Showing 518 items

matching marker

-

Bendigo Military Museum

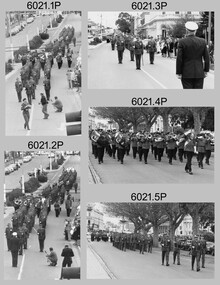

Bendigo Military MuseumPhotograph - Army Survey Regiment Freedom of Entry Parade, 1980

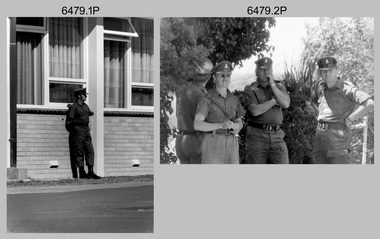

The Freedom of Entry to the City was an honour conferred by the Bendigo City Council to the Army Survey Regiment in 1970. 1980 was the third time the unit exercised its freedom of marching into the city with swords drawn, bayonets fixed and drums beating. The honour is usually bestowed upon local regiments, in recognition of their dedicated service, and it is common for military units to periodically exercise their freedom by arranging a parade through the city. Led by the Regiment’s CO – LTCOL Bob Skitch, the unit marched down View St in the CBD, along Pall Mall and up Gaol Rd to the Queen Elizabeth II Oval. The ceremonial parade followed with a march past the guests of honour, Mayor of Bendigo Councillor Paul Tomkinson and military dignitaries. The parade concluded after formal inspections of the troops. The Regiment also exercised its Freedom of Entry with anniversary parades in 1977, 1980, 1985, 1990 and 1995.These black and white photographs of the Army Survey Regiment were taken on the occasion of the Freedom of Entry parade to the City of Bendigo in 1980. The photographs were printed on photographic paper and are part of the Army Survey Regiment’s Collection. The photographs were scanned at 300 dpi. .1) Photo, black & white, L to R: MAJ Don Swiney, LTCOL Bob Skitch, WO1 Aub Harvey, unidentified, photographer in foreground – SGT Garran Hill .2) Photo, colour, black & white, L to R: MAJ Don Swiney, LTCOL Bob Skitch, WO1 Aub Harvey, unidentified .3) Photo, black & white, L to R: MAJ Don Swiney, WO1 Aub Harvey, LTCOL Bob Skitch, unidentified .4) Photo, black & white: 3rd MD Band .5) Photo, colour, L to R: MAJ Don Swiney, WO1 Aub Harvey, LTCOL Bob Skitch, unidentified .6) Photo, black & white, L to R: MAJ Don Swiney, WO1 Aub Harvey, unidentified, LTCOL Bob Skitch .7) Photo, black & white, L to R: SGT Stu Thaxter, LT Neil Taylor, CAPT Bob Roche .8) Photo, black & white, L to R: SPR Per Andersen – right marker .9) Photo, black & white, L to R: MAJ Peter Eddy .10) Photo, black & white, L to R: CPL Frank Lenane, CPL Flash Anderson, SGT Rhys De Laine, SPR Per Andersen .11) Photo, black & white, L to R: Mayor Paul Tomkinson .12) Photo, black & white, L to R: MAJ Don Swiney, WO1 Aub Harvey, unidentified, LTCOL Bob Skitch .13) Photo, black & white, L to R: unidentified personnel .14) Photo, black & white, L to R: unidentified personnel .15) Photo, black & white, L to R: unidentified personnel .16) Photo, black & white, L to R: unidentified personnel .18) Photo, black & white, L to R: CAPT Paddy Strunks, Mayor Paul Tomkinson, LTCOL Bob Skitch .19) Photo, black & white, L to R: Mayor Paul Tomkinson, CPL Bill Jones, CPL Gary Drummond, WO2 Tom Pattison .20) Photo, black & white, L to R: CAPT Paddy Strunks, WO1 Aub Harvey, Mayor Paul Tomkinson, SGT Rick Warren, CPL Andy Wilson …, WO2 Ted Burgess .21) Photo, black & white, L to R: LTCOL Bob Skitch, SPR Roy Hicks, Trevor Osborne, SPR Paul Baker, CAPT Stan Vote, CPL Bill Jones, Greg Francis-Wright .22) Photo, black & white, Air Survey Squadron inspection. Rear rank: SSGT Russell ‘Rusty’ Williams. Centre rank L to R: CPL Peter Treble, SGT Jim Beard, SPR Peter Hardy, SPR Steve Hilton, SPR John Lane, CPL Mick Hogan, Mayor – Councillor Paul Tomkinson. .23) Photo, black & white, L to R: Mayor Paul Tomkinson, CPL Marrianne (Van De Zee) De Groot, SPR Cathy Regan, SPR Ginny Turner, SPR Ilen Isaac, SPR Penny Knott, SPR Santina Argetto, SPR Gina Coore .24) Photo, black & white, L to R: Mayor Paul Tomkinson, SPR Cathy Regan, SPR Ginny Turner, SPR Ilen Isaac, SPR Penny Knott, SPR Santina Argetto, SPR Gina Coore, WO2 Pat Lumsden .25) Photo, black & white, L to R: LTCOL Bob Skitch, Mayor Paul Tomkinson, SPR Ilen Isaac, SPR Penny Knott, SPR Santina Argetto, SPR Gina Coore, WO2 Pat Lumsdenroyal australian survey corps, rasvy, fortuna, army survey regiment, army svy regt, asr -

Bendigo Military Museum

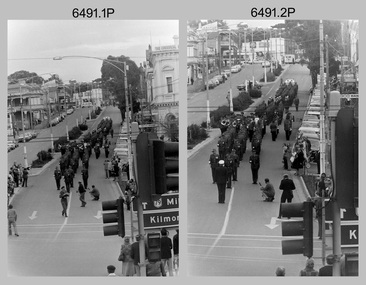

Bendigo Military MuseumPhotograph - Army Survey Regiment Freedom of Entry March, Bendigo CBD, 1980

The Freedom of Entry to the City was an honour conferred by the Bendigo City Council to the Army Survey Regiment in 1970. 1980 was the third time the unit exercised its freedom of marching into the city with swords drawn, bayonets fixed and drums beating. The honour is usually bestowed upon local regiments, in recognition of their dedicated service, and it is common for military units to periodically exercise their freedom by arranging a parade through the city. Led by the Regiment’s CO – LTCOL Bob Skitch, the unit marched down View St in the CBD, along Pall Mall and up Gaol Rd to the Queen Elizabeth II Oval. The ceremonial parade followed with a march past the guests of honour, Mayor of Bendigo Councillor Paul Tomkinson and military dignitaries. The parade concluded after formal inspections of the troops. The Regiment also exercised its Freedom of Entry with anniversary parades in 1977, 1980, 1985, 1990 and 1995. Some photos in this set were also printed on photo paper and catalogued under item 6021.25P. Photos of the parade are catalogued under item 6490.53P. Photos of the Freedom of Entry parade rehearsal are catalogued under item 6479.38P.This set of 19 black and white photographs of the Army Survey Regiment were taken on the occasion of the Freedom of Entry to the City of Bendigo March in 1980. The photographs are on 35mm negative film and scanned at 96 dpi. They are part of the Army Survey Regiment’s Collection. .1) - Photo, black & white, 1980. L to R: MAJ Don Swiney MBE, LTCOL Bob Skitch, WO1 Aub Harvey, ADJT CAPT John Harrison, photographer in foreground – SGT Garran Hill .2) to .4) - Photo, black & white, 1980. L to R: MAJ Don Swiney MBE, LTCOL Bob Skitch, WO1 Aub Harvey, ADJT CAPT John Harrison. .5) - Photo, black & white, 1980. Headquarters Squadron marches left wheels into Pall Mall followed by 3rd MD Band. L to R: WO2 Ted Burgess, WO1 Dave Thomson, WO2 George Graham, CPL Andy Wilson, unidentified (x2), SPR Jeff Ruiz, unidentified, SGT Rick Warren, remainder unidentified. .6) - Photo, black & white, 1980. Headquarters Squadron marches down Pall Mall followed by 3rd MD Band. Right file L to R: WO1 Alex Cairney, WO2 Ted Burgess, CPL Andy Wilson, unidentified, SGT Rick Warren, remainder unidentified. Centre file L to R: unidentified (x2), SGT Bruce Hammond, CPL Phil McGuire. .7) - Photo, black & white, 1980. 3rd MD Band marches down Pall Mall. .8) - Photo, black & white, 1980. Dignitaries on dais next to Soldiers Institute Memorial Hall. L to R: Colonel Commandant COL J.L. Stedman (Retd), Commander 3MD BRIG Geoffrey Cohen AM, unidentified aide de camp, Brigadier Lawrence Fitzgerald OBE (Retd), Mayor – Councillor Paul Tomkinson, CAPT Don Maskew. .9) - Photo, black & white, 1980. Lithographic Squadron marches down Pall Mall towards the dais. L to R: CPL Josh Degroot, CPL Rhys De Laine, unidentified, SPR Per Andersen – right marker, MAJ Sam Schwartz US Exchange, CAPT Stan Vote, OC MAJ Robin Blackburn. .10) - Photo, black & white, 1980. Headquarters Squadron salutes on the march past the dais. L to R: CPL Cliff Webb, unidentified officer, SGT Bob Croxton, unidentified, SGT Syd Davis, CAPT Bob Cooper. .11) - Photo, black & white, 1980. 3rd MD Band marches down Pall Mall towards the dais. .12) - Photo, black & white, 1980. 3rd MD Band marches past the dais. L to R: Colonel Commandant COL J.L. Stedman (Retd), Commander 3MD BRIG Geoffrey Cohen AM, unidentified aide de camp, Brigadier Lawrence Fitzgerald OBE (Retd), Mayor – Councillor Paul Tomkinson, CAPT Don Maskew, unidentified officer. .13) - Photo, black & white, 1980. 3rd MD Band salutes on the march past the dais. L to R: unidentified aide de camp, Colonel Commandant COL J.L. Stedman (Retd), Commander 3MD BRIG Geoffrey Cohen AM, CAPT Don Maskew, Brigadier Lawrence Fitzgerald OBE (Retd), Mayor – Councillor Paul Tomkinson, unidentified officer. .14) - Photo, black & white, 1980. 3rd MD Band salutes on the march past the dais. L to R: Colonel Commandant COL J.L. Stedman (Retd), Commander 3MD BRIG Geoffrey Cohen AM, Mayor – Councillor Paul Tomkinson, CAPT Don Maskew. .15) - Photo, black & white, 1980. Squadrons march past the dais. .16) - Photo, black & white, 1980. Female Contingent salutes on the march past the dais. L to R: Colonel Commandant COL J.L. Stedman (Retd), Commander 3MD BRIG Geoffrey Cohen AM, CAPT Don Maskew, Brigadier Lawrence Fitzgerald OBE (Retd), Mayor – Councillor Paul Tomkinson. .17) - Photo, black & white, 1980. Cartographic Squadron led by CAPT Bob Roche salutes on the march past the dais. L to R: Colonel Commandant COL J.L. Stedman (Retd), Commander 3MD BRIG Geoffrey Cohen AM, CAPT Don Maskew, Brigadier Lawrence Fitzgerald OBE (Retd), Mayor – Councillor Paul Tomkinson. .18) & .19) - Photo, black & white, 1980. Air Survey Squadron salutes on the march past the dais. L to R: Colonel Commandant COL J.L. Stedman (Retd), Commander 3MD BRIG Geoffrey Cohen AM, CAPT Don Maskew, Brigadier Lawrence Fitzgerald OBE (Retd), Mayor – Councillor Paul Tomkinson.There are no personnel identified. royal australian survey corps, rasvy, army survey regiment, army svy regt, fortuna, asr -

Ballarat Tramway Museum

Ballarat Tramway MuseumAlbum - Photo Album, Newstar, 1960s to 1970's

Photographic album containing 39 Colour postcards of Melbourne trams. The album consists of 30 leaves of dark grey heavy paper with three creases on left hand side of sheet, bound into a heavy bluey grey folder, embossed in gold 'Scrap Book" and bound with bluey grey string with two holes. The cover has been embossed with a the blue grey in swirls. Inside of back cover is a white label, "A New Star Product", with a please ask for No. with "425" stamped on. Postcards have been glued into the album. Entries have been kept to a single line - cards are able to be dated from buildings, whether the trams have marker lights, types of motor cars and general Melbourne history. Image files in page number order. Image 15 is of book. All taken with a electronic camera. Page 1 - Night photo - Flinders and Swanston St. - with "Greetings from Huntingdale" embossed in gold. Flinders St. station, with "Greetings from Huntingdale" embossed in gold. (post 1972 ) St. Kilda road with the Shrine of Remembrance in the background and W2 453 inbound on route 6. (post 1974) Page 2 - Bourke St, looking from Parliament House westwards, with Z8 inbound - after 13/8/1975 on route 89. Bourke St, looking east from Queen St., night photo, early 1970's. Princes Bridge looking towards Flinders St. Station Page 3 - Flinders St. Station, from Princes Gate buildings, - Photo E. Ludwig, John Hinde Studios. Bourke St. from Queen St, looking east, late 1960's - all W's. - W7 1026 east bound on route 88. Flinders St and Swanston St. corner, from Princes Bridge - night photo - W5 756 northbound route 15. Page 4 - W2 584 inbound route 64, St. Kilda Road and Nolan St., late 1960s - photograph. Princes Bridge, looking over Yarra River to the east. (pre Concert Hall) St. Kilda Road, with Shine of Remembrance in background, W2 303 inbound route 4D, mid 1960's. Page 5 - Flinders and Swanston St, W2 530 outbound route 8, early 1970's. Swanston and Collins St., W2 596 westbound in Collins St. City Square built - 1st version. (post 1972) St Kilda Road, with Shine in background, W2 298 and others, route 8 and 72. (post 1972) Page 6 - Flinders and Swanston St., W2, inbound route 5 on a wet evening. (mid 1970's) W2 515 outbound, Collins St., late 1960's, with Town Hall in background. (early 1970's, prior to lights) Collins St. looking west at Russell St with W2 637outbound route 42, early 1960's. Page 7 - Swanston St looking south at Little Bourke, W2's 373 route 67 and 374?(route 5), southbound, early 1970's Flinders St. Station, looking west in Flinders St., early 1970's, at dusk. Melbourne Town Hall with City Square from the North West (early 1970's) Page 8 - Bourke St looking east from Queen St. with W7 1005 inbound on route 96 - early 1970's. Bourke St. looking west from Exhibition St. with W6 976 outbound on route 95 - early 1970's. Swanston St. looking south from Lonsdale, with W2 484 on route 64, W2 228 and W2 364 in photo - early 1970's. Page 9 - Swanston looking south from north of Lonsdale St with many tramcars in photo - mid 1970's. St Kilda Road, with Shrine in background, W2 345 outbound route 4, SW6 913 inbound route 4 - prior to 1970. St Kilda Road, with Shrine in background, with trams in photo - early 1970's. (Photo loose in album - National View postcard by Murfett Ltd. Aust.) Page 10 - Postcard - TMSV? of 1041 and cable car set at Preston Workshops. 1041 in Bourke St., looking east from Queen St. - early 1970's - 1974? Collins St. looking east from Elizabeth St. with W2 253 inbound route 11, and W2 224 outbound - rout 47, early 1970's Page 11 - TMSV Postcard, X217 in Dandenong Road with L class in background. Shrine of Remberance from BP building, looking towards the city with St. Kilda Road on the left. Princes Gate and Flinders St. from the SEC buildings in Flinders St. looking south east - mid 1960's. Page 12 - Swanston St. at Flinders St. looking north at dusk. Flinders St. station at Swanston St with trams crossing at intersection - late 1960's Flinders St. station with W2 327 outbound. Page 13 - Temporary City Square at Collins and Swanston St. with tramcars at intersection. Wellington Parade (Mugs Alley), looking towards the City, with W2 546 inbound on route 38 - mid to late 1960's. Page 14 - Swanston St. looking south, at Lonsdale St, W2 432 inbound route 7 - late 1960's or early 1970's. Partly loose in album - National View postcard by Murfett Ltd. Aust. trams, tramways, photo album, melbourne, postcards -

Eltham District Historical Society Inc

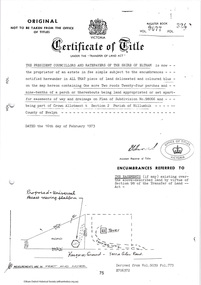

Eltham District Historical Society IncArchive Box, Shire of Eltham War Memorial

Material relating to the Shire of Eltham War Memorial located at Garden Hill, Kangaroo Ground. Also known as The Eltham Shire War Memorial Tower, Shire of Eltham Soldiers' Memorial and Kangaroo Ground War Memorial Park. Includes photocopies, newspaper clippings, correspondence and more beginning from early history 1919-2009. Contents: Archive Box 1 Folder 1 (Publication Proofs) The Tower of Remembrance and War Memorial Park On Garden Hill at Kangaroo Ground, Victoria 1919-2010 Folder 2 (Up to 1960) 1. Binder with plastic pockets. Photocopies. Minutes of the Kangaroo Ground War Memorial Bazaar Committee, 1922-1926 EDHS Newsletter No. 123 November 1998 PRESIDENT'S REPORT ACQUISITION FROM NILLUMBIK SHIRE'S MEMORABILIA Recently found in a storage box of old Shire of Eltham items was a school size, blue lined black covered writing book. It is recognized as the minute book and cash receipt book of the period 1922-1926 when the Memorial Park Committee, who it seems were part of the Shire of Eltham Soldier's Memorial League, was requested to raise funds for building the Shire of Eltham War Memorial Tower at Kangaroo Ground. History tells us that the tower, which is currently being refurbished, was officially opened by the Governor General of Australia, Lord Stonehaven on 11.11.26. The ladies invited to the first meeting at the Shire Hall did so on 21st September 1922. The minutes book reads: Present: Mesdames Bell, Bourchier, McMahon, Gosling, Cockcroft, Wraight, E Coutie, R Rogers, A Jones, AH White, Davies, Everitt and the Misses Lacey, Harris, N Weller, Gosling, Bell and D and G J Bourchier. These people became the Kangaroo Ground Memorial Bazaar Committee along with others named at further meetings. They conditionally accepted the role of raising funds, their condition being that the Bazaar Committee be given representation on any committee empowered to deal with the memorial in proportion to the amount of money raised by the bazaar'. The Andrew Ross Museum has the original book. We at Eltham District Historical Society have two photocopies for public perusal. 2. Transcriptions of newspaper articles 1919-1920. 6 pages. 3. Photocopy of program for thanksgiving service July 6th, 1919 held at Public Hall, Panton Hill. 4. Photocopies: a. Kangaroo Ground, The Advertiser, 17 Oct 1919 (working bee) b. The Advertiser August 1920 – advertisement for coach between Eltham and KG. c. Anzac Memorial Service, The Eltham & Whittlesea Shires Advertiser & Diamond Creek Advertiser, April 14, 1922 and April 28, 1922 d. Anzac Day services. April 27, 1923 e. Photocopy Anzac Commemoration, local newspaper, May 2, 1924 f. Shire of Eltham Memorial Service, The Advertiser April 23, 1926 g. Eltham Shire War Memorial Advertiser August 13,1926 h. Eltham Shire War Memorial The Advertiser October 26, 1926 i. Eltham The Advertiser, December 17, 1926 j. Kangaroo Ground April 26, 1929 5. Photocopy. Eltham War Memorial Tower article, The Advertiser, November 19, 1926 6. Typed transcription of parts of newspaper articles for three titles, November 1926 7. Transcription. Public Notice, October 16, 1926 8. Photocopy Kangaroo Ground Armistice Day local newspaper, November 25, 1927 9. Photocopy Kangaroo Ground Armistice Day local newspaper, November 16, 1928 10. Photocopy Kangaroo Ground, local newspaper, April 26 1929 11. 3 Original Copies. One Hardback. Dedication of memorial official brochure, 1951 original but damaged 12. Photocopy with notes from G.G. relating to the land transfer/acquisition/contract via White and Gepp. Folder 3 (1961-1970) 1. Original newspaper article: Place with a view at Kangaroo Ground, The Age, May 11, 1963, p18 Folder 4 (1981-1990) 1. Newspaper article, Memorial a fire watch. Diamond Valley News, March 16, 1982, 2 original copies. 2. Newspaper article. An Obvious Monument by Russell Yeoman article with photo: Network Nov/Dec 1984, p14. Folder 5 (1991-2000) 1. Original newspaper article: “Kangaroo Ground Tower is top spot”. Thought to be from a tourist information free newspaper, Mountain Country, Summer [1993] p39. 2. Newspaper article with reference to quoins – a contrasting edging or corner stone on the façade of a stone or brick house. Age August 2000 3. Program. Service program for Remembrance Day commemoration ceremony, 1996. 4. Speech by Harry Gilham for Remembrance Day commemoration ceremony, 1996 5. Newspaper article: Remembrance, Diamond Valley News, 20 November 1996 6. Word Document. A Tower of Strength by Dean Stewart April 1997 7. Newspaper articles: Tower group needed, Diamond Valley News, September 17, 1997, p3 and advertisement “Nillumbik, Nominations for Kangaroo Ground Memorial Tower and Grounds Advisory Committee”, Diamond Valley News, September 17, 1997 8. Newspaper article: Council apology; scaling new heights, 1997 about Aboriginal Reconciliation. Probably Diamond Valley News ca 1997. 9. Photocopy / Newspaper Article: Two newspaper clippings, “Memorial with a view” 30 April 1997 and “Funds boost to restore tower to its former glory”, Diamond Valley News, 3 December 1997. 10. Newspaper article: Kangaroo Ground Tower of Remembrance Nillumbik Mail, 9th August 2000 and Research notes (July 2000) by Harry Gilham pertaining to photo in August 2000 newspaper article. 11. Photocopy. Newspaper article: New lease of life for tower (Concept plan) Nillumbik Mail, September 27, 2000 12. Photocopy: 4 pages, War Memorials of Victoria; a pictorial record, c.1994 Folder 6 (2001-2010) 1. Newspaper article: $10,000 to start refurbishment, Nillumbik Mail, Feb 21, 2001 2. Circular. KG War Memorial Advisory committee circular August 2001 3. Newspaper article: Tower group retained 4. Program for re-dedication of the Kangaroo Ground War Memorial Tower 8th November 2001 with copies of pages 65-70 of from The Tower of Remembrance and War Memorial Park 1919-2001 (see Folder 1) - Speaking notes from the day from Nillumbik Shire Mayor, Cr. Sigmund Jorgensen and Harry Gilham and Speech by John Landy, Governor of Victoria 5. 2 pages of Harry Gilham notes – Draft of ‘book’ notes ‘Thank you’ for rededication ceremony to be held Thursday, Nov 8, 2001 - list of invitations, notifications and acknowledgements. 6. Proposed running sheet. Re-dedication of KGT. November 8, 2001 7. Newspaper article (2 copies) Century of war service, DVL November 14, 2001 page 6 8. Letter. Gov. John Landy to Harry Gilham. Thank you for visit. [2001] 9. Newsletter Clipping: Governor of Victoria re-dedicates KG War memorial Tower, Nillumbik News (NSC) Christmas 2001 10. Newspaper article: War Memorial to be restored: DVL November 19, 2003 11. Newspaper article: Memorial Facelift Sept 29 2004. 12. Folder. Collection of maps and context Yarra Water proposal to build water tanks 13. Newspaper clipping. Pressure on with new tank. Re installation of water tank near site. DVL March 2, 2005 14. Folder of emails and designs from Dennis Ward re poppies and prostrate rosemary for formal garden around base of tower April 2005 15. Folder. Letters and paperwork re the Victorian Government “Community Cabinet” and invitation for community groups to speak directly with a government minister. Actual submission not included in folder. 16. Newspaper clipping. Time to remember among the poppies, Diamond Valley Leader, 9 November 2005, p1 and 17. Newspaper clipping. Lone pine company for souls. DVL 9 November 2005 18. Folder. Restoring Community War Memorials Grants Program. Application and associated paperwork 2005/2006 January 2006 19. Newspaper article. Shared views. Valley Weekly, June 21 2006 20. Newspaper article: Kangaroo Ground, Restoration on schedule, DVL October 2006? 21. Newspaper article. Towering over the terrain. The Age August 8, 2009 22. Photocopy. Nillumbik Shire Council. Policy and service report re lease of land to Victoria Police for police radio communications and re-building of radio tower. December 9, 2009 23. Schematics: A3 photocopies, Kangaroo Ground memorial Tower, front and rear view, Tom Manley, 17 Apr 2001 Folder 7 (2011 on) 1. Magazine article and cover. Cover story – The Kangaroo Ground Memorial Tower, The Genealogist, March 2010 2. Newspaper article. (2 copies) Photo and caption. Diamond Valley Leader, July 14, 2010 3. Newspaper notice: Notice of application for a planning permit to construct radio communications tower, DVL, October 10, 2012 4. Copy. Reference enquiry to National Film and Sound Archive. 10 September 2012 5. Copy letter. Quotation/estimate for Shire of Nillumbik on renovation and underpinning of old care takers cottage, KG. 30 September, 2012 6. Story. The Kangaroo Ground Tower of Remembrance by Amy Shaw. Yarrambat Primary School Year 6 History speech, 2014. 7. Program: Remembrance Day service, 11th November 2014 8. Newspaper article. Tribute to bravery DVL, November 19, 2014. 9. Minutes. MAC meeting. 2 September 2016. Folder 8 (Interpretative Signs Grant 2000-2001) 1. Folder. Various including Letters. EDHS Grant project: Kangaroo Ground Park and Tower of Remembrance interpretative signage from Parks Victoria 2000-2001. Folder 9 (Miscellaneous) 1. Folder Gilham collection. Google earth images of Tower, Extract describing history of Tower, including honour roll for WW1 and WW2, 8 pages, Extract describing history of Tower, including honour roll for WW1 and WW2, 3 pages, 2002 and 2004; Kangaroo Ground Tower; Southwell-Keely M.; WAR MEMORIALS IN AUSTRALIA; 8 pages, https://web.archive.org/web/20080722161554/http://www.skp.com.au/memorials2/pages/30054.htm) 2. Letter. Undated, unsigned re application to council to proposed work to police radio masts behind caretaker’s cottage. 3. Brochure: Heritage Nillumbik. Includes cover photo and other information about site. Published by Nillumbik Shire Council. About 2006. 4. Folder of notes and photocopies of various Certificates of Title for property 5. Inward loan documents. Two. Andrew Ross Museum inward loan for collection items from “War Memorial Tower” 2003 6. Photocopies of postcards of Soldiers War Memorial: One taken c.1926 before completion around base, on colour print on paper (enlarged) of Soldiers War Memorial postcard c.1930s prior to gun placements with typed text pasted on and additional detail version mounted on card with handwritten explanatory notes by Harry Gilham. 7. Photocopy of photo of tower 1944 with guns in place from Gordon and explanatory notes plus A4 photo paper print of image (photoshopped cleaned up). 8. Miscellaneous photocopies of photos taken by Harry Gilham of Memorial Park entrance, model tower in font of tower entrance, caretaker’s cottage, spiral staircase, Menin Gate sign and possibly planting of Lone Pine. Folder 10 (Fire Spotting Operations) 1. Biographical notes on Herman Motschall 1969-1981 2. Newspaper article, Memorial Tower top site for fire spotter, Diamond Valley News, May 15, 1973. 3. Proper Officer's report on an addition to the Kangaroo Ground Memorial Tower for Fire Spotting purposes: "This report covers the history of the tower, its uses, and reasons why it should be put to greater use, benefiting the Shire Council and ratepayers" Includes detailed commentary around the proposal to use the Shire of Eltham War Memorial at Kangaroo Ground for fire spotting. From Shire of Eltham archives. H. J. Masefield Property Officer. 4. Eltham Shire Council meetings 14 and 24 September 1973 references to fire watching facilities. Summary of end of season reports from spotters 1965-1973. 5. Newspaper clipping; Memorial a fire watch by Marguerite Marshall Diamond Valley News 16 March 1982 6. Letter: Cover letter from Dennis Ward 20 Feb 2006 architect for CFA Cabin design and Proposal to upgrade the fire spotting cabin, 2007 including a cost and concept plan dated 7 February 2009. 7. Newspaper article. From that first puff of smoke – horror. Diamond Valley Leader, Feb 25, 2009, p. 7 8. Invitation: State Government announcement of refurbishment of KGWM Fire spotting tower 19 October 2009 9. Newspaper article. Tower– up, Black Saturday watch. Cover and page. Diamond Valley Leader, October 28, 2009 10. Invitation. Opening of newly upgraded fire spotting tower, 11 April 2010 11. Newspaper article. Incredible luxury at fire spotting tower, Diamond Valley Leader, April 21, 2010, p, 5 12. Printout of plan of base of tower including comms cabinet and ladder to CFA cabin. Dated 17/6/2010 Archive Box 2 Folder 11 (Moor-rul Viewing Platform) 1. Agenda. Planning and building committee 12 March 2003 Application for construction of a viewing platform and road entry refurbishment and coach parking bay. 2. Envelope. Letters, paperwork and emails, mainly from Dennis Ward re roof design for the viewing platform and order for poppy seeds. 2005 3. Newspaper article (enlarged and laminated). Stolen Red gum seats sap new project’s momentum. (Local paper), April 3, 2007 4. Convenor’s Notes – Opening of the Viewing Platform at Kangaroo Ground, Shire of Nillumbik 5. Folder. Nillumbik Reconciliation Charter. Opening of the Moor-rul viewing platform 17.4.2008. Compiled by Harry Gilham. Includes newspaper clipping, speech, photocopy of photos with captions. 6. Newspaper article. View from the hill is a thrill. Heidelberg and Diamond Valley Weekly, April 22, 2008 7. Newspaper article. A platform towards reconciliation. Diamond Valley Leader, 23 April 2008. 8. Newspaper article: 6 reasons to visit Hurstbridge, The Age, Jun 6 2012 9. Article: Aboriginal cultural values and heritage management issues 10. Folder: Material relating to design and construction of viewing platform Folder 12 - Shire of Nillumbik Advisory Committee 1. 2011 Diary, Harry Gilham, Kangaroo Ground Advisory Committee 2. Photocopy. Newspaper clipping. Nillumbik Council seeking nominations for new Kangaroo Ground Memorial Tower and grounds advisory committee. DVN 17 Sept 1997 3. Letter. From NSC to Dean Stewart re heritage listing status. 12 July 1998. 4. Business paper for NSC Council meeting: KG Memorial Tower and Grounds advisory committee, 12 March 2002. Includes Terms of Reference Folder 13 - Friends of Kangaroo Ground War Memorial Park Inc. 1. KG Tower and land occupational health & Safety (guidelines) for volunteers 2. Supplementary notes (not related to fire spotting) from Friends group or advisory group of Kangaroo Ground War Memorial Park including design of seating, proposed budget for works, hand written notes from meeting by H.G. about 1999. Folder 14 - Soldiers. 1. Folder of material pertaining to men from the Shire of Eltham who enlisted in WW1 and for whom the Shire of Eltham War Memorial was dedicated. 2. Folder on residents from Shire of Eltham who died in WW2 1939-1945 with listings of each from Commonwealth War Graves Commission, WW2 Nominal Roll for Eltham 3. Newspaper article: Mates join to recall past, Diamond Valley News, November 16, 1994 4. Newspaper article: Board replaced, Diamond Valley News, September 2, 1998 about Hurstbridge RSL Honour Roll Board 5. Newspaper article: Keeping the memories alive; VP Day honoured, Valley Weekly, August 17, 2005 6. Newspaper article: In our hearts; Tributes for war heroes, Diamond Valley Leader, November 9, 2005, p1 7. Newspaper article: Service honoured, Diamond Valley News, Leader, April 23, 2008 8. Newspaper article: Salute to last men standing, Diamond Valley Leader, April 20, 2011, p1 and Last of the world warriors, pp8-9 9. Newspaper article: We will remember, Diamond Valley Leader, April 25, 2012, p3 10. Newspaper article: Family legacy builds whole town, Diamond Valley Leader, Oct, 2013, p15 11. Photos and details of Honour Boards in the shire 12. Miscellaneous notes by Harry Gilham Folder 15 – Welcome Home Committee Meeting Minutes. 1. Extracts from Welcome Home Committee Meeting Minutes 18 August 1917 to 14 August 1919. Folder 16 – World War One Local Enlistments. 1. Lever arch binder containing records of local enlistments by name from the Diamond Valley including extracts from Commonwealth War Graves Commission records. Includes Newspaper article clipping "Digger's marker of respect: Temporary cross a poignant find after eight decades in dusty garage"; Sunday Herald Sun, November 10, 2024, p33 concerning Private Harry Conway who died April 1918 and whose tempory grave marker cros now housed at Montmorency-Eltham RSL. Archive Box with documentsharry gilham collection, fire spotting, kangaroo ground, shire of eltham war memorial, masefield h. j., cfa, kangaroo ground war memorial park, shire of eltham soldiers' memorial, eltham shire war memorial tower, harry conway, montmorency-eltham rsl sub-branch -

Bendigo Military Museum

Bendigo Military MuseumPhotograph - Army Survey Regiment Freedom of Entry Parade Rehearsal, Fortuna. Bendigo, 1980

This set of 38 black and white photographs were taken at the Army Survey Regiment’s parade rehearsal held at Fortuna, Bendigo in 1980. The rehearsal was for the Freedom of Entry parade held 1-2 weeks later in 1980. The exact date for the Freedom of Entry parade is not known. The Freedom of Entry to the City of Bendigo was an honour first conferred by the Bendigo City Council to the Army Survey Regiment in 1970. The Freedom of Entry parade in 1980 was the fourth time the unit exercised its right of freedom of entry. The Regiment also exercised its Freedom of Entry with anniversary parades in 1977, 1980 and 1995. Refer to items 6020.8P, 6021.25P, 6248P, 6266, 6409.2, 6430.39P, 6490.53P and 6491.19P for more Army Survey Regiment Freedom of Entry photographs, documents and certificates. See item 6471.2P for photos of Lithographic Squadron taken on the same day of this parade rehearsal. This set of 38 black and white photographs of the Army Survey Regiment (Army Svy Regt) were taken in a rehearsal for the Freedom of Entry parade to the City of Bendigo, held 1-2 weeks later in 1980. The photographs are on 35mm negative film and were scanned at 96 dpi. They are part of the Army Survey Regiment’s Collection. .1) - Photo, black & white, 1980. WO1 John McCulloch observes the rehearsal. .2) - Photo, black & white, 1980. RSM WO1 Aub Harvey, WO1 Dave Thomson and WO1 Roger Rix observe the rehearsal. .3) - Photo, black & white, 1980. Under command of SSM WO1 Bob Mason, Air Survey Squadron marches onto the parade ground - Front rank L to R: SPR Peter Jones, SPR Barry Miller, CPL Alan Hawkins. .4) - Photo, black & white, 1980. Air Survey Squadron marches on the parade ground - L to R: SPR Peter Jones, CPL Lyall Camp, SPR Barry Miller, SPR Geoff Havelberg, unidentified, CPL Alan Hawkins, CPL Peter Treble, unidentified (x2), SGT Mick Hogan, SGT Bruce Hammond, unidentified, SPR Steve Linane, SPR Jamie McRae, unidentified (x2). .5) - Photo, black & white, 1980. Air Survey Squadron formed up – CAPT Peter Ralston on far left. .6) - Photo, black & white, 1980. Air Survey Squadron inspection – L to R: CAPT Peter Ralston, CPL Alan Hawkins, CO LTCOL Bob Skitch, SGT Mick Hogan, SGT Bruce Hammond, SPR Jamie McRae. .7) - Photo, black & white, 1980. Air Survey Squadron inspection – L to R: SPR Peter Jones, unidentified, CPL Paul Hopes, unidentified, SGT Rick van der Bom, LTCOL Bob Skitch, SPR Steve Linane, CPL Mick Minchin, unidentified, SPR Gae (Robinson) Amato, unidentified, SPR Chris ‘CPL Peter Treble, Charlie’ Brown, SPR Ginny (Turner) Rowe. .8) - Photo, black & white, 1980. Lithographic Squadron marches onto the parade ground - Front rank L to R: SPR Brian Fauth, SPR Roy Hicks, SPR Per Andersen, commanded by LT Steve Cooper. .9) - Photo, black & white, 1980. Lithographic Squadron marches onto the parade ground - L to R: SSM WO1 Ken Slater, Front rank SPR Brian Fauth, SPR Roy Hicks, SPR Per Andersen, LT Steve Cooper. .10) - Photo, black & white, 1980. Lithographic Squadron inspection - L to R: CAPT Stan Vote, LT Steve Cooper, CO LTCOL Bob Skitch, SPR Neville Carr, SPR Laurie Justin, SPR Keith Quinton. .11) - Photo, black & white, 1980. Lithographic Squadron inspection - L to R: unidentified, LT Steve Cooper, CPL Frank Lenane, CPL Mick ‘Buddha’ Ellis, SPR Martin van de Maele, CO LTCOL Bob Skitch, unidentified (x2), SPR Garry Hudson, remainder unidentified. .12) - Photo, black & white, 1980. Lithographic Squadron inspection - L to R: LT Steve Cooper, CPL Rob Bogumil, unidentified, CO LTCOL Bob Skitch, CPL Bill Jones, CPL John ‘Flash’ Anderson, CPL Warren ‘Waldo’ Shirley, unidentified. .13) - Photo, black & white, 1980. Lithographic Squadron inspection - L to R: unidentified (x4), CO LTCOL Bob Skitch, unidentified, CPL Bill Jones, LT Steve Cooper, CPL Warren ‘Waldo’ Shirley. .14) - Photo, black & white, 1980. Lithographic Squadron performs form - right file L to R: SPR Brian Fauth, SPR Roy Hicks, SPR Per Andersen. .15) - Photo, black & white, 1980. Lithographic Squadron completes form at the halt. .16) - Photo, black & white, 1980. Lithographic Squadron marches in column of route – right file L to R: SPR Keith Quinton, SPR John Whaling, SPR Martin van de Maele, SPR John Whaling, SPR Garry Hudson, unidentified. Centre marker: CPL Warren ‘Waldo’ Shirley, remainder unidentified. .17) - Photo, black & white, 1980. Lithographic Squadron marches in column of route – right file L to R: SPR John Whaling, SPR Martin van de Maele, SPR John Whaling, SPR Garry Hudson, unidentified. Centre marker CPL Warren ‘Waldo’ Shirley, remainder unidentified. .18) - Photo, black & white, 1980. Lithographic Squadron marches in column of route – L to R: SPR Per Andersen, CPL Josh Degroot, SPR Neville Carr, SPR Laurie Justin, SPR Keith Quinton, SPR John Whaling, SPR Martin van de Maele, SPR John Whaling, SPR Garry Hudson, unidentified. .19) - Photo, black & white, 1980. Lithographic Squadron marches in column of route – L to R: SPR Per Andersen, CPL Josh Degroot, SPR Neville Carr, SPR Laurie Justin, SPR Keith Quinton, SPR Martin van de Maele, SPR John Whaling, SPR Garry Hudson, unidentified (x2), CPL Warren ‘Waldo’ Shirley, unidentified. .20) - Photo, black & white, 1980. Lithographic Squadron rehearses ‘rest on arms reverse.’ .21) - Photo, black & white, 1980. Cartographic Squadron marches onto the parade ground in column of route - L to R: SPR Cheryl Lofthouse, unidentified, SSM WO1 Gordon Lowery, unidentified, SPR Megan (McBurney) Reynolds, unidentified (x6), SPR Peter Main, CPL Stu Symonds, SPR Greg Else, SPR Rod Skidmore. .22) - Photo, black & white, 1980. Cartographic Squadron marches onto the parade ground in column of route - L to R: SPR Rod Skidmore, SPR Greg Else, CPL Phil McGuire, CPL Dennis Learmonth, CPL Brad Peppler, CPL Trevor Bottomley, SPR Gina (Coore) Neilson, SPR Carla Dell, CPL Lyn Johnson, commanded by CAPT Bob Williams. .23) - Photo, black & white, 1980. Cartographic Squadron inspection - L to R: unidentified officer, CAPT Bob Williams, SPR Greg Else, CO LTCOL Bob Skitch, CPL Phil McGuire, CPL Dennis Learmonth, CPL Brad Peppler, CPL Trevor Bottomley. .24) - Photo, black & white, 1980. Cartographic Squadron inspection - L to R: RSM WO1 Aub Harvey, unidentified officer, CAPT Bob Williams, CO LTCOL Bob Skitch. Front rank L to R: SPR Rod Skidmore, CPL Phil McGuire, CPL Dennis Learmonth, CPL Brad Peppler, CPL Trevor Bottomley, SPR Gina (Coore) Neilson, SPR Carla Dell, CPL Lyn Johnson. Centre rank L to R: CPL Terry Danger, SPR John Martin, SPR Bob Sheppard. SPR Megan (McBurney) Reynolds. .25) - Photo, black & white, 1980. Cartographic Squadron inspection - Front rank L to R: CPL Phil McGuire, CAPT Bob Williams, CPL Brad Peppler, CO LTCOL Bob Skitch, CPL Trevor Bottomley, SPR Gina (Coore) Neilson, SPR Carla Dell, CPL Lyn Johnson. .26) - Photo, black & white, 1980. Cartographic Squadron inspection - L to R: WO1 Roger Rix, RSM WO1 Aub Harvey, unidentified officer. Front rank L to R: SPR Rod Skidmore, SPR Greg Else, CPL Phil McGuire, CPL Brad Peppler, CPL Trevor Bottomley, SPR Gina (Coore) Neilson, SPR Carla Dell, CPL Lyn Johnson. Centre rank L to R: CPL Terry Danger, SPR John Martin, SPR Bob Sheppard. SPR Megan (McBurney) Reynolds. .27) - Photo, black & white, 1980. Cartographic Squadron inspection - L to R: CPL Dennis Learmonth, CPL Brad Peppler, CO LTCOL Bob Skitch, CPL Trevor Bottomley, SPR Gina (Coore) Neilson, SPR Carla Dell, CPL Lyn Johnson. .28) - Photo, black & white, 1980. Cartographic Squadron inspection - L to R: CAPT Bob Williams, unidentified, CO LTCOL Bob Skitch, SPR John Martin, SPR Bob Sheppard, SPR Megan (McBurney) Reynolds, rear rank L to R: SPR Peter Main, unidentified (x3). .29) - Photo, black & white, 1980. Cartographic Squadron rehearses ‘reverse arms’ - L to R: SPR Peter Main, CPL Stu Symonds, SPR Rod Skidmore, SPR Greg Else, remainder unidentified. .30) - Photo, black & white, 1980. Cartographic Squadron rehearses ‘rest on arms reverse.’ - Front rank L to R: SPR Rod Skidmore, SPR Greg Else, CPL Phil McGuire, CPL Dennis Learmonth, CPL Brad Peppler, CPL Trevor Bottomley. remainder unidentified. Centre rank L to R: unidentified (x2), SPR John Martin, SPR Bob Sheppard, SPR Megan (McBurney) Reynolds. Rear rank L to R: unidentified (x3), SPR Carla Dell on far right. .31) - Photo, black & white, 1980. Cartographic Squadron marches in column of route. .32) - Photo, black & white, 1980. Cartographic Squadron marches in column of route. Left file L to R: SPR Rod Skidmore, SPR Greg Else, CPL Phil McGuire, CPL Dennis Learmonth, CPL Brad Peppler, CPL Trevor Bottomley, SPR Gina (Coore) Neilson, SPR Carla Dell, CPL Lyn Johnson. Centre file L to R: unidentified (x2), SPR Dan Cirsky, SPR Bob Sheppard. Commanded by CAPT Bob Williams (foreground). .33) - Photo, black & white, 1980. Cartographic Squadron rehearses ‘order arms.’ Front rank L to R: SPR Rod Skidmore, SPR Greg Else, CPL Phil McGuire, CPL Dennis Learmonth, CPL Brad Peppler, CPL Trevor Bottomley, SPR Gina (Coore) Neilson, SPR Carla Dell, CPL Lyn Johnson. Centre rank L to R: unidentified (x2), SPR Dan Cirsky, SPR Megan (McBurney) Reynolds, SPR Ilen Isaac. Rear rank L to R: SPR Cathy Regan, unidentified, SPR Cheryl Lofthouse. .34) - Photo, black & white, 1980. Cartographic Squadron rehearses ‘right dress.’ Front rank L to R: SPR Rod Skidmore, SPR Greg Else, CPL Phil McGuire, CPL Dennis Learmonth, CPL Brad Peppler, CPL Trevor Bottomley, SPR Gina (Coore) Neilson, SPR Carla Dell, CPL Lyn Johnson. Centre rank L to R: SPR John Martin, SPR Bob Sheppard. SPR Megan (McBurney) Reynolds, SPR Ilen Isaac. Rear rank L to R: unidentified (x2), SPR Cathy Regan, unidentified, SPR Cheryl Lofthouse. Commanded by CAPT Bob Williams (far left). 35) - Photo, black & white, 1980. Air Survey Squadron section rehearses marching with reverse arms. L to R: SPR Bob Hopper, CPL Rick Downie, CPL Paul Hopes, unidentified (x2, SGT Rick van der Bom, SPR Steve Hilton, CPL Peter Treble, unidentified, SPR John Lane, remainder unidentified. .36) - Photo, black & white, 1980. Air Survey Squadron section rehearses marching with reverse arms. L to R: CPL Alan Hawkins, CPL John Smith, SPR Dave Jobe, unidentified (x2), SGT Mick Hogan, SPR Barry Miller, WO1 Dave Thomson. .37) - Photo, black & white, 1980. Cartographic Squadron sections practice drill. .38) - Photo, black & white, 1980. Air Survey Squadron rest break from drill practice. L to R: unidentified (x2), CPL Noel McNamara, SSGT Peter Warwick, SSGT Greg Buckingham (facing away), SGT Jim Beard, unidentified, SPR Sharon (Jones) Treble (foreground), unidentified, SGT Bruce Gordon, SPR Kristin (Isaac) Skidmore.There are no personnel identified. royal australian survey corps, rasvy, army survey regiment, army svy regt, fortuna, asr -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, Late 19th or early 20th Century

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/ The bowl is an example of kitchenware used in the 19th century and still in use today.Bowl white ceramic. Crack on side. Badly stained.Backstamp very faint and unable to be read.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, mixing bowl, food preparation, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/ This bowl is an example of kitchenware used in the 19th century and still in use today.Bowl white ceramic plain that has two sets of edging around lip. Inside bowl has plaster designed to look like cooking mixture.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, J & G Meakin, Late 19th or early 20th Century

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/This bowl was made by renowned pottery company J & G Meakin of England. The firm was established in the mid-1800's. The bowl is an example of kitchenware used in the 19th century and still in use today.Bowl; white ceramic, round and tapering inwards towards base. Made by J and G Meakin England.On base, 'Ironstone China Reg SOL 391413' with symbolflagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, mixing bowl, food preparation, j & g meakin, pottery, stoke-on-trent, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Plate