butter into 1lb lots. This butter was most typically meant for consumption by the family, but in some instances it may be taken away for consignment by commercial receivers of dairy produce. This item is typical of the period when food processing was done at home. It would have been before the time of mass food processing factories.A metal butter churn with cast iron hand crank on side. The bowl container has a steel lid. It sits on a tripod stand.dairy butter-churn farming -

Cheese World Museum

Cheese World MuseumRetailing equipment, Hamilton Beach Mfg Co, Milkshake mixer

... container. An extendable metal column (to H44cm) with a side clip... mixing container. An extendable metal column (to H44cm ...The Percy Uebergang family lived at Tooram Park, Allansford from 1912 until 1992. Percy and Myrtle Uebergang's children were twins, Ray and Joyce born in 1926 who lived at Tooram Park until their deaths, Ray in 1986 and Joyce in 1992. Neither Ray nor Joyce married and following the death of her brother Joyce set up the Ray and Joyce Uebergang Foundation which supports the local community. This milkshake maker is part of the collection of items given into the care of the Cheese World Museum. Uebergang catalogue No.N42 A single beater electric commercial milkshake maker with black lead, mounted on a white 'artificial marble' base with four rubber stops; and straight-sided aluminium mixing container. An extendable metal column (to H44cm) with a side clip attached is used to hold the container. The electric motor is housed in a slotted round metal casing.Hamilton Beach Mfg Co. Builders, Racine, Wisc. Made in USA. Pats Pending. Volts 220-50c. No.4N14412Aallansford, hamilton beach manufacturing company, usa, milkshake maker, milk, retailing equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Cocoa Tin, First half of 20th Century

The history of metal packaging began in Bohemia in the 1200s. Metal has been produced for a very long time. But the first metal used for packaging was tin. In particular, it was the process of tin plating that was invented in Bohemia. Before this no other metal was economically able to be used for packaging. Later, in 1667 Andrew Yarranton, and English engineer, and Ambrose Crowley brought the method to England. Here it was improved by ironmasters including Philip Foley. Then by 1697, John Hanbury had a rolling mill at Pontypool in South Wales. The method they developed involved rolling iron plates using cylinders. This process enabled more uniform blank plates to be produced than was possible by just hammering the tin. https://www.shilohplastics.com.au/history-of-metal-packaging/The use of tin to protect and store food and other items, revolutionised the world.Tin base and external tin lid, with round internal lid .Colour printed. Used for cocoa. Caption of a woman drinking cocoa, red Australian flag and British flag on other faces. Top embossed "H". Marked - "Old Dutch Cocoa", "Net Weight 8 ozs," (Display side) "Manufactured by Hoadley's Chocolates Ltd, Australia.Top embossed "H". Marked - "Old Dutch Cocoa", "Net Weight 8 ozs," "Manufactured by Hoadley's Chocolates Ltd, Australia.warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, shipwrecked-artefact, tin, tin plating, food containers -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Glass Bottle, W T Rawleigh, 1920s

... , glass, narrow neck rectangular base with metal screw top ...W.T. Rawleigh's & Co. manufactured various household products in a factory in Collins Place, Melbourne, between 1930 and 1935. The W.T. Rawleigh Company was an American company started by William Rawleigh in 1889. The company expanded to both Canada and Australia with the Rawleigh company specialising in medicines, remedies, food additives, cleaning products and toiletries. Due to increased demand, Rawleigh’s required a larger factory and thus built the factory in Dawson Street Brunswick Victoria and by 1950 the factory had been extended to include 98,000 square feet of floor space. The Brunswick factory ceased production in the late 1970s and manufacturing was moved to New South Wales. During the peak of production, more than 200 people were employed in the Brunswick factory and several independent sale representatives sold their products door-to-door throughout the country. The ‘Rawleigh’s man’ was a regular door-to-door salesman of inter war and post-war suburban Melbourne. Rawleigh’s products are still in production today.A significant item as it gives a snapshot into domestic life and social norms of the pre and post war period in Melbourne and throughout Australia and New Zealand. The item demonstrates how selling house hold products door to door was pioneered in Australia by the Rawleigh’s company in the early 1900s and is still in existence today.Bottle, glass, narrow neck rectangular base with metal screw top.label of Rawleigh's Furniture Polishflagstaff hill, warrnambool, flagstaff hill maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, bottle, rawleigh's furniture polish, furniture polish, rawleigh's, cleaning -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Lead shot, Circa 1877

This artifact is a sample of small caliber lead shot recovered by Flagstaff Hill divers from the wreck of the Loch Ard in 1975. Included in her diverse and valuable cargo were 22 tons of lead shot, packed in cloth bags and wooden casks. Bulk quantities of lead shot, uniformly round balls of dull grey metal ranging from 2mm “birdshot” to 8mm “buckshot”, were routinely exported to the Australian colonies. Shot was used mostly as projectiles fired from smooth bored guns to bring down moving targets such as wild ducks and small game. It was also useful as ballast, when a dense, “pourable” weight was required to fill cavities or establish volume within a measuring container. The production of consistently round spheres of lead shot required the pouring of molten metal through a sieve and then a long drop through the atmosphere to a water filled basin for final cooling and collection. This “shot tower” process was first patented by William Watts of Bristol in 1782. His calculation of a 150 feet fall was not only to form evenly spherical droplets through surface tension, but also to provide partial cooling and solidification to each shot before they hit the water below. The value of his innovation was the minimising of indentation and shape distortion, avoiding the expense of re-smelting and re-moulding the lead. Lead shot was already being produced in Australia at the time the Loch Ard sinking in March 1878. James Moir had constructed a 157 feet circular stone shot tower near Hobart in 1870, with a peak annual production of 100 tons of lead shot sold in 28 pound linen bags. However colonial demand exceeded this source of local supply. The continued strength of the market for lead shot in the Colony of Victoria prompted substantial investment in additional productive capacity in Melbourne in the next decade. In 1882 Richard Hodgson erected the 160 feet round chimney-shaped Clifton Hill shot tower on Alexandra Parade (VHR H0709) and in 1889 Walter Coop built the 160 feet square tower-shaped Melbourne Central shot tower on La Trobe Street (VHR H0067). At its peak, the Coop Tower produced 6 tons of lead shot per week, or 312 tons per annum. History of the Loch Ard: The Loch Ard got its name from "Loch Ard" a loch that lies to the west of Aberfoyle, and the east of Loch Lomond. It means "high lake" in Scottish Gaelic. The vessel belonged to the famous Loch Line which sailed many vessels from England to Australia. The Loch Ard was built in Glasgow by Barclay, Curle & Co. in 1873, the vessel was a three-masted square-rigged iron sailing ship that measured 79.87 meters in length, 11.58 m in width, and 7 m in depth with a gross tonnage of 1693 tons with a mainmast that measured a massive 45.7 m in height. Loch Ard made three trips to Australia and one trip to Calcutta before its fateful voyage. Loch Ard left England on March 2, 1878, under the command of 29-year-old Captain Gibbs, who was newly married. The ship was bound for Melbourne with a crew of 37, plus 17 passengers. The general cargo reflected the affluence of Melbourne at the time. Onboard were straw hats, umbrellas, perfumes, clay pipes, pianos, clocks, confectionery, linen, and candles, as well as a heavier load of railway irons, cement, lead, and copper. There were other items included that were intended for display in the Melbourne International Exhibition of 1880. The voyage to Port Phillip was long but uneventful. Then at 3 am on June 1, 1878, Captain Gibbs was expecting to see land. But the Loch Ard was running into a fog which greatly reduced visibility. Captain Gibbs was becoming anxious as there was no sign of land or the Cape Otway lighthouse. At 4 am the fog lifted and a lookout aloft announced that he could see breakers. The sheer cliffs of Victoria's west coast came into view, and Captain Gibbs realised that the ship was much closer to them than expected. He ordered as much sail to be set as time would permit and then attempted to steer the vessel out to sea. On coming head-on into the wind, the ship lost momentum, the sails fell limp and Loch Ard's bow swung back towards land. Gibbs then ordered the anchors to be released in an attempt to hold their position. The anchors sank some 50 fathoms - but did not hold. By this time the ship was among the breakers and the tall cliffs of Mutton Bird Island rose behind. Just half a mile from the coast, the ship's bow was suddenly pulled around by the anchor. The captain tried to tack out to sea, but the ship struck a reef at the base of Mutton Bird Island, near Port Campbell. Waves subsequently broke over the ship and the top deck became loosened from the hull. The masts and rigging came crashing down knocking passengers and crew overboard. When a lifeboat was finally launched, it crashed into the side of Loch Ard and capsized. Tom Pearce, who had launched the boat, managed to cling to its overturned hull and shelter beneath it. He drifted out to sea and then on the flood tide came into what is now known as Lochard Gorge. He swam to shore, bruised and dazed, and found a cave in which to shelter. Some of the crew stayed below deck to shelter from the falling rigging but drowned when the ship slipped off the reef into deeper water. Eva Carmichael a passenger had raced onto the deck to find out what was happening only to be confronted by towering cliffs looming above the stricken ship. In all the chaos, Captain Gibbs grabbed Eva and said, "If you are saved Eva, let my dear wife know that I died like a sailor". That was the last Eva Carmichael saw of the captain. She was swept off the ship by a huge wave. Eva saw Tom Pearce on a small rocky beach and yelled to attract his attention. He dived in and swam to the exhausted woman and dragged her to shore. He took her to the cave and broke the open case of brandy that had washed up on the beach. He opened a bottle to revive the unconscious woman. A few hours later Tom scaled a cliff in search of help. He followed hoof prints and came by chance upon two men from nearby Glenample Station three and a half miles away. In a complete state of exhaustion, he told the men of the tragedy. Tom then returned to the gorge while the two men rode back to the station to get help. By the time they reached Loch Ard Gorge, it was cold and dark. The two shipwreck survivors were taken to Glenample Station to recover. Eva stayed at the station for six weeks before returning to Ireland by steamship. In Melbourne, Tom Pearce received a hero's welcome. He was presented with the first gold medal of the Royal Humane Society of Victoria and a £1000 cheque from the Victorian Government. Concerts were performed to honour the young man's bravery and to raise money for those who lost families in the disaster. Of the 54 crew members and passengers on board, only two survived: the apprentice, Tom Pearce, and the young woman passenger, Eva Carmichael, who lost her family in the tragedy. Ten days after the Lochard tragedy, salvage rights to the wreck were sold at auction for £2,120. Cargo valued at £3,000 was salvaged and placed on the beach, but most washed back into the sea when another storm developed. The wreck of Lochard still lies at the base of Mutton Bird Island. Much of the cargo has now been salvaged and some items were washed up into Lochard Gorge. Cargo and artifacts have also been illegally salvaged over many years before protective legislation was introduced in March 1982. One of the most unlikely pieces of cargo to have survived the shipwreck was a Minton majolica peacock- one of only nine in the world. The peacock was destined for the Melbourne 1880 International Exhibition. It had been well packed, which gave it adequate protection during the violent storm. Today the Minton peacock can be seen at the Flagstaff Hill Maritime Museum in Warrnambool. From Australia's most dramatic shipwreck it has now become Australia's most valuable shipwreck artifact and is one of very few 'objects' on the Victorian State Heritage Register.The shipwreck of the Loch Ard is of significance for Victoria and is registered on the Victorian Heritage Register ( S 417). Flagstaff Hill has a varied collection of artifacts from Loch Ard and its collection is significant for being one of the largest accumulation of artifacts from this notable Victorian shipwreck of which the subject items are a small part. The collection's objects give us a snapshot of how we can interpret the story of this tragic event. The collection is also archaeologically significant as it represents aspects of Victoria's shipping history that allows us to interpret Victoria's social and historical themes of the time. Through is associated with the worst and best-known shipwreck in Victoria's history.Lead shot; a group of mixed -sized lead shot. Small 2mm shot is embedded in a sea sediment clump of concretion. Also in the group are also 5 single 2mm shot and 4 single 4mm shot that are clean and free of sediment. The shot was recovered from the wreck of the Loch Ard.Nonewarrnambool, shipwreck coast, flagstaff hill, flagstaff hill maritime village, flagstaff hill maritime museum, shipwreck artefact, lead shot, loch ard, colonial industry, melbourne shot towers, victorian metallurgy, colonial imports -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Barrel, 19th century

This small barrel looks well used. Unfortunately, the inscription on the barrel is indecipherable so its story is a mystery. However, the bungholes on the side are a clue that it was once used for storing liquid, likely to have been liquor. Barrels have been used over many centuries for transporting and storing a wide range of dry and liquid goods. They are made by tradesmen called coopers, who use heat and steam to bend and shape the wood to suit the work in hand. They add metal reinforcing, handles, spouts and suchlike, to complete they process. Their produce also includes buckets, casks and tubs. Ships transported bulk liquor in their cargo, stored in wooden barrels. The barrels' round shape allowed them to be easily moved by rolling them into place. The body's shape gave the barrels added strength and the iron bands helped the wooden sheaves stay in place. The tops and bottoms allowed for easy grip. The bungholes gave access to government representatives, who would sample the contents, measure the alcohol percentage, and charge the appropriate duty or tax; the process was called Ullaging and the instrument they used was a Hydrometer. Hundreds of barrels of cement were imported into Warrnambool in the late 19th century for the construction of the Warrnambool Breakwater. Barrel-shaped concrete blocks are still visible at shipwreck sites such as on the LOCH ARD wreck, which carried cement among its cargo.This small barrel is representative of 19th century containers used for transportation and storage of liquid such as liquor. It is a historic shape that is still used in modern times.Barrel; wooden barrel, cylindrical shape with metal bands or ribs for reinforcement. The side has two bungholes; one has a bung or stopper. Inscription on top (indecipherable). (indecipherable)flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, barrel, cask, small barrel, trade, coopering, cooper, casket, transport, storage, bunghole -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Basket

... , and rope handle. Also has metal strap around lip. Container Basket ...Basket cane round woven with rope reinforcing around lip, under base, and rope handle. Also has metal strap around lip.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, basket, cane basket, storage, luggage, fisheries, equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Basket, 20th century

Strong large cane wicker baskets such as this one were used for storage and transportation. This basket could have been used for storing sails on a vessel, or sending luggage, parcels or goods by rail, ship, wagon or cart from one location to another. The basket would also be suitable for laundry in hospitals, factories such as woollen mills, and other organisations for storing and moving equipment and goods. The inscription " A A S" has not yet been researched. It could be the name of an Australian- Service, or a - - Ship or even the initials of a person. This basket is an example of a large, strong container used for storage or transportation during the 19th and 20th centuries.Basket, natural coloured woven cane or wicker, rectangular shape with lid. Two leather straps and buckles fasten the lid to the basket. The basket has a strong rope handle on each side, metal reinforcing straps that support three wood strengthening lengths on the top of the hinged lid. The lid is hinged to the basket at the back with metal hinges. The inside frame is reinforced with wood. There is a large inscription in black paint is stencilled onto the lid of the basket."A A S"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, basket, sail storage, maritime furniture, luggage, transport storage basket, wicker hamper, vintage wicker chest, wicker trunk, cane storage basket, dispatch basket, a a s -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Cruet Set, William Hutton & Sons, Circa 1900

William Hutton & Sons were manufacturing silversmiths founded in 1800 in Birmingham with company transferring to Sheffield in 1832. William Hutton had established the firm and with the move to Sheffield, they also became platers having licensed the electroplating technique from the firm of Elkington's. This gave them much early success in the field of electroplating. William's son William Carr Hutton continued the business after his father's death using the same business name until 1864 it was then changed to William Hutton & Son when William Carr's son Herbert Hutton joined him. When William Carr died in 1865, the firm name was again changed to William Hutton & Sons when Herbert's brothers (James & Robert) joined the company. They opened a London showroom in Holborn in 1863 which they moved to Farringdon Road, in 1891 operating until 1918. Hutton's had developed a new nickel alloy that was good for plating and in the late 1800s becoming known as British Plate. They sent their machine-made silver flatware from Sheffield to be hallmarked in London. Hutton's went on to acquire Rupert Favell & Co in 1893 and also registered as a limited company as William Hutton & Sons Ltd in 1902. The Hutton's had also bought Creswick & Co and had started to use their crossed arrows trademark. Hutton's became renowned for the quality of their Arts & Crafts silverware items at the turn of the 19th and 20th centuries. In 1930 Hutton's were taken over by James Dixon & Sons. A significant item that was made around the time electroplating was being developed as a means of producing quality utilitarian items in quantity for domestic use that we're able to be purchased by working-class people.Cruet set of silver plated frame with upright handle protruding from tray base. Holds 5 containers of varying shape and size; 3 have metal lids. Inscription is on the base. Some containers have contents in them.On base "WMH&S" and "01548" etc.flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, cruet set, condiments set, kitchen ware, electroplate, britannia metal, w m hutton -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Tin

Tin, rectangular metal box painted black with gold and brown stripes and a lock in front. Hinged lid with swinging handle; possibly cash tinflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, tin box, cash tin, money tin, storage -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Preserving Jar, 1932-1948

The Mason jar, named after American tinsmith John Landis Mason, who patented it in 1858, is a molded glass jar used in home canning to preserve food. The jar's mouth has a screw thread on its outer perimeter to accept a metal ring or "band". The band, when screwed down, presses a separate stamped steel disc-shaped lid against the jar's rim. An integral rubber ring on the underside of the lid creates a hermetic seal. The bands and lids usually come with new jars, but they are also sold separately. While the bands are reusable, the lids are intended for single-use when canning. Glass jars and metal lids are still commonly used in home canning while they have been largely supplanted by other methods for commercial canning (such as tin cans and plastic containers). Item at this time cannot be associated with an historical event, person or place, provenance is unknown, item assessed as a collection asset.Clear glass preserving jar with metal screw lid grooved base for lid clip."AGEE / MASON / JAR" imprinted into side of glassflagstaff hill, warrnambool, flagstaff hill maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, jar, glass jar, preserving jar, food preserving, food storage, agee mason, agee mason jar, john landis mason -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Tin, Leggett Products Pty Ltd, 1966

The can is an example of a mid-20th-century car accessory cleaning product, a part of the evolution of vehicles.Tin; metal tin once containing Leggett's Hood Dressing. The label is marked with the product details and price. 15 Fluid Ounce Can."Motor Product" "4/6" (4 shillings and six pence)flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, leggett's, can, tin, great ocean road, hood dressing, car bonnet, car cleaning -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Box

A ship's rudder indicator is used for measuring the angle of slope or pitch of the vessel. The information can be used to adjust the steering of the ship to give safe navigation. The rudder indicator transmitter once contained in this box was battery operated, according to the label inside this box. Box, wooden, used to store a battery operated Siemen's ship's rudder indicator. Made in the United Kingdom. Descriptive leaflet glued inside hinged lid. Lid secured by hooked catch. Brass latch. Metal mounting plate. Hole drilled in back. Dovetail joints. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, siemen's brothers london, siemen's rudder indicator box, nautical instrument for measuring pitch or slope, scientific instrument box, navigational instrument box -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Tin

Tin metal rectangular roasting tin with folded corners and a ring at one end and is slightly rusted.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Tin

Tin metal round cake tin with turned lip, join line at side and metal ring. One fits inside the other.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Wooden Rolling Pin, First half of 20th Century

A rolling pin is a simple tool used to flatten dough. The first civilisation known to have used the rolling pin was the Etruscans. Their advanced farming ability, along with a tendency to cultivate many plants and animals never before used as food and turn them into sophisticated recipes, were passed to invading Greeks, Romans, and Western Europeans. Thanks to the Etruscans, these cultures are associated with gourmet cooking. To prepare their inventive foods, the Etruscans also developed a wide range of cooking tools, including the rolling pin. Although written recipes did not exist until the fourth century B.C., the Etruscans documented their love of food and its preparation in murals, on vases, and on the walls of their tombs. Cooking wares are displayed with pride; rolling pins appear to have been used first to thin-roll pasta that was shaped with cutting wheels. They also used rolling pins to make bread (which they called puls) from the large number of grains they grew. Natives of the Americas used more primitive bread-making tools that are favoured and unchanged in many villages. Chefs who try to use genuine methods to preserve recipes are also interested in both materials and tools. Hands are used as "rolling pins" for flattening dough against a surface, but also for tossing soft dough between the cook's two hands until it enlarges and thins by handling and gravity. Tortillas are probably the most familiar bread made this way. Over the centuries, rolling pins have been made of many different materials, including long cylinders of baked clay, smooth branches with the bark removed, and glass bottles. As the development of breads and pastries spread from Southern to Western and Northern Europe, wood from local forests was cut and finished for use as rolling pins. The French perfected the solid hardwood pin with tapered ends to roll pastry that is thick in the middle; its weight makes rolling easier. The French also use marble rolling pins for buttery dough worked on a marble slab. Glass is still popular; in Italy, full wine bottles that have been chilled make ideal rolling pins because they are heavy and cool the dough. Countries known for their ceramics make porcelain rolling pins with beautiful decorations painted on the rolling surface; their hollow centres can be filled with cold water (the same principle as the wine bottle), and cork or plastic stoppers cap the ends. Designs for most rolling pins follow long-established practices, although some unusual styles and materials are made and used. Within the family of wooden rolling pins, long and short versions are made as well as those that are solid cylinders (one-piece rolling pins) instead of the familiar style with handles. Very short pins called mini rolling pins make use of short lengths of wood and are useful for one-handed rolling and popular with children and collectors. Mini pins ranging from 5 to 7 in (12.7-17.8 cm) in length are called texturing tools and are produced to create steam holes and decorations in pastry and pie crusts; crafters also use them to imprint clay for art projects. These mini pins are made of hardwoods (usually maple) or plastic. Wood handles are supplied for both wood and plastic tools, however. Blown glass rolling pins are made with straight walls and are solid or hollow. Ceramic rolling pins are also produced in hollow form, and glass and ceramic models can be filled with water and plugged with stoppers. Tapered glass rolling pins with stoppers were made for many centuries when salt imports and exports were prohibited or heavily taxed. The rolling pin containers disguised the true contents. The straight-sided cylinder is a more recent development, although tapered glass pins are still common craft projects made by cutting two wine bottles in half and sealing the two ends together so that the necks serve as handles at each end.Tiny rolling pins are also twisted into shape using formed wire. The pins will not flatten and smooth pastry, and the handles do not turn. The metal pins are popular as kitchen decorations and also to hang pots, pans, and potholders. https://www.encyclopedia.com/sports-and-everyday-life/food-and-drink/food-and-cooking/rolling-pinThe use of the rolling pin to make thin pastry or pasta.Wooden rolling pin with some damage on cylinder section.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, rolling pin, cooking, pastry -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, Late 19th century or early 20th century

Glass manufacturing has evolved over thousands of years. Glass making has been traced back to 3500 BC in Mesopotamia. The earliest known glass objects were beads, perhaps made by accident while working with metal. In the late Bronze Age, several civilizations discovered how to make vessels and glass bottles by wrapping threads of melted glass around cores of sand or clay. Later, moulds were used to form dishes and table wares. Around the 1st century BC, glassblowing was discovered. This made glass containers less expensive than pottery. Mould-blown glass, the process of blowing a piece of molten glass into a wooden or metal mould, was invented during the 1st century AD. This technique was faster with more consistent results. It paved the way for mass production. It wasn’t until the late 1800s that the production process to become more efficient. In 1887, a company in England created a semi-automatic process that could produce up to 200 bottles an hour. This process has been refined to the point where modern machines can yield more than 600 containers per minute. Blown vs. Manufactured Glass Bottles Nowadays, glass bottles, jars, and cups are usually manufactured on a bigger scale than is found in individual glassblowing studios. If we still depended on hand-blown glass for all of our glass containers, we would see some major differences in the process of creating bottles and jars. First, there's the time. Hand blowing glass takes a significant amount of time, even for one simple container. In contrast, hundreds of jars per minute can be made using modern technology. This leads to the second advantage: price. Because of the automated and streamlined process, the price for manufactured containers is much lower than that of hand-blown glass. Third, manufactured bottles will be much more consistently uniform than bottles blown by hand. Automated glass manufacturing produces nearly identical batches of jars. Glass blowing is awesome for unique, beautiful pieces of art. But for lots of lower priced and uniformly shaped containers, automatic manufacturing is the preferred method to create glass bottles and jars. https://www.containerandpackaging.com/resources/glass-bottles-brief-history The invention and development of glass for domestic items including bottles, has been nothing short of revolutionary. The use of glass bottles, that could be easily washed, led to improved hygiene, and mass manufacturing of drinks of all types, including milk, cordial and alcoholic beverages.Green Glass Bottle Possibly a ginger beer bottle.Concave indentation at the base. Also on base are two raised lumps. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, glass -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Can Opener, Bottle Opener & Corkscrew

It took 15 years to invent the can. It took 100 more to invent a standard way to open it. In the 19th century, decades after the invention of canning, there were virtually no can openers. Canned food, such as sardines, came with its own "key" to peel back the tin lid. Birth of the can One of the oddest things about the can opener is that the can predates it by almost 150 years. Though common today, cans were once military-grade technology. In 1795, Napoleon, to whom the phrase "an army marches on its stomach" is attributed, offered 12,000 francs to anyone who could find a way to preserve food. Without any knowledge of bacteria or their role in food spoilage, scientists didn't even know where to begin. It took 15 years before a chef named Nicholas Appert claimed the prize after successfully jarring food. Soon after that, his countryman Philippe de Girard came up with a variant on Appert's method—metal tins—and sold the idea to the British. Spoiled food, and the sickness it caused, was a widespread problem. The public would have benefited from canned food, but for decades cans were almost exclusively for the army and the navy. The canning process, with its hours of boiling and steaming, its scrupulous cleanliness, its heated metal, and its need for a great deal of disposable material, made canned food far too expensive for anyone but the military. No can openers were needed or even possible. The metal of early cans was too thick to make openers practical. Soldiers and sailors had plenty of sharp objects on hand and made ample use of them when they wanted to eat. During the 19th century, the process of canning was refined and mechanised, and the metal wall of the average can slimmed down enough that a civilian could get it open—if that civilian had the right tool. No one had that tool yet, so early cans had to open themselves. In other words, they came with built-in openers. The result was a confusing but pleasing free-for-all, in terms of product engineering. Each type of food came with its own kind of can, and each kind of can came with its own kind of opener. Tinned fish and meat were often sold in rectangular cans. These cans were fitted with a "key" that would roll down the top of the can. Coffee, beans, and other types of meat were packaged in cylinders with metal strips that could be peeled back with their own kinds of built-in keys. Cans of milk, which didn't need to be completely opened, came with puncture devices. As tinned food became more common, its containers became more regular. A nice cylindrical can became the norm, and, as these cans filled kitchens, more engineers put their minds to finding a convenient way to open all of them. The first standalone can opener worked on a simple principle: point, stab, and pull. From the mid-19th century to the end of World War I, the typical can opener looked roughly like a wrench, if the lower 'jaw' of the wrench were replaced with a blade. People used the blade to puncture the top of the can near its edge, push the upper jaw against the side of the can, and drag the blade through the metal along the rim. Because meat was the first and most popular canned substance, these can openers were often shaped to look like cows and given the nickname 'bully beef can openers'. The bully beef can opener, popular in the mid-19th century, resulted in many lost fingers. Later, a corkscrew was added that was seated in the handle, and could be pulled out for use. Bully beef can openers were so common, effective, and sturdy that they are still frequently available on collectors' sites. Some are advertised as “still working,” and every last one of them is, without a doubt, soaked in the blood of our ancestors. Dragging a sharp blade along the edge of a can is certain to cause injury sooner or later. So once people got a reliable can shape and a reliable way to get the can open, the search was on for a reliable way to get a can open without the possibility of losing a finger. The answer came in 1925, from the Star Can Opener Company of San Francisco. This is probably the first can opener that resembles the one people have in their kitchens today. Instead of using a blade to pry open a metal can, buyers could clamp the edge of the can between two wheels and twist the handle of one of the wheels to move the blade around the lip. The Star can openers weren't perfect. Compared to the bully beef model, they were flimsy and breakable, but they probably prevented a few injuries. Six short years after the Star model came to market, the first electric can opener was invented. It was patented in 1931 by the Bunker Clancey Company of Kansas City, who had already been sued by the Star Can Opener Company for trying sell a double-wheeled can opener like the Star model (the case was dismissed). The electric can opener must have seemed like the wave of the future and a sure-fire seller, but it proved to be too far ahead of its time. In 1931 not that many households had electricity, and those that did weren't interested in buying can openers. The Bunker Clancey Company was subsequently bought by the Rival Company, which still makes small appliances like can openers today. It took another 25 years for electrically powered can openers to become practical. In the 1950s, Walter Hess Bodle and his daughter, Elizabeth Bodle, developed an electric can opener in the family garage. Walter came up with the opener's blades and motor, and Elizabeth sculpted the outside. Their can opener was a free-standing unit that could sit on the kitchen counter. The Udico brand of the Union Die Casting Company put it on the market in time for Christmas in 1956 and had great success with it. Over the next few years it came out in different styles and colours, and, like the bully beef can opener, has become a collector's item. Also like the bully beef model, Udico can openers often still work. They don't make 'em like they used to. Although there have been some design changes and refinements over the last sixty years, there have yet to be any more leaps forward in can opener technology. If you're resentfully opening a can, you are almost certainly doing it using the Star design, manually forcing the can between two wheels, or the Bodle design, clamping the can into a free-standing electrical opener. Whether or not you enjoy your holiday meals, at least you can be happy that you are not getting poisoned by your own food or cutting open your hand with the blade you use to get at it. That's something, right?The can opener, Bottle opener and the corkscrew are still very important and essential items in most kitchens.Metal can opener, chromed, with bottle opener, and a corkscrew seated in the handle.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, canning, can opener, corkscrew, bottle opener, kitchen equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Can Opener

It took 15 years to invent the can. It took 100 more to invent a standard way to open it. In the 19th century, decades after the invention of canning, there were virtually no can openers. Canned food, such as sardines, came with its own "key" to peel back the tin lid. Birth of the can One of the oddest things about the can opener is that the can predates it by almost 150 years. Though common today, cans were once military-grade technology. In 1795, Napoleon, to whom the phrase "an army marches on its stomach" is attributed, offered 12,000 francs to anyone who could find a way to preserve food. Without any knowledge of bacteria or their role in food spoilage, scientists didn't even know where to begin. It took 15 years before a chef named Nicholas Appert claimed the prize after successfully jarring food. Soon after that, his countryman Philippe de Girard came up with a variant on Appert's method—metal tins—and sold the idea to the British. Spoiled food, and the sickness it caused, was a widespread problem. The public would have benefited from canned food, but for decades cans were almost exclusively for the army and the navy. The canning process, with its hours of boiling and steaming, its scrupulous cleanliness, its heated metal, and its need for a great deal of disposable material, made canned food far too expensive for anyone but the military. No can openers were needed or even possible. The metal of early cans was too thick to make openers practical. Soldiers and sailors had plenty of sharp objects on hand and made ample use of them when they wanted to eat. During the 19th century, the process of canning was refined and mechanised, and the metal wall of the average can slimmed down enough that a civilian could get it open—if that civilian had the right tool. No one had that tool yet, so early cans had to open themselves. In other words, they came with built-in openers. The result was a confusing but pleasing free-for-all, in terms of product engineering. Each type of food came with its own kind of can, and each kind of can came with its own kind of opener. Tinned fish and meat were often sold in rectangular cans. These cans were fitted with a "key" that would roll down the top of the can. Coffee, beans, and other types of meat were packaged in cylinders with metal strips that could be peeled back with their own kinds of built-in keys. Cans of milk, which didn't need to be completely opened, came with puncture devices. As tinned food became more common, its containers became more regular. A nice cylindrical can became the norm, and, as these cans filled kitchens, more engineers put their minds to finding a convenient way to open all of them. The first standalone can opener worked on a simple principle: point, stab, and pull. From the mid-19th century to the end of World War I, the typical can opener looked roughly like a wrench, if the lower 'jaw' of the wrench were replaced with a blade. People used the blade to puncture the top of the can near its edge, push the upper jaw against the side of the can, and drag the blade through the metal along the rim. Because meat was the first and most popular canned substance, these can openers were often shaped to look like cows and given the nickname 'bully beef can openers'. The bully beef can opener, popular in the mid-19th century, resulted in many lost fingers. Bully beef can openers were so common, effective, and sturdy that they are still frequently available on collectors' sites. Some are advertised as “still working,” and every last one of them is, without a doubt, soaked in the blood of our ancestors. Dragging a sharp blade along the edge of a can is certain to cause injury sooner or later. So once people got a reliable can shape and a reliable way to get the can open, the search was on for a reliable way to get a can open without the possibility of losing a finger. The answer came in 1925, from the Star Can Opener Company of San Francisco. This is probably the first can opener that resembles the one people have in their kitchens today. Instead of using a blade to pry open a metal can, buyers could clamp the edge of the can between two wheels and twist the handle of one of the wheels to move the blade around the lip. The Star can openers weren't perfect. Compared to the bully beef model, they were flimsy and breakable, but they probably prevented a few injuries. Six short years after the Star model came to market, the first electric can opener was invented. It was patented in 1931 by the Bunker Clancey Company of Kansas City, who had already been sued by the Star Can Opener Company for trying sell a double-wheeled can opener like the Star model (the case was dismissed). The electric can opener must have seemed like the wave of the future and a sure-fire seller, but it proved to be too far ahead of its time. In 1931 not that many households had electricity, and those that did weren't interested in buying can openers. The Bunker Clancey Company was subsequently bought by the Rival Company, which still makes small appliances like can openers today. It took another 25 years for electrically powered can openers to become practical. In the 1950s, Walter Hess Bodle and his daughter, Elizabeth Bodle, developed an electric can opener in the family garage. Walter came up with the opener's blades and motor, and Elizabeth sculpted the outside. Their can opener was a free-standing unit that could sit on the kitchen counter. The Udico brand of the Union Die Casting Company put it on the market in time for Christmas in 1956 and had great success with it. Over the next few years it came out in different styles and colours, and, like the bully beef can opener, has become a collector's item. Also like the bully beef model, Udico can openers often still work. They don't make 'em like they used to. Although there have been some design changes and refinements over the last sixty years, there have yet to be any more leaps forward in can opener technology. If you're resentfully opening a can, you are almost certainly doing it using the Star design, manually forcing the can between two wheels, or the Bodle design, clamping the can into a free-standing electrical opener. Whether or not you enjoy your holiday meals, at least you can be happy that you are not getting poisoned by your own food or cutting open your hand with the blade you use to get at it. That's something, right?The can opener is still a very important and essential item in most kitchens.Can opener, right handed, metal, upper blade section serrated, inscription 'Peerless Pat.Feb 11-90'.Peerless Pat.Feb 11-90flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, cannning, can opener, kitchen equipment